Académique Documents

Professionnel Documents

Culture Documents

Srr320305 Design of Machine Members II

Transféré par

andhracollegesCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Srr320305 Design of Machine Members II

Transféré par

andhracollegesDroits d'auteur :

Formats disponibles

www.andhracolleges.

com The Complete Information About Colleges in Andhra Pradesh

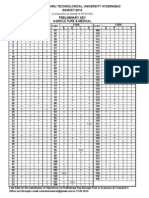

Code No: RR320305 Set No. 1

III B.Tech II Semester Supplimentary Examinations, Aug/Sep 2007

DESIGN OF MACHINE MEMBERS-II

( Common to Mechanical Engineering, Production Engineering and

Automobile Engineering)

Time: 3 hours Max Marks: 80

Answer any FIVE Questions

All Questions carry equal marks

www.andhracolleges.com

⋆⋆⋆⋆⋆

1. (a) Name the various bearing materials and name the important requirements of

bearing materials for efficient operation. [6]

(b) Design a full journal bearing of 100 mm long supports a radial load of 5 kN.

The shaft rotates at 500 rpm. The diametral clearance is 0.1 mm. The room

temperature is 25o C and temperature of the surface of the bearing is to be

limited to 55o C. The bearing is well ventilated and no artificial cooling is to

be used. Select a suitable oil to satisfy above requirements. [10]

2. (a) A roller bearing is selected to withstand a radial load of 40 kN and life of

1200 hrs at 600 rpm. What load rating would you look for in searching from

manufacturers catalogue if it specifies loud at speed 500 rpm and life 3000 hrs

[8]

(b) Select a suitable rolling bearing for a 55 mm diameter shaft. The bearing

should be capable of withstanding 3 kN radial and 1.5 kN axial load at 750

rpm. The bearing is to have a desired rated life of 2000 hrs at a reliability of

94% . There is a light shock load and inner ring rotates. [8]

www.andhracolleges.com

3. Following data refers to 4-stroke cycle diesel engine cylinder [16]

Cylinder bore = 0. 15 m

Stroke = 0.1875 m

Speed = 1200 rpm

Maximum gas pressure = 5.6 Mpa Determine

(a) The dimensions of an I-section connecting rod of forged steel with an elastic

limit compressive stress of 350 Mpa. The ratio of length of connecting rod to

the length of crank is 4 and factor of safety is 5 [10]

(b) The wrist pin and crank pin dimensions on the basis of the bearing pressure

of 10.5 Mpa and 6.5 Mpa. [6]

4. Design a center crankshaft for a single acting 175×175 mm air compressor working

at 360-rpm .The maximum pressure on the cylinder is 70N/sq.mm. Select suitable

material and factor of safety [16]

5. Design and draw a valve spring of a petrol engine for the following operating con-

ditions: [16]

Spring load when the valve is open = 400 N

Spring load when the valve is closed = 250 N

Seminar Topics - Scholarships - Admission/Entrance Exam Notifications

1 ofUSA-UK-Australia-Germany-France-NewZealand

2 Universities List

www.andhracolleges.com Engineering-MBA-MCA-Medical-Pharmacy-B.Ed-Law Colleges Information

www.andhracolleges.com The Complete Information About Colleges in Andhra Pradesh

Code No: RR320305 Set No. 1

Maximum inside diameter of spring = 25 mm

Length of the spring when the valve is open = 40 mm

Length of the spring when the valve is closed= 50 mm

Maximum permissible shear stress = 400 Mpa

6. A 8mm thick leather open belt connects two flat pulleys. The smaller pulley is 300

mm diameter and runs at 200 r.p.m. The angle of lap of this pulley is 1600 and

the coefficient of friction between the belt and the pulley is 0.25. The belt is on

www.andhracolleges.com

the point of slipping when 3kW is transmitted. The safe working stress in the belt

material is 1.6 N/mm2 . Design the drive for 20% overload capacity. [16]

