Académique Documents

Professionnel Documents

Culture Documents

Mechanical Flow Meters Specifications

Transféré par

Anonymous M0tjyW0 évaluation0% ont trouvé ce document utile (0 vote)

423 vues3 pagesSpecifications for flow meters

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentSpecifications for flow meters

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

423 vues3 pagesMechanical Flow Meters Specifications

Transféré par

Anonymous M0tjyWSpecifications for flow meters

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 3

2013/ /69 :

Mechanical Flow meters

Technical Specification for Water Meter Size (2,3,8,12 inches)

No.

2

3

4

5

DESCRIPTION

CONFIRMATION

The water meters shall be in accordance with ISO 4064

class B all position, and OIML certificate or an

equivalent from manufacture country.

The water meters shall be used to register quantities of

water pumped.

The water meters shall be capable to operate with

water having suspended solids.

The water meters shall be turbine type (axial flow

horizontal helix, or vertical turbine).

The meters shall be dry dial type and magnetic drive.

Water meters shall be provided with standard pulsar, or

optionally with high resolution pulsar capable of

transferring flow rate and flow direction ready for

connection to a data logger.

The meters shall be provided with hermetically

capsuled register reading in cubic meters.

The register shall have a test index circle divided into 10

equal parts.

10

11

12

13

14

15

Totalizer shall be digital type capable of

registering at least 999999 m3. The totalizer shall

be set at 0(zero).

The meters shall be tamper proof, and shall have

protective device which can be sealed in such a

way that after sealing, both before and after the

water meter has been correctly installed there is

no possibility of dismantling or altering the water

meter or its adjustment device without damaging

the protective devices.

Sealing material must be stainless steel wire and

aluminum seal.

The lid of meters shall be made of brass or high

qaulity plastic for protection purposes.

The working pressure shall not be less than (16 ) bar for

all items .

The entire flow range the permissible head loss shall not

exceed 1 bar.

The test pressure nevertheless shall be 1.6 times the

nominal pressure and twice the nominal pressure as

specified in the standards.

DEVIATION

No.

DESCRIPTION

16

The meters shall be supplied with flanged connections.

Flanges shall be of PN16 for all items.

17

Flanges drilling shall be in according to B. S. 45204.

18

19

20

21

22

23

24

25

26

27

CONFIRMATION

The meters shall be provided with steel companion

flanges, gaskets, bolts and nuts

The bodies of bulk water meters casing for flanged

ends meters shall be made of cast iron, or

Ductile (for PN 25), or steel for (PN 25&40).

The meters shall be protected against external

and internal by an epoxy powder coating and the

material of the meter shall be resistant to

corrosion .

Materials in contact with water shall be non

toxic and shall not affect the quality of the water .

The meters shall be capable to operate in a water

temperature up to 50co.

Materials of the meters shall be capable to resist

chlorine dose up to 5 ppm, also shall resist

impurities in water.

The measuring mechanism shall be removable

type. Therefore the measuring mechanism can be

completely removed from the meter casing. The

measuring mechanism shall also be secured

against removal from the body by a seal.

The permissible continuous load for meters of given size

shall conform with ISO 4064 and shall not be below

nominal flows ( Qn) given below :

DN50

15 m3/h

DN80

40 m3/h

DN200

250 m3/h

DN300

600 m3/h

All catalogues, operation and maintenance

manuals, spare parts list and price list etc. shall

be provided with the offer.

Evidence of compliance with technical

specifications and standard as well as the

certificate of testing for accuracy, pressure, and

capacities is required. Approval certificates of

relevant authorities, such as EEC, BS, or

AWWA, shall be provided.

DEVIATION

No.

28

29

30

DESCRIPTION

CONFIRMATION

The size , model , serial number , Q n ( nominal

flow rate in m3/h ) , direction of flow , year of

manuacturing , stamped with initial WAJ ,

meteorological class , working pressure ,

indicated on all meters , and all other marking

shall be in accordance to standards .

Aseparate price quotation shall be submitted for

the tenders recommended spare parts sufficient

for at least two years of meter maintenance. The

bidder shall however bid on the spare parts listed

in the bill of quantities.

Evaluation of tenders,

Any deviation from these specifications will result in

rejection of the tender as non- responsive. The purchaser

will evaluate all qualifying tenders based on price,

compliance with these specifications and any technical

features of specific value and importance to the

purchaser. A uniform rating sheet will be used to

evaluate all qualifying tenders.

