Académique Documents

Professionnel Documents

Culture Documents

Klingersil C 4400

Transféré par

Peter JordanTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Klingersil C 4400

Transféré par

Peter JordanDroits d'auteur :

Formats disponibles

KLINGERsil C-4400

High quality non-asbestos grade based on

aramid fibre with nitrile rubber binder. A

general purpose material for many industrialsealing applications.

The Klinger group has been

recognised as the market

leader in gaskets and

sealing for over a century.

Our research and

development laboratories

have investigated over 250

different fibre forms in the

search for asbestos free

alternatives. The search has

resulted in a range of high

quality and high

performance asbestos free

materials that have been

proven in service

General Properties

Good resistance to oils, fuels, hydrocarbons

Good creep resistance

Low leakage

Very successful in internal combustion engine applications

3xA anti-stick finish on both sides

Tests and Certifications

BS 7531 Grade Y

BS F 130 Type A

Firesafe HTB 90.0223.39.0

DIN-DVGW

0

BAM U W28 for use with oxygen 100 C / 80 Bar

KTW A 528/88/G

SVGW 89-053-7

Germanischer Lloyd 98 952 97 HH

TA-Luft (Clean Air) certificate acc. VDI 2440

Availability

Sheeting (m):

2.0 x 1.5*, 4.0 x 1.5, 1.5 x 1.0

Thickness (mm): 0.25, 0.4, 0.5, 0.75, 1.0, 1.5, 2.0, 2.5, 3.0

* - Denotes standard sheet size

Also available with re-inforcements:

KLINGERsil C-4408, mild steel mesh

KLINGERsil C-4409, expanded mild steel

KLINGERsil C-4400

Application

Guidelines

1.

2.

Usually satisfactory without reference.

Usually satisfactory, but suggest you

refer to Klinger for advice

3. Caution: May be suitable but essential

that you refer to Klinger for advice.

Chemical compatibility must be considered

in all cases.

Typical Specifications

Compressibility ASTM F 36 A

Recovery ASTM F 36 A

Stress relaxation DIN 52913

Stress relaxation BS 7531

Klinger cold/hot compression, 50MPa

Gas leakage according to DIN 3535/6

Thickness increase after fluid

immersion ASTM F 146

11%

55%

50MPa, 16h/175C

50MPa, 16h/300C

Thickness decrease 23C

Thickness decrease at 300C

Oil no.3:5h/150C

Fuel B:5h/23C

Chlorides (soluble)

Density

Average surface resistance

Average specific volume resistance

Average dielectric strength

Average power factor

Average dielectric constant

Thermal conductivity

Head Office

KLINGER Ltd

Wharfedale Road

Euroway Trading Estate

Bradford BD4 6SG

Tel: 01274 688 222

Fax: 01274 688 549

enquiries@klingeruk.co.uk

www.klingeruk.co.uk

32MPa

25MPa

23MPa

10%

20%

0.02ml/min

3%

5%

150ppm

3

1.6g/cm

ROA

D

1kHz,ca. 2mm thick

1kHz,ca.2mm thick

1.4x10E12

1.2x10E12 cm

21.6 kV/mm

0.075 tan

7.7 r

0.4-0.42W/mK

Klinger Ltd. Grangemouth

Tel: 01324 472 231

Fax: 01324 482 111

Klinger Ltd. Runcorn

Tel: 01928 577 030

Fax: 01928 575 223

Klinger Ltd. Aberdeen

Tel: 01224 772 962

Fax: 01224 772 953

Klinger Ltd. Middlesbrough

Tel: 01642 220 289

Fax: 01642 220 290

Klinger Ltd. Southampton

Tel: 023 8061 1855

Fax: 023 8061 0360

All information and recommendations contained in this specification sheet are to the best of our knowledge correct. Since

conditions of use are beyond our control, users must satisfy themselves that the products are suitable for the intended

processes and uses. No warranty is given or implied in respect of information or recommendations or that any use of

products will not infringe rights belonging to other parties. In any event or occurrence our liability is limited to our invoice value

of the goods delivered by us to you. We reserve the right to change product design and properties without notice

Vous aimerez peut-être aussi

- ASCE - 'Astoria Tunnel Profile Under The East River'Document109 pagesASCE - 'Astoria Tunnel Profile Under The East River'Colin PearcePas encore d'évaluation

