Académique Documents

Professionnel Documents

Culture Documents

A Critical Review On Applications of Natural Jute Fibres A Case Study

Transféré par

IAEME PublicationTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

A Critical Review On Applications of Natural Jute Fibres A Case Study

Transféré par

IAEME PublicationDroits d'auteur :

Formats disponibles

International Journal of Civil Engineering and Technology (IJCIET)

Volume 7, Issue 3, MayJune 2016, pp. 200210, Article ID: IJCIET_07_03_020

Available online at

http://www.iaeme.com/IJCIET/issues.asp?JType=IJCIET&VType=7&IType=3

Journal Impact Factor (2016): 9.7820 (Calculated by GISI) www.jifactor.com

ISSN Print: 0976-6308 and ISSN Online: 0976-6316

IAEME Publication

A CRITICAL REVIEW ON APPLICATIONS

OF NATURAL JUTE FIBRES A CASE

STUDY

Dr. T. Kiran Kumar

Associate Professor, Civil Engineering, K.S.R.M College, Andhrapradesh, India

B. Jagan

K.S.R.M College, Andhrapradesh, India

ABSTRACT

Soil reinforcement technique is one of the most popular techniques used

for improvement of poor soils. Metal strips, synthetic geotextiles, geogrid

sheets, natural geotextiles, randomly distributed, synthetic and natural fibres

are being used as reinforcing materials to soil. Further, the soil reinforcement

causes significant improvement in tensile strength, shear strength, other

properties, bearing capacity as well as economy. Use of natural fibre in civil

engineering for improving soil properties is advantageous because they are

cheap, locally available, biodegradable and environmental friendly. India has

large tracks resting on expansive soil covering an area of 0.8million square

meters which is about 20% of total area of India .These expansive soils

undergo causes volumetric changes with change in moisture contents, swelling

and shrinkage of these soil causes severe damage to the foundations,

buildings, roads, retaining structures etc.In this project an attempt is made to

study the influence of jute fibre reinforcement on cbr properties of expansive

soil with increasing percentages 1%, 2% &3%.

Tests result indicates that CBR properties of soil increases with the

increase in fibre content. It was also observed that increasing the percentage

of fibre further increases the CBR value of reinforced soil and this increase is

substantial at fibre content of about 3%. This significant increase in CBR

values of soil reinforced with Jute fibre can be used to substantially indicating

significant improvement in the engineering behavior.

Key words: Jute Geotextiles, Index Properties, CBR Value, Clay Soil

Cite this Article: Dr. T. Kiran Kumar and B. Jagan, A Critical Review on

Applications of Natural Jute Fibres A Case Study, International Journal of

Civil Engineering and Technology, 7(3), 2016, pp. 200210.

http://www.iaeme.com/IJCIET/issues.asp?JType=IJCIET&VType=7&IType=3

http://www.iaeme.com/IJCIET/index.asp

200

editor@iaeme.com

A Critical Review on Applications of Natural Jute Fibres A Case Study

INTRODUCTION

NEED FOR USE OF NATURAL FIBRES

The expansive soils having property of swelling and expansiveness with influence of

variance moisture in soil. It also shows shrinkage behavior when dried. To achieve the

economy and for proper performance of road, it is necessary to improve the soil by

adding jute fibre

The study of the contribution of jute geo-textile on the properties of clayey soils

and its feasibility for various civil engineering applications is evaluated. In order to

improve the performance of roads on such soils jute geotextile has scope as

reinforcement. It is expected that with the inclusion of jute geotextile layer below

Granular Subbase (GSB) layer would be helpful in restricting the movement of upper

pavement layers due to seasonal moisture variation in subgrade expansive, shrinkable

soil. Soil reinforcement is defined as a technique to improve the engineering

characteristics of soil. In this way, using natural fibres to reinforce soil is an old and

ancient idea. Consequently, randomly distributed fibre reinforced soils have recently

attracted increasing attention in geotechnical engineering The main aim of this paper,

therefore, is to review the history, benefits, applications; and possible executive

problems of using different types of natural fibres in soil reinforcement.