DEVIATION

Vous aimerez peut-être aussi

- Polycab Armoured Cables Price List Wef 14-11-2016 CustomerDocument1 pagePolycab Armoured Cables Price List Wef 14-11-2016 CustomernavneetPas encore d'évaluation

- L - T - Valves - Price - List - 01!04!2016 - Gate & Globe ValveDocument1 pageL - T - Valves - Price - List - 01!04!2016 - Gate & Globe ValveRavinder100% (1)

- Relief ValveDocument2 pagesRelief ValveAdil AzizPas encore d'évaluation

- FlowmeterDocument22 pagesFlowmeterAnandPas encore d'évaluation

- Selecting An HVAC Pump at HttpsDocument3 pagesSelecting An HVAC Pump at Httpsalone160162lPas encore d'évaluation

- Steam Balance Layout (TPH) ModelDocument1 pageSteam Balance Layout (TPH) ModelRemington SalayaPas encore d'évaluation

- Process Industry Practices Machinery: Pip Resp73V Application of ASME B73.2 - 2003Document31 pagesProcess Industry Practices Machinery: Pip Resp73V Application of ASME B73.2 - 2003m4metzPas encore d'évaluation

- 1 04 039 03 PDFDocument9 pages1 04 039 03 PDFanuragpugaliaPas encore d'évaluation

- Soot Deposits and Fires in Exhaust Gas BoilersDocument21 pagesSoot Deposits and Fires in Exhaust Gas BoilersJose G. CastilloPas encore d'évaluation

- Pumps and Cooling TowersDocument51 pagesPumps and Cooling TowersMikho SaliguePas encore d'évaluation

- SSP Process DescriptionDocument10 pagesSSP Process DescriptionChirag JaniPas encore d'évaluation

- McQuay MCC Data Sheet EngDocument1 pageMcQuay MCC Data Sheet EngSaeful Malik GintingPas encore d'évaluation

- Bill of Quantities of M. S. Pipe Fittings (O-14027)Document4 pagesBill of Quantities of M. S. Pipe Fittings (O-14027)Tanmoy DuttaPas encore d'évaluation

- Cooling Water System Control Philosophy (25Mw) : ObjectiveDocument8 pagesCooling Water System Control Philosophy (25Mw) : ObjectiveEric TaylorPas encore d'évaluation

- 100m3 Mkongoro Water TankDocument1 page100m3 Mkongoro Water TankamonPas encore d'évaluation

- FWT DIAPHRAGM Motor Dosing Pumps ENG Rev1 - 0215Document6 pagesFWT DIAPHRAGM Motor Dosing Pumps ENG Rev1 - 0215Imar KusumaPas encore d'évaluation

- Diode FailureDocument2 pagesDiode Failurepimco12Pas encore d'évaluation

- C&I Cable Schedule - 090710 E-12 PDFDocument139 pagesC&I Cable Schedule - 090710 E-12 PDFAnonymous vcadX45TD7Pas encore d'évaluation

- Butterfly Valve Catalogue PDFDocument25 pagesButterfly Valve Catalogue PDFPriyanka rajpurohitPas encore d'évaluation

- Epilux 155Document2 pagesEpilux 155Tejinder KumarPas encore d'évaluation

- General Specification For Electric Actuators - Integral Motor ControlDocument4 pagesGeneral Specification For Electric Actuators - Integral Motor ControlschgirlPas encore d'évaluation

- CPCB - Grain Based DistilleriesDocument37 pagesCPCB - Grain Based Distilleriesmyself_riteshPas encore d'évaluation

- Stationary Equipment List From SAPDocument132 pagesStationary Equipment List From SAPVajid MadathilPas encore d'évaluation

- Thermax BoilerDocument10 pagesThermax Boileramitrawal0100% (1)

- Gacl-Dahej Captive Co-Generation Power Plant Corrected Gas Turbines Output Calculation On Site ConditionDocument8 pagesGacl-Dahej Captive Co-Generation Power Plant Corrected Gas Turbines Output Calculation On Site Conditionakulahtu78Pas encore d'évaluation

- TurboDocument8 pagesTurboKorichiKarimPas encore d'évaluation

- Practical Guidelines For CTG Power PlantsDocument11 pagesPractical Guidelines For CTG Power Plantsandrei12320003181Pas encore d'évaluation

- Incinerator Maintenance ChartDocument1 pageIncinerator Maintenance ChartRejoGevargheseRajanPas encore d'évaluation