7. Design a cast iron spur gear drive for a crane hoist to transmit 3.75 kW at 1440

rpm. Maximum gear ratio in the gear box is 4. Each gear is expected to work

2 hours/day for 10 years. Determine the minimum centre distance, required face

width and module of the gear. [16]

8. A machine slide weighing 3 kN is elevated by a double start Acme threaded screw at

the rate of 0.84 m/min. If coefficient of friction is 0.12, calculate the power to drive

the slide. The end of the screw carries a thrust collar of 32 mm inside diameter and

58 mm outside diameter. Pitch of the screw thread is 7 mm and outside diameter

is 44 mm. If the screw is of C45 steel, is it strong enough to sustain the load? [16]

⋆⋆⋆⋆⋆

www.andhracolleges.com

Seminar Topics - Scholarships - Admission/Entrance Exam Notifications

2 ofUSA-UK-Australia-Germany-France-NewZealand

2 Universities List

www.andhracolleges.com Engineering-MBA-MCA-Medical-Pharmacy-B.Ed-Law Colleges Information

www.andhracolleges.com The Complete Information About Colleges in Andhra Pradesh

Code No: RR320305 Set No. 2

III B.Tech II Semester Supplimentary Examinations, Aug/Sep 2007

DESIGN OF MACHINE MEMBERS-II

( Common to Mechanical Engineering, Production Engineering and

Automobile Engineering)

Time: 3 hours Max Marks: 80

Answer any FIVE Questions

All Questions carry equal marks

www.andhracolleges.com

⋆⋆⋆⋆⋆

1. (a) Explain wedge film and squeeze film journal bearings. [4]

(b) The load on a 100 mm full hydrodynamic journal bearing is 9000 N. Speed

of the journal is 320 rpm. consider L/D = 1, C/D = 0.0011. The operating

temperature = 65o C and minimum oil film thickness = 0.022 mm. [12]

i. Select an oil that will closely accord with the stated conditions. For these

selected oil, determine

ii. the friction loss

iii. the hydrodynamic oil flow through the bearing

iv. the amount of leakage

v. the temperature rise of oil passes through the bearing and

vi. maximum oil pressure

2. (a) A roller bearing is selected to withstand a radial load of 40 kN and life of

1200 hrs at 600 rpm. What load rating would you look for in searching from

manufacturers catalogue if it specifies loud at speed 500 rpm and life 3000 hrs

[8]

www.andhracolleges.com

(b) Select a suitable rolling bearing for a 55 mm diameter shaft. The bearing

should be capable of withstanding 3 kN radial and 1.5 kN axial load at 750

rpm. The bearing is to have a desired rated life of 2000 hrs at a reliability of

94% . There is a light shock load and inner ring rotates. [8]

3. The following data refer to a 4-stroke single cylinder vertical engine [16]

Piston diameter = 125mm

Stroke=150mm

Speed of the engine=1200 r.p.m

Weight of the reciprocating parts = 45N

Design stress for the material used = 80N/sq.mm

Design bearing stress=10N/sq.mn

Design stress for bolts=35N/sq.mm

Design a suitable connecting rod and check for stresses due to inertia.

4. The over hung crank of an engine having a cylinder diameter of 250 mm and stroke

400 mm. The connecting rod is 5 times crank, the maximum explosion pressure in

the cylinder is 1.7 Mp and engine runs at 200 rpm. Assuming a suitable stress for

the material design the-over hung crank. Also calculate the maximum stress in the

crank arm when the crank is at 30o to the I.D.C position and the gas pressure is

0.8 Mpa. Take modulus of section for rectangular section as 0.269bt2 . [16]

Seminar Topics - Scholarships - Admission/Entrance Exam Notifications

1 ofUSA-UK-Australia-Germany-France-NewZealand

2 Universities List

www.andhracolleges.com Engineering-MBA-MCA-Medical-Pharmacy-B.Ed-Law Colleges Information

www.andhracolleges.com The Complete Information About Colleges in Andhra Pradesh

Code No: RR320305 Set No. 2

5. (a) Discuss the phenomenon of surge in spring, and how do you eliminate surge

in spring? [8]

