Académique Documents

Professionnel Documents

Culture Documents

4 Article

Transféré par

Baru Chandrasekhar RaoTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

4 Article

Transféré par

Baru Chandrasekhar RaoDroits d'auteur :

Formats disponibles

IAJPS 2016, 3 (8), 794-803

S.N.H Pratap et al

CODEN (USA): IAJPBB

ISSN 2349-7750

ISSN: 2349-7750

INDO AMERICAN JOURNAL OF

PHARMACEUTICAL SCIENCES

Available online at: http://www.iajps.com

Research Article

LIQUISOLID COMPACT TECHNOLOGY: A NOVEL

APPROACH FOR ENHANCEMENT OF DISSOLUTION AND

BIOAVAILABILITY OF KETOPROFEN

S. N. H. Pratap*, P. Spandana, A.H.V.Siddhardha Varma

Near R&B Bungalow, Opp to RCM Church, Cantonment, Vizianagaram,

Andhra Pradesh-535003.

Abstract:

Liquid solid compact technology is a novel approach to enhance bioavailability of a BCS class II drug by

improving its solubility and dissolution rate of the drug. Liquisols are the formulations which make the solid

drug transforms into its solubilized state and further it will be converted into a free flowing powder with good

flow properties that is suitable for per-oral administration.

Ketoprofen is a BCS class II drug with poor aqueous solubility and limited its bioavailability. In the present

study, liquid solid technique is used to enhance the bioavailability of Ketoprofen.

Liquisols

of

Ketoprofen were prepared using polyethylene glycol (PEG) 400 as liquid vehicle, Avicel pH 102 as carrier and

Aerosil 200 as coating material. All the nine formulations were prepared using 30%, 40% and 50%

concentration of drug in liquid vehicle and a Carrier: Coating ratios of 10:1, 15:1, 20:1. All the formulations

were subjected for preformulation studies for drug polymer compatibility, saturation solubility studies.

The unit doses were calculated and the flow properties of the powder were estimated using Carrs index,

Hausners ratio and angle of repose. The final preparations were filled in hard gelatin capsules and subjected

for dissolution studies using pH 7.4 phosphate buffer in order to find out the optimized formula. Finally, the

optimized formula was compared with a marketed tablet to study the enhancement in bioavailability and the

results showed a quick release of drug from Liquisols.

Keywords: Ketoprofen, Liquisols, Mathematical model, liquid load factor, Solubility, Dissolution,

Bioavailability

Corresponding author:

S.N.H.Pratap,

M.Pharm, (Ph.D)

Asst. Professor,

St.Ann's college of Pharmacy,

Vizianagaram..

pratappharma2012@gmail.com.

QR code

Please cite this article in press as S. N. H. Pratap al, Liquisolid Compact Technology: A Novel Approach for

Enhancement of Dissolution and Bioavailability of Ketoprofen, Indo Am. J. P. Sci, 2016; 3(8).

www.iajps.com

Page 794

IAJPS 2016, 3 (8), 794-803

S.N.H Pratap et al

INTRODUCTION

Among the solid dosage forms tablets and capsules

are the intact formulations that have good stability

and able to deliver the drug into the

Gastrointestinal tract. Solubility is defined as a

substance that dissolves in a unit volume of a liquid

substance to form a saturated solution under

specified conditions of temperature and pressure.

Dissolution is the rate limiting step for poorly

aqueous soluble drug belonging to BCS class II

particularly for oral dosage forms [1]. In order to

overcome the rate limiting step, enhancement of

solubility is desirable. Over the period of time

several techniques like solid dispersions, molecular

complexation, micronization, lyophilization, and

microencapsulation have shown to enhance the

solubility of the water insoluble drug [2]. Among

them liquid solid compacts is one of the promising

methods to enhance the drug delivery.

Liquisolid compacts (liquisols) are the solid dosage

forms

with

acceptable

flowability

and

compressibility nature using liquid medication (that

implied oily, liquid lipophilic drug or water

insoluble solid drugs dissolved in a suitable

nonvolatile liquid solvent system)[3]. The liquid

medication is further converted into free flowing

non-adherent and readily compressible powders by

absorbing them onto carrier and coating materials.

