Académique Documents

Professionnel Documents

Culture Documents

FAQ - Pump Tech Details

Transféré par

Raghavendra SarafTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

FAQ - Pump Tech Details

Transféré par

Raghavendra SarafDroits d'auteur :

Formats disponibles

FAQ Pump Tech Details

Calculating Horse power Required for your Pump

In order to Select a Pump all you need is the vertical height of the place where water has to be

pumped and the amount of water you will be needing per minute / hour.

After calculating the parameters there is a simple formula which can calculate how much HP

Pump is suitable for the job.

HP =

Q (flow) X H(Head / Hieght) X Specific Gravity (of the liquid to be pumped)

3960 X efficiency (which can be considered around 70 %)

Download Manuals

Dewatering Pumps Manual

Polder Pumps Manual

Portable Submesible Pumps Manual

Submesible Sewage Pumps Manual

HIghlight of Submerged Centrifugal Pumps in comparision with Centrifugal / Vertical

Turbine Pumps

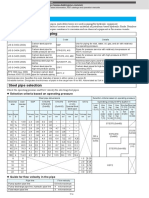

Different MOC guide

Type of liquid

Impeller

Volute

Motor body

Raw water

Cast Iron

Cast Iron

Cast Iron

DM water

SS 304 / Bronze

SS 304 / Bronze

Cast Iron (If surface

pump)

Steel Plant Slurry

Bronze / SS 316

Cast Iron

Cast Iron

Ash Slurry

Ni Hard / High

Chrome

SS 316

Cast Iron

Chemical transfer

SS 316 / SS 316 L /

Cast Steel

SS 316 / SS 316 L /

Cast Steel

Cast Steel

Commercial waste

Cast Iron / SS 304

Cast Iron

Cast Iron

Residential Sewage

Cast Iron / SS 304

Cast Iron

Cast Iron

Sea Water

SS 316 / SS 316 L

SS 316

SS 316

River water

Bronze

Cast Iron

Cast Iron

Cooling tower

Graded Cast Iron /

Bronze

Cast Iron

Cast Iron

Paper And Pulp

SS 316 / High

Chrome / SS 316 L

SS 316 / SS 316 L

Cast Iron

Mechanical Seal Selection Guide

Classification

Faces

Secondary Seal

Packing

Gland

Acids up to 65 C

Carbon / Silicon Carbide

Viton

Teflon

316 SS

Acids up to 150 c

Carbon / Ceramic

Teflon

Teflon

316 - SS

Ethylene

Propylene

316 - SS

Ethylene

Propylene

316 - SS

Viton

Viton

316 SS

Food products Non Carbon / Silicon Carbide

Abrasive

Food Products

Tungsten Carbide /

Silicon Carbide

Severely Abrasive

Heat Transfer Fluids Carbon / Silicon Carbide

upto 200 c

Heat Transfer Fluids

for horizontal

pumps which may

Caviate

Tungsten Carbide /

Tungsten Carbide

Annealed SS

Teflon

316 SS

Heat Transfer Fluids

above 200 c

Tungsten Carbide /

Tungsten Carbide

Annealed SS

Teflon

316 SS

Water with Abrasive

with salt up to 180 C

Tungsten Carbide /

Silicon Carbide

Ethylene

Propylene

Ethylene

Propylene

316 - SS

Paper Mill Fluids up

to 150 C

Tungsten Carbide /

Silicon Carbide

Ethylene

Propylene

316 - SS

http://www.mbhpumps.com/faq.htm

Vous aimerez peut-être aussi

- Coolant Pumps: Tough Engisol PVT LTDDocument3 pagesCoolant Pumps: Tough Engisol PVT LTDShila DixitPas encore d'évaluation

- HPS Trainning For PAM Ecuador 2019Document72 pagesHPS Trainning For PAM Ecuador 2019maleta roja6Pas encore d'évaluation

- A 02 1064Document4 pagesA 02 1064Marliton SalinasPas encore d'évaluation

- Vertical Sump PumpDocument6 pagesVertical Sump Pumpsahildhingra100% (1)

- Bornemann TSP HP Doble TornilloDocument8 pagesBornemann TSP HP Doble TornilloJosé Luis CoronadoPas encore d'évaluation