(b) With the aid of a diagram explain the modified soderberg line method for

various stresses in a spring. [8]

6. (a) Prove that the centrifugal tension must be 1/3rd of the maximum tension for

maximum power transmission. [6]

www.andhracolleges.com

(b) Design a cross belt drive having 1.5 m center distance between the two pulleys

The diameter of bigger and smaller pulleys are ’D’ and ’d’ respectively. The

smaller pulley rotates at 1000 r.p.m. and the bigger pulley at 500 r.p.m. The

flat belt is 6 mm thick and transmits 7.5 kW power at belt speed of 13 m/s

approximately. The coefficient of belt friction is 0.3 and the density of belt

material is 950 kg/m3 . The permissible tensile stress for the bet material is

1.75 MPa. [10]

7. A pair of gears is to be designed to transmit 30kW for a pinion speed of 1000 rpm

and a speed ratio of l:5. Design the gear pair. [16]

8. Design screw jack to lift a load of 50 kN with a possible eccentricity of 4 mm. The

following data are given: [16]

Allowable compressive stress in the screw material = 100 N/mm2 , ultimate tensile

stress in the tommy bar material = 480 N/mm2 , coefficient of friction in threads

= 0.14, coefficient of collar friction = 0.2.

⋆⋆⋆⋆⋆

www.andhracolleges.com

Seminar Topics - Scholarships - Admission/Entrance Exam Notifications

2 ofUSA-UK-Australia-Germany-France-NewZealand

2 Universities List

www.andhracolleges.com Engineering-MBA-MCA-Medical-Pharmacy-B.Ed-Law Colleges Information

www.andhracolleges.com The Complete Information About Colleges in Andhra Pradesh

Code No: RR320305 Set No. 3

III B.Tech II Semester Supplimentary Examinations, Aug/Sep 2007

DESIGN OF MACHINE MEMBERS-II

( Common to Mechanical Engineering, Production Engineering and

Automobile Engineering)

Time: 3 hours Max Marks: 80

Answer any FIVE Questions

All Questions carry equal marks

www.andhracolleges.com

⋆⋆⋆⋆⋆

1. (a) What are the various types of lubrication methods for journal bearings? [4]

(b) Design a suitable journal bearing for a centrifugal pump from the following

available data: [12]

Load on the bearing = 13.5 kN

Diameter of the journal = 75 mm

Speed = 1440 rpm

Bearing characteristic number at the working temperature of 75o C = 30

Permissible bearing pressure intensity = 0.7 N/mm2 to 1.4 N/mm2

Average atmospheric temperature = 30o C

Calculate the cooling requirements, if any

2. (a) A roller bearing is selected to withstand a radial load of 40 kN and life of

1200 hrs at 600 rpm. What load rating would you look for in searching from

manufacturers catalogue if it specifies loud at speed 500 rpm and life 3000 hrs

[8]

(b) Select a suitable rolling bearing for a 55 mm diameter shaft. The bearing

should be capable of withstanding 3 kN radial and 1.5 kN axial load at 750

www.andhracolleges.com

rpm. The bearing is to have a desired rated life of 2000 hrs at a reliability of

94% . There is a light shock load and inner ring rotates. [8]

3. Enumerate the design procedure for the connecting rod section considering it as a

simple compression or tension member subjected to fluctuating load [16]

4. What are the stresses to which an over hanging shaft is subjected to? How would

you proceed to design such a crank shaft. [16]

5. (a) Derive an expression for deflection of a helical spring. [6]

(b) Design a compression helical spring to carry a load of 500 N with a deflection

of 25 mm. The spring index may be taken as 8. Assume the following values

for the spring material: [10]

Permissible shear = 350 MPa

Modulus of rigidity = 84 kN/mm2

Wahl’s factor = [(4C-1) / (4C - 4)] + [0.615 /C], where C = spring index.

6. An open belt connects two flat pulleys. The pulley diameters are 300 mm and 450

mm and the corresponding angles of lap are 160o and 210o . The smaller pulley

runs at 200 r.p.m. The coefficient of friction between the belt and pulley is 0.25.

