Académique Documents

Professionnel Documents

Culture Documents

Weld Strenght

Transféré par

Raymond SabadoCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Weld Strenght

Transféré par

Raymond SabadoDroits d'auteur :

Formats disponibles

Steel Design to Eurocode 3

EN 1993-1-8 Clause 2.2

Joints

Partial safety factors, M for joints are given in

Table 2.1 of EC 3-8.

Eurocode 3 Part: 1-8

Refer to NA to get the required values of the

different partial safety factors

Resistance of bolts and welds, M2 = 1.25

Joint Types

CL 5.2.2.2 Nominally pinned joints are capable of

transmitting internal forces without developing

significant moments, and capable of accepting the

resulting rotations under the design loads.

CL 5.2.2.3 Rigid and full strength joints have

sufficient rotational stiffness to justify analysis based

on full continuity.

Bolted Joints Table 3.4

Table 3.4 of EN 1993-1-8 gives the different checks

required for individual fasteners subjected to shear

and/or tension.

Checks need to be carried out for a number of possible

failure modes:

Semi-rigid joints lie somewhere between nominally

pinned and rigid.

Eurocode 3

Principles mostly the same as BS 5950

Results are similar although EC3 results are slightly

more conservative and this is due to the larger

Shear resistance per shear plate

Bearing Resistance

Tension Resistance

Combined shear and tension

Bolted Joints Tension

Tension resistance for ordinary bolts:

partial safety factor (M2=1.25)

Bolt Strength

These values should be adopted as characteristic

values in design calculations :

Bolt classes

4.6

5.6

8.8

10.9

fyb (N/mm2)

240

300

640

900

fub (N/mm2)

400

500

800

1000

EN 1993-1-8 Table 3.1 - Nominal values of fyb and fub

for bolts

Steel Strength

2

fy (N/mm )

Steel

grade

S 275

S 355

fu (N/mm )

Nominal thickness of element

t (mm)

t 16

16 < t

40

40 < t

63

63 < t

80

275

265

255

245

355

345

335

325

Nominal

thickness of

element t

(mm)

3t

t<3

100

430

410

to

to

580

560

510

470

to

to

680

630

Extract from Table 7 of EN 10025-2

where:

As is the tensile stress area of the bolt

M2 = 1.25

fub is the ultimate tensile strength of the bolt

k2 = 0.63 for countersunk bolt, otherwise k2 = 0.9

Bolted Joints Shear

Shear resistance per shear plane for ordinary bolts

where the shear plane passes through the threaded

portion of the bolt:

where:

As is the tensile stress area of the bolt

fub is the ultimate tensile strength of the bolt

M2 = 1.25

Bolt classes

4.6

4.8

5.6

5.8

6.8

8.8

10.9

0.6

0.5

0.6

0.5

0.5

0.6

0.5

Shear resistance per shear plane for ordinary bolts

where the shear plane passes through the unthreaded

portion of the bolt:

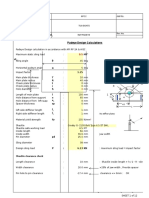

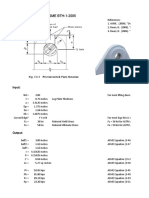

Welded Joints

Simplified method for design resistance of fillet

weld (CL 4.5.3.3 and Table 4.1 EN 1993-1-8)

Fw,Ed Fw,Rd

where:

A is the gross cross-section of the bolt

fub is the ultimate tensile strength of the bolt

M2 = 1.25

Fw,Ed

Bolted Joints Bearing

Fw,Rd

(4.2)

is the design value of the weld force per unit

length

is the design resistance per unit length

Bearing resistance for ordinary bolts:

Fw,Rd = fvw,da

where:

d

t

M2

fu

is the bolt diameter

is the thickness

= 1.25

is the ultimate tensile strength

fvw,d

is the design shear strength of the weld

is the effective throat thickness (see Figure 1)

for end bolts

for inner bolts

Perpendicular to the direction of load transfer:

for edge bolts

for inner bolts

Figure 1 effective throat thickness

Image Source: Design of Structural Elements (Arya,

2009) Page 421

Bolted Joints Position of Holes

Table 3.3 of EN 1993-1-8 gives the maximum and

minimum spacing, end and edge distances

(4.4)

fu

is the minimum ultimate tensile strength of the

connected parts

is a correlation factor (See Table 4.1)

M2 = 1.25

Image Source: ESDEP

Minimum distance

Steel grade

Correlation factor w

End distance e1

1.2d0

S275

0.85

Edge distance e2

1.2d0

S355

0.90

Spacing p1

2.2d0

Spacing p2

2.4d0

where d0 =hole diameter

Extract from Table 4.1 from EN 1993-1-8: Values for

correlation factor w

Vous aimerez peut-être aussi

- Lifting Lug AnalysisDocument3 pagesLifting Lug Analysisராபர்ட் ஆன்றோ ரெனி67% (3)

- Skid Lifitng Lug CalculationsDocument5 pagesSkid Lifitng Lug CalculationsinnovativekarthiPas encore d'évaluation

- Plate Girder Part 1Document12 pagesPlate Girder Part 1Muharamon Sania PutraPas encore d'évaluation

- Weld Design - Inplace and Accidental Conditions: InputDocument2 pagesWeld Design - Inplace and Accidental Conditions: InputinnovativekarthiPas encore d'évaluation

- Padeye .5MT CHKDocument12 pagesPadeye .5MT CHKDhanraj VasanthPas encore d'évaluation

- Libro 1Document6 pagesLibro 1Mario ManzanoPas encore d'évaluation

- Lifting BEAMSDocument90 pagesLifting BEAMSGogyPas encore d'évaluation

- Welding Calculations For Base PlateDocument116 pagesWelding Calculations For Base PlateSyedZainAli100% (2)

- Eurocode Weld and Bolt Info 11 - Joints - HandoutDocument2 pagesEurocode Weld and Bolt Info 11 - Joints - HandoutKishore KumarPas encore d'évaluation

- Fillet Weld Connections PDFDocument237 pagesFillet Weld Connections PDFPatrick PolujanPas encore d'évaluation

- 44.lifting Lug With Collar CalculationDocument44 pages44.lifting Lug With Collar CalculationAnonymous AyDvqg100% (1)

- End Plate Conn. To Hollow Col. EC2 OKDocument26 pagesEnd Plate Conn. To Hollow Col. EC2 OKRaymond SabadoPas encore d'évaluation

- Ulitization Ratio:: Check Bolt Bearing CapacityDocument1 pageUlitization Ratio:: Check Bolt Bearing CapacitySkylerYuanPas encore d'évaluation

- Fillet Welding ConnectionDocument1 pageFillet Welding ConnectionUmesh ChamaraPas encore d'évaluation

- Eurocode 3 steel joint design guideDocument2 pagesEurocode 3 steel joint design guideneverreturnPas encore d'évaluation

- Web Bearing and Buck1ling To BS en 1993Document3 pagesWeb Bearing and Buck1ling To BS en 1993antoninoPas encore d'évaluation

- 498 Plate Girder CombinedDocument1 page498 Plate Girder CombinedapooladiPas encore d'évaluation

- Welding Strength Calc (As Per B5950)Document13 pagesWelding Strength Calc (As Per B5950)niteshk_45100% (1)

- Final 175T Crane Spec DT 11.1.16 PDFDocument57 pagesFinal 175T Crane Spec DT 11.1.16 PDFRohan KulkarniPas encore d'évaluation

- Eccentric Loads on Vertical Parallel Weld GroupsDocument1 pageEccentric Loads on Vertical Parallel Weld GroupsPriodeep ChowdhuryPas encore d'évaluation

- #754 v-3103 Spreader & Lifting 60 DegreeDocument12 pages#754 v-3103 Spreader & Lifting 60 DegreeHafizi HZnumismatic100% (1)

