Académique Documents

Professionnel Documents

Culture Documents

10 Basics4StrokeEngines

Transféré par

ha naDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

10 Basics4StrokeEngines

Transféré par

ha naDroits d'auteur :

Formats disponibles

Automotive

The Basics

The Basics of Four-Stroke Engines

of

Four-Stroke Engines

Description

Students will be introduced to basic engine parts, theory and terminology. Understanding how

an engine works and knowing some key related parts and terminology is important for working

on any vehicle. The information is broken down into three major sections: Basic Engine Parts,

Basic Engine Terminology and Basic Four-Stroke Cycle Engine Theory.

Lesson Outcomes

The student will be able to:

Identify and explain the function of basic engine parts

Identify and explain basic engine terminology

Identify the four piston strokes of a four-stroke cycle engine

Describe the action and function of each piston stroke

Assumptions

The students will have little or no prior knowledge of how engines work, terminology or

parts.

The teacher is familiar with the information being taught.

Note: This information is given as a guide to the minimum amount of material to be covered

for a basic understanding of the engine and how it works. Much more can be added as the

instructor sees fit.

Terminology

Valve train: all the parts that are used to open and close valves. This may include parts such as

valve springs, keepers, lifters, cam followers, shims, rockers and push rods.

Any other terminology used will be explained as required during the activities.

Estimated time

90120 minutes (including a question and answer session)

Recommended number of students

20, based on the BC Technology Educators Best Practice Guide

Facilities

A classroom, computer lab or workshop with tables and chairs sufficient for 20 students.

Skills Exploration 1012

The Basics of Four-Stroke Engines

Automotive

Materials

Basic engine parts to show as examples, or images of them. A wide variety would be best

(1, 4, 6 and 8 cylinders)

Engine cutaway

Resources

Four Stroke Engine

Animation of four-stroke engine in motion. Other depicted engines can be found on the home

page.

www.animatedengines.com/otto.html

Automobile Engine: Introduction

www.emt-india.net/process/automobile/AutomobileEngineMechanism.htm

How Car Engines Work

www.howstuffworks.com/engine.htm

Worlds Largest and Most Powerful Diesel Engine

General interestdescription of the largest two-stroke diesel engine, designed for use in

container ships.

http://wonderfulengineering.com/worlds-largest-and-most-powerful-diesel-engine/

Print Resources

Stockel, Martin. Auto Mechanics Fundamentals. Goodheart-Wilcox Co., 1990.

McGraw-Hill Education (author). Automotive Excellence, Volume 1 (3rd Edition). Glencoe/McGrawHill, 2006.

Skills Exploration 1012

Automotive

The Basics of Four-Stroke Engines

Activity

This information can be presented in many different ways and formats: straight theory lessons,

worksheets, computer research assignments or textbook assignments. This information is meant

only to be the essential basics to build a foundation on how an engine functions.

1. Basic Engine Parts

Engine Block

The engine block is the foundation and centre of the engine. Blocks come in many different

sizes, shapes and styles.

The engine block holds the cylinder, the crankshaft, connecting rods (con rods) and pistons.

The large round holes in the block, called cylinders, are where the pistons slide up and down.

Figure 1Cylinder block with head attached

Skills Exploration 1012

The Basics of Four-Stroke Engines

Automotive

Piston

A piston slides up and down a cylinder and pushes the crankshaft around. The piston connects

to the crankshaft via the connecting rods.

Figure 2Piston

Figure 3Piston with connecting rod attached

Piston Rings

Each piston has two compression rings and one oil control ring to help seal the piston in the

cylinder.

First compression

ring groove

Second compression

ring groove

Oil control

ring groove

Skirt

Figure 4A piston with two compression rings and one oil control ring

Figure 5Piston rings (compression rings and oil control ring, left to right)

Skills Exploration 1012

Automotive

The Basics of Four-Stroke Engines

Connecting Rods

Connecting rods connect the pistons to the crank. They utilize an I-beam construction for

strength.

Figure 6Connecting rod

Crankshaft

The crankshaft is bolted to the bottom of the engine block through bearings so it can rotate

freely. It is sometimes referred to as the crank. The crankshaft converts the vertical motion of

the pistons and connecting rods to rotational motion. One end of the crankshaft is connected

to a flywheel that transfers the engine power to the wheels through a transmission (manual or

automatic).