Seminar Topics - Scholarships - Admission/Entrance Exam Notifications

1 ofUSA-UK-Australia-Germany-France-NewZealand

2 Universities List

www.andhracolleges.com Engineering-MBA-MCA-Medical-Pharmacy-B.Ed-Law Colleges Information

www.andhracolleges.com The Complete Information About Colleges in Andhra Pradesh

Code No: RR320305 Set No. 3

It is found that the belt is on the point of slipping when 3 kW is transmitted. To

increase the power transmitted two alternatives are suggested, namely [16]

(a) increasing the initial tension by 10%, and

(b) increasing the coefficient of friction by 10% by the application of a suitable

dressing to the belt. Which of these two methods would be more effective?

Find the percentage increase in power possible in each case and also design

www.andhracolleges.com

the system.

7. What should be the module, face width and number of teeth on each gear of a pair

of spur gears, a C45 steel pinion driving a cast iron gear, if they are to transmit

18.75 kW at 700 rev/min of the 0.18m pinion in continuous service? The velocity

ratio is 3, the teeth are 200 full depth and the load is smooth. Determine the

outside and root diameters. [16]

8. (a) Enumerate the differences between differential screw, ball screw and compound

screw. [6]

(b) Explain step by step procedure to design a lathe machine bed. [10]

⋆⋆⋆⋆⋆

www.andhracolleges.com

Seminar Topics - Scholarships - Admission/Entrance Exam Notifications

2 ofUSA-UK-Australia-Germany-France-NewZealand

2 Universities List

www.andhracolleges.com Engineering-MBA-MCA-Medical-Pharmacy-B.Ed-Law Colleges Information

www.andhracolleges.com The Complete Information About Colleges in Andhra Pradesh

Code No: RR320305 Set No. 4

III B.Tech II Semester Supplimentary Examinations, Aug/Sep 2007

DESIGN OF MACHINE MEMBERS-II

( Common to Mechanical Engineering, Production Engineering and

Automobile Engineering)

Time: 3 hours Max Marks: 80

Answer any FIVE Questions

All Questions carry equal marks

www.andhracolleges.com

⋆⋆⋆⋆⋆

1. (a) What are the desirable properties of bearing materials? [4]

(b) A hydrodynamic full journal bearing is to carry a load of 25 kN at a speed

of 3000 rpm. The journal diameter is 150 mm and the length of bearing is

75 mm. SAE 30 oil is used with an average operating temperature of 55o C.

If the radial clearance is 0.075 mm, calculate the power loss, the side leakage

and the minimum film thickness. [12]

2. (a) What is equivalent static load. [2]

(b) The radial reaction on a bearing is 9000 N. It also carries a thrust of 5000

N. The speed of the shaft is 1000 rpm. The outer ring stationary. Expected

average life of bearing is about 25,000 hours. The load on the bearing is

smooth, the service is 8 hours/day. Select, [14]

i. Suitable roller bearing

ii. What is the rated 90% life of selected bearing?

iii. Compute the probability of the selected bearing surviving 25,000 hours

www.andhracolleges.com

3. (a) Why I-section is selected for high-speed I.C engines? [4]

(b) A double acting steam engine has the following specifications

Cylinder bore =500 mm

Piston stroke=750 mm

Maximum pressure on piston=175 N/sq.cm

Connecting rod length= 1400 mm

Select the suitable material and design the connecting rod. [12]

4. What are the stresses to which an over hanging shaft is subjected to? How would

you proceed to design such a crank shaft. [16]

5. Design a helical spring for a spring loaded safely valve (Ramsbottom safely valve)

for the following conditions: Diameter of valve seat = 65 mm; operating pressure

= 0.7 N/mm2 ; Maximum pressure when the valve blows off freely = 0.75 N/mm2 ;

Maximum lift of the valve when the pressure rises from 0.7 to 0.75 N/mm2 = 3.5

mm; Maximum allowable stress = 550 MPa ; Modulus of rigidity = 84 kN/mm2 ;