Though the formulation looks solid, the drug will

be in solubilized and molecularly dispersed state.

Because of their intact mass flow properties may

influence the drug release however; due to the

wetting nature of solvent dissolution of the drug

increases in aqueous medium and thereby enhances

bioavailability of the drug.

Ketoprofen, a propionic acid derivative, is a

nonsteroidal anti-inflammatory drug (NSAID) with

analgesic and antipyretic properties [4]. It belongs

to biopharmaceutical classification system class II

drugs characterized by low solubility and high

permeability. Thus the rate limiting step for

bioavailability of ketoprofen is its poor solubility in

biological fluids and hence late onset of action.

In this study, Ketoprofen was selected as model

drug with poor solubility characteristics. The

flowability and compressibility of liquid solid

compacts were estimated simultaneously using

mathematical model of liquid systems which was

used to calculate amounts of carrier and coating

materials to be added based on new fundamental

powder properties called the flowable liquid

retention potential (-value).

MATERIALS AND METHODS:

Materials: The following materials were used in

the study: Ketoprofen (Yarrow Chem. Products,

Mumbai), Avicel pH 102 (Yarrow Chem. Products,

Mumbai), Aerosil 200(Otto chemi pvt.ltd.

Mumbai), Poly Ethylene Glycol 400 (Yarrow

Chem. Products, Mumbai) potassium dihydrogen

www.iajps.com

ISSN 2349-7750

phosphate, sodium hydroxide and magnesium

stearate (Qualigens fine chemicals, Mumbai).

Determination of Ketoprofen solubility [11]

Saturated solutions of Ketoprofen in various liquid

vehicles (Propylene glycol, PEG 400, Water,

Tween 80) were prepared by adding excess amount

of drug and mixed using mechanical shaker

overnight at 37 0.5C under constant vibration.

The solutions were then passed through 0.45

micron filter, diluted and analyzed for drug content

using UV spectrophotometer at 258nm.

Calibration Curve for Ketoprofen in pH 7.4

Phosphate buffer

Calibration of Ketoprofen was carried out in pH 7.4

phosphate buffer as per USP compendium [USPNF 29]. 10mg of drug was accurately weighed and

dissolved in 0.5 ml of methanol and make up to

100 ml using pH 7.4 phosphate buffer. The solution

is further diluted 10 times using phosphate buffer

to get 100g/ml. Serial dilutions of 2,4,6,8,10

g/ml were prepared with buffer and analyzed

using UV VIS spectrophotometer at max of 258

nm.

Preparation of Liquisolid Compacts using

mathematical model

Application of mathematical model for design of

liquid solid compacts

The formulations were prepared in the basis of

formulation design given by Spireas et al. [5]

In this study PEG 400 is used as non-volatile

solvent, avicel pH 102 and aerosol 200 were used

as carrier and coating materials respectively. The

drug concentrations were taken as 30%w/w,

40%w/w and 50%w/w and the carrier: coating ratio

(R) was 10:1, 15:1 and 20:1.

The excipients ratio R of powder is given by

R=Q/q ---- (1)

Where R is the ratio of carrier (Q) and coating (q)

materials present in the formulation.

Liquid loading factor (Lf) is defined as the ratio of

the weight of liquid medication over the weight of

the carrier powder in the liquisol system which

should be a free flowing system.

Lf = W/Q

----- (2)

Flowable liquid retention potential ( value) of

powder excipients was used to calculate the

required ingredients amounts.

Lf = + (1/R) ----- (3)

Where, and are the values of carrier and

coating materials respectively. Hence, to calculate

the required quantities of ingredients all the three

equations were used.

Page 795

IAJPS 2016, 3 (8), 794-803

S.N.H Pratap et al

Preparation of Conventional capsule of

Ketoprofen

A conventional capsule of Ketoprofen was

prepared using physical mixture of liquisolid

system containing 25mg of drug, 200mg of

AvicelpH 102, 10mg Aerosol 200, 5%

Croscarmellose

Sodium and 1% Magnesium

Stearate. All the ingredients were mixed thoroughly

and filled in a 00 size capsule.

