Académique Documents

Professionnel Documents

Culture Documents

Upgrading Acid Gas Streams

Transféré par

Ibhar Santos MumentheyCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Upgrading Acid Gas Streams

Transféré par

Ibhar Santos MumentheyDroits d'auteur :

Formats disponibles

ACID GAS ENRICHMENT

Upgrading acid

gas streams

Using the ProTreat amine simulator, T. K. Khanmamedov of

TKK Company and R. H. Weiland of Optimized Gas Treating,

Inc. analyse how Highsulf can produce a Claus plant

feedstock of excellent quality from sour gas streams such as

sulphur plant tail gas and raw gases that would otherwise

present disposal problems.

n many instances it is not possible to

remove the hydrogen sulphide from a

gas stream and simultaneously produce

a satisfactory sulphur plant feed using conventional gas treating technology. In these

cases the H2S, once removed from the

gas, can present a serious disposal problem because its concentration in the product acid gas stream is too low to be fed to

a sulphur plant but is far too high to be

incinerated. One option is to treat selectively the acid gas stream itself and raise

its H2S content to a level suitable for a sulphur recovery unit. However, conventional

enriching of the acid gas stream may still

fail to yield satisfactory results.

Sulphur plants operate best with a feed

containing 55% or more H2S. The balance of

the SRU feed stream is CO2 and water, with

small amounts of hydrocarbons, inerts, and

other components. Lower concentrations of

H2S can be processed only with increasing

levels of sulphur plant complexity, larger

equipment, and higher cost. Streams having

less than 32% or so H2S are near the lower

limit for a straight-through Claus process.

There are numerous sources of acid

gas streams that are too dilute for sulphur

recovery in Claus plants but too concentrated to vent. In plants treating high

CO2:H2S ratio gas, adequate CO2 slip even

using the most selective solvent often cannot produce an SRU feed of sufficient quality. For example, conventional treatment of

a high pressure gas containing 1-2% CO2

and a few 100s of ppmv H2S using even

the most selective amine available cannot

produce an acid gas stream with more than

80

a few mol-% H2S, completely inadequate for

a conventional Claus SRU. Even in plants

with a moderate CO2:H2S ratio of say 4:1,

if complete acid gas removal is necessary

(LNG for example), using a single contactor will necessarily produce an acid gas

stream containing only 20% H2S.

Highsulf (a trademark of the TKK Company) is a patented process strategy that

can be applied incrementally in amine treating plants to increase the H2S concentration in the off-gas from the regenerator and

produce an increasingly high quality Claus

sulphur plant feed.1-6 Some computer simulation runs of the Highsulf process, using

the ProTreat (trademark of Optimized Gas

Treating, Inc.) simulator, were presented,

discussed, analysed and published by Weiland14,15. A conventional amine treating

plant (in this instance, a tail gas treater, or

TGTU) is shown in simplified form in Fig. 1.

The tail gas is sulphur plant effluent, essentially a stream of H2S and CO2 diluted with

the nitrogen remaining after the combustion

and catalytic processes that convert H2S

into elemental sulphur in a Claus sulphur

plant. Frequently, the off-gas is of only very

marginal quality as a sulphur plant feed.

There are two approaches to making it

more suitable. One is to apply various levels of Highsulf directly to the TGTU. The

other is to reprocess the off-gas in another,

smaller amine plant and produce by selective absorption a second off-gas of higher

quality. This secondary treating unit (also

called an acid gas enrichment, or AGE, unit)

may also apply the Highsulf strategy. Highsulf recognises that the higher the H2S con-

tent of the gas being treated in an amine

unit, the greater will be the H2S concentration in the off-gas from the regenerator.

Highsulf processes produce a more concentrated product stream, as discussed by

Khanmamedov7-9.

The role of selectivity

Achieving the maximum selectivity for H2S

over CO2 is done by using the right solvent

under the right process conditions in the

right equipment. It is paramount to successful tail gas treatment and to the operation of AGE units. The perfect process in

these applications removes all the H2S and

none of the CO2 from the raw gas because

an acid gas consisting entirely of wet H2S is

produced upon solvent regeneration. This

would be perfect selectivity. Detailed discussions of selectivity have been presented

in many places including Khanmamedov7, 9,

Anderson et al.10 and Weiland et al.11, so

only a brief review is given here.

