Académique Documents

Professionnel Documents

Culture Documents

Prediction of Compressive Strength of High Performance Concrete Containing Industrial by Products Using Artificial Neural Networks

Transféré par

IAEME PublicationTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Prediction of Compressive Strength of High Performance Concrete Containing Industrial by Products Using Artificial Neural Networks

Transféré par

IAEME PublicationDroits d'auteur :

Formats disponibles

International Journal of Civil Engineering and Technology (IJCIET)

Volume 7, Issue 2, March-April 2016, pp. 302314, Article ID: IJCIET_07_02_026

Available online at

http://www.iaeme.com/IJCIET/issues.asp?JType=IJCIET&VType=7&IType=2

Journal Impact Factor (2016): 9.7820 (Calculated by GISI) www.jifactor.com

ISSN Print: 0976-6308 and ISSN Online: 0976-6316

IAEME Publication

PREDICTION OF COMPRESSIVE

STRENGTH OF HIGH PERFORMANCE

CONCRETE CONTAINING INDUSTRIAL BY

PRODUCTS USING ARTIFICIAL NEURAL

NETWORKS

Dr. B. Vidivelli

Professor, Department of Civil & Structural Engineering,

A. Jayaranjini

Research Scholar,

Department of Civil & Structural Engineering,

Annamalai University, Tamilnadu, India

ABSTRACT

This paper presents artificial neural network (ANN) based model to

predict the compressive strength of concrete containing Industrial Byproducts

at the age of 28, 56, 90 and 120 days. A total of 71 specimens were casted with

twelve different concrete mix proportions. The experimental results are

training data to construct the artificial neural network model. The data used

in the multilayer feed forward neural network models are arranged in a

format of ten input parameters that cover the age of specimen, cement, Fly

ash, Silica fume, Metakaolin, bottom ash, sand, Coarse aggregate, water and

Superplasticizer. According to these parameter in the neural network models

are predicted the compressive strength values of concrete containing

Industrial Byproducts. This study leads to the conclusion that the artificial

neural network (ANN) performed well to predict the compressive strength of

high performance concrete for various curing period.

Key word: Compressive Strength, High Performance Concrete, Industrial by

Products, Neurons, Neural Network.

Cite this Article: Dr. B.Vidivelli and A. Jayaranjini. Prediction of

Compressive Strength of High Performance Concrete Containing Industrial by

products Using Artificial Neural Networks, International Journal of Civil

Engineering and Technology, 7(2), 2016, pp. 302314.

http://www.iaeme.com/IJCIET/issues.asp?JType=IJCIET&VType=7&IType=2

http://www.iaeme.com/IJCIET/index.asp 302

editor@iaeme.com

Prediction of Compressive Strength of High Performance Concrete Containing Industrial by

products Using Artificial Neural Networks

INTRODUCTION

In view of the global sustainable development, it is imperative that supplementary

cementing materials be used in replace of cement in the concrete industry. The most

worldwide available supplementary cementing materials are silica fume (SF), a byproduct of silicon metal and fly ash (FA), a by-product of thermal power stations, and

blast-furnace slag (BS), a byproduct of steel mill. It is estimated that approximately

600 million tons of FA are available worldwide now, but at present, the current

worldwide utilization rate of FA in concrete is about 10%. However, the recent

development of green high performance concrete (GHPC) brings the abundant

utilization of these mineral mixtures. When these different reactive mineral admixtures are added into concrete at the same time, they develop their own characteristics

with the development. SF can increase the strength of the concrete significantly;

however, it affects the workability of the fresh concrete greatly, while adding large

amount of FA to the concrete contributes the workability of the concrete but not to the

strength. In addition, those mineral admixtures show different effects on the strength

of the concrete within different ages due to their different pozzolan reactions. The aim

of this study is to build models which have two different architectures in ANN system

to evaluate the effect of FA, MK, SF and BA on compressive strength of concrete. For

purpose of constructing this models, 12 different mixtures with 36 specimens of the

28 days compressive strength results of concrete containing FA, SF, MK and BA used

in training for ANN system were collected for the Experimental work. In training of

models constituted with different architectures. The age of specimen(AS), Cement(C),

Fly ash (FA), Silica fume(SF), Metakaolin(MK), Sand(S), Bottom ash (BA), Coarse

aggregate (CA), Water(W) and Superplasticizer(SP) were entered as input; while

compressive strength(fc) values were used as output. The models were trained with 71

data of experimental results were obtained.