- Etaline RDocument2 pagesEtaline RjoejumbooPas encore d'évaluation

- Vertical Multistage Pumps Series 4700: Solution OutlineDocument8 pagesVertical Multistage Pumps Series 4700: Solution OutlineProyecyma CAPas encore d'évaluation

- Peerless Full Product Line B-1270 - BrochureDocument12 pagesPeerless Full Product Line B-1270 - BrochureHuilber MartínezPas encore d'évaluation

- Vertical Sump Pumps GuideDocument12 pagesVertical Sump Pumps GuideMiguel V. PalPas encore d'évaluation

- Centrifugal Slurry PumpDocument3 pagesCentrifugal Slurry PumpJimmyhuPas encore d'évaluation

- Pump Catalog: Product Quality, Reliability and Support You ExpectDocument24 pagesPump Catalog: Product Quality, Reliability and Support You ExpectCharles Onyechere100% (1)

- FX6-10 Submersible PumpsDocument8 pagesFX6-10 Submersible PumpsAwaz E HaqPas encore d'évaluation

- OhnsDocument9 pagesOhnsspsurya2013Pas encore d'évaluation

- 993320E CAT Pump Catalog LoRDocument24 pages993320E CAT Pump Catalog LoRsriguruprasathsPas encore d'évaluation

- External Gear Pump PrinciplesDocument3 pagesExternal Gear Pump PrinciplesJam BabPas encore d'évaluation

- Slide - Piping and Fluid Moving DevicesDocument49 pagesSlide - Piping and Fluid Moving DevicesMrunaal NaseryPas encore d'évaluation

- Bombas de Cavidad ProgresivaDocument8 pagesBombas de Cavidad ProgresivaJohanna RojasPas encore d'évaluation

- MiningDocument28 pagesMiningUday GokhalePas encore d'évaluation

- Asco Pump: High Quality High Performance Axial Split Case PumpDocument8 pagesAsco Pump: High Quality High Performance Axial Split Case PumpNuM NaPas encore d'évaluation

- Sintech Make Pumps For Power Generation IndustryDocument16 pagesSintech Make Pumps For Power Generation Industrysahildhingra0% (1)

- Axially Splitcase Pumps - HS & HST SeriesDocument12 pagesAxially Splitcase Pumps - HS & HST SeriesSuhas Natu100% (1)

- Choosing the Right Vane Pump for Your ProcessDocument25 pagesChoosing the Right Vane Pump for Your ProcessGirlish JackiePas encore d'évaluation

- JTS Standard Vertical Turbine Pumps en E00727 6 2010Document8 pagesJTS Standard Vertical Turbine Pumps en E00727 6 2010yunusisPas encore d'évaluation

- KSB Centrifugal PumpsDocument12 pagesKSB Centrifugal Pumpswoodywheel100% (1)

- Sintech Pumps For Sugar Processing PlantDocument18 pagesSintech Pumps For Sugar Processing Plantsahildhingra100% (2)

- CAT Pump Catalog 2016 LDocument24 pagesCAT Pump Catalog 2016 LGustavo Adolfo Molina GuillenPas encore d'évaluation

- Manufacturing: Manufacturing Is To Produce Something (Articles) in A Manner of MachineDocument24 pagesManufacturing: Manufacturing Is To Produce Something (Articles) in A Manner of MachineCRS TirupatiPas encore d'évaluation

- Tsubaki Steel Mill ChainsDocument10 pagesTsubaki Steel Mill ChainsSandip GhoshPas encore d'évaluation

- Page Cogen HRSADocument1 pagePage Cogen HRSAandy131078Pas encore d'évaluation

- Massflow Engineers: Ss Centrifugal PumpsDocument4 pagesMassflow Engineers: Ss Centrifugal PumpsGabrielmatius GaboPas encore d'évaluation

- Vertical Turbine Submersible Pump BrochureDocument12 pagesVertical Turbine Submersible Pump BrochuremasatusPas encore d'évaluation

- Throu-Flex Technical Leaflet - Hydraulic Hose AssemblyDocument2 pagesThrou-Flex Technical Leaflet - Hydraulic Hose AssemblyThrou-FlexPas encore d'évaluation

- 00 AWWA StandardsDocument3 pages00 AWWA Standardsliviu_dovaPas encore d'évaluation