The equilibrium solubilities of H2S and

CO2 in selective solvents such as

methyldiethanolamine (MDEA) do not differ

radically. In other words, chemical solvents

do not have great thermodynamic selectivity so vapour-liquid equilibrium does not

play as critical a role as one might suppose.

The differences in absorption rates are

really determined partly by reaction kinetics, and partly by the hydraulic and mass

transfer characteristics of the contacting

equipment vis vis the relative magnitudes

of gas- and liquid-side mass transfer coefficients. The mass transfer characteristics

of the contacting equipment have been

largely overlooked by many practitioners,

possibly because of poor understanding of

separation equipment from the standpoint

of its inherent mass transfer rates and what

affects them.

Tertiary amines, of which MDEA is the

most commonly used in selective treating,

react with H2S and CO2 at chemical rates

that are at opposite ends of the spectrum.

H2S absorption is accompanied by an instantaneous proton transfer reaction associated

with H2S dissociation and amine protonation. Carbon dioxide, on the other hand,

reacts very slowly indeed, forming bicarbonate ion by reaction with water, but no amine

carbamate. Thus, from a reaction kinetic

standpoint, MDEA is highly selective for H2S.

As devices for carrying out mass transfer, trays and packing (both random and

structured) behave quite differently hydraulically. The most obvious reason for this dif-

Sulphur 318 | September -October 2008

ACID GAS ENRICHMENT

ference is that a properly operating tray

(froth regime, not spray regime) usually has

the liquid phase continuous and the gas

phase dispersed, while in packing the opposite is generally true. The liquid flows over

packing in films that are relatively quiescent

compared to the highly agitated state of the

liquid flowing across trays. Vapour flows are

quite turbulent for both trays and packing.

Therefore, these types of equipment should

be expected to have different mass transfer characteristics, most pronounced with

respect to their relative liquid-phase resistances, but also with respect to their vapourphase resistances (to an extent that

depends greatly on the exact internals

involved). These differences in characteristics are important to establishing selectivity

because the mass-transfer resistance to

H2S absorption is primarily in the gas phase,

while for CO2 it is in the liquid phase. The

result is that to some extent selectivity can

be controlled by controlling the relative

resistances to mass transfer offered by the

two phases through the judicious selection

of tower internals. Phase resistances are

functions of the type (trays, random packing, structured packing) and mechanical

details (tray passes, weir heights, packing

brand, size, crimp angle, etc.) of the contacting equipment itself as well as the way

it is operated hydraulically (flow rates and

phase properties that depend on temperature and pressure). Tail gas treating and

acid gas enrichment are processes whose

performance is completely dependent on

relative rates of mass transfer. Only a true

heat- and mass-transfer-rate based model

such as ProTreat stands any realistic

chance of reliably predicting performance in

a specific piece of equipment. Reliable simulations cannot be done unless the simulation tool itself is cognisant of the mass

transfer behaviour of the internals, and the

engineer doing the calculations also keeps

in mind the hydraulic regime in which the

column is operating (e.g., spray versus froth

regimes for trays).

All amines instantly react with (i.e., are

protonated by) H2S, so selectivity is a function of the reaction rate of CO2 with the

amine. Because CO2 does not react with tertiary and sterically-hindered amines, these

are the only amine-based solvents that

make any sense in highly selective treating

applications such as TGTUs and AGEs.

Commercially, this makes them the only

contenders, with MDEA (perhaps assisted

by partial neutralisation) and the hindered

amines being the only realistic candidates.

Because the hindered amines currently in

commercial use are all members of the Flexsorb family and are proprietary to ExxonMobil Corporation, the remainder of this

article focuses on generic MDEA, including

phosphoric acid as a promoter.

Two applications of Highsulf are considered, tail gas treating and acid gas enrichment. In both applications, in addition to

examining the effect of Highsulf on SRU feed

quality, scrutiny is also given to the value of

phosphoric acid as a stripping promoter.

Tail gas treating

The base-case unit is a conventional TGTU

using 35 wt-% MDEA. The 6-ft diameter contactor is packed with 20-ft of Flexipac 2Y

structured packing. The regenerator is 6-ft

diameter and it contains 30 generic one-

pass valve trays. A process flow diagram is

shown in Fig. 1.