Spring index = 6. Draw a neat sketch of the free spring showing the main dimen-

sions. [16]

6. (a) Prove that the centrifugal tension must be 1/3rd of the maximum tension for

maximum power transmission. [6]

Seminar Topics - Scholarships - Admission/Entrance Exam Notifications

1 ofUSA-UK-Australia-Germany-France-NewZealand

2 Universities List

www.andhracolleges.com Engineering-MBA-MCA-Medical-Pharmacy-B.Ed-Law Colleges Information

www.andhracolleges.com The Complete Information About Colleges in Andhra Pradesh

Code No: RR320305 Set No. 4

(b) Design a cross belt drive having 1.5 m center distance between the two pulleys

The diameter of bigger and smaller pulleys are ’D’ and ’d’ respectively. The

smaller pulley rotates at 1000 r.p.m. and the bigger pulley at 500 r.p.m. The

flat belt is 6 mm thick and transmits 7.5 kW power at belt speed of 13 m/s

approximately. The coefficient of belt friction is 0.3 and the density of belt

material is 950 kg/m3 . The permissible tensile stress for the bet material is

1.75 MPa. [10]

www.andhracolleges.com

7. Design the teeth for a pair of cast iron spur gears with cast teeth to transmit 26kW.

The pinion runs at 50 rev/min and the velocity ratio is to be 2.5. Decide upon a

suitable grade of cast iron and find the module, face, and diameters, and centre

distance for the gears. Check for dynamic load. [16]

8. The lead screw of a lathe has 50 x 8 threads. The screw must exert and axial

pressure of 2500 N in order to drive the tool carriage. The thrust is carried on a

collar 110 mm outside diameter and 55 mm inside diameter and the screw rotates

at 30 rpm. Determine: [16]

(a) the power required to drive the screw and

(b) the efficiency of the lead screw. Assume a coefficient of friction of 0.15 for the

screw and 0.12 for the collar.

⋆⋆⋆⋆⋆

www.andhracolleges.com

Seminar Topics - Scholarships - Admission/Entrance Exam Notifications

2 ofUSA-UK-Australia-Germany-France-NewZealand

2 Universities List

www.andhracolleges.com Engineering-MBA-MCA-Medical-Pharmacy-B.Ed-Law Colleges Information

Vous aimerez peut-être aussi

- Polycet2014 Web Counselling NotificationDocument2 pagesPolycet2014 Web Counselling NotificationandhracollegesPas encore d'évaluation

- JEE Advanced 2014 Paper I PHYSICS Paper Answer SolutionsDocument6 pagesJEE Advanced 2014 Paper I PHYSICS Paper Answer SolutionsandhracollegesPas encore d'évaluation

- Eamcet Agriculture Last Ranks Cutoffs Andhracolleges Eamcet 2013 CutoffsDocument3 pagesEamcet Agriculture Last Ranks Cutoffs Andhracolleges Eamcet 2013 Cutoffsandhracolleges33% (3)

- Polycet 2014 ST Certificatates Verification DatesDocument1 pagePolycet 2014 ST Certificatates Verification DatesandhracollegesPas encore d'évaluation

- JEE Main Advanced 2014 Paper I Maths Paper Answer SolutionsDocument4 pagesJEE Main Advanced 2014 Paper I Maths Paper Answer Solutionsandhracolleges100% (1)

- Eamcet 2014 Engineering Jntu Preliminary Key AndhracollegesDocument1 pageEamcet 2014 Engineering Jntu Preliminary Key AndhracollegesandhracollegesPas encore d'évaluation

- JEE Main Advanced Paper I Answer Key 25 May 2014Document1 pageJEE Main Advanced Paper I Answer Key 25 May 2014andhracollegesPas encore d'évaluation

- JEE Advanced 2014 Paper I Chemistry Paper Answer SolutionsDocument4 pagesJEE Advanced 2014 Paper I Chemistry Paper Answer SolutionsandhracollegesPas encore d'évaluation