- Engineering Materials PDFDocument24 pagesEngineering Materials PDFPradeepkumarKatgiPas encore d'évaluation

- Armani Casa Penthouse Floor PlanDocument4 pagesArmani Casa Penthouse Floor PlanSarah Elles BoggsPas encore d'évaluation

- LS160-280 LS25S Parts ManualDocument73 pagesLS160-280 LS25S Parts ManualAnh Vo100% (3)

- Dissertation RPSDocument35 pagesDissertation RPSRaghvendra Pratap Singh100% (1)

- TAYLOR FORGE - SIF CALCS - ES 3.9.2 r0, Design & Forming of Extruded OutletsDocument6 pagesTAYLOR FORGE - SIF CALCS - ES 3.9.2 r0, Design & Forming of Extruded OutletsDDPas encore d'évaluation

- SAEP-352 - Welding Procedures Review and Approval PDFDocument14 pagesSAEP-352 - Welding Procedures Review and Approval PDFsilvrsurfr637Pas encore d'évaluation

- Blueprint Project DilationsDocument2 pagesBlueprint Project DilationsDatta KamblePas encore d'évaluation

- Klingersil C-4430 DataDocument2 pagesKlingersil C-4430 DataangelelpedrosaPas encore d'évaluation

- Gasket KlingersilDocument2 pagesGasket KlingersilBagusRekaPas encore d'évaluation

- Poly Water Tank (Completed) PDFDocument2 pagesPoly Water Tank (Completed) PDFSopi LabuPas encore d'évaluation

- Thermoseal Klingersil C-4401Document2 pagesThermoseal Klingersil C-4401timwright999Pas encore d'évaluation

- NTN DES 019 Pipe Support SpacingDocument1 pageNTN DES 019 Pipe Support Spacingjdsa123Pas encore d'évaluation

- CalcvesselDocument11 pagesCalcvesselHami Keserci100% (1)

- Din 6618 1Document10 pagesDin 6618 1Rad Imam VinoPas encore d'évaluation

- AMRI ISORIA 10 Type Series Booklet Data PDFDocument20 pagesAMRI ISORIA 10 Type Series Booklet Data PDFMurrali Raj Jeyagapal50% (2)

- Flanges Connecting Dimension According To DIN EN 1092-1 and DIN 2501-1Document2 pagesFlanges Connecting Dimension According To DIN EN 1092-1 and DIN 2501-1Lasandu WanniarachchiPas encore d'évaluation

- Vaporizers LP GasDocument7 pagesVaporizers LP Gastariq wazedPas encore d'évaluation

- Orifice Plate BrochureDocument39 pagesOrifice Plate Brochureronzies100% (1)

- High Density Polyethylene - HDPE - Pipe and FittingsDocument8 pagesHigh Density Polyethylene - HDPE - Pipe and Fittingsnilesh_erusPas encore d'évaluation

- Material 11373Document1 pageMaterial 11373Deepak MadnaikPas encore d'évaluation

- VALVULA VAPOR Joseestrada PDFDocument5 pagesVALVULA VAPOR Joseestrada PDFRaulRodriguezPas encore d'évaluation

- Sa 420Document10 pagesSa 420Widya widyaPas encore d'évaluation

- Cable Tray 27Document37 pagesCable Tray 27Sri Ravindra Yadav PattapogulaPas encore d'évaluation

- En 1092-1 PN-10 Steel Pipe Flange - ValviasDocument5 pagesEn 1092-1 PN-10 Steel Pipe Flange - ValviasHoria ZecheruPas encore d'évaluation

- Co-Efficient of Friction For Pipe Supporting During Stress Analysis Using Caesar IIDocument2 pagesCo-Efficient of Friction For Pipe Supporting During Stress Analysis Using Caesar IIHmd MokhtariPas encore d'évaluation

- Ventilación en Altura-Bolivia PDFDocument67 pagesVentilación en Altura-Bolivia PDFGrace Ayala EspinozaPas encore d'évaluation

- Nema sm23Document62 pagesNema sm23dg997Pas encore d'évaluation

- Aws Welding SymbolsDocument2 pagesAws Welding SymbolsAlessio BarbonePas encore d'évaluation