LITERATURE REVIEW

Noorzaei et al. (2007) focused on development of artificial neural networks (ANNs)

for prediction of compressive strength of concrete after 28 days. To predict the

compressive strength of concrete six input parameters cement, water, silica fume,

super plasticizer, fine aggregate and coarse aggregate were identified considering

two hidden layers for the architecture of neural network. The results of the study

indicated that ANNs have strong potential as a feasible tool for predicting the

compressive strength of concrete. Atici et al., (2009) applies multiple regression

analysis and an artificial neural network in estimating the compressive strength of

concrete that contains varying amounts of blast furnace slag and fly ash. The results

reveal that the artificial neural network models performed better than multiple

regression analysis models. Serkan subas (2009) investigated that the estimation

ability of the effects of utilizing different amount of the class C fly ash on the

mechanical properties of cement using artificial neural network and regression

methods. Experimental results were used in the estimation methods. The developed

models and the experimental results were compared in the testing data set. As a result,

compressive and flexural tensile strength values of mortars containing various

amounts class C fly ash can be predicted in a quite short period of time with tiny error

rates by using the multilayer feed-forward neural network models than regression

techniques. Seyed et.al (2011) studied the application of artificial neural networks to

predict compressive strength of high strength concrete (HSC). A total of 368 different

data of HSC mix-designs were collected from technical literature. The authors

concluded that that the relative percentage error (RPE) for the training set was 7.02%

http://www.iaeme.com/IJCIET/index.asp 303

editor@iaeme.com

Dr. B.Vidivelli and A. Jayaranjini

and the testing set was 12.64%. The ANNs models give high prediction accuracy, and

the research results demonstrate that using ANNs to predict concrete strength is

practical and beneficial. Vijay et al., (2013) predicted the compressive strength of

concrete using Artificial Neural Network (ANN). The authors compared the predicted

compressive strength with the obtained actual compressive strength of concrete and

also the authors proposed equations for different models. The authors concluded that a

good co-relation has been obtained between the predicted compressive strength by

these models and experimental results. Sakshigupta et.al., (2013) used Artificial

Neural Network (ANN) to predict the compressive strength of concrete containing

nano-silica. The author developed a model for predicting 28 days compressive

strength of concrete with partial replacement of cement with nano-silica for which the

data has been taken from various literatures. The author concluded that compressive

strength values of concrete can be predicted in ANN models without attempting any

experiments in a quite short period of time with some error rates. Wankhade et.al,

(2013) used Artificial Neural Network (ANN) to predict the compressive strength

of concrete. To train the networks back propagation and JordanElman algorithms

are used. Networks are trained and tested at various learning rate and momentum

factor and after many trials these were kept constant for this study. Performance of

networks were checked with statistical error criteria of correlation coefficient, root

mean squared error and mean absolute error. The authors concluded that artificial

neural networks can predict compressive strength of concrete with 91 to 98 %

accuracy.

EXPERIMENTAL INVESTIGATION

M30 grade of concrete were used for the present investigation. Mix design was done

based on IS 10262 2009 (17). The concrete mix proportion 1:1.73:3.2 with w/c 0.45

considered in this study. Twelve HPC mixes were prepared for this test by volumetric

method. The conventional concrete mix CC and Combinations of HPC mixes (S1S11) as given in Table.1. The volume of water is 172.8 lit/m3 and Coarse aggregate

(CA) is 1220 kg/m3 were kept constant while the volume of cement, sand and

Superplasticizer (SP) were varied for all the mixes. The mix Combinations and mix

proportions are given in table 1 & 2. The selected 4 HPC mixes are having the

maximum compressive strength at 28 days including CC & S3, S7, S10 and S11.

PREPARATION OF TEST SPECIMEN

Concrete cubes and cylinders were casted for all five mixes. For each combination,

trial mixes were carried out. In total 71 were casted for all mixes. All the materials

were thoroughly mixed in dry state by machine so as to obtain uniform colour. The

required percentage of superplasticizer was added to the water calculated for the

particular mix. The slump tests were carried out on fresh concrete for all the mixes.

The entire test Specimens were cast using Standard steel mould and the concrete were

compacted on a vibrating table. The specimens were demoulded after 24 hours and

cured in water for 28 days. The test results were carried out confirming to IS 5161959 (16) to obtain compressive strength of concrete. The cubes were tested using

compression testing machine (CTM) of capacity of 2000KN.

http://www.iaeme.com/IJCIET/index.asp 304

editor@iaeme.com

Prediction of Compressive Strength of High Performance Concrete Containing Industrial by

products Using Artificial Neural Networks

S.No

Mix designation

Table 1 Combinations of Mixes

Combinations

CC

(C+S+CA)

S1

(C+FA20%)+S+CA)

S2

(C+SF10%)+S+CA

S3

(C+MK10%)+S+CA

S4

C+(S+BA20%)+CA

S5

(C+FA20%)+(S+BA20%)+CA)

S6

(C+SF10%)+(S+BA20%)+CA

S7

(C+MK10%)+(S+BA20%)+CA

S8

(C+FA20%+SF10%)+(S+BA20%)+CA

10

S9

(C+FA20%+MK10%)+(S+BA20%)+CA

11

S10

(C+SF10%+MK10%)+(S+BA20%)+CA

12

S11

(C+FA20%+SF10%+MK10%)+(S+BA20%)+CA

ARTIFICIAL NEURAL NETWORK

Artificial neural network are nonlinear information (signal) processing devices, which

are built from interconnected elementary processing devices called neurons. An

artificial neural network (ANN) is an information processing paradigm that is inspired

by the way biological nervous system such as the brain, process information. The key

element of this paradigm is the novel structure of the information processing system.