- Polycet 2014 SC BC Oc Certificatates Verification DatesDocument1 pagePolycet 2014 SC BC Oc Certificatates Verification DatesandhracollegesPas encore d'évaluation

- Eamcet 2014 Engineering Key Solutions AndhracollegesDocument42 pagesEamcet 2014 Engineering Key Solutions Andhracollegesandhracolleges75% (8)

- ICET 2014 Preliminary Key Primary Key AndhracollegesDocument2 pagesICET 2014 Preliminary Key Primary Key AndhracollegesandhracollegesPas encore d'évaluation

- EAMCET 2014 Agriculture & Medical Preliminary Answer KeysDocument1 pageEAMCET 2014 Agriculture & Medical Preliminary Answer KeysLohith_EnggPas encore d'évaluation

- Eamcet 2012 Medical PaperDocument60 pagesEamcet 2012 Medical Paperandhracolleges100% (1)

- Eamcet 2014 Medical Question Paper AndhracollegesDocument62 pagesEamcet 2014 Medical Question Paper Andhracollegesandhracolleges100% (1)

- Eamcet 2014 Engineering Key SolutionsDocument42 pagesEamcet 2014 Engineering Key Solutionsandhracolleges100% (1)

- Eamcet 2013 Engineering PaperDocument62 pagesEamcet 2013 Engineering Paperandhracolleges0% (1)

- Eamcet 2014 Medical Question Paper With Key Solutions AndhracollegesDocument62 pagesEamcet 2014 Medical Question Paper With Key Solutions Andhracollegesandhracolleges100% (1)

- Eamcet 2012 Engineering Paper KeyDocument1 pageEamcet 2012 Engineering Paper KeyandhracollegesPas encore d'évaluation

- Andhracollege Eamcet 2014 Engineering Question Paper With Key SolutionsDocument62 pagesAndhracollege Eamcet 2014 Engineering Question Paper With Key Solutionsandhracolleges50% (4)

- Polycet 2014 Question PaperDocument24 pagesPolycet 2014 Question PaperandhracollegesPas encore d'évaluation

- Eamcet 2012 Medical Paper KeyDocument1 pageEamcet 2012 Medical Paper KeyandhracollegesPas encore d'évaluation

- Eamcet 2012 Engineering Paper KeyDocument1 pageEamcet 2012 Engineering Paper KeyandhracollegesPas encore d'évaluation

- Eamcet 2013 Medical PaperDocument62 pagesEamcet 2013 Medical PaperandhracollegesPas encore d'évaluation

- Eamcet 2011 Engineering PaperDocument61 pagesEamcet 2011 Engineering PaperandhracollegesPas encore d'évaluation

- Eamcet 2012 Engineering PaperDocument62 pagesEamcet 2012 Engineering Paperandhracolleges100% (1)

- Eamcet 2009 Engineering Chemistry PaperDocument16 pagesEamcet 2009 Engineering Chemistry PaperandhracollegesPas encore d'évaluation

- Eamcet 2008 Engineering PaperDocument62 pagesEamcet 2008 Engineering PaperandhracollegesPas encore d'évaluation

- Eamcet 2010 Medical PaperDocument63 pagesEamcet 2010 Medical PaperandhracollegesPas encore d'évaluation

- Eamcet 2007 Engineering PaperDocument13 pagesEamcet 2007 Engineering Paperandhracolleges100% (1)

- Eamcet 2006 Engineering PaperDocument14 pagesEamcet 2006 Engineering PaperandhracollegesPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (72)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- 2015 Seadoo 4-Tec Service ManualDocument1 453 pages2015 Seadoo 4-Tec Service ManualZack BurichPas encore d'évaluation

- Variable Displacement Pump A4VGDocument44 pagesVariable Displacement Pump A4VGАртурPas encore d'évaluation

- Metric Fasteners - DIN 985 Nylon Insert Stop Nuts - DimensionsDocument1 pageMetric Fasteners - DIN 985 Nylon Insert Stop Nuts - DimensionssnorklingmonkeyPas encore d'évaluation