Characterization of prepared Ketoprofen

Liquisols

Drug Polymer compatibility Studies (FTIR) [10]

FTIR studies of Ketoprofen and prepared

formulations were recorded for transmittance

within the range of 4000 cm-1 to 400cm1

(shimadzu, Japan FT-IR 8400 S). Samples were

prepared in KBr discs (2 mg in 200mg in KBr)

with a hydrostatic press at a force of 5 cm-2 for 5

min and the resolution was 4 cm-1. Finished

product samples of Ketoprofen Liquisols also were

analyzed for drug compatibility studies between

drug and other polymers.

Flow properties of Ketoprofen Liquisols [6]

Angle of repose ()

The frictional forces in a loose powder cab be

measured by the angle of repose. It is indicative of

flow properties of the powder. It is defined as

maximum angle possible between the surface of the

pile of power and the horizontal plane.

= tan-1(h/r) ---- (4)

Where, h is the height of the pile and r is the

radius of the pile occupied in cms. The powder

mixture was allowed to flow through the funnel

fixed to a stand at fixed height (h) and the angle of

repose was calculated measuring the height and

radius of the heap of powder.

Table 1: Standard Values for Angle of Repose

S.No.

1

2

3

4

5

6

Angle of Repose

Flow Property

Excellent

Good

Fair aid not needed

Passable may hang up

Poor must agitate,

vibrate

Very poor

Angle of

Repose()

25-30

31-35

36-40

41-45

46-55

56-65

Compressibility Index or Carrs Index

It is the simplest way to measure the free flow of

powder. It is the ease with which a material can be

induced to flow is given by the compressibility

www.iajps.com

ISSN 2349-7750

index of the granules was determined by Carrs

compressibility index I which is given by

=

------ (5)

Where, Dt is tapped density of the powder and Db is

bulk density of the powder.

Hausners Ratio [7]

Hausners ratio is an indirect index of ease of

powder flow. It is calculated by the following

formula

=

-------- (6)

Table 2: Standard Values for Carrs index and

Hausners ratio

Compressibility

Index (%)

10

11-15

16-20

21-25

26-31

32-37

38

Flow

Character

Excellent

Good

Fair

Passable

Poor

Very poor

Extremely

poor

Hausners

Ratio

1-1.11

1.12-1.18

1.19-1.25

1.26-1.34

1.35-1.45

1.46-1.59

> 1.60

Uniformity of weight

This test is performed to maintain the uniformity of

weight of each capsule which should be in the

prescribed range. 20 capsules of each type were

weighed individually using an electronic balance,

average weight was calculated and individual

weight was then compared with average value to

find out the deviation in weight.

In Vitro DisintegratingTesting [8]

The test was carried out using 6 capsules in pH 7.4

buffer using Inco tablet disintegrating tester

maintained at 37 0.5C

for all formulations

three capsuleseach. The time in seconds required

for complete disintegration of the capsule with no

palable mass remaining in the bowl was measured.

In vitro Dissolution studies [9]

The dissolution profile of prepared capsules was

studied using USP dissolution apparatus type II

(LABINDIA DS 8000, India). A volume of 900 ml

pH 7.4 phosphate buffer was used as dissolution

medium maintained at 37 0.5C and rotating

speed was set at 50rpm. 2 ml aliquots of medium

was collected and the same amount was replaced

using fresh medium at time intervals of

1,2,3,4,5,6,7,8,9,10 minutes. The collected samples

were analyzed using UV spectrophotometer

(ELICO SL-210, India). Cumulative percent drug

release was calculated using an equation obtained

from standard curve.

Page 796

IAJPS 2016, 3 (8), 794-803

S.N.H Pratap et al

RESULTS AND DISCUSSION:

Solubility Studies of Ketoprofen in various

solvents [12]

Selection of non volatile solvent is the prerequisite

step for the drug as it will enhance the solubility of

the drug. The solubility of Ketoprofen in PEG 400

was found to be 3450 mg/ml which is very much

higher than in water, propylene glycol and Tween

80 as were represented in the table 3. Hence, PEG

400 was selected as solvent.

Table 3: Solubility of Ketoprofen in various

solvents

S.NO.