The tail gas is 1% H2S and 3.4% CO2,

balance nitrogen and trace inerts, and is

flowing at 3 MMSCFD and a pressure of 1

psig. The solvent flow to the regenerator is

94 US gpm and it is preheated in the crossexchanger to 205oF. These basic parameters correspond to an actual TGTU in a

refinery. Under these conditions, the treated

gas going to incineration was about 50

ppmv H2S, which corresponds fairly closely

to the simulation value of 52.6 ppmv.

Although its composition was not measured, the feed to the SRU is simulated to be

37.8 mol-% H2S, 54.9% CO2, the balance

being water vapour and a trace of nitrogen,

and essentially the same numbers result

from a component balance around the

entire TGTU. Although this gas is certainly

suitable as an SRU feed, the SRU could be

hydraulically unloaded and its performance

streamlined if the feed were richer in H2S.

Highsulf is a way to achieve this.

Table 1 shows a comparison between

this base case (Case 0) and the more important performance metrics that result when

Highsulf is applied to increasing extents. The

percent CO2 slipped through the absorber is

based on the tail gas feeding the column

and the CO2 flow in the gas to incineration.

Vigorously applying Highsulf (Cases 5

and 6) almost doubles the H2S content of

the SRU feed, from 38% to about 70% and

still maintains the gas to incineration at

below 100 ppmv. But the system collapses

for Case 6. It is important to point out that

as Highsulf is applied with increasing

vigour, nothing else in the simulated plant

was changedthe important parameters of

Fig 1: Tail gas treating unit

to incinerator

3

to SRU

trim cooler

recycle

2

18

CB

11

12

16

17

13

controller

contactor

8

15

regenerator

10

X exchanger

tail gas from SRU

4

7

Sulphur 318 | September -October 2008

14

81

ACID GAS ENRICHMENT

Table 1: Effect of Using Highsulf technology on TGTU Performance

Case

Relative extent of Highsulf application

H2S in SRU Feed (%)

H2S to Incineration (ppmv)

CO2 Slipped (%)

0

37.9

53.2

57.7

1

41.1

55.5

63.3

2

45.6

58.5

69.9

3

52.7

65.1

78.0

4

65.4

85.3

88.0

5

6

70.4 75.9

130 1,600

91.0 94.9

Table 2: Effect of using Highsulf technology on TGTU performance when a

stripping promoter is used

Case

Relative extent of Highsulf application

H2S in SRU Feed (%)

H2S to Incineration (ppmv)

CO2 Slipped (%)

0

38.6

5.3

58.8

1

41.8

6.4

64.2

2

46.4

7.3

70.8

3

53.6

9.3

78.7

4

66.3

16.6

88.5

5

6

71.4 77.7

40.2 1,520

91.4 95.4

Fig 2: Profiles of H2S concentration in the TGTU contactor for various

extents of Highsulf application

depth in packing, ft

0

2

case

0

3

4

10

12

14

16

18

20

1.E-05

1.E-04

1.E-03

1.E-02

1.E-01

H2S, mole fraction

Fig 3: Vapour flow through regenerator as a function of Highsulf application

0

case

0

1

2

tray from top

10

3

4

15

5

6

20

25

30

50

100

150

vapour flow, lb mol/hr

82

200

reboiler duty and solvent circulation rate, as

well as all other parameters, were held

fixed so there is no operating cost associated with this application of Highsulf. Its

not a great oversimplification to say that

nothing much more than a minor rerouting

of piping is needed to achieve a truly

remarkable increase in SRU feed quality.

It is instructive to enquire as to the

cause of the escalation in the H2S level in

the treated gas. Figure 2 shows profiles of

H2S in the gas versus position down the

packed bed corresponding to the various

cases in Table 1. For Cases 0 through 5, the

H2S profiles shift to higher concentrations

more or less in proportion to how vigorously

Highsulf is applied. However, when Highsulf

is over-applied, the column goes from leanend to rich-end pinched and H2S breaks

through into the incinerator gas. The breakthrough is precipitous. The relative flatness

of the profiles at the lean end (top) of the

column is witness to the lean-end pinch condition. The flatness at the rich end in Case

6 indicates a rich-end pinch condition.

Figure 3 shows that in Case 5 the

vapour flow through the regenerator begins

to collapse. By Case 6, the reboiler with its

constant duty is unable to keep up with the

demand for stripping steam and all the

vapour generated is consumed over the

bottom five trays, with none being left to do

any further stripping over the 20 stripping

trays above. The top five trays in this column are wash trays, rich amine entering

onto the sixth tray from the top.

