Académique Documents

Professionnel Documents

Culture Documents

Srr410309 Unconventional Machining Process

Transféré par

andhracollegesCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Srr410309 Unconventional Machining Process

Transféré par

andhracollegesDroits d'auteur :

Formats disponibles

www.andhracolleges.

com The Complete Information About Colleges in Andhra Pradesh

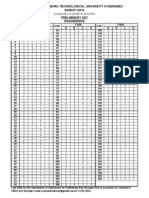

Code No: RR410309 Set No. 1

IV B.Tech I Semester Supplementary Examinations, February 2007

UNCONVENTIONAL MACHINING PROCESS

( Common to Mechanical Engineering and Production Engineering)

Time: 3 hours Max Marks: 80

Answer any FIVE Questions

All Questions carry equal marks

⋆⋆⋆⋆⋆

www.andhracolleges.com

1. (a) Write a note on tool wear in ultrasonic machining process. [8]

(b) Explain the economic factors considered while selecting the ultrasonic machin-

ing process. [8]

2. (a) Write a note on the accuracy and surface finish levels achieved in abrasive jet

machining. [8]

(b) Write a note on the accuracy and surface finish levels achieved in water jet

machining. [8]

3. (a) Distinguish between etch rate and etch factor. Why are they important in

Chemical Machining? How do you estimate them? [3+3+4=10]

(b) What is the care required in demasking? How is it achieved? [3+3=6]

4. (a) A Nimonic 75 alloy has the following composition. Ni -72.5%, Cr -19.5%,

Fe- 5.0%, Ti -0.4% and the rest of elements can be ignored. The atomic

weights of Ni, Cr, Fe, and Ti are 58.71, 51.99, 55.85 and 47.9 respectively and

their valencies are 2, 3, 2, and 2 respectively. This is machined using Electro

Chemical Machining at a current of 560 Amp. Determine the theoretical

machining rate using the percentage weight method. Time of machining 10

www.andhracolleges.com

minutes. State the assumptions made, if any. [6]

(b) Calculate the anodic efficiency in the above case if the actual metal removal

rate is found as 174 gms and comment on the result. [6]

(c) Can the efficiency value in the above case be improved? If so, suggest a

method? [4]

5. What are the different modes of dielectric flushing used in E.D.M. Which method

of flushing the inter electrode gap yields improved M.R.R. and why? [5+2+9]

6. (a) What are the various process parameters which influence the MRR? [8]

(b) What materials are used for Electrodes? Mention the relative advantages.

[4+4]

7. (a) Discuss the main industrial applications of plasma cutting systems. [8]

(b) What are the advantages and disadvantages of plasma cutting process? [4+4]

8. (a) Explain the general requirements of hydrostatic extrusion facility. [8]

(b) Explain the general requirements of radial extrusion facility. [8]

⋆⋆⋆⋆⋆

Seminar Topics - Scholarships - Admission/Entrance Exam Notifications

1 ofUSA-UK-Australia-Germany-France-NewZealand

1 Universities List

www.andhracolleges.com Engineering-MBA-MCA-Medical-Pharmacy-B.Ed-Law Colleges Information

www.andhracolleges.com The Complete Information About Colleges in Andhra Pradesh

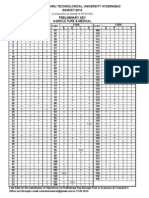

Code No: RR410309 Set No. 2

IV B.Tech I Semester Supplementary Examinations, February 2007

UNCONVENTIONAL MACHINING PROCESS

( Common to Mechanical Engineering and Production Engineering)

Time: 3 hours Max Marks: 80

Answer any FIVE Questions

All Questions carry equal marks

⋆⋆⋆⋆⋆

www.andhracolleges.com

1. (a) Explain the various factors considered in selecting a machining process.

(b) Explain how the modern machining processes are classified.