- Estimate weight and compressive force calculationsDocument2 pagesEstimate weight and compressive force calculationsAmi PutraPas encore d'évaluation

- Plate Girder DesignDocument23 pagesPlate Girder DesignMatthew Chin100% (1)

- Design Manual For Structural Stainless Steel Design Example 7 enDocument6 pagesDesign Manual For Structural Stainless Steel Design Example 7 enAl7amdlellah100% (1)

- DESIGN OF LOWER PADEYE - Connected With Spreader Beam BottomDocument11 pagesDESIGN OF LOWER PADEYE - Connected With Spreader Beam BottomAsaru DeenPas encore d'évaluation

- Bolt TighteningDocument6 pagesBolt TighteningahmedbeaetPas encore d'évaluation

- Perhitungan Untuk Mencari Alat Bantu AngkatDocument6 pagesPerhitungan Untuk Mencari Alat Bantu AngkatGame Just forPas encore d'évaluation

- Design Lifting Hook Plate LiftingDocument3 pagesDesign Lifting Hook Plate LiftingSaravan KumarPas encore d'évaluation

- Structural Steel Design to Eurocode 3 and AISC SpecificationsD'EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsPas encore d'évaluation

- Mathcad - Pipe To Shoe Weld CheckDocument3 pagesMathcad - Pipe To Shoe Weld CheckValentinPas encore d'évaluation

- Heat Exchanger Strength Calculation: Shell Side Design Data Tube Side Design DataDocument2 pagesHeat Exchanger Strength Calculation: Shell Side Design Data Tube Side Design DataSteve MoonPas encore d'évaluation

- BS EN 1991-1-1:2002, BS EN 1993-1-1:2005 - Chequered Plate Design 3/14/2020Document88 pagesBS EN 1991-1-1:2002, BS EN 1993-1-1:2005 - Chequered Plate Design 3/14/2020MohMohkPas encore d'évaluation

- Latest Lifting LugDocument8 pagesLatest Lifting Lugjagannadha varmaPas encore d'évaluation

- LiftingLug TrunnionDocument22 pagesLiftingLug Trunnionrichardchiam100% (2)

- Shackle Verification DimensionDocument1 pageShackle Verification DimensionnaimPas encore d'évaluation

- TQ-0305-R00 - Calculo Estrutura PDFDocument4 pagesTQ-0305-R00 - Calculo Estrutura PDFPeterson MagroPas encore d'évaluation

- End-Plate-Design BS CodeDocument15 pagesEnd-Plate-Design BS CodeRaymond SabadoPas encore d'évaluation

- Weld Strengths To BS5950 01.01.03Document1 pageWeld Strengths To BS5950 01.01.03Pallavi DalviPas encore d'évaluation

- Eff - RD V.eff V.eff V.eff V, Eff V.eff: OK!!! OK!!! 1.0 OK!!!Document2 pagesEff - RD V.eff V.eff V.eff V, Eff V.eff: OK!!! OK!!! 1.0 OK!!!ChangHangWingPas encore d'évaluation

- Perma PipeDocument83 pagesPerma PipemohamadPas encore d'évaluation

- Connection Calculation: Dop Dop WdopDocument2 pagesConnection Calculation: Dop Dop WdopbobbynebaPas encore d'évaluation

- Capacity of Bolts in Bearing Connection Based On AISC-ASD 9th EditionDocument1 pageCapacity of Bolts in Bearing Connection Based On AISC-ASD 9th EditionThiha KyawPas encore d'évaluation

- Corrosion SlidesDocument65 pagesCorrosion SlidesAnshul ShuklaPas encore d'évaluation

- End Plate Conn. To Hollow Col. EC2Document26 pagesEnd Plate Conn. To Hollow Col. EC2Raymond SabadoPas encore d'évaluation

- LIFTING LUG CALCULATIONDocument2 pagesLIFTING LUG CALCULATIONhuangjlPas encore d'évaluation