With all other conditions constant, there

is a limit to how vigorously Highsulf can be

applied before the operation collapses.

However, it is remarkable that when the

optimal extent of Highsulf is applied, the

SRU feed quality can be nearly doubled for

zero operating cost.

The fact that the TGTU contactor is leanend pinched says that the H2S leak to

incineration is determined by lean-amine

acid-gas loadings and this suggests that

using a stripping promoter will help achieve

a reduced H2S. The most commonly used

stripping promoter is phosphoric acid, proposed in a patent to Dibble12. Typically,

concentrations below about 1 wt-% are

used. The mechanism by which small quantities of organic and inorganic acids (including heat stable salts) achieve great

reductions in residual acid gas loadings in

stripped solvents has been described in

detail by Hatcher et al.13 and Weiland14,15.

Briefly, small amounts of acid permanently

protonate a small fraction of the amine. At

Sulphur 318 | September -October 2008

ACID GAS ENRICHMENT

Table 3: Effect of Highsulf processing on AGE performance

Case

Relative extent of Highsulf application

0

H2S in SRU Feed (%)

28.6

32.9

38.9

48.3

66.1

76.3

78.3

464

313

1,488

1,283

1,068

840

586

H2S to Incineration (ppmv)

Mass flow to SRU (lb/hr)

19.1

24.9

34.6

52.5

90.2 4,490 27,400

CO2 Slipped (%)

80.0

83.6

87.5

91.6

96.2

98.0

98.8

Table 4: Effect of H3PO4 on Highsulf performance in AGE

Case

Relative extent of Highsulf application

0

H2S in SRU Feed (%)

Mass flow to SRU (lb/hr)

H2S to Incineration (ppmv)

CO2 Slipped (%)

29.1

33.4

39.5

48.9

67.2

73.0

76.0

1,463

1,262

1,051

829

575

519

447

0.5

0.6

0.7

1.0

4.1

80.4

84.0

87.8

91.9

96.4

the very low loadings typical of the reboiler

in a regenerator, the amount of protonated

amine is extremely small. Artificially

increasing it by using an acid drives the

decomposition reaction to the left, towards

free unreacted acid gas, removing still

more H2S from the solution.

The work already described was

repeated with 3,000 ppmw phosphoric acid

added to the same 35 wt-% MDEA solvent.

Nothing else was altered in any way. The

performance measures shown in Table 1

are repeated in Table 2 after the stripping

promoter is added.

Comparison with Table 1 shows a trivially

small effect of the phosphoric acid additive

on SRU feed quality; however, H2S leak to

incineration is reduced by factors of

between 3 and 5 until once again the

process collapses under the load of excessively applied Highsulf, when the contactor

goes into a rich-end pinched state and H2S

breaks through. The reason H2S leak rates

to incineration are so greatly reduced is that

the lean solvent loading of H2S, is lowered

by factors of between 15 (Case 5) and more

than 30 (Case 0 with no Highsulf application). These reductions do not translate fully

into lowered H2S leak values because the

phosphate additive also increases the H2S

backpressure in the absorber. However, the

effect of reduced lean loading exceeds that

of elevated H2S backpressure, and the

result is still a very substantial reduction in

H2S leak from the contactor. Incidentally, the

same effect has been observed in plants

with similar levels of heat stable salts, and

occasionally a plant will fail to meet treating

84

380 8,160

97.4

98.1

specifications immediately after an aggressive solvent reclaiming operation because

the stripping promoters have been removed.

Highsulf also results in a substantial

reduction in the total gas flow to the SRU

while maintaining essentially the same flow

of H2S. For example, in Case 4, the SRU

processes only one-half the total gas that

there would be without Highsulf. In the present case, Highsulf enables nearly a doubling

in SRU feed quality and at the same time it

unloads the sulphur plant by 50%. Its operating cost is zero, and negligible capital

investment. Rarely is nature so gratuitous.