2. (a) Explain Abrasive Jet Machining (AJM)

(b) Explain the effect of following parameters in AJM

i. the abrasive

ii. the gas

iii. the size and position of the nozzle

[8]

[8]

[4]

[4]

[4]

[4]

3. (a) Explain the use of Electro Chemical Machining in air craft industries. [5]

(b) With a suitable sketch explain the tooling arrangement to produce one of the

products for aircraft industry. [5]

(c) Perform economic analysis on the above product with data assumed. Suitably.

[6]

4. (a) What are the various advantages of using ECM? [8]

www.andhracolleges.com

(b) What are the various limitations of ECM? [8]

5. Why E.D.M. is called un-conventional machining processes? How it differs from

conventional machining process -Discuss. [8+8]

6. Describe the advantages and limitations of power supply with rotary impulse gen-

erator circuit used in EDM. [8+8]

7. (a) With a neat sketch of the setup explain the principle of operation of EBM

setup for machining applications. [3+5]

(b) Why vacuum is needed and what is its order in electron beam processing

operations? [4+4]

8. With the help of a neat sketch explain the construction, principle of operation,

advantages, disadvantages and applications of compression type of electro- magnetic

forming process. [3+3+3+3+4]

⋆⋆⋆⋆⋆

Seminar Topics - Scholarships - Admission/Entrance Exam Notifications

1 ofUSA-UK-Australia-Germany-France-NewZealand

1 Universities List

www.andhracolleges.com Engineering-MBA-MCA-Medical-Pharmacy-B.Ed-Law Colleges Information

www.andhracolleges.com The Complete Information About Colleges in Andhra Pradesh

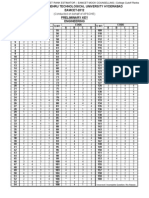

Code No: RR410309 Set No. 3

IV B.Tech I Semester Supplementary Examinations, February 2007

UNCONVENTIONAL MACHINING PROCESS

( Common to Mechanical Engineering and Production Engineering)

Time: 3 hours Max Marks: 80

Answer any FIVE Questions

All Questions carry equal marks

⋆⋆⋆⋆⋆

www.andhracolleges.com

1. (a) What is the principle of rotary ultrasonic machine? Explain how it improves

the material removal rate. [3+5=8]

(b) A hole in to be drilled in 20mm thick tungsten carbide sheet by ultrasonic

method. The slurry in made of 1 part of 320 grit (15 micron radius) boron

carbide mixed with 1 parts of water. The static stress is 1.4 × 10−2 kg/mm2

and the amplitude of tool oscillation is 0.025mm. The machine operates at

25,000 cycles/sec. The compression fracture strength of tungsten carbide is

225 kg/mm2 . Calculate the time required for drilling the required hole. As-

sume that the pulse efficiency is 10%. [8]

2. (a) What are the materials machined with Water Jet Machining? [8]

(b) State the advantages of Water Jet Machining. [8]

3. (a) Distinguish between etch rate and etch factor. Why are they important in

Chemical Machining? How do you estimate them? [3+3+4=10]

(b) What is the care required in demasking? How is it achieved? [3+3=6]

4. (a) Explain the process of Chemical Machining and its advantages. [4+4]

www.andhracolleges.com

(b) What are the important industrial applications of Chemical Machining? [8]

5. (a) Describe the Electrode feed control used in EDM to maintain the correct gap

during machining. [8]

(b) What are the effects of break down voltage, supply voltage & capacitance on

the mental removal rate in EDM. [2+3+3]

6. (a) Discuss the factors influencing the choice of electrode material in EDM? [8]

(b) How the surface finish and accuracy of machining are influenced by the process

parameters in EDM? [4+4]

7. (a) What do you mean by Laser Beam machining (LBM)? [6]

(b) What is a spontaneous emission? [4]

(c) Explain the physical principal of laser with suitable diagram. [4+2]

8. With the help of a neat sketch explain the construction, principle of operation,

advantages, disadvantages and applications of expanding type of electro-magnetic

forming process. [3+3+3+3+4]

⋆⋆⋆⋆⋆

Seminar Topics - Scholarships - Admission/Entrance Exam Notifications

1 ofUSA-UK-Australia-Germany-France-NewZealand

1 Universities List

www.andhracolleges.com Engineering-MBA-MCA-Medical-Pharmacy-B.Ed-Law Colleges Information

www.andhracolleges.com The Complete Information About Colleges in Andhra Pradesh

Code No: RR410309 Set No. 4

IV B.Tech I Semester Supplementary Examinations, February 2007

UNCONVENTIONAL MACHINING PROCESS

( Common to Mechanical Engineering and Production Engineering)

Time: 3 hours Max Marks: 80

Answer any FIVE Questions

All Questions carry equal marks

⋆⋆⋆⋆⋆

www.andhracolleges.com

1. (a) Explain the various factors considered in selecting a machining process.