It is composed of a large number of highly interconnected processing elements

(neurons) working in union to solve specific problems. An ANN is configured for a

specific application, such as pattern recognition or data classification, through a

learning process. Learning is biological systems involves adjustments to the synaptic

connection that exist between the neurons. ANNs are a type of artificial intelligence

that attempts to imitate the way a human brain works. Rather than using a digital

model, in which all computations manipulate zeros and ones, a neural networks by

creating connection between processing elements, the computer equivalent of

neurons. The organization and weights of the connections determine the output.

http://www.iaeme.com/IJCIET/index.asp 305

editor@iaeme.com

Dr. B.Vidivelli and A. Jayaranjini

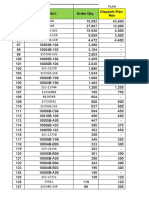

Table.2 Proportion of mixes

S.N

o

Mix

Cement(C

) (kg/m3)

Fly ash

(FA)

(kg/m3

)

1

2

3

4

5

6

7

8

9

10

11

12

CC

S1

S2

S3

S4

S5

S6

S7

S8

S9

S10

S11

384

307.2

345.6

345.6

384

307.2

345.6

345.6

268.8

268.8

307.2

230.4

0

76.8

0

0

0

76.8

0

0

76.8

76.8

0

76.8

A

S

C

F

A

Silica

fume

(SF)

(kg/m3

)

0

0

38.4

0

0

0

38.4

0

38.4

0

38.4

38.4

Metakao

lin (MK)

(kg/m3)

Fine

aggregat

e (S)

(kg/m3)

Bottom

ash

(BA)

(kg/m3)

SP

(lit/m3)

Slum

p

(mm)

0

0

0

38.4

0

0

0

38.4

0

38.4

38.4

38.4

665

623

644

649

508

476

500

508

461

467

492

463

0

0

0

0

133

133

133

133

133

133

133

133

2.49

3.37

3.97

3.45

3.84

3.99

4.83

4.49

4.03

3.49

4.60

3.80

55

57

55

56

58

55

52

57

59

58

57

58

N

1

N

2

N

3

S

F

N

4

M

KF

N

5

N

6

N

7

N

8

N

9

B

A

W

S

C

A

Experimental

Compressive

strength for

28

days(N/mm2)

36.5

34.54

37.03

41.34

35.33

37.21

39.31

42.79

37.25

39.22

44.69

40.0

S

P

N10

Input

layer

1. Hidden

layer

fc

Figure 1 The System used in ANN-I model

http://www.iaeme.com/IJCIET/index.asp 306

editor@iaeme.com

Prediction of Compressive Strength of High Performance Concrete Containing Industrial by

products Using Artificial Neural Networks

A

S

N1

N11

N2

N12

F

A

N3

N13

S

F

N4

N14

M

K

N5

N15

B

A

N6

N16

N7

N17

N8

N18

C

A

N9

N19

S

P

N10

N20

Input

layer

1.Hidden

layer

2.Hidden

layer

fc

3.Output

layer

Figure 2 The System used in ANN-II model

FEED FORWARD NEURAL NETWORK

In a feed forward neural network, the artificial neurons are arranged in layers, and all

the neurons in each layer have connections to all the neurons in the next layer.

However, there is no connection between neurons of the same layer or the neurons

which are not in successive layers. The feed forward network consists of one input

layer, one or two hidden layers and one output layer of neurons.

http://www.iaeme.com/IJCIET/index.asp 307

editor@iaeme.com

Dr. B.Vidivelli and A. Jayaranjini

Table 3 The Input and Output quantities used in ANN model.

Data used in training the models

Minimum

Maximum

Datas

Input Variables

Age of Specimen (day)

Cement (Kg/m3)

Silica fume (Kg/m3)

Metakaolin (Kg/m3)

Fly ash (Kg/m3)

Bottom ash (Kg/m3)

Sand (Kg/m3)

Coarse Aggregate (Kg/m3)

Superplasticizer (l/m3)

Output variable

Compressive strength

28

230.4

0

0

0

0

461

1220

2.49

120

384

38.4

38.4

76.8

133

665

1220

4.6

36.31

47.38

Table 4 Experimental results with Predicted results from models for 28 days

Compressive strength (N/mm2) 28 days

Mix Designation

Experimental result

ANN-I

ANN-II

% Error

CC-1

CC-2

CC-3

S3-1

S3-2

S3-3

S7-1

S7-2

S7-3

S10-1

S10-2

S10-3

S11-1

S11-2

S11-3

36.310

36.890

36.620

41.020

41.330

41.690

42.040

42.310

44.040

43.960

44.090

46.040

38.980

39.980

41.020

36.823

36.823

36.823

41.493

41.493

41.493

43.225

43.225

43.225

44.124

44.124

44.124

39.980

39.980

39.980

36.452

36.452

36.452

41.302

41.302

41.302

42.951

42.951

42.951

43.950

43.950

43.950

39.951

39.951

39.951

-0.513

0.067

-0.203

-0.473

-0.163

0.197

-1.185

-0.915

0.815

-0.164

-0.034

1.916

-1.000

0.000

1.040

http://www.iaeme.com/IJCIET/index.asp 308

editor@iaeme.com

Prediction of Compressive Strength of High Performance Concrete Containing Industrial by