- Extended-Design and Analysis of A Network Arch BridgeDocument10 pagesExtended-Design and Analysis of A Network Arch BridgehansPas encore d'évaluation

- CE 632 Earth PressureDocument18 pagesCE 632 Earth PressureBala Sutharshan100% (1)

- CE 632 Earth PressureDocument18 pagesCE 632 Earth PressureBala Sutharshan100% (1)

- 6.5T Shackle Design and AnalysisDocument82 pages6.5T Shackle Design and AnalysisSeymur AkbarovPas encore d'évaluation

- Base Plate, Anchor & Foundation (Pipe)Document39 pagesBase Plate, Anchor & Foundation (Pipe)nizardsouissiPas encore d'évaluation

- API 650 Pipe Column DesignDocument4 pagesAPI 650 Pipe Column DesignJoselito CalagosPas encore d'évaluation

- S BeamDocument12 pagesS Beamwisnu_bayusaktiPas encore d'évaluation

- Calculation For Beam Connection AISC 14th Edition 2011: LRFD Method Material and Load PropertiesDocument7 pagesCalculation For Beam Connection AISC 14th Edition 2011: LRFD Method Material and Load PropertiesYunizar Putra MahardikaPas encore d'évaluation

- Capacities of UB SectionsDocument48 pagesCapacities of UB SectionsRohan KarandePas encore d'évaluation

- 39FX - PD Ahu DesignDocument60 pages39FX - PD Ahu DesignHanan SFPas encore d'évaluation

- Fatigue Check As Per EurocodeDocument20 pagesFatigue Check As Per EurocodeViplawPas encore d'évaluation

- Prestressed Concrete Design Lecture NotesDocument52 pagesPrestressed Concrete Design Lecture NotesChristopher John Natividad100% (1)

- Ec4 Composite StructuresDocument52 pagesEc4 Composite StructuresV B Shiva PrasadPas encore d'évaluation

- Padeye calculations for HTCC RoomDocument28 pagesPadeye calculations for HTCC Roomhyoung65Pas encore d'évaluation

- Iso 14224 2016 187 192Document6 pagesIso 14224 2016 187 192Ostap SepykPas encore d'évaluation

- Weld CalcDocument8 pagesWeld CalcOmil RastogiPas encore d'évaluation

- Example 4Document4 pagesExample 4dane05Pas encore d'évaluation

- Design of fillet weld as per BS EN 1993 1 8 CL 4.5.3Document2 pagesDesign of fillet weld as per BS EN 1993 1 8 CL 4.5.3Giri DharanPas encore d'évaluation

- Bolts Design Strength Tables EN 1993-1-8Document2 pagesBolts Design Strength Tables EN 1993-1-8ValentinPas encore d'évaluation

- Torsion Validation ShayanDocument10 pagesTorsion Validation ShayanGicuPas encore d'évaluation

- Comp 2Document9 pagesComp 2YYo YudiPas encore d'évaluation

- Beams in bending: Tension cracks and stress diagramsDocument23 pagesBeams in bending: Tension cracks and stress diagramsHarold Jackson MtyanaPas encore d'évaluation

- Load analysis and strength evaluation of vessel lifting lugDocument3 pagesLoad analysis and strength evaluation of vessel lifting lugMudasir MughalPas encore d'évaluation

- Buckling strength analysis of stiffened flat plateDocument8 pagesBuckling strength analysis of stiffened flat plateding liuPas encore d'évaluation

- Wheel Calculation IDEA Analyzes Wheel Material OptionsDocument35 pagesWheel Calculation IDEA Analyzes Wheel Material Optionsbambang satryojatiPas encore d'évaluation

- Ucpb Housing Loan Application Page 1Document1 pageUcpb Housing Loan Application Page 1Raymond SabadoPas encore d'évaluation

- AustraliaBoltingpage53 58Document6 pagesAustraliaBoltingpage53 58qaz111wsx222Pas encore d'évaluation

- Anbearthretainingbs 8002 CalcsDocument16 pagesAnbearthretainingbs 8002 Calcsapi-305101869Pas encore d'évaluation