- Informacion Cat 236D Motor C3.3B Serie 8de2123 Serie Maquina 236dampw00297Document13 pagesInformacion Cat 236D Motor C3.3B Serie 8de2123 Serie Maquina 236dampw00297hector100% (3)

- SKF CatalogueDocument64 pagesSKF CatalogueGeorgios Papakostas0% (1)

- Çukurova RC3Document357 pagesÇukurova RC3Andreea BoacaraPas encore d'évaluation

- Acert EcmDocument49 pagesAcert EcmMahmoud Elsayed80% (5)

- 5vz-Fe Timing Belt InstallationDocument6 pages5vz-Fe Timing Belt InstallationJorge RisquezPas encore d'évaluation

- Spare Part List HGX8 3220-4Document6 pagesSpare Part List HGX8 3220-4Helal JaberPas encore d'évaluation

- Diesel vs Gasoline Engines ComparedDocument10 pagesDiesel vs Gasoline Engines ComparedAnonymous 9ztGz6rPas encore d'évaluation

- Alpha One Generation II Stern DriveDocument37 pagesAlpha One Generation II Stern DriveAndrea Ignacia Ibieta100% (1)

- F100betl 2005Document78 pagesF100betl 2005Ray Cepeda MenaPas encore d'évaluation

- 793 793b 793cDocument8 pages793 793b 793cJulio Elias Mayta RamosPas encore d'évaluation

- Round Tapered Fluted Steel FL210: SpecificationsDocument2 pagesRound Tapered Fluted Steel FL210: SpecificationskrishPas encore d'évaluation

- Rigger Load Charts PDFDocument8 pagesRigger Load Charts PDFShafa Ullah Khan NiaziPas encore d'évaluation

- John Crane Europe, Asia, Africa Dry Gas Seal InspectionDocument14 pagesJohn Crane Europe, Asia, Africa Dry Gas Seal Inspectionchimmy chinPas encore d'évaluation

- Engine - 1.5L EcoBoost (110kW-150PS) 1.5L EcoBost (132kW-180PS) - Timing BeltDocument17 pagesEngine - 1.5L EcoBoost (110kW-150PS) 1.5L EcoBost (132kW-180PS) - Timing BeltRamon Pujol PerramonPas encore d'évaluation

- Hydraulic SealsDocument19 pagesHydraulic SealsVenkatesh VenkyPas encore d'évaluation

- Section7 FlexCablesforServos MotorsDocument24 pagesSection7 FlexCablesforServos MotorstotovasiPas encore d'évaluation

- Dts-I Engine Technology 2021-22Document24 pagesDts-I Engine Technology 2021-22YATHISH M GPas encore d'évaluation

- Engine BearingsDocument22 pagesEngine Bearingsandrew munyivaPas encore d'évaluation

- CL4NX Printer Parts ListDocument29 pagesCL4NX Printer Parts Listval civPas encore d'évaluation

- Manual B7Document156 pagesManual B7Thiago Augusto100% (1)

- L RH-3 Type T/C: Item Type Designation Qty P.No Qty Parts NoDocument1 pageL RH-3 Type T/C: Item Type Designation Qty P.No Qty Parts NoStefas DimitriosPas encore d'évaluation

- Turbocharger Maintenance StandardsDocument17 pagesTurbocharger Maintenance StandardsanggiePas encore d'évaluation

- Martillo Komac KB2000 Parts Manual PDFDocument12 pagesMartillo Komac KB2000 Parts Manual PDFJOHN FRADER ARRUBLA LOPEZ100% (1)

- Ford Service Manual 1920 Tractor Diesel Compact 2120 TractorDocument18 pagesFord Service Manual 1920 Tractor Diesel Compact 2120 Tractornmclaugh0% (1)

- American Wire Gauge PDFDocument5 pagesAmerican Wire Gauge PDFHarshal VaidyaPas encore d'évaluation

- HR2470Document4 pagesHR2470Cata100% (1)

- Xevl 2021 GPRS 1.D04 Esp 01Document168 pagesXevl 2021 GPRS 1.D04 Esp 01Francisco InfantePas encore d'évaluation