products Using Artificial Neural Networks

Table 5 Experimental results with Predicted results from models for 56 days

Mix

Designation

CC-1

CC-2

CC-3

S3-1

S3-2

S3-3

S7-1

S7-2

S7-3

S10-1

S10-2

S10-3

S11-1

S11-2

S11-3

Compressive strength (N/mm2) 56 days

Experimental

ANN-I

ANN-II

result

36.670

36.814

37.094

36.970

36.814

37.094

36.620

36.814

37.094

42.500

42.513

42.941

41.500

42.513

42.941

43.500

42.513

42.941

44.100

43.936

44.071

43.200

43.936

44.071

44.500

43.936

44.071

46.800

45.485

45.456

44.700

45.485

45.456

45.000

45.485

45.456

41.000

41.254

40.790

39.500

41.254

40.790

41.500

41.254

40.790

% Error

-0.424

-0.124

-0.474

-0.441

-1.441

0.559

0.029

-0.871

0.429

1.315

-0.785

-0.485

-0.254

-1.754

0.246

Table 6 Experimental results with Predicted results from models for 90 days

Compressive strength (N/mm2) 90 days

Mix Designation

CC-1

CC-2

CC-3

S3-1

S3-2

S3-3

S7-1

S7-2

S7-3

S10-1

S10-2

S10-3

S11-1

S11-2

S11-3

Experimental

result

37.110

37.280

37.200

43.200

42.500

44.300

44.600

44.100

45.800

46.540

45.820

45.970

41.520

41.360

42.380

ANN-I

37.750

37.750

37.750

43.662

43.662

43.662

44.652

44.652

44.652

46.639

46.639

46.639

42.446

42.446

42.446

http://www.iaeme.com/IJCIET/index.asp 309

ANN-II

37.242

37.242

37.242

43.200

43.200

43.200

44.856

44.856

44.856

46.160

46.160

46.160

41.761

41.761

41.761

% Error

-0.640

-0.470

-0.550

-0.462

-1.162

0.638

-0.256

-0.756

0.944

-0.099

-0.819

-0.669

-0.926

-1.086

-0.066

editor@iaeme.com

Dr. B.Vidivelli and A. Jayaranjini

Table 7 Experimental results with Predicted results from models for 120 days

Compressive strength (N/mm2) 120 days

Mix

Experimental

Designation

result

ANN-I

ANN-II

CC-1

37.550

37.628

37.622

CC-2

37.680

37.628

37.622

CC-3

37.600

37.628

37.622

S3-1

44.580

43.323

44.329

S3-2

42.500

43.323

44.329

S3-3

44.170

43.323

44.329

S7-1

45.310

45.142

44.846

S7-2

44.150

45.142

44.846

S7-3

45.160

45.142

44.846

S10-1

47.380

46.650

46.306

S10-2

46.390

46.650

46.306

S10-3

46.250

46.650

46.306

S11-1

42.530

42.765

42.361

S11-2

42.160

42.765

42.361

S11-3

43.000

42.765

42.361

% Error

-0.078

0.052

-0.028

0.251

-1.829

-0.159

0.168

-0.992

0.018

0.730

-0.260

-0.400

-0.235

-0.605

0.235

Two different multilayer artificial neural network architectures namely ANN-I

and ANN-II were built. In training and testing of the ANN-I and ANN-II models

constituted with two different architectures AS, C, FA, SF, MK, BA, S, CA, W and

SP were input values, while fc value were used as output. In the ANN-I & ANN-II, 71

data of experimental results were used for training. In ANN-I model, one hidden layer

were selected as shown in fig.1 In the hidden layer 10 neurons were determined due to

its minimum absolute percentage error values for training sets. In ANN-II model, two

hidden layers were selected as shown in fig.2. In the first hidden layer 10 neurons and

in the second hidden layer 10 neurons were determined due to its minimum absolute

percentage error values for training sets. In the ANN-I and ANN-II models, the

neurons of neighboring layers are fully interconnected by weights. Finally the output

layer neuron produces the network prediction as a result. Momentum rate, learning

rate, error after learning cycle were determined for both models were trained through

iterations. The trained models were only tested with the input values and the results

found were close to experimental results.