Figure 7Crankshaft with pistons and connecting

rods attached

Skills Exploration 1012

Figure 8Crankshaft of a 1-cylinder engine with

connecting rod attached

The Basics of Four-Stroke Engines

Automotive

Cylinder Head

The cylinder head is bolted to the top of the cylinder block. It serves as a cover for the cylinders

and pistons. The cylinder head helps to create the top part of the combustion chamber. An

engine breathes through the cylinder head. It lets an air/gas mixture into the engine and

exhaust out of the engine. The valves and valve train control the breathing of the engine by

opening and closing the valves at the appropriate time.

Figure 9Top view of cylinder head with camshafts attached

Figure 10Bottom view of cylinder head showing where the valves sit

Note: This has four valves per cylinder (two intake and two exhaust).

Skills Exploration 1012

Automotive

The Basics of Four-Stroke Engines

Figure 11Cylinder head being attached to engine block

Valves

Valves can be divided into two groups:

Intake valves control the flow of the air/gas mixture into the engine.

Exhaust valves control the flow of exhaust out of the engine.

Figure 12Exhaust and intake valves

Skills Exploration 1012

Figure 13Valve

The Basics of Four-Stroke Engines

Automotive

Camshaft

The camshaft controls the opening and closing of the valves. There is one lobe on the camshaft

for each valve in the engine. Camshaft lobe design dictates three things:

How far the valve opens

How fast the valve opens

How long the valve opens

Depending on the engine type, the camshaft can be located either in the engine block or over

the head (OHC) or double OHC (DOHC).

Figure 14Cam lobe profile showing the opening and closing angles

Figure 15Camshaft

Skills Exploration 1012

Automotive

The Basics of Four-Stroke Engines

Figure 16In-the-block camshaft

Figure 17Camshaft located over the head

Lifters (Tapetts)

Lifters are the link between the cam and valves. They are so named because they actually lift as

the cam lobe rotates and open the valves. There are two basic types of lifters:

The hydraulic lifter

The solid lifter

Skills Exploration 1012

The Basics of Four-Stroke Engines

Automotive

Timing Chain/Belt/Gears

These parts are used in different combinations and configurations to connect the crankshaft

to the camshaft. They keep the valves opening and closing timed with the piston movement.

Timing belts should be replaced every 100,000 km or every five years.

Valve Train

The valve train includes all the parts that are used to open and close valves. This may include

parts like valve springs, keepers, lifters, cam followers, shims, rockers and push rods.

Figure 18Diagram of an engine with overhead camshafts, demonstrating valve train components

Flywheel

The flywheel attaches to the crankshaft, and uses its momentum to power the engine through

the three non-power strokes (intake, compression and exhaust). Because an 8-cylinder car has

more power strokes than a 4-cylinder car, the flywheel will be smaller and lighter as there is less

need for the momentum carry capabilities.

Flywheels are used in standard transmissions.

Flexplates are used in automatic transmissions.

Flywheels and flexplates have a ring gear for the starter.

10

Skills Exploration 1012

Automotive

The Basics of Four-Stroke Engines

2. Basic Engine Terminology

Bore: the distance across the cylinder (or the diameter).

Bottom dead centre (BDC): the lowest point in the cylinder that the piston reaches.

Combustion chamber: the space left at the top of the cylinder when the piston is at top dead

centre (TDC). This also includes any space in the cylinder head.

Compression: the squishing or squeezing of the air/fuel mixture from BDC to TDC. The more

the mixture is compressed, the more power it can produce.

Compression ratio: the difference as expressed through a ratio of the space left in the cylinder

when the piston is at TDC versus BDC. For example, 8:1 means that the space when the piston

is at BDC is 8 times bigger than when the piston is at TDC.

Cubic inch displacement (CID): the engine size. For example, Chevy 350 (cubic inches),

Mustang 5.0 (cubic litres) or Honda 1800 cc (cubic centimetres). Even though 5.0 L and 1800 cc

are metric measurements, they are often referred to as the CID of an engine.

