Académique Documents

Professionnel Documents

Culture Documents

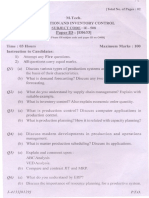

PE 04 703 Production Management MAY 2013

Transféré par

rasoolnkDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

PE 04 703 Production Management MAY 2013

Transféré par

rasoolnkDroits d'auteur :

Formats disponibles

"Vidya Digital Library"

C 42745

(Pages: 3)

Name........................................ .

Reg. No.................................... .

SEVENTH SEMESTER B.TECH. (ENGINEERING) DEGREE EXAMINATION

MAY 2013

PE 04 703-PRODUCTION MANAGEMENT

(2004 Admissions)

Maximum: 100 Marks

Time: Three Hours

Answer all questions.

I.

1 Define production system. State the different types of production system.

2 What are the possible approaches of forecasting demand for new product? Explain.

3 How does manufacturing resource planning differ from material requirement planning?

4 Following table shows the minimum time (in hours) for five jobs on two different machines.

Passing is not allowed. Find the optimal sequence in which jobs should be processed

Job

Machine Ml

Machine M2

5 Explain the function of Purchase Management.

6 Describe briefly the HML analysis of inventory control.

7 What is the necessity for plant layout?

8 What are the economic factors of the material handling system ?

(8 x 5 = 40 marks)

Answer all questions.

II. (A) Discuss briefly the various methods of forecasting demand and point out their limitations.

What are the criteria of a good forecasting method?

(15 marks)

Or

(B) Define master production scheduling with an example explain the factors that need to be

taken into account while developing master production schedule.

(15 marks)

Turn over

-----'---------------------~~~----~----~--~--- ..... ~--.,..~

"Vidya Digital Library"

"Vidya Digital Library"

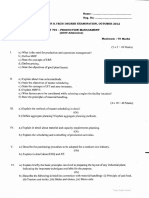

C 42745

2

III. (A)

(i)

Explain the concept of MRP and describe its inputs and their relationship.

(12 marks)

(3 marks)

(ii) What are the advantages of ERP ?

Or

(B)

(i) What is manufacturing resource planning? How does it benefit the management of a

factory.

(7 marks)

(ii) What are the differences between capacity planning and resource requirement

planning? Explain the function of each.

(8

IV. (A)

marks)

(i) A dealer supplies you the following information with regard to a product dealt in

..

by him:--':"

Annual demand

6000 units

Buying cost

::::

Rs. 250. 00 per order

Inventory carrying cost

::::

30% per year

Price

::::

Rs. 100.00 per unit.

The dealer is considering the possibility of allowing home back orders to occur for the

product. He has estimated that the annual cost of back ordering (allowing shortages) the

product will be Rs. 10.00 per unit.

(1) What quantity ofthe product should be allow to be back ordered.

(6 marks)

(2) How much additional cost will be have to incur on inventory ifhe does not permit

back-ordering?

(6 marks)

(ii) What is an inventory system? Explain the term safety stock.

(3 marks)

Or

(B)

(i) ABC manufacturing company needs balls bearing of worth Rs. 28,800 per year. The cost

of placing an order is Rs. 48 and inventory carrying cost as a percentage of inventory

investment is 12%. Determine

en

Value of each assignment.

(in Number of orders per year.

(6 marks)

(3 marks)

(ii) What is the concept of ABC analysis? How is it used for inventory control. What is the

procedure?

(6 marks)

"Vidya Digital Library"

"Vidya Digital Library"

3

V. (A)

(i) Explain the different types of layout with neat sketch.

(ii) Explain the factors influencing the plant layout.

C 42745

(9 marks)

(6 marks)

Or

(B)'

(i)

Explain the principles and importance of material handling system.

(ii) State the different types of material handling equipments.

(12 marks)

(3 marks)

[4 x 15 = 60 marks]

"Vidya Digital Library"

_ . _., . _ J

Vous aimerez peut-être aussi

- Squeegee Collaborative Working Action PlanDocument27 pagesSqueegee Collaborative Working Action PlanTim SwiftPas encore d'évaluation

- Project Management Tools & TechniquesDocument104 pagesProject Management Tools & TechniquesAdib Tawfiq100% (10)

- 4 DmodelDocument11 pages4 DmodelPreeti SoniPas encore d'évaluation

- Comparative Company Analyses - Presentation: Content of AnalysisDocument2 pagesComparative Company Analyses - Presentation: Content of Analysisholo2016Pas encore d'évaluation

- Hay Job Evaluation WP From Hay WebsiteDocument18 pagesHay Job Evaluation WP From Hay WebsiteAnushree RastogiPas encore d'évaluation