- Cantilever Retaining Wall - Metric PDFDocument16 pagesCantilever Retaining Wall - Metric PDFJebin JacobPas encore d'évaluation

- 0625 - w10 - Ms - 22documentation of PhysicsDocument6 pages0625 - w10 - Ms - 22documentation of PhysicsAhmed HossainPas encore d'évaluation

- Fluid Mechanics - BuoyancyDocument6 pagesFluid Mechanics - BuoyancyAbduljalil AlabidiPas encore d'évaluation

- EN15242 Ventilation Calculation Air Flow RatesDocument52 pagesEN15242 Ventilation Calculation Air Flow RatesBrandon LowPas encore d'évaluation

- Vertical Irregularities in StructuresDocument3 pagesVertical Irregularities in StructuresAbhijit SarkarPas encore d'évaluation

- Calculation of effective section properties for a cold-formed lipped channel section in bendingDocument10 pagesCalculation of effective section properties for a cold-formed lipped channel section in bendingAnca SimaPas encore d'évaluation

- Datasheet Uni Flex ASB Open Top RadiusDocument4 pagesDatasheet Uni Flex ASB Open Top RadiusIkki Muhammad AssidqiPas encore d'évaluation

- Tugasan BDC4013 - Sem 2 0809Document4 pagesTugasan BDC4013 - Sem 2 0809Shinee JayasilanPas encore d'évaluation

- El Salvador SeismicDocument11 pagesEl Salvador SeismicMadPas encore d'évaluation

- VFR & 118Document1 pageVFR & 118Moeen Iqbal ShahPas encore d'évaluation

- Relativity Theory PPT (Group-1'B')Document15 pagesRelativity Theory PPT (Group-1'B')Akash RajPas encore d'évaluation

- Studies On Effect of Change in Dynamic Behavior of Crack Using FemDocument7 pagesStudies On Effect of Change in Dynamic Behavior of Crack Using FemMatthew SmithPas encore d'évaluation

- Sol-Gel Synthesis of Zinc Oxide Nanoparticles Using Citrus Aurantifolia ExtractsDocument4 pagesSol-Gel Synthesis of Zinc Oxide Nanoparticles Using Citrus Aurantifolia ExtractsAnonymous ix7WERGPas encore d'évaluation

- BIOSEMDocument18 pagesBIOSEMAllan DuplaPas encore d'évaluation

- Hq153en Balinit-Dlc SeriesDocument4 pagesHq153en Balinit-Dlc SeriesJoão TarelhoPas encore d'évaluation

- B-144 - Datasheet - PSVDocument6 pagesB-144 - Datasheet - PSVRameez AhmedPas encore d'évaluation

- SNI 4658-2008-Pelek Kategori LDocument4 pagesSNI 4658-2008-Pelek Kategori LDimazNugrahaPas encore d'évaluation

- Phy 9 Ans SchandDocument115 pagesPhy 9 Ans SchandAmit KumarPas encore d'évaluation

- Suhu Masuk Coke TowerDocument6 pagesSuhu Masuk Coke TowerDendy Wahyu RadityaPas encore d'évaluation

- Heat Shrinking AllDocument46 pagesHeat Shrinking AllCaylie KirbyPas encore d'évaluation

- Astm C39Document5 pagesAstm C39Sergio Pascual50% (2)

- Wps For Smaw06-001 (Pipe 6g CS)Document10 pagesWps For Smaw06-001 (Pipe 6g CS)walitedisonPas encore d'évaluation

- Coriolis Force: Classical MechanicsDocument9 pagesCoriolis Force: Classical MechanicsVanellope VonschweettzPas encore d'évaluation

- How smartphone camera specs affect low light performanceDocument2 pagesHow smartphone camera specs affect low light performanceSatyendra KumarPas encore d'évaluation

- Module-2 Fundamentals of SurveyingDocument2 pagesModule-2 Fundamentals of Surveyingnonononoway100% (1)