For the development of any country, a satisfactory mode of transport and

communication is indispensable. This can be achieved through a transportation

system, which is economically viable. Economy in road network can be achieved

through economical pavement design. Quality of subgrade available is the input

parameter in pavement design. Practically it is not possible to have good subgrade

always. Poor subgrade necessitates a greater pavement thickness resulting in

increased construction cost. With the aim of reducing pavement thickness on poor

subgrade new techniques of construction and soil stabilization have been continuously

explored. Poor natural soils make them practically unsuitable for many civil

engineering construction activities including road pavements. In such cases natural

soils are being treated with different kinds of materials to improve their engineering

properties. The techniques of improving the engineering properties of soil are called

soil stabilization, which has been quite successfully used in many engineering

problems. In the present study jute fibre is used to improve the engineering properties

of the subgrade, so that required pavement thickness may be reduced for particular

traffic intensity. Jute fibres of different diameters and lengths were mixed in the

subgrade in different percentage and the improvements in the subgrade are studied in

terms of California Bearing Ratio (CBR).

NATURAL GEOTEXTILES

Natural fibres are extracted from plants and are then converted into yarns by spinning.

These fabrics are sometimes treated with rot resistance materials or reinforced with

synthetic fibres to enhance their durability under different soil conditions without

affecting its strength and other properties. Natural fibres such as jute, coconut and coir

bricks are used to improve soilstrength, soilerosion control and drainage applications.

http://www.iaeme.com/IJCIET/index.asp

201

editor@iaeme.com

Dr.T.Kiran Kumar and B.Jagan

JUTE FIBRE

Jute geo textile abbreviated as JGT has come out as the best as well as strong

alternative to synthetic geo textiles. Jute geotextile fabric is widely used for varied

civil engineering applications like separation, drainage and filtration over synthetic

one. Jute geo textile is available with inherent advantage of being designed from

natural fibre that is completely biodegradable. Jute is an organic fibre that brings eco

friendly nature to the textile. A user can easily discard them by decomposing them

without any pollution.

Today, jute geo textile fabric is available in two different varieties, one is woven

and other is non-woven fabric. Both the varieties are reckoned for high moisture

absorption capacity. Their flexibility and excellent drainage properties are the reason

behind their usage in agricultural sector to conserve soil erosion. Their long life span

makes them perfect to be used in those sectors that required long-term applications.

Due to their high durability and long life performance, they are in huge demand to be

used as separator, vegetation growing mesh, vertical drains, etc.

Development of this completely natural and strong Jute geo textile is likely to

enable it to be widely accepted in the varied soil reinforcement applications that may

include the construction of rural roads, access roads, and road and flood

embankments. Their superior drape ability, jute geo textile has come up as the ideal

solution for accomplishing varied tasks. Widely accepted for greater moisture

retention capacity, they have given a competitive edge to the geo textiles of other

fabric. Easy to install and remove, they are on the top whenever it comes to quality,

durability, sturdiness and strong nature. They can be availed in various sizes and

dimensions to match the requirement of every task. Jute geotextile is available in the

market at very lowest prices than the synthetic geo textiles.

JUTE GEOTEXTILE (JGT)

Jute GeoTextile is a permeable textile fabric available in woven, non-woven and open

weave forms used in or on soil to improve its engineering performance. Woven JGT

performs the functions of separation, filtration, initial re-enforcement and drainage

when used in the interface of road sub-grade and sub-base, thereby helps soil

consolidation and increases the CBR%. Woven JGT overlain with non woven JGT

when applied on the surface of weak formation arrest scope of infringement of

http://www.iaeme.com/IJCIET/index.asp

202

editor@iaeme.com

A Critical Review on Applications of Natural Jute Fibres A Case Study

ballasts into the soil bellow and also allow passage of precipitation along the plane of

the fabric thereby keeps the soil dry and tight and ultimately check the possibility of

settlement of railway tracks. Properly designed woven JGT with appropriate

porometry treated with suitable additives is used as filter material in river bank

protection.

OBJECTIVES

To study the characteristics of existing soils in the area.

To determine strength of the soil sample with jute fibre and without jute fibre

of normal soil.