Figure 3 Experimental Results with training results of ANN-I

http://www.iaeme.com/IJCIET/index.asp 310

editor@iaeme.com

Prediction of Compressive Strength of High Performance Concrete Containing Industrial by

products Using Artificial Neural Networks

Figure 4 Experimental Results with training results of ANN-I

Figure 5 Experimental Results with training results of ANN-I

Figure 6 Experimental Results with training results of ANN-I

http://www.iaeme.com/IJCIET/index.asp 311

editor@iaeme.com

Dr. B.Vidivelli and A. Jayaranjini

RESULTS AND DISCUSSION

In the training of ANN-I and ANN-II models, various experimental data are used. In

the ANN-I and ANN-II models, 71 data of Experimental results were used for

training. All results obtained from experimental studies and predicted by using the

training results of ANN-I models for 28, 56, 90 and 120 days fc were given in fig.3, 4,

5 and 6 respectively. The linear least square fit line, its equation and the R 2 values

were shown in these figures for the training data. Also, input values and Experimental

results with training results obtained from ANN-I and ANN-II models were given in

table.1, 4, 5, 6 and 7. The results of training phase in Fig.3, 4, 5 and 6 shows that

these models are capable of generalized between input and output variables with

reasonably good predictions.

The statistical values of all the values such as Root Mean Square (RMS), Mean

Square Error (MSE), Mean Absolute Percentage Error (MAPE) and R2 training are

given in table. While these values of RMS, MSE, MAPE and R2 from training in the

ANN-I model were found as 0.787, 0.619, 1.384% and 99.9% respectively. The best

value of R2 is 99.9% for training set in the ANN-I model. The minimum value of R2 is

99.6% for training set in the ANN-I model. All of the statistical value in table 9 show

that the proposed ANN-I and ANN-II models are suitable and predict the 28, 56, 90

and 180 days compressive strength (fc) values are very close to the experimental

values.

Table.8 The fc statistical values of proposed ANN-I and ANN-II models

ANN-II

ANN-I

ANN-II

ANN-I

ANN-II

120 days

ANN-I

90 days

ANN-II

56 days

ANN-I

28 days

Statistical

parameter

(Training

set)

RMSE

0.787

0.790

0.764

0.763

0.716

0.525

0.591

0.626

MSE

0.619

0.625

0.584

0.583

0.513

0.276

0.349

0.392

MAPE

(%)

1.384

1.345

1.370

1.499

1.453

0.939

1.019

0.916

R2

0.999

0.996

0.999

0.999

0.999

0.9997

0.9998

0.999

CONCLUSIONS

In this Study, using these beneficial properties of artificial neural networks in order to

predict the 28, 56, 90 and 120 days compressive strength values of concrete

containing Industrial Byproducts with attempting experiments were developed two

different architectures namely ANN-I and ANN-II. In two models developed on ANN

method, a multilayer feed forward neural network in a back propagation algorithm

were used. In ANN-I model, one hidden layer were selected. In the hidden layers 10

neurons were determined. In ANN-II model, two hidden layers were selected. In the

first hidden layers 10 neurons and in the second hidden layer 10 neurons were

determined. The models were trained with input and output data. The compressive

strength values predicted from training for ANN-I & ANN-II models were very close

to the experimental results. Furthermore, according to the compressive strength results

predicted by using ANN-I and ANN-II models, the results of ANN-II model are

closer to the experimental results. RMSE, MSE, R2 and MAPE statistical values that

are calculated for comparing experimental results with ANN-I and ANN-II model

results have shown this situation. As a result, compressive strength values of

http://www.iaeme.com/IJCIET/index.asp 312

editor@iaeme.com

Prediction of Compressive Strength of High Performance Concrete Containing Industrial by

products Using Artificial Neural Networks

concretes containing Industrial Byproducts can be predicted in the multilayer feed

forward artificial neural networks models with attempting experiments in a quite short

period of time with tiny error rates. ANN can be suggested to predict the concrete

compressive strength with high accuracy.

REFERENCES

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

[11]

[12]

[13]

[14]

[15]

[16]

Noorzaei J, Hakim S, Jaafar M, Thanoon W. Development of Artificial Neural

Networks For predicting Concrete Compressive Strength. International

Journal of Engineering and Technology. 2007, Vol. 4, 141-153.

Atici C, Prediction of the strength of mineral admixture concrete using

multivariable regression analysis and an artificial neural network Engineering

Faculty, Nigde University, Nigde 51245, Turkey. Expert Systems with

Applications. 08/2011; 38(8):9609-9618.

Serkan Subas, Prediction of mechanical properties of cement containing class

C fly ash by using artificial neural network and regression technique, Scientific

Research and Essay Vol. 4 (4) pp. 289-297, April, 2009.

Seyed Jamalaldin Seyed Hakim, Jamaloddin Noorzaei, M. S. Jaafar, Mohammed

Jameel and Mohammad Mohammadhassani Application of artificial neural

networks to predict compressive strength of high strength concrete. 2011 Vol. 6(5),

pp. 975-981.