CID is a mathematical calculation that takes into account the bore and stroke of the cylinder

times the number of cylinders in the engine. It basically measures how much volume or air a

cylinder can displace or push out from BDC to TDC.

Engine types: engines can be classified in many different ways, but three basic engine types

likely to be encountered in an automotive shop are:

Four-stroke cycle enginetakes four stokes of the piston to complete a cycle

Two-stroke cycle enginetakes two strokes of the piston to complete a cycle

Diesel(two or four stroke) uses heat of compression rather than a spark plug to ignite

the fuel that is directly injected into the cylinder

Each of these engines can come in several different configurations.

Four-stroke cycle: four movements of the piston equals one cycle.

Stroke: the distance the piston travels from TDC to BDC or from BDC to TDC.

Top dead centre (TDC): the highest point in the cylinder that the piston reaches.

Skills Exploration 1012

11

The Basics of Four-Stroke Engines

Automotive

3. Basic Four-Stroke Engine Theory

Regardless of its design, an engine needs four things in order to deliver a substantial amount of

useful energy or work:

1. Air

2. Fuel to burn

3. Ignition source to ignite the fuel

4. Compression of the air/fuel mixture to maximize the power potential of the fuel

Take away any of these items and an engine will not run. Therefore all engine designs are based

on allowing these key factors to work in harmony for a smooth, powerful and efficiently running

engine.

Example: You could pour out some gas on a small plate and light it on fire. Although it would

produce some light and heat, it would not be a great source of power. However, taking that

same plate of gas and compressing the air around it by placing a bowl over it and igniting the

gas would produce enough power to blow the bowl off the plate. This is the basics of how an

engine works.

The Four-Stroke Cycle

Nickolaus Otto is credited with building the first four-stroke cycle engine in 1867, considered the

basis of our modern engines. In his honour it is often called the Otto cycle engine.

1. Intake stroke

The piston moves from TDC to BDC (down).

The intake valve is open.

The exhaust valve is closed.

The piston creates a suction (vacuum) and air and fuel are sucked into the cylinder.

Intake valve

open

Exhaust valve

closed

Top dead centre

(TDC)

Stroke

Bottom dead centre

(BDC)

Figure 19Intake stroke

12

Skills Exploration 1012

Automotive

The Basics of Four-Stroke Engines

2. Compression stroke

The piston moves from BDC to TDC (up).

Both valves are closed.

The piston compresses the air and fuel mixture.

Intake valve

closed

Exhaust valve

closed

Top dead centre

(TDC)

Stroke

Bottom dead centre

(BDC)

Figure 20Compression stroke

3. Power stroke

The piston moves from TDC to BDC (down).

Both valves are closed.

The spark plug fires.

The fuel mixture burns rapidly. This expanding heated mixture forces the piston down.

Intake valve

closed

Exhaust valve

closed

Top dead centre

(TDC)

Stroke

Bottom dead centre

(BDC)

Figure 21Power stroke

Skills Exploration 1012

13

The Basics of Four-Stroke Engines

Automotive

4. Exhaust stroke

Piston moves from BDC to TDC (up).

The intake valve is closed.

The exhaust valve is open.

The piston pushes the exhaust out.

Intake valve

closed

Exhaust valve

open

Top dead centre

(TDC)

Stroke

Bottom dead centre

(TDC)

Figure 22Exhaust stroke

The cycle repeats itself.

The four-stroke cycle is presented in chart form below. Note the following:

The piston direction has a distinct pattern.

The intake valve is only open during the intake stroke.

The exhaust valve is only open during the exhaust stroke.

Intake

Compression

Power

Exhaust

Piston Direction

Down

Up

Down

Up

Intake Valve

Open

Closed

Closed

Closed

Exhaust Valve

Closed

Closed

Closed

Open

Sucked In

Being Squished

Ignited

Pushed Out

Mixture Action

Remember ICPE: intake, compression, power, exhaust.

The cycle repeats itself. This order cannot change!