The main objective of our study is to evaluate the effect of jute fibre inclusions

on CBR PARAMETERS of clay soil.

In the present work locally available sub-grade Red clay soil of the road is

modified by addition of natural fibre material in different percentages 1%, 2%

& 3% respectively.

Natural Jute fibres of different diameters and lengths were mixed in the

subgrade in different percentages.

Similarly jute fibre is been used for improvement in properties of soft murrum

soil has also been studied.

In order to achieve the objectives a detailed laboratory test were conducted on

normal soil sample and fibre reinforced clay. The test result are tabulated and

compared

LITERATURE REVIEW

Barnali Ghosh, Dr V Ramesh, Rajarajeswari B Vibhuti (2014)

Analysis and comparison of properties of two different clayey soils is carried out with

and without reinforcement. Jute geo-textile (grade TD-5) was used as reinforcing

material to stabilize both peat and black cotton soil. Almost all the standard laboratory

tests as well as field tests were conducted. Finally study of the contribution of jute

geo-textile on the properties of clayey soils and its feasibility for various civil

engineering applications is evaluated. The results show the increment of soil

properties like shear strength, dry density and CBR(California Bearing ratio) while

permeability and settlement .decreased on introduction of jute geo-textile, indicating

significant improvement in the engineering behavior.

T. Sanyal P. K. Choudhury D. N. Goswami (2006)

Has studied the Growth of appropriate vegetation on exposed soil surface is facilitated

by use of natural geotextiles such as Jute Geotextiles (JGT). Properly designed JGT

laid on slopes or any other exposed soil surface provides a cover over exposed soil

lessening the probability of soil detachment and at the same time reduces the velocity

of surface run-off, the main agent of soil dissociation. Appropriately designed Jute

GeoTextiles lay on the shoulder and along the slope helped retain the soilparticles and

prevented detachment of soil particles from the prepared slope. Establishment of

vegetation ensured stabilization of the soil on the slope surface. Jute Geotextiles, a

bio-degradable natural geotextile, can conveniently be used for controlling surface

soil erosion and help growth of vegetation as a bio-engineering measure. JGT after

http://www.iaeme.com/IJCIET/index.asp

203

editor@iaeme.com

Dr.T.Kiran Kumar and B.Jagan

biodegradation coalesces with the soil and adds nutrient to it and fosters growth of

vegetation.

Praveen Aggarwal, Bajinder Sharma, vol (1), (April 2011)

With the aim of reducing pavement thickness on poor subgrade new techniques of

construction and soil stabilization have been continuously explored. Poor natural soils

make them practically unsuitable for many civil engineering construction activities

including road pavements. In such cases natural soils are being treated with different

kinds of materials to improve their engineering properties. The techniques of

improving the engineering properties of soil are called soil stabilization, which has

been quite successfully used in many engineering problems. In the present study jute

fibre is used to improved engineering properties of the subgrade,

D. S. Tolia, O. P. Yadav, Kanwar Singh.(march2003)

Over the last decade, the use of geotextiles of all types has recorded a tremendous

increase; Geotextiles are being increasingly employed in various Civil Engineering

activities andespecially Geotechnical and Highway Engineering to facilitate

construction, ensure better performance of the structure and reduce maintenance. In

view of this wide spread interest, the Central Road Research Institute has taken up a

project for the development and promotion of jute based geotextiles for Highway

Engineering applications. Accordingly, a number of field trials have been carried out

using jute based geotextiles for various applications such as filtration, separation,

drainage and reinforcement.

Ramaswamy & Aziz 1989

Percentage elongation at break of JGT is significantly lower than that of synthetic

geotextiles (maximum 15% against more than 50 % of SGT). Substantial reduction

(more than 50%) in rut depth under dynamic load tests with JGT.

H. P. SINGH, (October 2012)

Soil reinforcement technique is one of the most popular techniques used for

improvement of poor soils. Metal strips, synthetic geotextiles, geogrid sheets, natural

geotextiles, randomly distributed, synthetic and natural fibres are being used as

reinforcing materials to soil. Further, the soil reinforcement causes significant

improvement in tensile strength, shear strength, other properties, bearing capacity as

well as economy.