Acid gas enrichment

The acid gas enrichment (AGE) plant is

schematically identical with the TGTU

shown in Figure 1 except that now the feed

to the contactor is actually a relatively

dilute stream of H2S in wet CO2 coming

from the regenerator of a conventional gas

treating plant. In this example, the contactor contains 20 valve trays in a 4-ft diameter shell and operates at 3 psig. The

regenerator is at 20 psig and it has 23

stripping trays (valve trays at 24-in tray

space) and 5 wash trays (bubble-cap trays

at 30-in tray space) in a 4.5-ft diameter

shell. In the base case (Case 0) where

Highsulf is not used at all, both columns

operate at about 25% of jet and downcomer-choke flood so they are operating in

the froth regime. Raw gas enters the contactor at 495 ft3/min, 120oF and 15 psig,

with 8 mol-% H2S and 92 mol-% CO2 on a

dry basis and is water saturated. The sol-

vent is 50 wt-% MDEA at 100 US gpm and

90F. The reboiler uses 6,000 lb/h of 65

psig steam. These data correspond to an

actual operating plant. As Highsulf is

applied with increasing vigour (Cases 2

6), the basic operating parameters are

kept constant so the effect of increasing

the extent of Highsulf application alone can

be isolated.

Table 3 shows performance metrics for

the base case, how various degrees of Highsulf application improve enrichment, and

the cost in terms of increased H2S leak to

incineration. Just as for the tail gas treating

example, CO2 slip through the absorber is

assessed on the basis of the raw gas feeding the column and the gas to incineration.

As Highsulf continues to be applied

more vigorously, the quality of the SRU feed

steadily climbs and by Case 4 it contains

nearly two and a half times the concentration of H2S. As shown in Fig. 4, at levels of

application beyond Case 4, the H2S leak

goes through the roof so Case 4 represents

the practical maximum enrichment unless

other process conditions are changed.

Figure 5 shows how Highsulf can

enhance SRU feed quality. At the same

time, the total gas load on the SRU

decreases by 60%. And all of this is

achieved by Highsulf at zero operating cost

and next-to-zero capital investment.

In addition, the Highsulf system provides a simple and very stable means of

controlling the degree of enrichment and

the amount of H2S leakage from the AGE

units contactor2, 3.

The contactor in this AGE unit is also

lean-end pinched so phosphoric acid can

also be used here to improve solvent regeneration and thereby reduce H2S leak from the

contactor. Simulation shows that H2S leaks

of below 1 ppmv can be achieved using only

5,000 ppmw of phosphoric acid and that

even in Case 4, the H2S leak is only 4 ppmv.

Summary data are shown in Table 4.

Again it can be seen that using a stripping promoter provides a tremendous

improvement in H2S leak from the contactor,

without significantly affecting the efficacy of

Highsulf to produce a greatly improved SRU

feed. The CO2 slip, which is based on the

external feed to the AGE unit, is extraordinarily high but quite consistent with the high

H2S content of the SRU feed stream. As long

as the contactor remains lean-end pinched,

phosphoric acid continues to provide great

benefit; however, once the contactor

become rich-end pinched no further benefit

accrues.

Sulphur 318 | September -October 2008

ACID GAS ENRICHMENT

Fig 4: Dependence of H2S leak on how vigorously

Highsulf is applied

Fig 5: Response of SRU feed quality to how

energetically Highsulf is applied

80

H2S to SRU, mole %

H2S leak, ppmv

1,000

100

10

0

70

60

50

40

30

20

0

relative application of Highsulf

References

Khanmamedov, T. K., U.S. Patent 5,556,606

Khanmamedov, T. K., U.S. Patent 5,718,872

Khanmamedov, T. K., U.S. Patent 5,716,587

Khanmamedov, T. K., U.S. Patent 6,506,349

Khanmamedov, T. K., Canada Patent 2,204,351

Khanmamedov, T. K., PCT/US1995/013768

Khanmamedov, T. K., NPRA Q&A Answer

Book, V. Energy & Environmental Management, Atlanta, GA, p.14, 1998

8. Khanmamedov, T. K., National Meeting of the

American Chemical Society, San Diego, CA,

2000

1.

2.

3.

4.

5.

6.

7.

Sulphur 318 | September -October 2008

relative application of Highsulf

9. Khanmamedov, T. K., Superior gas sweetening, Hydrocarbon Engineering, v. 8, No.

12, December, p.20-24, 2003

12. Dibble, J. H., European Patent Publication

10. Anderson, M. D., Hegarty, M. J., Johnson, J.

E.: Flexible Selective Solvent Design, Paper

presented to 71st Annual Convention of the

Gas Processors Association, March 1618,

1992.