- Resistencia Al Desgaste Abrasivo Según Norma Astm 105Document9 pagesResistencia Al Desgaste Abrasivo Según Norma Astm 105Robin J. Pico MontesPas encore d'évaluation

- Hempadur 85530Document2 pagesHempadur 85530kumarnowabuPas encore d'évaluation

- Asme Sec X 2017Document6 pagesAsme Sec X 2017SARSAN NDTPas encore d'évaluation

- Texas Flange - Product Catalog PDFDocument47 pagesTexas Flange - Product Catalog PDFFranco Saenz SolisPas encore d'évaluation

- KSB Sicca HP Cast Gate Valve PDFDocument4 pagesKSB Sicca HP Cast Gate Valve PDFJamalPas encore d'évaluation

- 45 Perlite For Non-Evacuated CryogenicDocument2 pages45 Perlite For Non-Evacuated CryogenicAhmar Bhatti100% (1)

- Constrution For Lining RC PoolDocument4 pagesConstrution For Lining RC Poolmuchamad yasinPas encore d'évaluation

- 880 Series Inverted Bucket Steam TrapsDocument2 pages880 Series Inverted Bucket Steam TrapsCherbee FerrerPas encore d'évaluation

- Velan High Pressure Steam Trapping Brochure PDFDocument8 pagesVelan High Pressure Steam Trapping Brochure PDFSH1961Pas encore d'évaluation

- GPS PE Pipe Systems DimensionsDocument92 pagesGPS PE Pipe Systems DimensionsM S AnandPas encore d'évaluation

- Wavin PE Pressure Pipes Data SheetDocument2 pagesWavin PE Pressure Pipes Data SheetConspiracy_PTPas encore d'évaluation

- Unlock-Durcomet 100 (CD-4MCu)Document8 pagesUnlock-Durcomet 100 (CD-4MCu)Dimas Pratama PutraPas encore d'évaluation

- ASME B31.1-2001-12 Table 121.5Document1 pageASME B31.1-2001-12 Table 121.5karim hilalPas encore d'évaluation

- KIRK KWM Mist EliminatorsDocument3 pagesKIRK KWM Mist EliminatorsperrychemPas encore d'évaluation

- Forbes Marshall Piston ValvesDocument8 pagesForbes Marshall Piston ValvesAnonymous 0CnvpxSPas encore d'évaluation

- Analogi MaterialovDocument8 pagesAnalogi MaterialovrouquinPas encore d'évaluation

- Halar-Lined Tank Questionnaire Rev3Document2 pagesHalar-Lined Tank Questionnaire Rev3maxpower1984Pas encore d'évaluation

- Filter MRS Tartarini EmersonDocument12 pagesFilter MRS Tartarini EmersonbayuPas encore d'évaluation

- 04 Buttweldfitt Tee Din2615Document7 pages04 Buttweldfitt Tee Din2615ivanmatijevicPas encore d'évaluation

- Suction Heaters and Heating Coils Suction Heaters and Heating CoilsDocument3 pagesSuction Heaters and Heating Coils Suction Heaters and Heating CoilsDaysianne100% (1)

- Gasket BrochureDocument8 pagesGasket BrochureKumar JbsPas encore d'évaluation

- Marvac CatalogueDocument40 pagesMarvac CataloguedhavaleshPas encore d'évaluation

- Thermowell Calculation Guide V1.3Document19 pagesThermowell Calculation Guide V1.3AymanelorbanyPas encore d'évaluation

- Natural Gas Filtration & Separation: To Separate Solid & Liquid Impurities From Natural GasDocument7 pagesNatural Gas Filtration & Separation: To Separate Solid & Liquid Impurities From Natural GasMehdi Hajd KacemPas encore d'évaluation

- Jacketed PipesDocument11 pagesJacketed PipesvuongPas encore d'évaluation

- GB Teguflex A4 2015Document8 pagesGB Teguflex A4 2015eliasx1Pas encore d'évaluation

- Piping Design StandardDocument16 pagesPiping Design StandardHướng PhạmPas encore d'évaluation

- Cast - Basket Strainers - 2nd EditionDocument27 pagesCast - Basket Strainers - 2nd EditionmartinnovelPas encore d'évaluation