STUDY AREA

The study area of soil is taken from the portions of highway road near Chennur road

in Kadapa District.The soil is collected from that area. By-Pass is constructed with its

road consisting silty-clay soil. Height of embankment in some stretches of road ranges

from 10 m to 12 m. Embankment fills are finished in 1:2 slopes. As the embankment

heights are appreciably high the denuded slopes were subjected to rain splash erosion

with formation of rain-cuts and gullies due to surface run-off. Soil samples were

collected from two sites of road.

http://www.iaeme.com/IJCIET/index.asp

204

editor@iaeme.com

A Critical Review on Applications of Natural Jute Fibres A Case Study

Physical Condition of Road

So much of damage is there in national highway by moving vehicles with heavy

loads, so we have to increase the strength of the soil by adding jute geotextile and in

also embankments we use jute fibre sheets to avoid erosion control.

Chennur Highway Road for Roads

Silt & clay = 80% to 85%

Sand = 10% to 15%

d50 of soil = 0.033 mm

Liquid Limit = 33%

Plastic Limit = 20%

Plastic Index = 13%

Angle of internal friction of soil = 29

METHODOLOGY

Tests on Soil Sample

Sieve Analysis

This is the name given to the operation of dividing a sample of aggregate in to various

fractions each consisting of particles of the same size.The sieve analysis is conducted

to determine the particle size distribution in a sample of aggregate, which we call

gradation.

Plastic Limit

Plastic limit is the water content corresponding to an arbitrary limit between the

plastic and semisolid states of consistency of a soil. It is the minimum water content at

which the soil will just begin to crumble when rolled in to a thread approximately

3mm in diameter.

http://www.iaeme.com/IJCIET/index.asp

205

editor@iaeme.com

Dr.T.Kiran Kumar and B.Jagan

Liquid Limit

Liquid limit is the minimum water content corresponding to arbitrary limit between

liquid and plastic states of consistency of a soil. It is the minimum water content at

which the soil is still in the liquid state but has a small shearing strength against

flowing, which can be measured by standard available means.

STANDARD PROCTOR TEST

The standard proctor test is carried out by taking 3kgs of air dried soil sample passing

through 4.75 mm IS sieve and thoroughly mixing with suitable amount of water. Then

the moist sample is placed in three layers of approximately equal thickness in a mould

attached with extension collar and each layer is given 25 blows by rammer of 2.6kg

dropped from a height of 310mm above the soil.

CBR Test for Normal Soil Sample

CBR test is used to determine the strength of soil

The amount of soil is taken is 6 kgs with water content percentage

Give 56 blows using tampering rod at 3 parts, and in middle of 1 part tampering we

place the jute fibre and tampering the soil at a height of 31 cm

CBR Test for Soil Sample by Using Jute Fibre

The procedure is same as normal soil sample. In that sample the percentage of jute

fibre is mixing with normal soil sample.

The jute fibre is cut by small pieces, which the shape of the jute is cut by a cbr mould

round shape we have to cut the fibre

The amount of fibre is taken at soil sample of 6 kgs .we have to take 60 gms of jute

fibre is taken.

RESULTS AND DISCUSSIONS

Sieve Analysi

GRAPH 1:

120

% passing through

100

80

60

40

20

0

Aperture size (mm)

http://www.iaeme.com/IJCIET/index.asp

206

editor@iaeme.com

A Critical Review on Applications of Natural Jute Fibres A Case Study

Results

Effective size of the particle D10 = 0.68 mm

Uniformity coefficient

Cu = 2.21 mm

Coefficient of curvature

Cc = 1.66 mm

For a gravel to be classified as well graded, the following must be met:

Cu > 4 for well graded soil, so Cu=2.21 < 4 ,it is poorly graded soil

Liquid Limit

Results:

Liquid limit of the soil (LL)

= 31%

PLASTIC LIMIT

Results:

Plastic limit of the soil (PL)

