Académique Documents

Professionnel Documents

Culture Documents

Stanley S300 Detector de Vigas

Transféré par

Walter Villar RojoCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Stanley S300 Detector de Vigas

Transféré par

Walter Villar RojoDroits d'auteur :

Formats disponibles

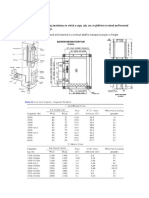

Marking Channel

4 When the unit is calibrated the

Ready icon will appear on the LCD.

3 sec

S300

Live Wire Warning LED

Keep holding the activation button

during all of the following procedures.

Note: Once the Activation button is

released, the unit shuts off.

LCD Display

Activation Button

10

STUD or METAL / AC Mode Selection

10 If all segments of the LCD flash on and off when

the activation button is pressed, move the Stud Sensor

300 to a different location and try again. Releasing the

activation button will turn off the sensor.

METAL SCAN Mode

AC TRACKING Mode

Live Wire Detected

Depth Detection Mode

10

Note: While calibrating, the Stud Sensor 300 must not

be placed directly over a stud, dense material such as

metal, or over a wet or newly painted area, or it will not

properly calibrate.

STUD Mode

Stud Location Graphic

Low Battery Indicator

Self-Calibration Complete

STHT77407

REV A 08

Stanley Stud Sensor 300

The Stud Sensor 300 will not detect objects in concrete, mortar, block or brick

work, carpeting, foil faced materials, metallic surfaces or ceramic tiles. The

Stud Sensor 300 is not designed to locate non-ferrous or plastic objects such

as pipes.

OPERATING INSTRUCTIONS

8 Slide the Stud Sensor 300 slowly across the surface in a straight line.

As it detects a stud, the unit will display the relative position of the stud

on the screen.

Battery

1 Open door on back of unit and connect a 9 volt battery

(not included) to clip. Put battery back into case and close

back battery door.

The Stud Sensor 300 uses electronic signals to locate the center of studs, joists

or live AC wires through drywall or other common building materials. Once

the center of a stud has been detected in one pass across the surface, the

Stud Sensor 300 gives a visual display and sounds an audible tone. A marking

channel allows you to easily note the stud center and edges on the wall.

Note: Recommend to replace a new 9 volt battery

when low battery - Low Battery will appear on the

LCD.

Note: Read all instructions prior to operating the Stud Sensor 300 and DO NOT

remove any labels from the tool.

WARNING:

Protect Your Eyes, Wear Safety Goggles.

Usage

Detecting Wood / Metal Studs

2 Hold the Stud Sensor 300 flat

against the surface, making firm

contact.

3 Press in and hold the activation

button. A series of tones will sound.

Note: The unit cannot be moved before

calibration is complete.

77407

6 / 7 When it detects the stud

center, the Center icon will appear on

the LCD and an audible tone will sound.

Use the marking channel located at the

top of the unit to mark the stud center.

Detecting Live AC Wires

9 The live wire red LED will illuminate, the AC

icon will appear on the LCD, and the Stud Sensor 300

sounds an audible tone, warning when in the proximity

(typically within 4 to 18 along the surface) from a live

wire.

IMPORTANT SAFETY NOTICE

Insure proper detection of live wires. Always hold the Stud Sensor 300 in the

handle area only. Grasp between fingers and thumb while making contact with

your palm.

Cautions on Operating

You should always use caution when nailing, cutting and drilling in walls,

ceilings and floor that may contain wiring and pipes near the surface. Always

remember that studs or joists are normally spaced 16 inches or 24 inches

apart and are 1 inches in width. To avoid surprises, be aware that anything

closer together or of a different width may not be a stud.

When the unit is calibrated the Ready icon will

appear on the LCD.

Keep holding the activation button during all of the

following procedures.

77407

OPERATING TIPS

The Stud Sensor 300 is designed for use only on interior surfaces.

Prevent Interference

To ensure best performance from the Stud Sensor 300, keep your free hand at

least 6 inches away from the unit and wall surface while testing or scanning

surfaces.