- C-J Catalog N - Cooker-CoolersDocument4 pagesC-J Catalog N - Cooker-CoolersSky SpectrePas encore d'évaluation

- Positron Heat Exchangers LeafletDocument6 pagesPositron Heat Exchangers Leafletkvp0107Pas encore d'évaluation

- SAE L6, Steel Grades, Tool SteelDocument1 pageSAE L6, Steel Grades, Tool SteelMayur12345dt0% (1)

- Cooling Tower SpecificationDocument14 pagesCooling Tower SpecificationAmzad DPPas encore d'évaluation

- Waste Heat Recovery BoilerDocument28 pagesWaste Heat Recovery BoilerNath Boyapati100% (2)

- Lowara Cat GeralDocument288 pagesLowara Cat GeralVitor Padrão100% (1)

- Hydraulic PipingDocument1 pageHydraulic Pipingpandunugraha04Pas encore d'évaluation

- PumpsDocument62 pagesPumpsvenkateshPas encore d'évaluation

- Complete Range of Sintech Make PumpsDocument8 pagesComplete Range of Sintech Make PumpssahildhingraPas encore d'évaluation

- SERIES 2000 TEMPERATURE REGULATOR SPECIFICATIONSDocument8 pagesSERIES 2000 TEMPERATURE REGULATOR SPECIFICATIONSLuis Gutiérrez AlvarezPas encore d'évaluation

- PumpDocument14 pagesPumpdhineshpPas encore d'évaluation

- Design Features Applications: CLH Vertical Centrifugal Pump CatalogueDocument2 pagesDesign Features Applications: CLH Vertical Centrifugal Pump CatalogueMas Dwi Lestari100% (1)

- Industrial PumpsDocument24 pagesIndustrial PumpsMANASPas encore d'évaluation

- CVT Vertically Suspended Sump PumpDocument6 pagesCVT Vertically Suspended Sump PumpJose CarlosPas encore d'évaluation

- BakerSPD Choke Tech Handbook 5-9-06 PDFDocument14 pagesBakerSPD Choke Tech Handbook 5-9-06 PDFCassielAlexzylalas LiambaPas encore d'évaluation

- SPX Twin Screw Pumps PDFDocument8 pagesSPX Twin Screw Pumps PDFarunkumar17Pas encore d'évaluation

- DT 50 HZ Technical CatalogDocument44 pagesDT 50 HZ Technical Catalogphuocdungnguyen_2760Pas encore d'évaluation

- Passenger Coach Design for Easy MaintenanceDocument129 pagesPassenger Coach Design for Easy Maintenanceravi_entertainfoPas encore d'évaluation

- CR, CRN High Pressure: Grundfos Product GuideDocument48 pagesCR, CRN High Pressure: Grundfos Product Guiderodriguez.gaytanPas encore d'évaluation

- Bơm EurofloDocument8 pagesBơm EuroflokimcucspktPas encore d'évaluation

- J J Water Tech 2023Document3 pagesJ J Water Tech 2023oliviaPas encore d'évaluation

- 13 Solid Carbide Milling CuttersDocument309 pages13 Solid Carbide Milling CuttersManu GimenezPas encore d'évaluation

- Tespl Waste Heat Recovery BoilerDocument14 pagesTespl Waste Heat Recovery BoilerJoão Paulo VissottoPas encore d'évaluation

- Fundamentals of Vacuum Technology: 00.200.02 Kat.-Nr. 199 90Document199 pagesFundamentals of Vacuum Technology: 00.200.02 Kat.-Nr. 199 90Anshul JainPas encore d'évaluation

- Pump Suction ArrangementsDocument24 pagesPump Suction ArrangementskidseismicPas encore d'évaluation

- Guia de Seleccion Baldor para ElevacionDocument54 pagesGuia de Seleccion Baldor para ElevacionJesus MontesPas encore d'évaluation

- Poonam Catalogue PDFDocument20 pagesPoonam Catalogue PDFAbrar AhmadPas encore d'évaluation

- Aalco Stainless Steel Tube Product GuideDocument92 pagesAalco Stainless Steel Tube Product GuideAnonymous 5S5j8wOPas encore d'évaluation

- VACUUM AND PRESSURE SYSTEMS HANDBOOK - Gastmfg PDFDocument20 pagesVACUUM AND PRESSURE SYSTEMS HANDBOOK - Gastmfg PDFDayo IdowuPas encore d'évaluation