13. Hatcher, A. A., Keller, A. E., Weiland, R. H.,

11. Weiland, R. H., Sivasubramanian, M. S.,

Dingman, J. C.: Effective Amine Technology:

Controlling Selectivity, Increasing Slip, and

Reducing Sulfur, Laurence Reid Gas Conditioning Conference, Norman, OK, 2003.

Number 0134948, Application Number

8417586.4, March 27, 1985.

Sivasubramanian, M. S.: Are Your Simulation

Amines Too Clean?, Laurence Reid Gas Conditioning Conference, Norman, OK, 2006.

14. Weiland, R. H.: Acid Gas Enrichment - Maximizing Selectivity, Laurence Reid Gas Conditioning Conference, Norman, OK, 2008

15. Weiland, R. H.:, Acid Gas Enrichment II: Maximizing Selectivity, PTQ Gas, Spring, 2008

85

Vous aimerez peut-être aussi

- Total Cooler 30 Plates General Arrangement: - Aansluiting Niveau Meter ? - Positie Support ? - Temperature Sensor ?Document1 pageTotal Cooler 30 Plates General Arrangement: - Aansluiting Niveau Meter ? - Positie Support ? - Temperature Sensor ?Ibhar Santos MumentheyPas encore d'évaluation

- Floating Suction SystemDocument12 pagesFloating Suction SystemnainpinglePas encore d'évaluation

- Nevada Slurry Valve 2014 LiteDocument2 pagesNevada Slurry Valve 2014 LiteIbhar Santos MumentheyPas encore d'évaluation

- Water HammerDocument1 pageWater HammerIbhar Santos MumentheyPas encore d'évaluation

- PVDF Material Data Sheet - 1Document1 pagePVDF Material Data Sheet - 1Ibhar Santos MumentheyPas encore d'évaluation

- PVDF PipeDocument4 pagesPVDF PipeIbhar Santos MumentheyPas encore d'évaluation

- 02-02 Customer Talking PointsDocument4 pages02-02 Customer Talking PointsIbhar Santos MumentheyPas encore d'évaluation

- 19-09 - Assembly of The Main ValveDocument19 pages19-09 - Assembly of The Main ValveIbhar Santos MumentheyPas encore d'évaluation

- 02-06 - LESER in FranceDocument15 pages02-06 - LESER in FranceIbhar Santos MumentheyPas encore d'évaluation

- Customer Talking PointsDocument4 pagesCustomer Talking PointsIbhar Santos MumentheyPas encore d'évaluation

- Codes and Standards: (Extension of ASME)Document14 pagesCodes and Standards: (Extension of ASME)Ibhar Santos MumentheyPas encore d'évaluation

- General Information For Integral Horsepower (Ihp) Motors On Variable Frequency Drives (VFDS)Document3 pagesGeneral Information For Integral Horsepower (Ihp) Motors On Variable Frequency Drives (VFDS)Ibhar Santos MumentheyPas encore d'évaluation

- 20-01 Design Din en Iso enDocument19 pages20-01 Design Din en Iso enIbhar Santos MumentheyPas encore d'évaluation

- 02-06 - LESER in FranceDocument15 pages02-06 - LESER in FranceIbhar Santos MumentheyPas encore d'évaluation

- Volume 3-The Origins of ProtreatDocument2 pagesVolume 3-The Origins of ProtreatIbhar Santos MumentheyPas encore d'évaluation

- Brochure B1510-60Hz Horizontal, Inline Selection PDFDocument34 pagesBrochure B1510-60Hz Horizontal, Inline Selection PDFIbhar Santos MumentheyPas encore d'évaluation

- IQ Range: Reliability For Critical ApplicationsDocument48 pagesIQ Range: Reliability For Critical ApplicationsIbhar Santos MumentheyPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- PVAI VPO - Membership FormDocument8 pagesPVAI VPO - Membership FormRajeevSangamPas encore d'évaluation

- Experiment On Heat Transfer Through Fins Having Different NotchesDocument4 pagesExperiment On Heat Transfer Through Fins Having Different NotcheskrantiPas encore d'évaluation

- 5 Deming Principles That Help Healthcare Process ImprovementDocument8 pages5 Deming Principles That Help Healthcare Process Improvementdewi estariPas encore d'évaluation

- The Internal Environment: Resources, Capabilities, Competencies, and Competitive AdvantageDocument5 pagesThe Internal Environment: Resources, Capabilities, Competencies, and Competitive AdvantageHenny ZahranyPas encore d'évaluation