Vijay Pal Singh, Yogesh Chandra Kotiyal, Prediction of Compressive Strength

Using Artificial Neural Network International Journal of Civil, Environmental,

Structural, Construction and Architectural Engineering Vol:7, No:12, 2013

Sakshi Gupta Using Artificial Neural Network to Predict the Compressive Strength

of Concrete containing Nano-silica Civil Engineering and Architecture 1(3): 96102, 2013

Wankhade M W and Kambekar , A Prediction of Compressive Strength of

Concrete using Artificial Neural Network IJSRR 2013, 2(2), 11-26

Abdullah.M, Al-Mattarneh.H.M.A, Mohammed B.S. Statistical of Lightweight

Concrete mixtures , European journal of scientific re-search, Vol. 31,pp.124131, 2009.

Padmanaban.I. , Kandasamy.S and Natesan S.C, Statistical of High and Low

Volume of Fly Ash High Compressive Strength Concrete Inter-national Journal

of Applied Engineering Research, Vol 4, pp.1161-1167, 2009.

Raghu Prasad BK, Eskandari H, Venkatarama Reddy BV. Prediction of

compressive strength of SCC and HPC with high volume fly ash using ANN,

Constr Build Mater 23; 2009: 11728.

Marai M. Alshihri, Ahmed M. Azmy, Mousa S. El-Bisy, Neural networks for

predicting compressive strength of structural light weight concrete, Constr Build

Mater 2009; 23: 2214-9.

Parichatprecha R, Nimityongskul P. Analysis of durability of high performance

concrete using artificial neural networks, Constr Build Mater 2009; 23: 910-7.

IS 8112:2013. Indian standard Ordinary Portland Cement, 43grade

Specification (Second Revision).

IS: 383-1970. Specifications for Coarse and Fine Aggregates from Natural

Sources for Concrete. Bureau of Indian Standards, New Delhi.

IS.9103.1999 Admixtures Indian Standard concrete admixtures specification

IS: 516-1959 Methods of test for strength of concrete. New Delhi; Bureau of

Indian Standards.

http://www.iaeme.com/IJCIET/index.asp 313

editor@iaeme.com

Dr. B.Vidivelli and A. Jayaranjini

[17]

[18]

[19]

[20]

IS: 10262:2009, Recommended Guidelines for Concrete Mix Design Indian

Standard Institution, New Delhi.

IS: 456-2000. Plain and Reinforced Concrete. Code of Practice. Bureau of

Indian Standards, New Delhi.

Mustafa saridemir, Prediction of compressive strength of concrete containing

metakaolin and silica fume by artificial neural networks, Constr Build Mater

2009; 40: 350-5.

Dr Saman H. Al-Hamawandi Dr Abdul-Ilah Y. Mohammed and Dr Rafa H.AlSuhaili. Watershed Modeling Using Artificial Neural Networks, International

Journal of Civil Engineering and Technology, 6(4), 2015, pp. 3945.

[21]

Santosh Patil and Shriniwas Valunjkar. Forecasting of Daily Runoff Using

Artificial Neural Networks, International Journal of Civil Engineering and

Technology, 5(1), 2014, pp. 1320.

[22]

P.J.Patel, Mukesh A. Patel and Dr. H.S. Patel. Effect of Coarse Aggregate

Characteristics on Strength Properties of High Performance Concrete Using

Mineral and Chemical Admixtures, International Journal of Civil

Engineering and Technology, 4(2), 2013, pp. 8995.

Topu IB, Sardemir M. Prediction of compressive strength of concrete

containing fly ash using artificial neural network and fuzzy logic, Comp Mater

Sci 2008; 41(3): 30511.

[23]

http://www.iaeme.com/IJCIET/index.asp 314

editor@iaeme.com

Vous aimerez peut-être aussi

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Impact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesDocument10 pagesImpact of Emotional Intelligence On Human Resource Management Practices Among The Remote Working It EmployeesIAEME PublicationPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Voice Based Atm For Visually Impaired Using ArduinoDocument7 pagesVoice Based Atm For Visually Impaired Using ArduinoIAEME PublicationPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Broad Unexposed Skills of Transgender EntrepreneursDocument8 pagesBroad Unexposed Skills of Transgender EntrepreneursIAEME PublicationPas encore d'évaluation

- A Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiDocument16 pagesA Study On Talent Management and Its Impact On Employee Retention in Selected It Organizations in ChennaiIAEME PublicationPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- A Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaDocument9 pagesA Study of Various Types of Loans of Selected Public and Private Sector Banks With Reference To Npa in State HaryanaIAEME PublicationPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Modeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyDocument14 pagesModeling and Analysis of Surface Roughness and White Later Thickness in Wire-Electric Discharge Turning Process Through Response Surface MethodologyIAEME PublicationPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- A Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurDocument7 pagesA Study On The Impact of Organizational Culture On The Effectiveness of Performance Management Systems in Healthcare Organizations at ThanjavurIAEME PublicationPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Various Fuzzy Numbers and Their Various Ranking ApproachesDocument10 pagesVarious Fuzzy Numbers and Their Various Ranking ApproachesIAEME PublicationPas encore d'évaluation