- A 1 KDocument5 pagesA 1 KSumantrra ChattopadhyayPas encore d'évaluation

- DSFSDFDVDFDocument33 pagesDSFSDFDVDFfahmi azisPas encore d'évaluation

- KLINGERsilC-4500 Gasket MaterialDocument2 pagesKLINGERsilC-4500 Gasket MaterialHardik AcharyaPas encore d'évaluation

- Graphite PSM AsDocument2 pagesGraphite PSM AspandiangvPas encore d'évaluation

- AFM34 E-AnsichtDocument2 pagesAFM34 E-AnsichtDaniel Grajeda CortesPas encore d'évaluation

- K 1000Document2 pagesK 1000Ikhsan LyPas encore d'évaluation

- AC Plastiques 1,2,3 - General Catalog PDFDocument5 pagesAC Plastiques 1,2,3 - General Catalog PDFRicardo BustamantePas encore d'évaluation

- 175 Degree Heat Shrink PVDF TubingDocument2 pages175 Degree Heat Shrink PVDF Tubingsales3167Pas encore d'évaluation

- Kooltherm PipeDocument8 pagesKooltherm Pipenaseema1Pas encore d'évaluation

- OPA356 OPA2356: Description FeaturesDocument18 pagesOPA356 OPA2356: Description FeaturesPeter JordanPas encore d'évaluation

- Lmv60X 1-Mhz, Low-Power, General-Purpose, 2.7-V Operational AmplifiersDocument38 pagesLmv60X 1-Mhz, Low-Power, General-Purpose, 2.7-V Operational AmplifiersPeter JordanPas encore d'évaluation

- Tim WilliamsDocument54 pagesTim WilliamsPeter JordanPas encore d'évaluation

- Clase D 200wattsDocument3 pagesClase D 200wattsPeter JordanPas encore d'évaluation

- Milli Ohm AdapterDocument6 pagesMilli Ohm AdapterPeter JordanPas encore d'évaluation

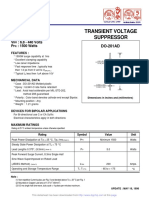

- 1.5ke Series: Transient Voltage SuppressorDocument4 pages1.5ke Series: Transient Voltage SuppressorPeter JordanPas encore d'évaluation

- Amp 30 DDocument2 pagesAmp 30 DPeter JordanPas encore d'évaluation

- Class D 200 Wrms With 2 Mosfet Single Sided Ucd Style Schematic PDFDocument1 pageClass D 200 Wrms With 2 Mosfet Single Sided Ucd Style Schematic PDFPeter JordanPas encore d'évaluation

- NPN Silicon AF and Switching Transistor: V V V I I I I T PDocument7 pagesNPN Silicon AF and Switching Transistor: V V V I I I I T PPeter JordanPas encore d'évaluation

- Domadol: Tramadol HydrochlorideDocument1 pageDomadol: Tramadol HydrochloridePeter JordanPas encore d'évaluation

- JCV8034Document1 pageJCV8034Peter JordanPas encore d'évaluation

- Description: EGS002 Sinusoid Inverter Driver Board User ManualDocument6 pagesDescription: EGS002 Sinusoid Inverter Driver Board User ManualPeter JordanPas encore d'évaluation

- NTE5411 Thru NTE5416 Silicon Controlled Rectifier (SCR) 4 Amp, Sensitive Gate, TO126Document3 pagesNTE5411 Thru NTE5416 Silicon Controlled Rectifier (SCR) 4 Amp, Sensitive Gate, TO126Peter JordanPas encore d'évaluation

- Ax4, Ax5 ManualDocument16 pagesAx4, Ax5 ManualPeter JordanPas encore d'évaluation

- Principles and Applications of The ICL7660 CMOS Voltage Converter PDFDocument10 pagesPrinciples and Applications of The ICL7660 CMOS Voltage Converter PDFPeter JordanPas encore d'évaluation

- Voltronicpower Axpert Mks-4000 Ks-5000 Charger-Inverter SMDocument27 pagesVoltronicpower Axpert Mks-4000 Ks-5000 Charger-Inverter SMPeter Jordan60% (5)

- Unit Rode Linear Integrated Circuits Data BookDocument824 pagesUnit Rode Linear Integrated Circuits Data BookPeter JordanPas encore d'évaluation