11

(At 35-55% relative humidity)

9 volt (not included)

Battery

Wood or Metal Studs

Up to 1-1/2 (38 mm) through drywall

Live AC Wires (120 volts AC)

Up to 2 (50 mm) through drywall

METAL SCAN Mode

Up to 3 (76 mm) through drywall

Accuracy - Stud Center

Wood

1/8 (3 mm)

Metal

1/4 (6 mm)

1x

1

2x

12

3 sec

Press in and hold the activation button. A series of

tones will sound.

SPECIFICATIONS

Depth Range

AC TRACKING Mode

Double click (depress two times - 2x) the AC /

METAL button. The AC TRACKING icon will be

illuminated on the LCD.

12

Ceilings

When dealing with a rough surface such as a sprayed ceiling, utilize a

piece of cardboard when scanning the surface. Run through the calibration

technique described earlier with the piece of cardboard too, to assure best

performance of the unit. Also, it is particularly important in this application

to remember to keep your free hand away from the unit.

Note: The thickness, density and moisture content of the surface material

will affect the sensing depth.

Warning: Shielded wires or wires in metal conduits, casings, metallized

walls or thick, dense walls will not be detected. Always turn off AC power

when working near wiring.

With the METAL SCAN or AC SCAN icon

illuminated, hold the Stud Sensor 300 flat against the

surface, making firm contact.

13

Note: Static electrical charges that can develop on

drywall and other surfaces will spread the voltage

detection area many inches on each side of the actual

electrical wire. To aid in locating the wire position, scan

holding the unit away from the wall surface or place

your other hand on the surface approximately 12 from

sensor.

METAL SCAN / AC TRACKING Mode 11

METAL SCAN Mode

Depress the AC / METAL button once (1x). The

METAL SCAN icon will be illuminated on the LCD.

13 Slide the Stud Sensor 300 slowly across the surface. As it detects metal

(METAL SCAN mode) or a live AC wire (AC TRACKING mode), the unit will

display the relative intensity of the position of the metallic object / live wire

on the screen as shown below.

13

Automatic Sensitivity Selection

The unit is initially set at its highest sensitivity for stud detection. To get

the most accurate readings from the unit, slide it past the first stud that

is detected. The unit will beep and the sensitivity will automatically self

correct to the best level for the wall and stud materials found during the

first pass. This will give the best stud center and edge detection accuracy.

Conventional Construction

Doors and windows are commonly constructed with additional studs and

headers for added stability. The Stud Sensor 300 detects the edge of these

double studs and solid headers as a single, wide stud.

Surface Differences

The Stud Sensor 300 will scan through common building materials, Including:

Gypsum drywall

Plywood sheathing

Hardwood floors

Linoleum over wood

Wallpaper

The sensor cannot scan through:

Carpeting

Foil faced materials

Ceramic tile

Cement or concrete

Metal & plaster walls

Wallpaper

There will be no difference in the function of the Stud Sensor 300 on

surfaces covered with wallpaper or fabric unless the coverings used

contain metallic foil or fibers.

Operating Temperature

+32F to +120F (-0C to +49C)

Surface Temperature

-4F to +150F (-20C to +66C)

WARRANTY

Stanley Tools warrants the Stud Sensor 300 against defects in material and

workmanship for one year from the date of purchase. Stanleys liability under

this warranty is limited the replacement of the unit. Any attempt to repair the

product by other than factory authorized personnel will void this warranty.

Calibration, batteries and maintenance are the responsibility of the user. Where

permitted by law, Stanley is not responsible for incidental or consequential

damages. Agents of Stanley cannot change this warranty. Stanley is not

responsible for damage resulting from wear, abuse or alteration of this product.

The user is expected to follow ALL operating instructions. This warranty may

provide you with additional rights that vary by state, province or nation.