= 14.8%

Plasticity index of the soil (PI) = 16.2%

STANDARD PROCTOR TEST

GRAPH 2

1.7

Dry density

1.65

1.6

1.55

1.5

1.45

0

10

15

20

25

Moisture content

Results:

Optimum moisture content (omc) =15.38 %

Maximum dry density

(mdd) =1.68 g/cc

A. CBR TEST FOR NORMAL SOIL SAMPLE:

CBR test is used to determine the strength of soil

B. Results:

1. CBR value of soil at 2.50 mm penetration = 14.74 %

2. CBR value of soil at 5.00 mm penetration = 15.18 %

3. CBR value of given soil = 15.18 %

http://www.iaeme.com/IJCIET/index.asp

207

editor@iaeme.com

Dr.T.Kiran Kumar and B.Jagan

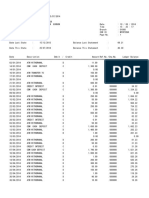

C. CBR TEST FOR SOIL SAMPLE BY US ING JUTE FIBRE

D. 1) CBR VALUE BY MIXING WITH JUTE FIBRE IN SOIL AT 1 %:

CBR value for jute fibre at 2.5 mm penetration is=15.28%

CBR value for jute fibre at 5.0 mm penetration is=15.93%

2) CBR VALUE BY MIXING WITH JUTE FIBRE IN SOIL AT 2 %

CBR value for Jute Fibre at 2.5 mm penetration is=16.39%

CBR Value for Jute Fibre at 5.0 mm penetration is=16.93%

3) CBR VALUE BY MIXING WITH JUTE FIBRE IN SOIL AT 3 %

GRAPH 3

450

400

350

Load(kg)

300

250

200

150

100

50

0

0

for normal soil

Penetration(mm)

soil by using jute fibre

RESULTS

CBR value of soil by mixing with jute fibre at 2.50 mm penetration = 17.07 %

CBR value of soil by mixing with jute fibre at 5.0 mm penetration = 18.09%

CBR value of soil by mixing with jute fibre =18.09%

DISCUSSIONS

Results of jute fibre reinforced soil are compared with that of plain soil sample in two

groups as:

1). Effect of the jute reinforcement on the maximum dry density and optimum

moisture content.

http://www.iaeme.com/IJCIET/index.asp

208

editor@iaeme.com

A Critical Review on Applications of Natural Jute Fibres A Case Study

Optimum moisture content (omc) =15.38 %

Maximum dry density

(mdd) =1.68 g/cc

2) .Effect of the jute reinforcement on California bearing ratio

CBR value of soil by mixing with out jute fibre = 15.18%

CBR value of soil by mixing with jute fibre = 18.09 %

CONCLUSION

From the above discussion it can be concluded that the CBR value of given soil

increases by mixing with natural jute fibre from 15.18% to 18.09%.

Jute fibre reinforcement reduces the maximum dry density and increases the optimum

moisture content of the subgrade soil. The CBR value of the subgrade soil increases

with the inclusion of jute fibre at 3% of fiber content. further adding of fibre

percentage will decrease the cbr value.

Appropriately designed JGT laid on the shoulder and along the slope helped retain the

soil particles and prevented detachment of soil particles from the prepared slope.

Establishment of vegetation ensured stabilization of the soil on the slope surface.

JGT, a bio-degradable natural geotextile, can conveniently be used for controlling

surface soil erosion and help growth of vegetation as a bio-engineering measure. JGT

after biodegradation coalesces with the soil and adds nutrient to it and fosters growth

of vegetation.

Overall it can be concluded that jute fibre reinforced soil can be considered to be good

Ground improvement technique Specially in engineering projects on weak soils.

Jute fibre reinforcement increases the sub-grade strength of the soil and thus reduces

the thickness of pavement. Jute fibre is a good reinforcing material which is bio

degradable.

Jute fibre can be considered as a good reinforcement material.

REFERENCES

[1]

Aggarwal P, Sharma B, 2010. Application of jute Fibre in the improvement of

subgrade characteristics. In: Proc of intconf on advances in civil engineering,

Trabzon, Turkey.