- Single Phase Automatic Voltage Regulator DesignDocument9 pagesSingle Phase Automatic Voltage Regulator DesignPeter JordanPas encore d'évaluation

- LMC6034 CMOS Quad Operational Amplifier: General DescriptionDocument13 pagesLMC6034 CMOS Quad Operational Amplifier: General DescriptionPeter JordanPas encore d'évaluation

- RO2 Optical SensorsDocument1 pageRO2 Optical SensorsPeter JordanPas encore d'évaluation

- Sn74als109 TDocument19 pagesSn74als109 TPeter JordanPas encore d'évaluation

- Installation Module: Xarios RangeDocument20 pagesInstallation Module: Xarios Rangefaza1111Pas encore d'évaluation

- AISI 1045 Mechanical PropertiesDocument1 pageAISI 1045 Mechanical PropertiesDaniela Almeida0% (1)

- Caterpillar Disassembly and Assembly Transmission 950g and 962g Wheel LoaderDocument20 pagesCaterpillar Disassembly and Assembly Transmission 950g and 962g Wheel Loaderpatrick100% (40)

- 20 THDocument2 pages20 THdohamatePas encore d'évaluation

- Innova M3 New: 3. InstallationDocument8 pagesInnova M3 New: 3. InstallationAndreea DanielaPas encore d'évaluation

- Span TS 3005Document25 pagesSpan TS 3005Muhamad Farhan0% (1)

- R 22Document22 pagesR 22Luis MartinezPas encore d'évaluation

- WBS For Metro ProjectDocument3 pagesWBS For Metro ProjectPooja PawarPas encore d'évaluation

- Product Guide Fiber Reinforced Polymer (GFRP) Bars For Concrete ReinforcementDocument9 pagesProduct Guide Fiber Reinforced Polymer (GFRP) Bars For Concrete ReinforcementBayram Aygun100% (1)

- Testing & Commissioning of Domestic Water PumpsDocument5 pagesTesting & Commissioning of Domestic Water PumpsHishamGharbiahPas encore d'évaluation

- The Possible Possible Automotive Applications Automotive Applications of Glass Microspheres of Glass MicrospheresDocument30 pagesThe Possible Possible Automotive Applications Automotive Applications of Glass Microspheres of Glass MicrospheresFJNovaes454Pas encore d'évaluation

- E Yanmar 2v78caDocument42 pagesE Yanmar 2v78caDannyPas encore d'évaluation

- K EjectionDocument21 pagesK EjectionAmolPagdalPas encore d'évaluation

- Standard Chain Link Design DetailDocument3 pagesStandard Chain Link Design Detailregkray01Pas encore d'évaluation

- Ladder Stiles Retractable Data SheetDocument1 pageLadder Stiles Retractable Data SheetnandanaPas encore d'évaluation

- Construction Crystal PerliteDocument8 pagesConstruction Crystal PerlitenandanaPas encore d'évaluation

- Tolerances Monorail BeamDocument9 pagesTolerances Monorail BeamLuis MogrovejoPas encore d'évaluation

- Multiline-Stone Coated Roofing Balinese ShakesDocument2 pagesMultiline-Stone Coated Roofing Balinese ShakesjbonvierPas encore d'évaluation

- Camden Central Community UmbrellaDocument98 pagesCamden Central Community UmbrellaTom YoungPas encore d'évaluation

- Vbe Calculation Washington State DOT SOP732Document18 pagesVbe Calculation Washington State DOT SOP732DigantPas encore d'évaluation

- 04 FORM Personal Daily Report HSEDocument4 pages04 FORM Personal Daily Report HSEArga Sakti YusnandarPas encore d'évaluation

- Pipe Is 3601Document5 pagesPipe Is 3601Tarun VermaPas encore d'évaluation

- KAT-A 1912 DUOJET Edition13 02-01-2017 ENDocument6 pagesKAT-A 1912 DUOJET Edition13 02-01-2017 ENwinston11Pas encore d'évaluation

- Durability of Concrete Exposed To Marine Environment-A Fresh LookDocument30 pagesDurability of Concrete Exposed To Marine Environment-A Fresh LookElizabeth CruzPas encore d'évaluation