- WK Operating InstructionsDocument39 pagesWK Operating InstructionsR PrasadPas encore d'évaluation

- Attachment 5 - Valve Design Table PDFDocument8 pagesAttachment 5 - Valve Design Table PDFbisworupmPas encore d'évaluation

- Technical Support Section in The Preface To This ManualDocument19 pagesTechnical Support Section in The Preface To This ManualJesusMamaniMamaniPas encore d'évaluation

- BPCL Training ReportDocument34 pagesBPCL Training ReportVishalVaishPas encore d'évaluation

- N1P 1.5 P1T2 BLK LDocument2 pagesN1P 1.5 P1T2 BLK LRijo RajanPas encore d'évaluation

- MQ SP M 4002 PDFDocument28 pagesMQ SP M 4002 PDFjaseelPas encore d'évaluation

- All Process - Pumps - Re - 014 PDFDocument21 pagesAll Process - Pumps - Re - 014 PDFWRTPas encore d'évaluation

- O & M ManualDocument37 pagesO & M ManualNguyễn Thanh Lâm0% (1)

- Vacuum System ParametersDocument7 pagesVacuum System ParametersOmar Ahmed ElkhalilPas encore d'évaluation

- Vol III Rev 0Document871 pagesVol III Rev 0Anonymous nwByj9LPas encore d'évaluation

- Is.10392.1982 Feed Water BoilerDocument11 pagesIs.10392.1982 Feed Water BoilerAngelina YunitaPas encore d'évaluation

- Utopian Sugars DPR - 28!3!2017Document142 pagesUtopian Sugars DPR - 28!3!2017Prashant Bahirgonde100% (1)

- ME6701-Power Plant EngineeringDocument16 pagesME6701-Power Plant EngineeringNizam MAPas encore d'évaluation

- Chapter-Ii Project Description 2.1 Type of ProjectDocument20 pagesChapter-Ii Project Description 2.1 Type of ProjectOMSAINATH MPONLINEPas encore d'évaluation

- Mechanical Data Sheet - Air Filter (031-GN-002AB)Document5 pagesMechanical Data Sheet - Air Filter (031-GN-002AB)Gaurav PandeyPas encore d'évaluation

- Biomass Boiler FLOW DIAGRAM SAMPLE PDFDocument1 pageBiomass Boiler FLOW DIAGRAM SAMPLE PDFRandyPas encore d'évaluation

- PRE START VALVE LINE UP CHECK LISTcondensate SystemDocument3 pagesPRE START VALVE LINE UP CHECK LISTcondensate Systemmd abPas encore d'évaluation

- Package ACDocument52 pagesPackage ACWee WeePas encore d'évaluation

- How To Read PIDDocument4 pagesHow To Read PIDlennisavilaPas encore d'évaluation

- Up Labour Departmant-Boiler RulesDocument6 pagesUp Labour Departmant-Boiler RulesSun100% (2)

- Specific Size Agitator Selection Process & Specification PDFDocument12 pagesSpecific Size Agitator Selection Process & Specification PDFParth ThakarPas encore d'évaluation

- Technical Specifications - CompDocument57 pagesTechnical Specifications - CompAnonymous gr5Pr9AVPas encore d'évaluation

- Topsoe Sec Ref Cat RKS 2Document5 pagesTopsoe Sec Ref Cat RKS 2Vo Duc Minh MinhPas encore d'évaluation

- Group # 01: Production of 163 Tonns Per Day of Ammonium Sulfate From Acid Gase Waste StreamDocument47 pagesGroup # 01: Production of 163 Tonns Per Day of Ammonium Sulfate From Acid Gase Waste StreamAhmer SohailPas encore d'évaluation

- Uong Bi 300 MW Extension Power Plant: OwnerDocument32 pagesUong Bi 300 MW Extension Power Plant: OwnerAmEnPro100% (1)

- Dosing Pump DocumentsDocument7 pagesDosing Pump Documentsbmanojkumar16Pas encore d'évaluation

- T1 - Al Hassan PDFDocument7 pagesT1 - Al Hassan PDFNadim JilaniPas encore d'évaluation

- Air Compressor Curve ToolDocument14 pagesAir Compressor Curve Toollutfi awnPas encore d'évaluation

- JACOBS Flow Instrument SpecDocument9 pagesJACOBS Flow Instrument Specshantanubiswas1Pas encore d'évaluation