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Influence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiDocument16 pagesInfluence of Talent Management Practices On Organizational Performance A Study With Reference To It Sector in ChennaiIAEME PublicationPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- A Multiple - Channel Queuing Models On Fuzzy EnvironmentDocument13 pagesA Multiple - Channel Queuing Models On Fuzzy EnvironmentIAEME PublicationPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Application of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDDocument19 pagesApplication of Frugal Approach For Productivity Improvement - A Case Study of Mahindra and Mahindra LTDIAEME PublicationPas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- EXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POLYMER COMPOSITESDocument9 pagesEXPERIMENTAL STUDY OF MECHANICAL AND TRIBOLOGICAL RELATION OF NYLON/BaSO4 POLYMER COMPOSITESIAEME PublicationPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Attrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesDocument15 pagesAttrition in The It Industry During Covid-19 Pandemic: Linking Emotional Intelligence and Talent Management ProcessesIAEME PublicationPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Role of Social Entrepreneurship in Rural Development of India - Problems and ChallengesDocument18 pagesRole of Social Entrepreneurship in Rural Development of India - Problems and ChallengesIAEME PublicationPas encore d'évaluation

- Financial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelDocument9 pagesFinancial Literacy On Investment Performance: The Mediating Effect of Big-Five Personality Traits ModelIAEME PublicationPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Analysis of Fuzzy Inference System Based Interline Power Flow Controller For Power System With Wind Energy Conversion System During Faulted ConditionsDocument13 pagesAnalysis of Fuzzy Inference System Based Interline Power Flow Controller For Power System With Wind Energy Conversion System During Faulted ConditionsIAEME PublicationPas encore d'évaluation

- Knowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentDocument8 pagesKnowledge Self-Efficacy and Research Collaboration Towards Knowledge Sharing: The Moderating Effect of Employee CommitmentIAEME PublicationPas encore d'évaluation

- Optimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsDocument13 pagesOptimal Reconfiguration of Power Distribution Radial Network Using Hybrid Meta-Heuristic AlgorithmsIAEME PublicationPas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Moderating Effect of Job Satisfaction On Turnover Intention and Stress Burnout Among Employees in The Information Technology SectorDocument7 pagesModerating Effect of Job Satisfaction On Turnover Intention and Stress Burnout Among Employees in The Information Technology SectorIAEME PublicationPas encore d'évaluation

- Dealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsDocument8 pagesDealing With Recurrent Terminates in Orchestrated Reliable Recovery Line Accumulation Algorithms For Faulttolerant Mobile Distributed SystemsIAEME PublicationPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Analysis On Machine Cell Recognition and Detaching From Neural SystemsDocument9 pagesAnalysis On Machine Cell Recognition and Detaching From Neural SystemsIAEME PublicationPas encore d'évaluation

- A Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksDocument10 pagesA Proficient Minimum-Routine Reliable Recovery Line Accumulation Scheme For Non-Deterministic Mobile Distributed FrameworksIAEME PublicationPas encore d'évaluation

- Sentiment Analysis Approach in Natural Language Processing For Data ExtractionDocument6 pagesSentiment Analysis Approach in Natural Language Processing For Data ExtractionIAEME PublicationPas encore d'évaluation

- A Review of Particle Swarm Optimization (Pso) AlgorithmDocument26 pagesA Review of Particle Swarm Optimization (Pso) AlgorithmIAEME PublicationPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- A Overview of The Rankin Cycle-Based Heat Exchanger Used in Internal Combustion Engines To Enhance Engine PerformanceDocument5 pagesA Overview of The Rankin Cycle-Based Heat Exchanger Used in Internal Combustion Engines To Enhance Engine PerformanceIAEME PublicationPas encore d'évaluation

- Formulation of The Problem of Mathematical Analysis of Cellular Communication Basic Stations in Residential Areas For Students of It-PreparationDocument7 pagesFormulation of The Problem of Mathematical Analysis of Cellular Communication Basic Stations in Residential Areas For Students of It-PreparationIAEME PublicationPas encore d'évaluation

- Quality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceDocument7 pagesQuality of Work-Life On Employee Retention and Job Satisfaction: The Moderating Role of Job PerformanceIAEME PublicationPas encore d'évaluation

- Prediction of Average Total Project Duration Using Artificial Neural Networks, Fuzzy Logic, and Regression ModelsDocument13 pagesPrediction of Average Total Project Duration Using Artificial Neural Networks, Fuzzy Logic, and Regression ModelsIAEME PublicationPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Ion Beams' Hydrodynamic Approach To The Generation of Surface PatternsDocument10 pagesIon Beams' Hydrodynamic Approach To The Generation of Surface PatternsIAEME PublicationPas encore d'évaluation

- Evaluation of The Concept of Human Resource Management Regarding The Employee's Performance For Obtaining Aim of EnterprisesDocument6 pagesEvaluation of The Concept of Human Resource Management Regarding The Employee's Performance For Obtaining Aim of EnterprisesIAEME PublicationPas encore d'évaluation