- Material SpecificationDocument50 pagesMaterial SpecificationSangyt Karna0% (2)

- Power Factor Testing of Stator Winding InsulationDocument5 pagesPower Factor Testing of Stator Winding InsulationMichael Parohinog GregasPas encore d'évaluation

- How To Inspect A GearboxDocument17 pagesHow To Inspect A GearboxRaghavendra SarafPas encore d'évaluation

- Bi-Metallic Overload Relays Selection Guide - Rockwell Automation PDFDocument14 pagesBi-Metallic Overload Relays Selection Guide - Rockwell Automation PDFRaghavendra SarafPas encore d'évaluation

- S Tubes PDFDocument32 pagesS Tubes PDFRagu RajanPas encore d'évaluation

- Formula: Engineering FormulaeDocument2 pagesFormula: Engineering FormulaeRaghavendra SarafPas encore d'évaluation

- Overload RelayDocument21 pagesOverload RelayRoshan ShanmughanPas encore d'évaluation

- Troubleshoot Poor or Distorted PictureDocument8 pagesTroubleshoot Poor or Distorted PicturePedro Alarcon100% (2)

- Sound & Vibration in Rolling BearingsDocument9 pagesSound & Vibration in Rolling BearingsRaghavendra SarafPas encore d'évaluation

- Surge Suppressors: How The Surge Suppressor WorksDocument1 pageSurge Suppressors: How The Surge Suppressor WorksRaghavendra SarafPas encore d'évaluation

- Automotive Porosity Sealing by Design - LoctiteDocument20 pagesAutomotive Porosity Sealing by Design - LoctiteRaghavendra SarafPas encore d'évaluation

- What Is ResonanceDocument10 pagesWhat Is ResonanceRaghavendra SarafPas encore d'évaluation

- 2-Pole Turbo-Gen Eccentricity Diagnosis by Split-Phase Current Signature Analysis PDFDocument10 pages2-Pole Turbo-Gen Eccentricity Diagnosis by Split-Phase Current Signature Analysis PDFRaghavendra SarafPas encore d'évaluation

- Document Conversion FormatsDocument39 pagesDocument Conversion FormatsRaghavendra SarafPas encore d'évaluation

- Hardness Table: Rockwell, Brinell, Vickers ScalesDocument3 pagesHardness Table: Rockwell, Brinell, Vickers ScalesRaghavendra SarafPas encore d'évaluation

- 2-Pole Turbo-Gen Eccentricity Diagnosis by Split-Phase Current Signature Analysis PDFDocument10 pages2-Pole Turbo-Gen Eccentricity Diagnosis by Split-Phase Current Signature Analysis PDFRaghavendra SarafPas encore d'évaluation

- Formula: Engineering FormulaeDocument2 pagesFormula: Engineering FormulaeRaghavendra SarafPas encore d'évaluation

- Compressed Air QualityDocument5 pagesCompressed Air QualityRaghavendra SarafPas encore d'évaluation

- Bibilography Relevant To Surge Voltage Protection of AC MachineryDocument9 pagesBibilography Relevant To Surge Voltage Protection of AC MachineryRaghavendra SarafPas encore d'évaluation

- Important Electrical Properties of CRGO & Hi - B CRGO Grades SteelDocument5 pagesImportant Electrical Properties of CRGO & Hi - B CRGO Grades SteelRaghavendra SarafPas encore d'évaluation

- Hazardous Area StandardsDocument17 pagesHazardous Area StandardsRaghavendra SarafPas encore d'évaluation

- Care & Maint. of Bearings - NTN PDFDocument26 pagesCare & Maint. of Bearings - NTN PDFRaghavendra Saraf100% (1)

- Methods of extraction: Pyrometallurgy Techniques (Stage 2Document22 pagesMethods of extraction: Pyrometallurgy Techniques (Stage 2Oluwasegun OkajarePas encore d'évaluation

- Acids, Bases and Salts PDFDocument2 pagesAcids, Bases and Salts PDFHakim Abbas Ali PhalasiyaPas encore d'évaluation

- Nitrobenzene ManufacturingDocument21 pagesNitrobenzene ManufacturingHajra AamirPas encore d'évaluation