14

Skills Exploration 1012

Vous aimerez peut-être aussi

- Southern Marine Engineering Desk Reference: Second Edition Volume IiD'EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IiPas encore d'évaluation

- Donny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionD'EverandDonny’S Unauthorized Technical Guide to Harley-Davidson, 1936 to Present: Volume Iv: Performancing the EvolutionÉvaluation : 4 sur 5 étoiles4/5 (1)

- Auto MechanicDocument106 pagesAuto Mechanicamigoscribd100% (1)

- Mercedes E Class Petrol Workshop Manual W210 & W211 SeriesD'EverandMercedes E Class Petrol Workshop Manual W210 & W211 SeriesPas encore d'évaluation

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceD'EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenancePas encore d'évaluation

- 1.5l Duratorq-Tdci Timing BeltDocument62 pages1.5l Duratorq-Tdci Timing Beltsuysuy00100% (1)

- Engine Mechanical TextbookDocument69 pagesEngine Mechanical TextbookTrương Ngọc ThắngPas encore d'évaluation

- Unit 1Document32 pagesUnit 1Rakeshkumarceg100% (1)

- Ic EngineDocument23 pagesIc EngineGanesh kumar100% (1)

- JohnsonEvinrude Internal Engine PartsDocument23 pagesJohnsonEvinrude Internal Engine Partswguenon100% (1)

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorD'EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorPas encore d'évaluation

- Small Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsD'EverandSmall Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsPas encore d'évaluation

- Fundamentals of Engine Construction and OperationDocument11 pagesFundamentals of Engine Construction and OperationBill Erick CastilloPas encore d'évaluation

- Construction and Manufacture of AutomobilesD'EverandConstruction and Manufacture of AutomobilesÉvaluation : 5 sur 5 étoiles5/5 (1)

- Volvo Parts Book Engines Tad1640ge Tad1641ge Tad1642ge Tad1640ge Tad1641ge Tad1642ge Twd1643geDocument189 pagesVolvo Parts Book Engines Tad1640ge Tad1641ge Tad1642ge Tad1640ge Tad1641ge Tad1642ge Twd1643geHAROLDPas encore d'évaluation

- Internal Combustion EngineDocument136 pagesInternal Combustion Enginepreethu02Pas encore d'évaluation

- Flow Doc1Document6 pagesFlow Doc1Jozef100% (1)

- Construction Details PDFDocument58 pagesConstruction Details PDFP.Prem Kumar AP - I - MechanicalPas encore d'évaluation

- Experiment - No.2: To Study The Parts and Working of Four Stroke Petrol EngineDocument6 pagesExperiment - No.2: To Study The Parts and Working of Four Stroke Petrol EngineHafeez AliPas encore d'évaluation

- YC4108 Fuel Injection PumpDocument3 pagesYC4108 Fuel Injection PumpCarlos GuajardoPas encore d'évaluation

- Aircraft SystemsDocument40 pagesAircraft SystemsRadu Andrei100% (1)

- Deutz 913 SpecsDocument6 pagesDeutz 913 SpecsIrwin JosePas encore d'évaluation

- 4 Strock (1) M - MergedDocument13 pages4 Strock (1) M - MergedDilshadPas encore d'évaluation

- Basics 4 Stroke EnginesDocument14 pagesBasics 4 Stroke EnginesAli JawadPas encore d'évaluation

- Memorandum Technical Document SpecsDocument4 pagesMemorandum Technical Document Specsapi-289450260Pas encore d'évaluation

- Ae LabDocument53 pagesAe LabAnkit DahiyaPas encore d'évaluation

- Four Stroke Four Cylinder Petrol Engine and Development Engineering EssayDocument19 pagesFour Stroke Four Cylinder Petrol Engine and Development Engineering EssayJashanBassiPas encore d'évaluation

- 4 Stroke Petrol Engine1699240011Document7 pages4 Stroke Petrol Engine1699240011Masoud doski100% (1)

- Lathe Machine TDocument10 pagesLathe Machine TAdebisi IbraheemPas encore d'évaluation

- How Car Engines Work: Different Types of EngineDocument13 pagesHow Car Engines Work: Different Types of EngineMuhammad NaveedPas encore d'évaluation

- Tejay L. Tolibas BSCE - 3EDocument3 pagesTejay L. Tolibas BSCE - 3ETejay TolibasPas encore d'évaluation

- ACTIVITIESDocument14 pagesACTIVITIESlamsonmarkninoePas encore d'évaluation

- Chapter 1 IntroductionDocument19 pagesChapter 1 IntroductionIslam El Sibaie100% (1)