- Summary On Republic Act 6713 Code of Conduct and Ethical Standards For Public Officials and EmployeesDocument3 pagesSummary On Republic Act 6713 Code of Conduct and Ethical Standards For Public Officials and EmployeesAndrei AndoyPas encore d'évaluation

- Operations ManagementDocument7 pagesOperations ManagementPrabhamohanraj MohanrajPas encore d'évaluation

- Industrial Engineering Model Question PaperDocument2 pagesIndustrial Engineering Model Question PaperKailas Sree Chandran100% (1)

- The OC Curve of Attribute Acceptance PlansDocument7 pagesThe OC Curve of Attribute Acceptance PlansOusmane CissePas encore d'évaluation

- HW 1Document8 pagesHW 1Vijay Thakkar0% (1)

- Optimizing Factory Performance: Cost-Effective Ways to Achieve Significant and Sustainable ImprovementD'EverandOptimizing Factory Performance: Cost-Effective Ways to Achieve Significant and Sustainable ImprovementPas encore d'évaluation

- ProductionPlanningAndControl MB065 QuestionDocument22 pagesProductionPlanningAndControl MB065 QuestionAiDLoPas encore d'évaluation

- Operaton Q. PDocument47 pagesOperaton Q. PPravin KeskarPas encore d'évaluation

- ProductionAndOperationsManagement MB014 QuestionDocument29 pagesProductionAndOperationsManagement MB014 QuestionAiDLo100% (1)

- PM April-May 2013 PDFDocument2 pagesPM April-May 2013 PDFShashi Bhushan PatelPas encore d'évaluation

- Maximum: 100 Marks Part A 40 Marks) : OCTOBER 2008Document9 pagesMaximum: 100 Marks Part A 40 Marks) : OCTOBER 2008shikhatiwari777Pas encore d'évaluation

- Production Engineering V SEM SET-1Document3 pagesProduction Engineering V SEM SET-1Shathish GunasekaranPas encore d'évaluation

- Production Planning and ControlDocument8 pagesProduction Planning and ControlKamal ChaitanyaPas encore d'évaluation

- MBA - PDF OctDocument153 pagesMBA - PDF OctMayur KasarPas encore d'évaluation

- MBA22 - Production & Operations ManagementDocument2 pagesMBA22 - Production & Operations ManagementNayan KanthPas encore d'évaluation

- Question Bank Operations Management MGA 602Document6 pagesQuestion Bank Operations Management MGA 602Jennifer JosephPas encore d'évaluation

- PM QBDocument7 pagesPM QBmayur_mechPas encore d'évaluation

- OM - I-III Chaptetrs Question BankDocument5 pagesOM - I-III Chaptetrs Question Bankchandrarao chPas encore d'évaluation

- PPC Model QPDocument2 pagesPPC Model QPS Deva PrasadPas encore d'évaluation

- P.G. Diploma Examination - 2010: (Applied Operations Research)Document3 pagesP.G. Diploma Examination - 2010: (Applied Operations Research)Ayswarya SrinivasanPas encore d'évaluation

- Karunya University: M.B.A. Trimester Examination - January 2010Document2 pagesKarunya University: M.B.A. Trimester Examination - January 2010nandhuPas encore d'évaluation

- PPCE Important QuestionsDocument22 pagesPPCE Important Questionspaneer selvamPas encore d'évaluation

- 13Document2 pages13itachi uchihaPas encore d'évaluation

- HT TP: //qpa Pe R.W But .Ac .In: 2010-11 Production Planning & Materials ManagementDocument4 pagesHT TP: //qpa Pe R.W But .Ac .In: 2010-11 Production Planning & Materials ManagementAparna DuggiralaPas encore d'évaluation

- MS 51Document4 pagesMS 51Rkrishna APas encore d'évaluation

- (2015 Onwards) : M.Sc. Software Systems Degree Examin Tions, April 2018Document6 pages(2015 Onwards) : M.Sc. Software Systems Degree Examin Tions, April 2018Aravind KumarPas encore d'évaluation

- Cost Control Techniques PDFDocument3 pagesCost Control Techniques PDFHosamMohamed100% (1)

- Production Planning and ControlDocument8 pagesProduction Planning and Control19-4094 S Surya tejaPas encore d'évaluation

- Dba 1651 Sem IIDocument11 pagesDba 1651 Sem IIthamiztPas encore d'évaluation

- Test+Full+O R +++ABC+++Service+SectorDocument4 pagesTest+Full+O R +++ABC+++Service+SectorSameer AhmedPas encore d'évaluation