(b) Explain how the modern machining processes are classified.

2. (a) What are the applications of Abrasive jet machining? Explain.

3. (a) Compare and contrast Electro Chemical Grinding with Conventional Grinding

operation. [8]

[8]

[8]

[3+5=8]

(b) Explain the effects of various parameters on metal removal rate in abrasive jet

machining. [8]

(b) What are the advantages and limitations of Electro Chemical Grinding? [4+4=8]

4. (a) Explain the process of Chemical Machining and its advantages. [4+4]

(b) What are the important industrial applications of Chemical Machining? [8]

5. Explain the various industrial applications of Electric Discharge Machining (E.D.M.)

with examples. [8+8]

6. What are the various power circuits used for electrical machining? Briefly, discuss

www.andhracolleges.com

with reference to metal removal rate. [4+12]

7. (a) What is plasma? How it can be used for material processing? [3+5]

(b) What are the different types of plasmotrons used in material cutting applica-

tions? [8]

8. What types of defects are observed in unconfined explosive forming? What are the

reasons for them? What remedies are suggested by you to avoid these defects?

[4+6+6]

⋆⋆⋆⋆⋆

Seminar Topics - Scholarships - Admission/Entrance Exam Notifications

1 ofUSA-UK-Australia-Germany-France-NewZealand

1 Universities List

www.andhracolleges.com Engineering-MBA-MCA-Medical-Pharmacy-B.Ed-Law Colleges Information

Vous aimerez peut-être aussi

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Vibration Is EverythingDocument4 pagesVibration Is EverythinganescuveronicaPas encore d'évaluation

- CO2 Handbook IIARDocument190 pagesCO2 Handbook IIAROnofreHalberPas encore d'évaluation

- Prestressed Concrete Design Lecture NotesDocument52 pagesPrestressed Concrete Design Lecture NotesChristopher John Natividad100% (1)

- The TDC Device - Synopsis of Email CorrespondencesDocument7 pagesThe TDC Device - Synopsis of Email Correspondencestriple7incPas encore d'évaluation

- Astm D156 - 15Document6 pagesAstm D156 - 15mancja100% (2)

- Eamcet Agriculture Last Ranks Cutoffs Andhracolleges Eamcet 2013 CutoffsDocument3 pagesEamcet Agriculture Last Ranks Cutoffs Andhracolleges Eamcet 2013 Cutoffsandhracolleges33% (3)

- Polycet2014 Web Counselling NotificationDocument2 pagesPolycet2014 Web Counselling NotificationandhracollegesPas encore d'évaluation

- JEE Advanced 2014 Paper I PHYSICS Paper Answer SolutionsDocument6 pagesJEE Advanced 2014 Paper I PHYSICS Paper Answer SolutionsandhracollegesPas encore d'évaluation

- Eamcet 2014 Engineering Jntu Preliminary Key AndhracollegesDocument1 pageEamcet 2014 Engineering Jntu Preliminary Key AndhracollegesandhracollegesPas encore d'évaluation

- ICET 2014 Preliminary Key Primary Key AndhracollegesDocument2 pagesICET 2014 Preliminary Key Primary Key AndhracollegesandhracollegesPas encore d'évaluation

- Eamcet 2014 Engineering Key Solutions AndhracollegesDocument42 pagesEamcet 2014 Engineering Key Solutions Andhracollegesandhracolleges75% (8)

- JEE Main Advanced 2014 Paper I Maths Paper Answer SolutionsDocument4 pagesJEE Main Advanced 2014 Paper I Maths Paper Answer Solutionsandhracolleges100% (1)