1

2

3

4

SOLVENTS

Preparative procedure for ketoprofen LSC

using mathematical design [13]

The mathematical model equation for Avicel pH

102 and Aerosil 200 in PEG 400 can be given

according to the and values as given by spireas

et al., [5] as follows:

Lf = 0.005 + 3.26 (1/R) ----- (3)

SOLUBILITY

Water

Polyethylene glycol400

Propylene glycol

Tween-80

3.56mg/ml

3450 mg/ml

ISSN 2349-7750

The

1125 mg/ml

1350 mg/ml

Based on this equation liquid loading factor was

calculated followed by calculating W and finally

carrier and coating amounts were computed. The

final unit dose was calculated including

disintegrant and anti adherent.

Liquisols of ketoprofen were prepared as

represented in table no. 4.

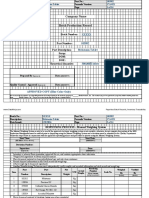

Table 4: Composition of Ketoprofen Liquisolid formulas prepared according to mathematical model (All

Liquisolid formulas contain 25 mg of Ketoprofen)

Liquid

solid

system

Drug conc.

In liquid

medication

(%w/w)

Carrier:

Coating

ratio (R)

Liquid

load

factor

(Lf)

Liquid

vehicle

(mg)

PEG

400

Carrier

Q (mg)

Avicel

pH 102

Coating

(mg)

Aerosil

200

Disintegrant

Croscarmellos

e sodium (mg)

Lubricant

Mag.

Stearate

Unit

Dose

(mg)

LSC-1

30

10

0.331

58.33

176.22

17.62

14.55

2.91

291.

72

LSC-2

30

15

0.222

58.33

262.74

17.51

19.08

3.91

382.

66

LSC-3

30

20

0.168

58.33

347.20

17.36

23.54

4.80

472.

04

LSC-4

40

10

0.331

37.5

82.32

8.23

7.57

1.5

152

LSC-5

40

15

0.222

37.5

122.74

8.18

10.75

2.15

203.

6

LSC-6

40

20

0.168

37.5

162.20

8.11

11.64

2.4

225

LSC-7

50

10

0.331

25

75.52

7.55

7.05

1.4

140.

12

LSC-8

50

15

0.222

25

112.61

7.5

9.01

1.8

182.

11

LSC-9

50

20

0.168

25

148.8

7.44

10.93

2.18

219.

35

www.iajps.com

Page 797

IAJPS 2016, 3 (8), 794-803

S.N.H Pratap et al

ISSN 2349-7750

carboxylic acid, a weak peak at 1443.31 cm-1 CH

deformation of CH asymmetrical, 1370.55 cm for

CH deformation of CH symmetrical. All these

peaks of pure Ketoprofen were present in the FTIR

graphs of Liquisol products indicating no

interaction take place in between drug and

excipients.

4000

3000

2000

1500

1076.77

1028.55

966.37

863.94

827.51

809.95

786.07

716.11

695.15

641.19

612.10

1696.50

1653.79

1600.38

1576.74

1477.78

1443.31

1417.57

1370.55

1284.43

1225.90

1174.37

1911.88

2500

1827.23

2536.49

2731.16

2624.39

3055.00

3500

2977.97

2937.79

2876.10

3451.87

3750.90

20

Transmittance [%]

60

40

80

100

Drug Polymer Compatibility studies: FTIR

Graphs [10]

The FTIR spectrum of pure ketoprofen shows a

weak peak at 2977.97-2937.79 cm-1 due to the

presence Aromatic C-H stretch. It shows

characteristic peak at 1653.79 cm-1 for C=O stretch

of keto group and 1696.50 cm-1 for C=O stretch of

1000

W avenumber cm-1

C:\Program Files\OPUS_65\MEAS\.413

PURE DRUG

04/04/2016

Page 1/1

4000

3500

3000

2500

1697.05

1655.32

1619.95

1574.36

1554.83

1536.62

1518.26

1503.11

1476.71

1440.19

1413.20

1371.24

1317.37

1284.46

1161.58

1076.94

898.68

866.79

809.54

786.84

716.52

703.28

692.14

672.39

642.45

614.75

2130.48

2360.88

2900.37

3347.97

3441.93

3859.97

3849.65

3834.29

3747.37

20

Transmittance [%]