- A Technical Report On (Final)Document27 pagesA Technical Report On (Final)Nohid Chougle50% (2)

- Advantages and Disadvantages of Different Types of EngineDocument11 pagesAdvantages and Disadvantages of Different Types of EngineJerome BalatbatPas encore d'évaluation

- محركاتDocument20 pagesمحركاتYasmin RedaPas encore d'évaluation

- MD ProjectDocument35 pagesMD ProjectDar AkhtPas encore d'évaluation

- Lesson One: Understanding Principles of Operation of Internal Combustion EnginesDocument45 pagesLesson One: Understanding Principles of Operation of Internal Combustion Engineswaleed yehiaPas encore d'évaluation

- Chapter 1 - ICEDocument51 pagesChapter 1 - ICEsubPas encore d'évaluation

- Practical #11: To Study Cutaway Models of Petrol and Diesel Engine Heat EngineDocument9 pagesPractical #11: To Study Cutaway Models of Petrol and Diesel Engine Heat EngineMuhammad Arslan AfzalPas encore d'évaluation

- Course: Ic Engine LabDocument8 pagesCourse: Ic Engine LabUsman Ali Usman AliPas encore d'évaluation

- 2.meel06 Ic Unit I - 1st Chapter Fundamentals of Ic EnginesDocument41 pages2.meel06 Ic Unit I - 1st Chapter Fundamentals of Ic EnginesManoj NaiduPas encore d'évaluation

- Automobile Labs ManualDocument49 pagesAutomobile Labs ManualSEAN WALLACEPas encore d'évaluation

- L-3 IceDocument38 pagesL-3 IcePuneet GargPas encore d'évaluation

- Vehicle EngineDocument31 pagesVehicle EnginenoahPas encore d'évaluation

- AURTTE008Document7 pagesAURTTE008yash KhatodePas encore d'évaluation

- Laboratory Manual Automobile Engineering ME-314-F: Naresh Kumar (Brcm-Bahal)Document45 pagesLaboratory Manual Automobile Engineering ME-314-F: Naresh Kumar (Brcm-Bahal)RaviUttamPas encore d'évaluation

- IC EnginesDocument17 pagesIC EnginesJames ContiPas encore d'évaluation

- Chapter 01 OutlineDocument4 pagesChapter 01 Outlinerim zamzamiPas encore d'évaluation

- Ch2Document34 pagesCh2papipapiiPas encore d'évaluation

- Engine Fundamental (2) 2Document50 pagesEngine Fundamental (2) 2andualem nigussiePas encore d'évaluation

- Presentation of Communication SkillsDocument32 pagesPresentation of Communication SkillsFadhliana UzalliPas encore d'évaluation

- Consultant Expert DR Mohamed Seif Al Den TahaDocument46 pagesConsultant Expert DR Mohamed Seif Al Den Tahaconsultant expert dr mohamed seif al den tahaPas encore d'évaluation

- Internal Combustion EngineDocument14 pagesInternal Combustion EngineSamridhiPas encore d'évaluation

- To Study The Stationary and Moving Automobile Parts PDFDocument16 pagesTo Study The Stationary and Moving Automobile Parts PDFTAHIR QAMAR100% (2)

- To Automobile Engineering: Unit-1Document71 pagesTo Automobile Engineering: Unit-1Nikhilraj rudraPas encore d'évaluation

- General Overview of Automotive Systems: Entoto Polytechnic CollegeDocument9 pagesGeneral Overview of Automotive Systems: Entoto Polytechnic CollegeHenokPas encore d'évaluation

- Petrol Engine (Nehru Garden, JalandharDocument7 pagesPetrol Engine (Nehru Garden, Jalandharapi-3731257Pas encore d'évaluation

- Car Engine Parts: Cylinder Block of Four Cylinder Engine (Image 01)Document10 pagesCar Engine Parts: Cylinder Block of Four Cylinder Engine (Image 01)Ibrahima DioufPas encore d'évaluation

- Lab ReportDocument14 pagesLab ReportHammad Hassan100% (5)

- Internal Combustion Engines Chapter 1. IntroductionDocument8 pagesInternal Combustion Engines Chapter 1. IntroductionJerry B CruzPas encore d'évaluation