[2]

Aziz, M.A. And Ramaswamy, S.D., 1984. Studies on Jute Fabric Upon Coir Grid

Matting For Subgrade Strengthening, Henin International Journal of Scientific

Engineering and Technology (ISSN : 22771581) Vol. 3 (7), pp : 880884

[3]

Chandra S., Viladkar, M.N. and Nagrrale P.P. 2008. Mechanistic Apporoach for

fibre reinforced flexible pavements, Journals of Transportation Engineering,

Volume, 134, 1523.

[4]

Dhariwal, A., 2003. Performance studies on California bearing ratio values of fly

ash reinforced with jute and non woven geofibres. National seminar on advances

in construction materials, pp 4551.

[5]

Ghavami K, Filho R, Barbosa P, 1999. Behaviour of composite soil reinforced

with natural fibres. Cement Concrete Compos, 21, pp 3948.

[6]

IS: 2720, Part XVI, 1965. Laboratory determination of moisture content density

relation using light compaction Bureau of Indian Standards; New Delhi.

http://www.iaeme.com/IJCIET/index.asp

209

editor@iaeme.com

Dr.T.Kiran Kumar and B.Jagan

[7]

IS: 2720 Part-V-1985 Determination of Liquid limit and Determination of

Plastic limit.

[8]

Ravishankar. R, Dr. K. Chandrashekara and Rudramurthy, Experimental

Investigation and Analysis of Mechanical Properties of Injection Molded Jute and

Glass Fibers Reinforced Hybrid Polypropylene Composites, International

Journal of Mechanical Engineering and Technology, 4(4), 2013, pp. 197206.

[9]

Aleya Fardausy , Md. Alamgir Kabir , Humayun Kabir , M. Mahbubur Rahman ,

Khadiza Begam , Farid Ahmed , Md. Abul Hossain , Md. Abdul Gafur, Study of

Physical, Mechanical and Thermal Properties of Unidirectional Jute Fiber

Reinforced PVC Film Composites International Journal of Mechanical

Engineering and Technology, 3(2), 2012, pp. 267274.

[10]

IS: 2720 Part III, Section 11980 Determination of Specific gravity of soil. IS:

2720 Part X (1973), Determination of Unconfined compression strength ISI

New Delhi, 1973.

http://www.iaeme.com/IJCIET/index.asp

210

editor@iaeme.com

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Week 7 Apple Case Study FinalDocument18 pagesWeek 7 Apple Case Study Finalgopika surendranathPas encore d'évaluation

- Impact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesDocument10 pagesImpact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesIAEME PublicationPas encore d'évaluation

- A Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurDocument7 pagesA Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurIAEME PublicationPas encore d'évaluation

- Modeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyDocument14 pagesModeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyIAEME PublicationPas encore d'évaluation

- Broad Unexposed Skills of Transgender EntrepreneursDocument8 pagesBroad Unexposed Skills of Transgender EntrepreneursIAEME PublicationPas encore d'évaluation

- Voice Based Atm For Visually Impaired Using ArduinoDocument7 pagesVoice Based Atm For Visually Impaired Using ArduinoIAEME PublicationPas encore d'évaluation

- A Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiDocument16 pagesA Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiIAEME PublicationPas encore d'évaluation

- A Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaDocument9 pagesA Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaIAEME PublicationPas encore d'évaluation

- Dealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsDocument8 pagesDealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsIAEME PublicationPas encore d'évaluation

- Influence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiDocument16 pagesInfluence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiIAEME PublicationPas encore d'évaluation

- Attrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesDocument15 pagesAttrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesIAEME PublicationPas encore d'évaluation

- Role of Social Entrepreneurship in Rural Development of India - Problems and ChallengesDocument18 pagesRole of Social Entrepreneurship in Rural Development of India - Problems and ChallengesIAEME PublicationPas encore d'évaluation

- A Multiple - Channel Queuing Models On Fuzzy EnvironmentDocument13 pagesA Multiple - Channel Queuing Models On Fuzzy EnvironmentIAEME PublicationPas encore d'évaluation

- EXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POLYMER COMPOSITESDocument9 pagesEXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POLYMER COMPOSITESIAEME PublicationPas encore d'évaluation