- Polycet 2014 ST Certificatates Verification DatesDocument1 pagePolycet 2014 ST Certificatates Verification DatesandhracollegesPas encore d'évaluation

- Polycet 2014 SC BC Oc Certificatates Verification DatesDocument1 pagePolycet 2014 SC BC Oc Certificatates Verification DatesandhracollegesPas encore d'évaluation

- JEE Main Advanced Paper I Answer Key 25 May 2014Document1 pageJEE Main Advanced Paper I Answer Key 25 May 2014andhracollegesPas encore d'évaluation

- EAMCET 2014 Agriculture & Medical Preliminary Answer KeysDocument1 pageEAMCET 2014 Agriculture & Medical Preliminary Answer KeysLohith_EnggPas encore d'évaluation

- JEE Advanced 2014 Paper I Chemistry Paper Answer SolutionsDocument4 pagesJEE Advanced 2014 Paper I Chemistry Paper Answer SolutionsandhracollegesPas encore d'évaluation

- Eamcet 2014 Medical Question Paper AndhracollegesDocument62 pagesEamcet 2014 Medical Question Paper Andhracollegesandhracolleges100% (1)

- Eamcet 2014 Medical Question Paper With Key Solutions AndhracollegesDocument62 pagesEamcet 2014 Medical Question Paper With Key Solutions Andhracollegesandhracolleges100% (1)

- Polycet 2014 Question PaperDocument24 pagesPolycet 2014 Question PaperandhracollegesPas encore d'évaluation

- Andhracollege Eamcet 2014 Engineering Question Paper With Key SolutionsDocument62 pagesAndhracollege Eamcet 2014 Engineering Question Paper With Key Solutionsandhracolleges50% (4)

- Eamcet 2012 Engineering Paper KeyDocument1 pageEamcet 2012 Engineering Paper KeyandhracollegesPas encore d'évaluation

- Eamcet 2014 Engineering Key SolutionsDocument42 pagesEamcet 2014 Engineering Key Solutionsandhracolleges100% (1)

- Eamcet 2013 Engineering PaperDocument62 pagesEamcet 2013 Engineering Paperandhracolleges0% (1)

- Eamcet 2012 Medical Paper KeyDocument1 pageEamcet 2012 Medical Paper KeyandhracollegesPas encore d'évaluation

- Eamcet 2011 Engineering PaperDocument61 pagesEamcet 2011 Engineering PaperandhracollegesPas encore d'évaluation

- Eamcet 2012 Medical PaperDocument60 pagesEamcet 2012 Medical Paperandhracolleges100% (1)

- Eamcet 2009 Engineering Chemistry PaperDocument16 pagesEamcet 2009 Engineering Chemistry PaperandhracollegesPas encore d'évaluation

- Eamcet 2012 Engineering Paper KeyDocument1 pageEamcet 2012 Engineering Paper KeyandhracollegesPas encore d'évaluation

- Eamcet 2010 Medical PaperDocument63 pagesEamcet 2010 Medical PaperandhracollegesPas encore d'évaluation

- Eamcet 2006 Engineering PaperDocument14 pagesEamcet 2006 Engineering PaperandhracollegesPas encore d'évaluation

- Eamcet 2012 Engineering PaperDocument62 pagesEamcet 2012 Engineering Paperandhracolleges100% (1)

- Eamcet 2013 Medical PaperDocument62 pagesEamcet 2013 Medical PaperandhracollegesPas encore d'évaluation

- Eamcet 2008 Engineering PaperDocument62 pagesEamcet 2008 Engineering PaperandhracollegesPas encore d'évaluation

- Eamcet 2007 Engineering PaperDocument13 pagesEamcet 2007 Engineering Paperandhracolleges100% (1)

- Tugasan BDC4013 - Sem 2 0809Document4 pagesTugasan BDC4013 - Sem 2 0809Shinee JayasilanPas encore d'évaluation