60

40

80

100

Fig1: FTIR graph for pure drug Ketoprofen

2000

1500

1000

W avenumber cm-1

C:\Program Files\OPUS_65\MEAS\.412

F-1

04/04/2016

Page 1/1

4000

3500

3000

2500

2000

1500

642.56

722.26

806.02

955.34

1161.94

1087.37

1728.91

1656.52

1614.08

1552.01

1520.06

1475.53

1441.73

1377.20

1353.84

1286.64

2359.41

2914.25

3350.94

3437.52

20

Transmittance [%]

60

40

80

100

Fig 2: FTIR graph for formulation LSC 2

1000

W avenumber cm-1

C:\Program Files\OPUS_65\MEAS\.414

F-2

04/04/2016

Page 1/1

Fig 3: FTIR graph for formulation LSC 3

www.iajps.com

Page 798

IAJPS 2016, 3 (8), 794-803

S.N.H Pratap et al

ISSN 2349-7750

Calibration curve for Ketoprofen in pH 7.4 Buffer [14].

Table 5: Calibration data for Ketoprofen in pH 7.4 buffer.

S.NO

CONCENTRATION

(g/ml)

0

2

4

6

8

10

1

2

3

4

5

6

0

0.1045

0.236

0.3579

0.445

0.5903

CALIBRATION CURVE FOR KETOPROFEN IN

pH 7.4 PHOSPHATE BUFFER @ 258nm

0.7

0.6

0.5

ABSORBANCE

ABSORBANCE

y = 0.0585x - 0.0035

R = 0.9971

0.4

0.3

0.2

0.1

0

-0.1

10

12

CONCENTRATION (MCG/ML)

Fig 4: Calibration curve for Ketoprofen in pH 7.4 buffer at 258 nm

Evaluation studies:

Flow properties of Ketoprofen Liquisols

All the formulations were subjected to test for bulk

density and tapped density, the values were used to

compute Hausners ratio and Carrs index which

indicate interparticulate friction. Except LSC 5 &8

all the formulations showed good flow and LSC-5

&8 showed moderate flow. The angle of repose

indicates friction and resistance between particles.

The angle of repose for all the formulation blends

were within the range of 27.5-31.4 indicating that

all the formulations showed excellent to good flow.

The moderate flow in the powder blend might be

due to the wetting of non volatile liquid and

hydrophilic carrier.

Table 6: Flow Properties of prepared liquisolid compacts

S.No.

LSC-1

LSC-2

LSC-3

LSC-4

LSC-5

LSC-6

LSC-7

LSC-8

LSC-9

www.iajps.com

Angle of Repose

(Avg. of n=3)

27.5

30.45

29.5

27.9

31.3

29.9

30.9

31.4

29.6

Hausners Ratio

(Avg of n=3)

1.21

1.19

1.20

1.26

1.33

1.28

1.18

1.33

1.32

Carrs Index

(Avg of n=3)

21.5

24.5

22.3

23.78

22.3

24

20.38

25

24.24

Page 799

IAJPS 2016, 3 (8), 794-803

S.N.H Pratap et al

ISSN 2349-7750

weight variation studies were conducted for all unit

doses according to Indian pharmacopoeia and all

the results indicate within their limits.

The drug content for all the formulations were

performed in pH 7.4 phosphate buffer and all the

formulations showed an average content of 85% to

98.39% indicating that uniform mixing and

homogenous distribution of drug throughout the

batches.

Evaluation of finished dosage form

Liquisols of Ketoprofen were studied for various

parameters like weight variation, disintegration and

drug content. The values were reported in table no.

6. The disintegration time was found between 26

40 sec. it was observed that there is a direct

relationship between amount of carrier added and

disintegration time. As the amount of carrier

increase, disintegration time decreased in

formulations LSC-3, LSC-6 and LSC-9. The

Table 7: Evaluation studies of Ketoprofen liquisol capsules

S.No.