- Application of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDDocument19 pagesApplication of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDIAEME PublicationPas encore d'évaluation

- Various Fuzzy Numbers and Their Various Ranking ApproachesDocument10 pagesVarious Fuzzy Numbers and Their Various Ranking ApproachesIAEME PublicationPas encore d'évaluation

- A Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksDocument10 pagesA Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksIAEME PublicationPas encore d'évaluation

- Optimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsDocument13 pagesOptimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsIAEME PublicationPas encore d'évaluation

- Knowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentDocument8 pagesKnowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentIAEME PublicationPas encore d'évaluation

- Quality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceDocument7 pagesQuality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceIAEME PublicationPas encore d'évaluation

- Analysis of Fuzzy Inference System Based Interline Power Flow Controller For Power System With Wind Energy Conversion System During Faulted ConditionsDocument13 pagesAnalysis of Fuzzy Inference System Based Interline Power Flow Controller For Power System With Wind Energy Conversion System During Faulted ConditionsIAEME PublicationPas encore d'évaluation

- A Overview of The Rankin Cycle-Based Heat Exchanger Used in Internal Combustion Engines To Enhance Engine PerformanceDocument5 pagesA Overview of The Rankin Cycle-Based Heat Exchanger Used in Internal Combustion Engines To Enhance Engine PerformanceIAEME PublicationPas encore d'évaluation

- Sentiment Analysis Approach in Natural Language Processing For Data ExtractionDocument6 pagesSentiment Analysis Approach in Natural Language Processing For Data ExtractionIAEME PublicationPas encore d'évaluation

- Prediction of Average Total Project Duration Using Artificial Neural Networks, Fuzzy Logic, and Regression ModelsDocument13 pagesPrediction of Average Total Project Duration Using Artificial Neural Networks, Fuzzy Logic, and Regression ModelsIAEME PublicationPas encore d'évaluation

- Financial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelDocument9 pagesFinancial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelIAEME PublicationPas encore d'évaluation

- Moderating Effect of Job Satisfaction On Turnover Intention and Stress Burnout Among Employees in The Information Technology SectorDocument7 pagesModerating Effect of Job Satisfaction On Turnover Intention and Stress Burnout Among Employees in The Information Technology SectorIAEME PublicationPas encore d'évaluation

- Formulation of The Problem of Mathematical Analysis of Cellular Communication Basic Stations in Residential Areas For Students of It-PreparationDocument7 pagesFormulation of The Problem of Mathematical Analysis of Cellular Communication Basic Stations in Residential Areas For Students of It-PreparationIAEME PublicationPas encore d'évaluation

- Ion Beams' Hydrodynamic Approach To The Generation of Surface PatternsDocument10 pagesIon Beams' Hydrodynamic Approach To The Generation of Surface PatternsIAEME PublicationPas encore d'évaluation

- Analysis On Machine Cell Recognition and Detaching From Neural SystemsDocument9 pagesAnalysis On Machine Cell Recognition and Detaching From Neural SystemsIAEME PublicationPas encore d'évaluation

- A Review of Particle Swarm Optimization (Pso) AlgorithmDocument26 pagesA Review of Particle Swarm Optimization (Pso) AlgorithmIAEME PublicationPas encore d'évaluation

- Evaluation of The Concept of Human Resource Management Regarding The Employee's Performance For Obtaining Aim of EnterprisesDocument6 pagesEvaluation of The Concept of Human Resource Management Regarding The Employee's Performance For Obtaining Aim of EnterprisesIAEME PublicationPas encore d'évaluation

- Bank Statement SampleDocument6 pagesBank Statement SampleRovern Keith Oro CuencaPas encore d'évaluation

- Supreme Court of The United StatesDocument296 pagesSupreme Court of The United StatesABC News PoliticsPas encore d'évaluation

- 1grade 9 Daily Lesson Log For Demo 1 4Document5 pages1grade 9 Daily Lesson Log For Demo 1 4cristy olivaPas encore d'évaluation