- Of Operation of Internal Combustion EnginesDocument31 pagesOf Operation of Internal Combustion EnginesNaveen KumarPas encore d'évaluation

- IC Engine Lec 4 Fall 2018Document35 pagesIC Engine Lec 4 Fall 2018Muhammad AliPas encore d'évaluation

- Unit 1Document40 pagesUnit 1Ram SaacePas encore d'évaluation

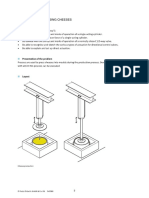

- Before Removal: Special Tools Description Part No. QtyDocument3 pagesBefore Removal: Special Tools Description Part No. QtyPhomma Khinphommavong0% (1)

- Heroparts PDFDocument313 pagesHeroparts PDFLohitRamakrishnaKotapatiPas encore d'évaluation

- Ford Timing Set Installation Instructions: Thrust BearingsDocument4 pagesFord Timing Set Installation Instructions: Thrust BearingsmasakpPas encore d'évaluation

- Lab 01 Myp (E1-E4)Document31 pagesLab 01 Myp (E1-E4)peter parkerPas encore d'évaluation

- Um2kc1 Cylinder HeadDocument3 pagesUm2kc1 Cylinder HeadBurik8Pas encore d'évaluation

- Pistoane JapanDocument293 pagesPistoane JapanCatalin NistorescuPas encore d'évaluation

- 250 kVA To 320 kVADocument2 pages250 kVA To 320 kVAkrish659Pas encore d'évaluation

- r15.v3 Monstar Indo 2020Document56 pagesr15.v3 Monstar Indo 2020Omar SahadatPas encore d'évaluation

- Applied Thermodynamics Lab 2k9ee-834Document22 pagesApplied Thermodynamics Lab 2k9ee-834himsdon100% (1)

- Suyash Preci-Lap AidsDocument22 pagesSuyash Preci-Lap AidsCarlos RamirezPas encore d'évaluation

- 02 T105 Crypton Crankshaft & Piston PDFDocument1 page02 T105 Crypton Crankshaft & Piston PDFRoni SuhendarPas encore d'évaluation

- Beijing Jincheng Mining Technology Co., LTD: No. Description Model Q'Ty Unit Unit Price Amount Fob Beijing UsdDocument2 pagesBeijing Jincheng Mining Technology Co., LTD: No. Description Model Q'Ty Unit Unit Price Amount Fob Beijing UsdDenPas encore d'évaluation

- Perkins Engine 1306C-E87TAG6 SERIES SPARE PARTSDocument2 pagesPerkins Engine 1306C-E87TAG6 SERIES SPARE PARTSIbrahim YunusPas encore d'évaluation

- Term Paper On Ic EngineDocument7 pagesTerm Paper On Ic Engineaflsqrbnq100% (1)

- Daihatsu / Applause: Oem Number Oem NumberDocument4 pagesDaihatsu / Applause: Oem Number Oem NumberBobCavPas encore d'évaluation

- Parts Catalogue YSD4900Document33 pagesParts Catalogue YSD4900Willem van der BerghPas encore d'évaluation

- Servicio Nacional de Aprendizaje SenaDocument4 pagesServicio Nacional de Aprendizaje SenaAbnner GabrielPas encore d'évaluation

- 3tna72e UasDocument25 pages3tna72e UasjanosPas encore d'évaluation

- CleanairpermitDocument2 pagesCleanairpermitibrahim salemPas encore d'évaluation

- Ic EngineDocument17 pagesIc EngineRajeswar KumarPas encore d'évaluation

- Gtu Weightage Acet Sem-Vii 2022Document3 pagesGtu Weightage Acet Sem-Vii 2022Jyotin KateshiaPas encore d'évaluation

- The Engine For Construction Equipment.: 187 - 440 KW at 1500 - 2100 MinDocument6 pagesThe Engine For Construction Equipment.: 187 - 440 KW at 1500 - 2100 MinSiding BarroPas encore d'évaluation

- Lec1-Overview+Diesel Engines-28Sep22Document48 pagesLec1-Overview+Diesel Engines-28Sep22Jawwad AhmedPas encore d'évaluation