- Comparative Tracking Index of Electrical Insulating MaterialsDocument6 pagesComparative Tracking Index of Electrical Insulating MaterialsAbu Anas M.SalaheldinPas encore d'évaluation

- Sluice Gates ExportDocument20 pagesSluice Gates ExportsaishankarlPas encore d'évaluation

- 4 Rec. ITU-R BS.775-3: Reference Loudspeaker Arrangement With Loudspeakers L/C/R and LS/RSDocument3 pages4 Rec. ITU-R BS.775-3: Reference Loudspeaker Arrangement With Loudspeakers L/C/R and LS/RSPaulo PiresPas encore d'évaluation

- Help - Translating A CAD Stewart Platform - Computer-Aided Design Translation (SimMechanics™ Link)Document8 pagesHelp - Translating A CAD Stewart Platform - Computer-Aided Design Translation (SimMechanics™ Link)ĐinhĐứcAnhPas encore d'évaluation

- Oil & Gas Asset Integrity IssuesDocument15 pagesOil & Gas Asset Integrity Issuesyogolain100% (2)

- Session 5 PDFDocument26 pagesSession 5 PDFToufic HagePas encore d'évaluation

- Delhi Public School Bangalore North ACADEMIC SESSION 2021-2022 Ut2 Revision Work Sheet TOPIC: Sorting Materials Into Group Answer KeyDocument6 pagesDelhi Public School Bangalore North ACADEMIC SESSION 2021-2022 Ut2 Revision Work Sheet TOPIC: Sorting Materials Into Group Answer KeySumukh MullangiPas encore d'évaluation

- 100ah - 12V - 6FM100 VISIONDocument2 pages100ah - 12V - 6FM100 VISIONBashar SalahPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Reef Wayfinding Plan and Signage Design Concept 28 August 2019Document51 pagesThe Reef Wayfinding Plan and Signage Design Concept 28 August 2019Michele MontoloPas encore d'évaluation

- Schematic Lenovo ThinkPad T410 NOZOMI-1Document99 pagesSchematic Lenovo ThinkPad T410 NOZOMI-1borneocampPas encore d'évaluation

- Behringer UB2222FX PRODocument5 pagesBehringer UB2222FX PROmtlcaqc97 mtlcaqc97Pas encore d'évaluation

- Huawei ACU2 Wireless Access Controller DatasheetDocument12 pagesHuawei ACU2 Wireless Access Controller Datasheetdexater007Pas encore d'évaluation

- Mechanical Workshop Practice ReportDocument6 pagesMechanical Workshop Practice ReportMuhd AkmalPas encore d'évaluation

- Ball Mill SizingDocument10 pagesBall Mill Sizingvvananth100% (1)

- Portland CementDocument46 pagesPortland Cementni putu diah untariningsihPas encore d'évaluation

- Estimation Software For Presure VesselDocument36 pagesEstimation Software For Presure VesselKarthikeyan Shanmugavel0% (1)

- Using Dapper Asynchronously inDocument1 pageUsing Dapper Asynchronously inGiovani BrondaniPas encore d'évaluation

- Problems PDFDocument9 pagesProblems PDFEduarGelvezPas encore d'évaluation

- Comfort and Performance Your Customers DemandDocument18 pagesComfort and Performance Your Customers Demandgizex2013Pas encore d'évaluation

- Q3 NSP - SLP - RLPDocument41 pagesQ3 NSP - SLP - RLPRushi RavalPas encore d'évaluation

- Makita 2708Document29 pagesMakita 2708Reuel JacintoPas encore d'évaluation

- PT14 Engine Monitor 1Document2 pagesPT14 Engine Monitor 1BJ DixPas encore d'évaluation

- 4 and 6 Pole MotorDocument6 pages4 and 6 Pole Motorarajamani78100% (1)

- 8th ICCIT - 2005 - 564Document5 pages8th ICCIT - 2005 - 564Amit BiswasPas encore d'évaluation

- Bs en 00378 3 2016Document30 pagesBs en 00378 3 2016Darius VinPas encore d'évaluation

- Huawei: Quidway Full Series Ethernet Routing SwitchesDocument90 pagesHuawei: Quidway Full Series Ethernet Routing SwitchesWalter Aguiar0% (1)

- Order Qty Vs Dispatch Plan - 04 11 20Document13 pagesOrder Qty Vs Dispatch Plan - 04 11 20NPD1 JAKAPPas encore d'évaluation

- Differences Between VSI and CSI Converter Operation Modes.Document1 pageDifferences Between VSI and CSI Converter Operation Modes.Sushil NamoijamPas encore d'évaluation

- Softening Point of AsphaltDocument2 pagesSoftening Point of AsphaltMuhammad Rizal RamliPas encore d'évaluation

- Sewer Connection Application Guidance PDFDocument7 pagesSewer Connection Application Guidance PDFSamuel FuentesPas encore d'évaluation