- Process Planning and Cost Estimation Nov / Dec 2013 Important Questions Unit-I (Workstudy and Ergonomics)Document2 pagesProcess Planning and Cost Estimation Nov / Dec 2013 Important Questions Unit-I (Workstudy and Ergonomics)RajeshKumarPas encore d'évaluation

- MBAThird Semester Winter 2009Document13 pagesMBAThird Semester Winter 2009THE MANAGEMENT CONSORTIUM (TMC) ‘All for knowledge, and knowledge for all’Pas encore d'évaluation

- Manufacturing Example PDFDocument6 pagesManufacturing Example PDFAbdul RahmanPas encore d'évaluation

- B eDocument651 pagesB eRohit GaikwadPas encore d'évaluation

- Question Bank 4th SemesterDocument16 pagesQuestion Bank 4th SemesterJeevanandam ShanmugasundaramPas encore d'évaluation

- Iem 102Document4 pagesIem 102Aparna DuggiralaPas encore d'évaluation

- ME2Document478 pagesME2आकाश संगीता प्रकाश पवारPas encore d'évaluation

- ME323 Assignment 1Document2 pagesME323 Assignment 1sbsharma5190Pas encore d'évaluation

- Sree Vidyanikethan Engineering College: CODE No.:10BT60301Document2 pagesSree Vidyanikethan Engineering College: CODE No.:10BT60301Soumya BsoumyaPas encore d'évaluation

- ME2027 Question BankDocument12 pagesME2027 Question BankSenthil Kumar Periyasamy0% (1)

- MS 51 Previous Year Question Papers by IgnouassignmentguruDocument72 pagesMS 51 Previous Year Question Papers by IgnouassignmentguruAravind MoluguPas encore d'évaluation

- Karunya University: M.B.A. Trimester Examination - April/May 2010Document1 pageKarunya University: M.B.A. Trimester Examination - April/May 2010daksh shuklaPas encore d'évaluation

- Ie-508 Id-E0633Document2 pagesIe-508 Id-E0633VikasPas encore d'évaluation

- MM 2007Document8 pagesMM 2007andhracollegesPas encore d'évaluation

- Afin317 FPD 1 2020 1Document8 pagesAfin317 FPD 1 2020 1Daniel Daka100% (1)

- MMS AssignmentDocument4 pagesMMS AssignmentLalit SharmaPas encore d'évaluation

- R7410301 Operations ResearchDocument8 pagesR7410301 Operations ResearchsivabharathamurthyPas encore d'évaluation

- Board Exam Qns - IEM (M - Scheme)Document10 pagesBoard Exam Qns - IEM (M - Scheme)T2L KISHOREPas encore d'évaluation

- Review QuestionsDocument8 pagesReview QuestionsSylvie LombiPas encore d'évaluation

- 711i NSV .: UI (-P-3-PtoductiiDocument4 pages711i NSV .: UI (-P-3-Ptoductiihindustani888Pas encore d'évaluation

- 2724610Document2 pages2724610alpeshrptlPas encore d'évaluation

- f2 MGMT Accounting August 2017Document20 pagesf2 MGMT Accounting August 2017MSHANA ALLYPas encore d'évaluation

- F065 - Assignment II For OMDocument2 pagesF065 - Assignment II For OMsubrat sarangiPas encore d'évaluation

- Operation Management and Information SystemDocument32 pagesOperation Management and Information SystemaanandlPas encore d'évaluation

- P. G. D. B. M. (Semester - I) Examination - 2010: InstructionsDocument77 pagesP. G. D. B. M. (Semester - I) Examination - 2010: InstructionsyaminididiPas encore d'évaluation

- Management Information SystemsDocument2 pagesManagement Information SystemsnvemanPas encore d'évaluation

- P1 Question May 2022Document6 pagesP1 Question May 2022S.M.A AwalPas encore d'évaluation

- Industrial Objectives and Industrial Performance: Concepts and Fuzzy HandlingD'EverandIndustrial Objectives and Industrial Performance: Concepts and Fuzzy HandlingPas encore d'évaluation

- Business Management for Scientists and Engineers: How I Overcame My Moment of Inertia and Embraced the Dark SideD'EverandBusiness Management for Scientists and Engineers: How I Overcame My Moment of Inertia and Embraced the Dark SidePas encore d'évaluation

- Data Mining and Machine Learning in Building Energy AnalysisD'EverandData Mining and Machine Learning in Building Energy AnalysisPas encore d'évaluation

- PE 04 602 Industrial Automation DEC 2009Document2 pagesPE 04 602 Industrial Automation DEC 2009rasoolnkPas encore d'évaluation