- Ficha Tecnica NordelDocument2 pagesFicha Tecnica NordelStephany HernándezPas encore d'évaluation

- Dust CleanerDocument2 pagesDust CleanercendraPas encore d'évaluation

- Topic 10 TestDocument10 pagesTopic 10 TestJi Bin SorPas encore d'évaluation

- Practical No 10 - Natural IndicatorsDocument6 pagesPractical No 10 - Natural Indicatorscarbon dioPas encore d'évaluation

- Research Progress On Sustainability of Key Tire MaDocument28 pagesResearch Progress On Sustainability of Key Tire MasagarPas encore d'évaluation

- Extraction and Estimation of Essential Oils and Other Extracts from Eucalyptus camadulensis LeavesDocument12 pagesExtraction and Estimation of Essential Oils and Other Extracts from Eucalyptus camadulensis Leavesmagdy edreesPas encore d'évaluation

- Reducing Agents in The Leaching of Manganese Ores - A Comprehensive ReviewDocument19 pagesReducing Agents in The Leaching of Manganese Ores - A Comprehensive ReviewDaniela AbarcaPas encore d'évaluation

- Peenya RtiDocument25 pagesPeenya Rtisatish vermaPas encore d'évaluation

- Kinetik Technologies Product GuideDocument40 pagesKinetik Technologies Product GuidegowestcreativePas encore d'évaluation

- SFR Prueba de Entrenamiento Jean RamosDocument6 pagesSFR Prueba de Entrenamiento Jean Ramosjean ramos marinPas encore d'évaluation

- Nov 2006 Paper 3 Mark SchemeDocument12 pagesNov 2006 Paper 3 Mark SchemeilnukPas encore d'évaluation

- Report of Industrial Visit at BELUR MATHDocument3 pagesReport of Industrial Visit at BELUR MATHSîdDhàñt SätYãmPas encore d'évaluation

- Questions For Well Life Cycle SessionDocument17 pagesQuestions For Well Life Cycle SessionShubham PatelPas encore d'évaluation

- 5 Centrifuge Tubes Evaporating Dish Test Tube Holder Crucible Tongs Two Droppers Latex Gloves LabelsDocument16 pages5 Centrifuge Tubes Evaporating Dish Test Tube Holder Crucible Tongs Two Droppers Latex Gloves LabelsMatti MendozaPas encore d'évaluation

- Chemistry - Test PrepDocument7 pagesChemistry - Test PrepMCHPas encore d'évaluation

- Indole and Pyrrole Synthesis PDFDocument19 pagesIndole and Pyrrole Synthesis PDFAnuar HernandezPas encore d'évaluation

- Bourne 2003Document38 pagesBourne 2003Gopal KasatPas encore d'évaluation

- Environment - Energy & Alternative Sources-NewDocument32 pagesEnvironment - Energy & Alternative Sources-NewkirannrgPas encore d'évaluation

- Zinc Phosphate CementDocument19 pagesZinc Phosphate CementNaghman ZuberiPas encore d'évaluation

- Oil Companies PakistanDocument1 pageOil Companies PakistanAnonymous HjB1bhmPas encore d'évaluation

- Extraction of Caffein From Tea and Sublimation of Crude CaffeinDocument4 pagesExtraction of Caffein From Tea and Sublimation of Crude CaffeinMargel PeconPas encore d'évaluation

- Preparation of Unlead BSCCO Superconductor With Critical Temperature 110KDocument4 pagesPreparation of Unlead BSCCO Superconductor With Critical Temperature 110KAdhitya DwijayanthoPas encore d'évaluation

- Noble Chlor Electrochlorination Systems PDFDocument2 pagesNoble Chlor Electrochlorination Systems PDFVenkatesha RaoPas encore d'évaluation

- D5819-05 (Reapproved 2016)Document11 pagesD5819-05 (Reapproved 2016)mithileshPas encore d'évaluation

- Pipe & Tube SpecificationsDocument3 pagesPipe & Tube SpecificationsIbrahim Ali100% (1)

- 3 Fire and HeatDocument10 pages3 Fire and HeatMahbub AlamPas encore d'évaluation

- Safety Data Sheet: 1. Product and Company IdentificationDocument7 pagesSafety Data Sheet: 1. Product and Company Identificationmohamed AdelPas encore d'évaluation