- Banjara EmbroideryDocument34 pagesBanjara EmbroideryKriti Rama ManiPas encore d'évaluation

- 7 TariffDocument22 pages7 TariffParvathy SureshPas encore d'évaluation

- PLT Lecture NotesDocument5 pagesPLT Lecture NotesRamzi AbdochPas encore d'évaluation

- Separation PayDocument3 pagesSeparation PayMalen Roque Saludes100% (1)

- Anaphylaxis Wallchart 2022Document1 pageAnaphylaxis Wallchart 2022Aymane El KandoussiPas encore d'évaluation

- Evaluating Project Scheduling and Due Assignment Procedures An Experimental AnalysisDocument19 pagesEvaluating Project Scheduling and Due Assignment Procedures An Experimental AnalysisJunior Adan Enriquez CabezudoPas encore d'évaluation

- STM - Welding BookDocument5 pagesSTM - Welding BookAlvin MoollenPas encore d'évaluation

- Powerpoint Presentation: Calcium Sulphate in Cement ManufactureDocument7 pagesPowerpoint Presentation: Calcium Sulphate in Cement ManufactureDhruv PrajapatiPas encore d'évaluation

- Cancellation of Deed of Conditional SalDocument5 pagesCancellation of Deed of Conditional SalJohn RositoPas encore d'évaluation

- Embedded Systems DesignDocument576 pagesEmbedded Systems Designnad_chadi8816100% (4)

- Abu Hamza Al Masri Wolf Notice of Compliance With SAMs AffirmationDocument27 pagesAbu Hamza Al Masri Wolf Notice of Compliance With SAMs AffirmationPaulWolfPas encore d'évaluation

- What Caused The Slave Trade Ruth LingardDocument17 pagesWhat Caused The Slave Trade Ruth LingardmahaPas encore d'évaluation

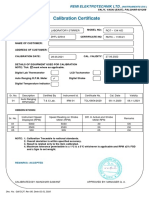

- Calibration CertificateDocument1 pageCalibration CertificateSales GoldClassPas encore d'évaluation

- Year 9 - Justrice System Civil LawDocument12 pagesYear 9 - Justrice System Civil Lawapi-301001591Pas encore d'évaluation

- How To Create A Powerful Brand Identity (A Step-by-Step Guide) PDFDocument35 pagesHow To Create A Powerful Brand Identity (A Step-by-Step Guide) PDFCaroline NobrePas encore d'évaluation

- Convention On The Rights of Persons With Disabilities: United NationsDocument13 pagesConvention On The Rights of Persons With Disabilities: United NationssofiabloemPas encore d'évaluation

- A. The Machine's Final Recorded Value Was P1,558,000Document7 pagesA. The Machine's Final Recorded Value Was P1,558,000Tawan VihokratanaPas encore d'évaluation

- HandloomDocument4 pagesHandloomRahulPas encore d'évaluation

- Heavy LiftDocument4 pagesHeavy Liftmaersk01Pas encore d'évaluation

- (X-09485) XYLENE RECTIFIED Extra Pure (Mix Isomers)Document9 pages(X-09485) XYLENE RECTIFIED Extra Pure (Mix Isomers)Bharath KumarPas encore d'évaluation

- Ucm6510 Usermanual PDFDocument393 pagesUcm6510 Usermanual PDFCristhian ArecoPas encore d'évaluation

- CLAT 2014 Previous Year Question Paper Answer KeyDocument41 pagesCLAT 2014 Previous Year Question Paper Answer Keyakhil SrinadhuPas encore d'évaluation

- Kaitlyn LabrecqueDocument15 pagesKaitlyn LabrecqueAmanda SimpsonPas encore d'évaluation

- Water Hookup Kit User Manual (For L20 Ultra - General (Except EU&US)Document160 pagesWater Hookup Kit User Manual (For L20 Ultra - General (Except EU&US)Aldrian PradanaPas encore d'évaluation

- Exp. 5 - Terminal Characteristis and Parallel Operation of Single Phase Transformers.Document7 pagesExp. 5 - Terminal Characteristis and Parallel Operation of Single Phase Transformers.AbhishEk SinghPas encore d'évaluation

- G.R. No. 185449, November 12, 2014 Del Castillo Digest By: DOLARDocument2 pagesG.R. No. 185449, November 12, 2014 Del Castillo Digest By: DOLARTheodore DolarPas encore d'évaluation