2012 STANLEY TOOLS

www.STANLEYTOOLS.com

701 East Joppa Road

Towson, Maryland 21286

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Plumbing NotesDocument14 pagesPlumbing NotesMrityunjoy Dutta50% (2)

- ### Todos Medidas de Moveis para Dollhouse Cu31924075367825Document164 pages### Todos Medidas de Moveis para Dollhouse Cu31924075367825admiradao100% (1)

- LaticreteDocument44 pagesLaticreteHarsa VardhanPas encore d'évaluation

- SOP - BOQ TSUCHIYA Inspection Room Expansion Edit01Document209 pagesSOP - BOQ TSUCHIYA Inspection Room Expansion Edit01MJ100% (1)

- Bill of Quantities For POP False Ceiling No. Area Name Punning Area Didaction Total Ground FloorDocument6 pagesBill of Quantities For POP False Ceiling No. Area Name Punning Area Didaction Total Ground FloorAvinesh KumarPas encore d'évaluation

- Acoustic MaterialsDocument6 pagesAcoustic MaterialsLeanne Mae Patuga0% (1)

- (Architecture Article) Architectural Review - July01.modernist NewsDocument2 pages(Architecture Article) Architectural Review - July01.modernist NewsMaria ArgentiPas encore d'évaluation

- Division 01Document15 pagesDivision 01Geeryl TayonePas encore d'évaluation

- Sanctuary Magazine Issue 1 - Making Waves - Port Fairy, Victoria Green Home ProfileDocument3 pagesSanctuary Magazine Issue 1 - Making Waves - Port Fairy, Victoria Green Home ProfileSanctuary MagazinePas encore d'évaluation

- Hydraulic Elevators Basic ComponentsDocument16 pagesHydraulic Elevators Basic ComponentsIkhwan Nasir100% (2)

- Structure Design of Parking Building Sun PDFDocument16 pagesStructure Design of Parking Building Sun PDFHoHo WindyantoPas encore d'évaluation

- A-Series PanelboardsDocument1 pageA-Series PanelboardsReginald D. De GuzmanPas encore d'évaluation

- Rezoning The WaterfrontDocument16 pagesRezoning The WaterfrontThe Lo-DownPas encore d'évaluation

- Portal Method of Approximate AnalysisDocument4 pagesPortal Method of Approximate AnalysisMuhammad Ilyas LanjarPas encore d'évaluation

- Design Procedure For Steel Frame Structures According To Bs 5950Document46 pagesDesign Procedure For Steel Frame Structures According To Bs 5950Ali Gaffar100% (2)

- Assignment ELEVATORDocument7 pagesAssignment ELEVATORRenzo LopezPas encore d'évaluation

- Civil Engineers GuideDocument46 pagesCivil Engineers GuideSrinivasan Reddy88% (17)

- Masonry and FoundationsDocument73 pagesMasonry and Foundationsgowthami sirana baluPas encore d'évaluation

- I. Ifugao and Its TribeDocument8 pagesI. Ifugao and Its TribeGerard EscandaPas encore d'évaluation

- Layher Scaffolding CatalogueDocument10 pagesLayher Scaffolding CataloguefresitoPas encore d'évaluation

- Masonry Building Design ExampleDocument102 pagesMasonry Building Design Examplegullipalli100% (3)

- Production RatesDocument29 pagesProduction RatesSam Monte0% (1)

- 9 Specification For Mechanical Pipework Insulation PDFDocument4 pages9 Specification For Mechanical Pipework Insulation PDFAgung Pramu AjiPas encore d'évaluation

- Bomaw Volume OneDocument349 pagesBomaw Volume Onepassionpony0% (1)

- Relative Clauses - DefiningDocument2 pagesRelative Clauses - Defining_jude_Pas encore d'évaluation

- Parador Laminate Flooring Guide (Melamine Resin-Coated)Document26 pagesParador Laminate Flooring Guide (Melamine Resin-Coated)patkariukiPas encore d'évaluation

- Welded Moment ConnectionsDocument26 pagesWelded Moment ConnectionsBalaji SampathPas encore d'évaluation

- Ceramic Tile InstallationDocument4 pagesCeramic Tile InstallationAjit Singh RathorePas encore d'évaluation

- Silay City Watersports and Recreation Park (Appendices)Document103 pagesSilay City Watersports and Recreation Park (Appendices)Aisa Castro ArguellesPas encore d'évaluation

- Cellar of Death-6Document1 pageCellar of Death-6Bo SunPas encore d'évaluation