- PE 04 403 Theory of Mechanism FEB 2013Document2 pagesPE 04 403 Theory of Mechanism FEB 2013rasoolnkPas encore d'évaluation

- Maximum: Marks: "Vidya Digital Library"Document1 pageMaximum: Marks: "Vidya Digital Library"rasoolnkPas encore d'évaluation

- PE 04 804 D Supply Chain Management DEC 2012Document2 pagesPE 04 804 D Supply Chain Management DEC 2012rasoolnkPas encore d'évaluation

- Series TT S7 July 2014Document2 pagesSeries TT S7 July 2014rasoolnkPas encore d'évaluation

- Kwi-B-SSfpw DØ-c-ßfpw : Phone:0494 2401144 315Document1 pageKwi-B-SSfpw DØ-c-ßfpw : Phone:0494 2401144 315rasoolnkPas encore d'évaluation

- 30-12 PKDocument1 page30-12 PKrasoolnkPas encore d'évaluation

- Primavera - Lecture No. 1 PDFDocument26 pagesPrimavera - Lecture No. 1 PDFInaam Ullah MughalPas encore d'évaluation

- Department of Labor: Owcp-Pt4Document36 pagesDepartment of Labor: Owcp-Pt4USA_DepartmentOfLaborPas encore d'évaluation

- Role of Nomination CommitteeDocument10 pagesRole of Nomination CommitteesusmritiPas encore d'évaluation

- Reviewer - Personnel Planning and RecruitmentDocument21 pagesReviewer - Personnel Planning and RecruitmentjarellePas encore d'évaluation

- Tugas Mik VWDocument31 pagesTugas Mik VWAndri Nur RahmadiPas encore d'évaluation

- Enterprise Resource Planning (ERP) ABAC April 6-2008Document23 pagesEnterprise Resource Planning (ERP) ABAC April 6-2008Subash SharmaPas encore d'évaluation

- Healthpro Vs MedbuyDocument3 pagesHealthpro Vs MedbuyTim RosenbergPas encore d'évaluation

- Jasper Vincent Hootsman PADDocument70 pagesJasper Vincent Hootsman PADrentinghPas encore d'évaluation

- NSTP Unit 3Document21 pagesNSTP Unit 3francisfebuarryPas encore d'évaluation

- 4.0 HR Department Organizational ChartDocument4 pages4.0 HR Department Organizational ChartHafiz akbarPas encore d'évaluation

- Article 1 IPRI Journal XXII I Dr. Muntasser Majeed HameedDocument23 pagesArticle 1 IPRI Journal XXII I Dr. Muntasser Majeed HameedMoiz ur rehman100% (1)

- Evms and The Controversy Surrounding ItDocument1 pageEvms and The Controversy Surrounding ItAnany UpadhyayPas encore d'évaluation

- Cobit5 Enabling Process: Align, Plan and Organise (APO)Document1 pageCobit5 Enabling Process: Align, Plan and Organise (APO)Missed MilkPas encore d'évaluation

- Accountability and Performance: Evidence From Local GovernmentDocument18 pagesAccountability and Performance: Evidence From Local GovernmentDEDY KURNIAWANPas encore d'évaluation

- Presentation April05 Partners - ppt.43309Document53 pagesPresentation April05 Partners - ppt.43309Haitham HidmiPas encore d'évaluation

- Strategic Planning Checklist Template in ExcelDocument2 pagesStrategic Planning Checklist Template in ExcelFrancisco SalazarPas encore d'évaluation

- Sexual Assault at The University of British Columbia: Prevention, Response, and AccountabilityDocument52 pagesSexual Assault at The University of British Columbia: Prevention, Response, and AccountabilityCKNW980Pas encore d'évaluation

- Global Consensus On Social Accountability of Medical SchoolsDocument16 pagesGlobal Consensus On Social Accountability of Medical SchoolsFrancinePas encore d'évaluation

- AADHAAR Exam Chapter 9 - Questions & Answers - 2021Document8 pagesAADHAAR Exam Chapter 9 - Questions & Answers - 2021SD20ME009 gokul jadhavPas encore d'évaluation

- Baybay City, LeyteDocument2 pagesBaybay City, LeyteSunStar Philippine NewsPas encore d'évaluation

- Value Chain Analysis Template 11Document3 pagesValue Chain Analysis Template 11Pramod PandeyPas encore d'évaluation

- NGO Work in TanzaniaDocument36 pagesNGO Work in TanzaniaLusajo Lazarus MwaisakaPas encore d'évaluation

- 02.1-Project Management FrameworkDocument13 pages02.1-Project Management Frameworkhieupv227Pas encore d'évaluation