- 779 Water MetersDocument18 pages779 Water MetersKathiravan ManimegalaiPas encore d'évaluation

- Water MetersDocument3 pagesWater MetersRashedPas encore d'évaluation

- Flow Meters & Waste MetersDocument7 pagesFlow Meters & Waste MetersSankalpa KarunarathnePas encore d'évaluation

- Ch2mhill Arrowsmith Lake Reservoir Water SupplyDocument11 pagesCh2mhill Arrowsmith Lake Reservoir Water SupplyAnonymous M0tjyWPas encore d'évaluation

- Contracts ManualDocument78 pagesContracts ManualAnonymous M0tjyWPas encore d'évaluation

- The Complete HOBAS GuideDocument76 pagesThe Complete HOBAS GuideJoe RayPas encore d'évaluation

- Hydraulic Grade LineDocument0 pageHydraulic Grade LinemuazeemKPas encore d'évaluation

- nrcs142p2 024926Document20 pagesnrcs142p2 024926Anonymous M0tjyWPas encore d'évaluation

- Design Installation Drainage SystemDocument6 pagesDesign Installation Drainage SystemAnonymous M0tjyWPas encore d'évaluation

- Industrial ApplicationsDocument7 pagesIndustrial ApplicationsAnonymous M0tjyWPas encore d'évaluation

- Hydraulic Design For Gravity Based Water Schemes Publication 2014Document29 pagesHydraulic Design For Gravity Based Water Schemes Publication 2014Anonymous M0tjyWPas encore d'évaluation

- Manual For Developing and Reviewing Water QualityDocument43 pagesManual For Developing and Reviewing Water QualityAnonymous M0tjyWPas encore d'évaluation

- Composite MaterialsDocument170 pagesComposite MaterialsAnonymous M0tjyW100% (1)

- Environmental Flows PDFDocument74 pagesEnvironmental Flows PDFAnonymous M0tjyWPas encore d'évaluation

- MHP 6Document94 pagesMHP 6Anonymous M0tjyWPas encore d'évaluation

- Liquid Pipeline HydraulicsDocument68 pagesLiquid Pipeline Hydraulicsarpitkr100% (3)

- Variable Speed DriveDocument16 pagesVariable Speed DriveAnonymous M0tjyWPas encore d'évaluation

- Equation CoûtDocument8 pagesEquation CoûtAnonymous M0tjyWPas encore d'évaluation

- Manual For Conducting Public HearingsDocument41 pagesManual For Conducting Public HearingsAnonymous M0tjyWPas encore d'évaluation

- AWS SummaryReport Part1 Pg1-34Document34 pagesAWS SummaryReport Part1 Pg1-34Anonymous M0tjyWPas encore d'évaluation

- Stream3 FNoceraDocument14 pagesStream3 FNoceraAnonymous M0tjyWPas encore d'évaluation

- Hydraulic Design For Gravity Based Water Schemes Publication 2014Document29 pagesHydraulic Design For Gravity Based Water Schemes Publication 2014Anonymous M0tjyWPas encore d'évaluation

- Draft Prefeasibility - Feasibility ReportDocument105 pagesDraft Prefeasibility - Feasibility ReportAnonymous M0tjyWPas encore d'évaluation

- WEAP Iwrm JackSieberDocument26 pagesWEAP Iwrm JackSieberAnonymous M0tjyWPas encore d'évaluation

- Low Cost IrrigationDocument7 pagesLow Cost IrrigationAnonymous M0tjyWPas encore d'évaluation

- Equation CoûtDocument8 pagesEquation CoûtAnonymous M0tjyWPas encore d'évaluation

- Molle Irrigation JordanDocument12 pagesMolle Irrigation JordanAnonymous M0tjyWPas encore d'évaluation

- EW2 wk1 D2-1Document141 pagesEW2 wk1 D2-1Anonymous M0tjyWPas encore d'évaluation

- Design of Water Treatment Plants CourseDocument47 pagesDesign of Water Treatment Plants CourseAnonymous M0tjyW100% (1)

- Jordan - Evaluation of Irrigation MethodsDocument24 pagesJordan - Evaluation of Irrigation MethodsAnonymous M0tjyW100% (1)

- Improvement of Extension ServicesDocument12 pagesImprovement of Extension ServicesAnonymous M0tjyWPas encore d'évaluation