Formulation code

Disintegration

Weight variation

time (sec)

(mg)

% Drug content

LSC-1

352.5

287.51.18

94.451.77

LSC-2

302.09

3782.64

87.402.55

LSC-3

263.78

470.51.56

90.682.50

LSC-4

375.85

147.31.33

97.243.08

LSC-5

351.52

200.51.56

92.491.32

LSC-6

291.52

240.161.91

85.273.0

LSC-7

402.08

138.91.54

98.391.95

LSC-8

392.08

180.311.15

94.132.25

LSC-9

302

2102.64

91.502.58

Table 8: in-vitro studies of Ketoprofen capsules for various formulations

S.No.

Time

(min)

% Drug Release

LSC-1

0

LSC-2

0

LSC-3

0

LSC-4

0

LSC-5

0

LSC-6

0

LSC-7

0

LSC-8

0

LSC-9

0

30.98

2.09

8.852

2.05

64.64

2.55

42.049

2.51

10.09

2.05

64.25

2.51

2.951

1.52

4.426

1.51

30.486

2.09

52.377

1.91

61.967

2.41

62.705

1.51

64.918

1.61

75.246

2.31

80.410

2.55

81.885

2.11

85.574

1.96

26..48

2.00

55.37

2.55

61.54

1.63

78.50

1.85

79.99

2.31

81.59

1.7

86.16

2.11

97.06

2.5

68.625

2.43

73.25

1.43

90.46

1.68

91.18

1.31

95.48

1.92

99.11

2.11

-

36.88

2.50

42.78

2.61

45

2.11

48.68

1.52

64.91

2.51

75.24

3.00

92.21

1.55

95.90

2.51

86.17

2.11

93.22

1.51

93.65

1.41

94.07

2.50

98.55

1.09

100.21

1.71

-

10

55.32

2.50

76.75

.3.1

78.125

1.63

82.25

2.75

83.875

1.91

85.5

2.11

90.625

2.03

96.375

2.72

7.525

1.68

10.475

2.51

14.016

2.55

37.033

1.95

52.377

2.11

75.984

2.34

83.951

1.52

85.279

1.61

8.705

2.34

52.52

1.85

60.93

1.61

80.705

2.43

83.501

2.23

85.728

1.54

92.803

1.68

95.148

2.21

59.790

1.61

70.152

1.23

85.16

1.51

89.46

1.98

96.186

1.68

98.670

2.49

99.154

2.55

-

11

10

99.715

1.68

100.39

1.22

89.262

1.81

90.738

1.25

99.12

1.65

www.iajps.com

Page 800

IAJPS 2016, 3 (8), 794-803

S.N.H Pratap et al

compared with conventional capsule, marketed

tablet and pure drug as shown in the figure 9. It can

be seen clearly that the optimized preparation LSC

3 released the drug within 8 minutes which is

markedly higher than marketed tablet and

conventional capsule.

In vitro dissolution study

In vitro drug release studies were performed in

phosphate buffer pH 7.4 for all the prepared

formulations using USP I apparatus, rotating basket

method. The values for all the formulations are

reported in table no 7 and the graphs are shown in

figure 5.

The release rate of the drug from all the

formulations was proportional to amount of liquid

loaded within the compacts i.e., the drug release is

greater for 30% drug concentration than that of

40% and 50% concentrations.

It was observed that drug release was also

depending on amount of carrier added. As the

carrier to coat ratio increases as shown in the

figures 6-8, the amount of Avicel pH 102 added

increased and wetting of the compact increased and

eventually drug was released quickly[15].