- Type 6010, 6011, and Whisper Disk Inline Diffusers: Bulletin 80.1:6010Document6 pagesType 6010, 6011, and Whisper Disk Inline Diffusers: Bulletin 80.1:6010Datt NguyenPas encore d'évaluation

- GWH Module 1 NotesDocument6 pagesGWH Module 1 NotesSahil AmeerPas encore d'évaluation

- 1-PbSO4 Leaching in Citric Acid Sodium Citrate Solution and Subsequent ...Document10 pages1-PbSO4 Leaching in Citric Acid Sodium Citrate Solution and Subsequent ...Gregorio Antonio Valero VerdePas encore d'évaluation

- Unit 7 Future Home (English For Technology 2)Document2 pagesUnit 7 Future Home (English For Technology 2)Set S. Pirath0% (1)

- Phy 9 Ans SchandDocument115 pagesPhy 9 Ans SchandAmit KumarPas encore d'évaluation

- SSC-JE Mechanical Obj. Paper 9789389269475Document23 pagesSSC-JE Mechanical Obj. Paper 9789389269475Shivam AgrawalPas encore d'évaluation

- Quality Meets Efficiency: DR6000 UV-VIS SpectrophotometerDocument8 pagesQuality Meets Efficiency: DR6000 UV-VIS SpectrophotometerOudah AliPas encore d'évaluation

- 2mark With Answer UCM M.E 6004 PDFDocument22 pages2mark With Answer UCM M.E 6004 PDFl8o8r8d8s8i8v8100% (1)

- Cast iron component failure investigationDocument4 pagesCast iron component failure investigationdelta lab sangliPas encore d'évaluation

- SNI 4658-2008-Pelek Kategori LDocument4 pagesSNI 4658-2008-Pelek Kategori LDimazNugrahaPas encore d'évaluation

- 7 PDFDocument103 pages7 PDFmuhammad izzulPas encore d'évaluation

- PSA Participant Manual May 2022 ApprovedDocument103 pagesPSA Participant Manual May 2022 Approvedlidyamengistu12Pas encore d'évaluation

- Section 10.2: Theoretical Acid-Base Definitions: Chapter 10: Acids and BasesDocument2 pagesSection 10.2: Theoretical Acid-Base Definitions: Chapter 10: Acids and BasesPavni ChandaniPas encore d'évaluation

- Steel Structure Analysis Seminar ProjectDocument16 pagesSteel Structure Analysis Seminar ProjectDnyaneshwar GawaiPas encore d'évaluation

- New Steel Construction Technical Digest 2019Document32 pagesNew Steel Construction Technical Digest 2019tein teinPas encore d'évaluation

- Modeling - Rigid End OffsetsDocument7 pagesModeling - Rigid End OffsetsAnonymous DNb6yWERfB100% (1)

- Reduction of Air Pollution Using Smog-Free-Tower A Review PaperDocument5 pagesReduction of Air Pollution Using Smog-Free-Tower A Review PaperVivace SystmPas encore d'évaluation

- Tecco System: Ruvolum Workshop - Armin RodunerDocument95 pagesTecco System: Ruvolum Workshop - Armin RodunerNam TrinhPas encore d'évaluation

- Heat Transfer FundamentalsDocument44 pagesHeat Transfer FundamentalsSamuel Jade RoxasPas encore d'évaluation

- EN 287-1-2011-Otkl (Grupi Celici)Document1 pageEN 287-1-2011-Otkl (Grupi Celici)Vasko MandilPas encore d'évaluation

- BEMACID-BEMAPLEX Applikation enDocument12 pagesBEMACID-BEMAPLEX Applikation en宋德欽Pas encore d'évaluation

- Precipitation Modelling in Ni-AlloysDocument35 pagesPrecipitation Modelling in Ni-AlloysИлья ЧекинPas encore d'évaluation

- Material Science L-Photonic MaterialsDocument28 pagesMaterial Science L-Photonic MaterialsSaheer ShaikPas encore d'évaluation

- Heat Transfer Presentation: Modes and LawsDocument16 pagesHeat Transfer Presentation: Modes and LawsmehediPas encore d'évaluation