- EW2 wk1 D2-2 PDFDocument18 pagesEW2 wk1 D2-2 PDFAnonymous M0tjyWPas encore d'évaluation

- KSR KueblerDocument22 pagesKSR KueblerlavascudoPas encore d'évaluation

- Kafexhiu VGB ReferenceDocument5 pagesKafexhiu VGB ReferenceKuppuraj ParamsivamPas encore d'évaluation

- Tutorial 1Document3 pagesTutorial 1Raiham EffendyPas encore d'évaluation

- Flange Cross HeadsDocument2 pagesFlange Cross Headsvishal.nithamPas encore d'évaluation

- F1267Document6 pagesF1267pratishgnairPas encore d'évaluation

- Material Science and Metallurgy Question BankDocument3 pagesMaterial Science and Metallurgy Question BankVinay KorekarPas encore d'évaluation

- July 2017: Understanding The Basics of Hand Taps and Carbide TapsDocument24 pagesJuly 2017: Understanding The Basics of Hand Taps and Carbide TapswinasharPas encore d'évaluation

- TS en 10120 - 2010Document12 pagesTS en 10120 - 2010Çağlar EbeperiPas encore d'évaluation

- 6 6 NLDocument8 pages6 6 NLblindjaxxPas encore d'évaluation

- ASTM Designations For Steel Properties PDFDocument5 pagesASTM Designations For Steel Properties PDFHumberto GalvezPas encore d'évaluation

- Day 1 Questions Easy FirstDocument63 pagesDay 1 Questions Easy Firsthaoues23100% (1)

- Nitoseal 215 (I)Document2 pagesNitoseal 215 (I)Prasenjit AdhikaryPas encore d'évaluation

- Auto Gradation Sensor A1 Parts ListDocument28 pagesAuto Gradation Sensor A1 Parts ListAndres CotrinoPas encore d'évaluation

- BMT WeldingGuide 1017 2Document8 pagesBMT WeldingGuide 1017 2kcarmachPas encore d'évaluation

- 1 - Eklund, Jon - British Eighteenth-Century Chemical Terms - Part 1 - 2 - 3 - The Best For Learning All Alchemical GlossaryDocument116 pages1 - Eklund, Jon - British Eighteenth-Century Chemical Terms - Part 1 - 2 - 3 - The Best For Learning All Alchemical GlossaryAB236Pas encore d'évaluation

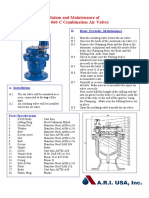

- Installation and Maintenance D-060C ARI USADocument1 pageInstallation and Maintenance D-060C ARI USAwylie01Pas encore d'évaluation

- C75C - Ck75 Steel DataDocument2 pagesC75C - Ck75 Steel DatavinibePas encore d'évaluation

- Question Paper For Snr. WeldingDocument3 pagesQuestion Paper For Snr. WeldingThulasi Ram100% (1)

- Coke Drum SpecDocument33 pagesCoke Drum SpecMahendra Rathore100% (1)

- EWC Short Profile.1Document12 pagesEWC Short Profile.1Sharookhan ShajahanPas encore d'évaluation

- Wasi Polar EngDocument5 pagesWasi Polar Engserban_elPas encore d'évaluation

- Classification of Zinc Die Casting DefectsDocument20 pagesClassification of Zinc Die Casting DefectsAnshuman RoyPas encore d'évaluation

- (India) PVT LTD: FJ5705 1/6 - SS 75 6008/I 140597101Document22 pages(India) PVT LTD: FJ5705 1/6 - SS 75 6008/I 140597101netsavy71Pas encore d'évaluation

- GALVALUMEDocument5 pagesGALVALUMEEdgarDavidDiazCamposPas encore d'évaluation

- Distortion in Weld JointDocument54 pagesDistortion in Weld JointDiVik BhargAva100% (1)

- Stainless Steel SAE J405Document14 pagesStainless Steel SAE J405Radu BurloiuPas encore d'évaluation

- API 510 Quick NotesDocument350 pagesAPI 510 Quick NotesMohammed Shakil91% (11)

- Bilder Architektur BauDocument27 pagesBilder Architektur BauChristina ChristovaPas encore d'évaluation

- Tornos Metallogenetic EvolutionDocument39 pagesTornos Metallogenetic Evolutionamandi1290Pas encore d'évaluation

- CHAPTER 9 - Lecture NotesDocument40 pagesCHAPTER 9 - Lecture NotesAlex100% (2)