Based on the release rates, optimized formulation

was selected as LSC 3 and the release rate was

Optimized Formulation

LSC-3

Angle of repose

29.5

Hausners ratio

1.17

Carrs index

20.3

Weight variation

470.51.56

Drug content

90.682.50

Disintegrating Time

263.78 sec

T100%

7 minutes

Comparitive In-vitro release of all Liquisol formulations

120

Cumulative % Drug release

ISSN 2349-7750

100

LSC 1

80

LSC 2

60

LSC 3

LSC 4

40

LSC 5

20

LSC 6

0

0

6 min

Time in

10

LSC 7

12

Fig 5: Comparative In-Vitro release of all Liquisolid formulations

CUMULATIVE %DRUG RELEASE

In Vitro drug release of liquisols with carrier:coating of 10:1

120

100

80

60

LSC 1

40

LSC 4

20

LSC 7

0

0

10

12

time in min

Fig 6: In Vitro drug release of Liquisols with carrier: coating of 10:1

www.iajps.com

Page 801

IAJPS 2016, 3 (8), 794-803

S.N.H Pratap et al

ISSN 2349-7750

In Vitro drug release of liquisols with carrier:coating of 15:1

CUMULATIVE %DRUG RELEASE

120

100

80

60

LSC 2

40

LSC 5

20

LSC 8

0

0

10

12

time in min

Fig 7: In Vitro drug release of Liquisols with carrier: coating of 15:1

CUMULATIVE %DRUG RELEASE

In Vitro drug release of liquisols with carrier:coating of 20:1

120

100

80

60

LSC 3

40

LSC 6

20

LSC 9

0

0

time in min

Fig 8: In Vitro drug release of Liquisols with carrier: coating of 20:1

cummulative %drug release

120

Dissolution Profile of Ketoprofen

100

80

60

pure drug

40

conventional capsule

20

ketofen marketed tablet

optimized formula

0

0

10

20

30

40

50

60

70

Time in min

Fig 9: Comparative In Vitro release studies of prepared liquisol with marketed product

www.iajps.com

Page 802

IAJPS 2016, 3 (8), 794-803

S.N.H Pratap et al

CONCLUSION:

Liquisolid compacts of Ketoprofen was prepared

using 30%, 40% and 50% drug concentrations

with carrier to coat ratios of 10:1, 15:1 and 20:1.

The flow properties and the in vitro release for all

the formulation studies revealed that 30% drug

concentration with Excipient ratio of 20 is the

best formulation, in terms of good flow and rapid

release of drug from dosage form. It can also be

concluded that the drug release is directly

proportional to Excipient ratio and inversely

proportional to drug concentration in liquid

vehicle.

The increase in drug release from all the

formulation is because the drug in liquid vehicle

dispersed in molecular level and the surface area

for dissolution is increased by addition of

hydrophilic carrier. Therefore, liquid solid

technique provides a promising delivery for fast

release of poorly aqueous soluble drugs.

REFERENCES:

1.Amjad khan, zafar Iqbal, Yasae Shah et. al.,

Enhancement of dissolution rate of class II drug

(Hydrochlorothiazide); a comparative study of the

two novel approaches; solid dispersion and liquisolid techniques. Saudi Pharmaceutical Journal.

23: 650-657

2.Dhiya R. Joda Altememy, Jaafar Jabir

Altememy (2014) Formulation and evaluation of

meloxicam liquisolid compact. Int. J. Pharm. &

Pharm. Sci. 6: 453-463

3.Naveen Chella, Nalini Shastri, Rama rao

Tadikonda Use of the liquid solid compact

technique for improvement of the dissolution rate

of valsartan. Acta Pharmaceutica Sinica B 2: 502508

4.Nassim Belkacem et al., (2015) Effect of

ultrasound on the physicochemical properties of

poorly

soluble

drugs:

Antisolvent

sonocrystallization of Ketoprofen. Pharm. Par.

Tech. 285:16-24

www.iajps.com

ISSN 2349-7750

5.Spireas S. (2002) Liquisolid systems and

methods of preparing same. United State Patent

6423, 339 B1.

6.Liao C. C. (1983) physicochemical properties

of selected powder drug solutions, New York: 95176. [Ph.D. Thesis. St. Johns University].

7.Shashidher Burra, Madhusudhanarao Yamsani,

Venhateswarlu Vobalaboina the Liquisolid

technique: an overview. Braz. J. Phar. Sci. 47:

475-482

8.Abdou M. In: HM Abdou (Ed.). (1989)

Dissolution, bioavailability and bioequivalence.

Easton, Mack Pub Co, PA; 53-72.