- Exoskeleton ArmDocument5 pagesExoskeleton Armc214ocPas encore d'évaluation

- Validation of AnalyticalDocument307 pagesValidation of AnalyticalJagdish ChanderPas encore d'évaluation

- IP Based Fingerprint Access Control & Time Attendance: FeatureDocument2 pagesIP Based Fingerprint Access Control & Time Attendance: FeaturenammarisPas encore d'évaluation

- Application of ARIMAX ModelDocument5 pagesApplication of ARIMAX ModelAgus Setiansyah Idris ShalehPas encore d'évaluation

- Document 3Document3 pagesDocument 3AdelePas encore d'évaluation

- Ssasaaaxaaa11111......... Desingconstructionof33kv11kvlines 150329033645 Conversion Gate01Document167 pagesSsasaaaxaaa11111......... Desingconstructionof33kv11kvlines 150329033645 Conversion Gate01Sunil Singh100% (1)

- Fr-E700 Instruction Manual (Basic)Document155 pagesFr-E700 Instruction Manual (Basic)DeTiEnamoradoPas encore d'évaluation

- Journal of Economic LiteratureDocument28 pagesJournal of Economic LiteratureEkoKurniadiPas encore d'évaluation

- Bug Head - Fromjapanese To EnglishDocument20 pagesBug Head - Fromjapanese To EnglishAnonymous lkkKgdPas encore d'évaluation

- Paul Milgran - A Taxonomy of Mixed Reality Visual DisplaysDocument11 pagesPaul Milgran - A Taxonomy of Mixed Reality Visual DisplaysPresencaVirtual100% (1)

- Tendernotice 1Document42 pagesTendernotice 1Hanu MittalPas encore d'évaluation

- UBITX V6 MainDocument15 pagesUBITX V6 MainEngaf ProcurementPas encore d'évaluation

- Soneri Bank Compensation PolicyDocument20 pagesSoneri Bank Compensation PolicySapii Mandhan100% (1)

- CNG Fabrication Certificate16217Document1 pageCNG Fabrication Certificate16217pune2019officePas encore d'évaluation

- Managerial Accounting-Fundamental Concepts and Costing Systems For Cost Analysis Module 1Document40 pagesManagerial Accounting-Fundamental Concepts and Costing Systems For Cost Analysis Module 1Uzma Khan100% (1)

- Brief Curriculum Vitae: Specialisation: (P Ea 1. 2. 3. Statistical AnalysisDocument67 pagesBrief Curriculum Vitae: Specialisation: (P Ea 1. 2. 3. Statistical Analysisanon_136103548Pas encore d'évaluation

- Kompetensi Sumber Daya Manusia SDM Dalam Meningkatkan Kinerja Tenaga Kependidika PDFDocument13 pagesKompetensi Sumber Daya Manusia SDM Dalam Meningkatkan Kinerja Tenaga Kependidika PDFEka IdrisPas encore d'évaluation

- Elliot WaveDocument11 pagesElliot WavevikramPas encore d'évaluation

- SettingsDocument3 pagesSettingsrusil.vershPas encore d'évaluation

- Is.14785.2000 - Coast Down Test PDFDocument12 pagesIs.14785.2000 - Coast Down Test PDFVenkata NarayanaPas encore d'évaluation

- Possession: I. A. Definition and Concept Civil Code Art. 523-530 CasesDocument7 pagesPossession: I. A. Definition and Concept Civil Code Art. 523-530 CasesPierrePrincipePas encore d'évaluation

- Stock Prediction SynopsisDocument3 pagesStock Prediction SynopsisPiyushPurohitPas encore d'évaluation

- Modulation and Frequency Synthesis X Digital Wireless RadioDocument233 pagesModulation and Frequency Synthesis X Digital Wireless Radiolcnblzr3877Pas encore d'évaluation

- HandbookDocument194 pagesHandbookSofia AgonalPas encore d'évaluation

- Practitioners Guide For Business Development Planning in FPOsDocument70 pagesPractitioners Guide For Business Development Planning in FPOsMythreyi ChichulaPas encore d'évaluation

- Project Job Number EngineerDocument2 pagesProject Job Number Engineertekno plus banatPas encore d'évaluation