9.Rania H. F, Kassem M.A. (2008) enhancement

of famotidine dissolution rate through liquisolid

tablets formulation and in vitro and in vivo

evaluation. Eur.J. Pharm. Biopham 69: 993-1003

10.G Vijayaranga Vittal, R Deveswaran et al.,

(2012) Formulation and characterization of

Ketoprofen Liquisolid compacts by Box Behnken

Design. Int. J. Pharm. Investig. 2: 150-156

11.Vijaykumar Nagabandi, Ramarao Tadikonda

and K.N.Jayaveera (2011) Enhancement of

dissolution rate and micromeritics of poorly

soluble drug ketoprofen by liquidsolid technique.

J. Pharm & Biomed. Sci. 9: 1-6

12.P.V. Kamalakumari, M. TrinadhaRao et al.,

(2015) Formulation and evaluation of ketoprofen

by liquid solid compact method. Int. J. Pharm.

Sci. Rev. Res. 33: 45-49

13.Spireas S, Sadu S, Grover R. (1998) In vitro

release and evaluation of hydrocortisone

liquisolid tablets. J. Pharm. Sci. 87: 867-872

14.Abid Hussain, Gul Majid Khan, Shefaat Ullah

Shah et. al., development of a novel Ketoprofen

transdermal patch: Effect of almond oil as

penetration enhancers on in-vitro and ex-vivo

penetration of Ketoprofen through rabbit skin.

Pak. J. Pharm. Sci. 25: 227-232.

15.Mays A. Al-Sarraf et al., (2014). Dissolution

enhancement of Telmisartan by liquisolid

compacts. International Journal of Pharmacy and

Pharmaceutical Sciences. Vol 6: 743-749

Page 803

Vous aimerez peut-être aussi

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Assessment of Correlation Between Physical Activity and Academic Performance Among The Students of Gujranwala Medical College, GujranwalaDocument7 pagesAssessment of Correlation Between Physical Activity and Academic Performance Among The Students of Gujranwala Medical College, GujranwalaBaru Chandrasekhar RaoPas encore d'évaluation

- Pharmaceutical Process Validation - Nash Wachter PDFDocument904 pagesPharmaceutical Process Validation - Nash Wachter PDFSkuukzky baePas encore d'évaluation

- Types of Dosage FormsDocument92 pagesTypes of Dosage Formsneha_dand1591Pas encore d'évaluation

- GranulationDocument32 pagesGranulationSantosh Payghan100% (1)

- TabletDocument37 pagesTabletPranjul ShrivastavaPas encore d'évaluation

- Assignment1-UnaniMedicine Dosage LabellingDocument12 pagesAssignment1-UnaniMedicine Dosage LabellingFarhat JahanPas encore d'évaluation

- Dow Home Care SolutionsDocument25 pagesDow Home Care SolutionsChemist Technologist100% (1)

- The Role of Clinical Pharmacist in Pharmacovigilance and Drug Safety in Teritiary Care Teaching HospitalDocument11 pagesThe Role of Clinical Pharmacist in Pharmacovigilance and Drug Safety in Teritiary Care Teaching HospitalBaru Chandrasekhar RaoPas encore d'évaluation

- Zinc Oxide PasteDocument9 pagesZinc Oxide Pastekriss Wong100% (1)

- Internship Report of Pharmaceutical IndustryDocument39 pagesInternship Report of Pharmaceutical IndustryAhmad HassanPas encore d'évaluation

- Pharmaceutical Industrial Training ReportDocument58 pagesPharmaceutical Industrial Training ReportRajat Rastogi 143Pas encore d'évaluation

- Genetic Enhancment of Groundnut (Arachis Hypogaea L.) Through Induced Muiation.Document5 pagesGenetic Enhancment of Groundnut (Arachis Hypogaea L.) Through Induced Muiation.Baru Chandrasekhar RaoPas encore d'évaluation

- Development and Validation of Stability Indicating Assay Method For Estimation of Teriflunomide in Tablet Dosage FormDocument11 pagesDevelopment and Validation of Stability Indicating Assay Method For Estimation of Teriflunomide in Tablet Dosage FormBaru Chandrasekhar RaoPas encore d'évaluation

- Formulation, Optimization and Evaluation Colon Targated Drug Delivery System For OrniadazoleDocument9 pagesFormulation, Optimization and Evaluation Colon Targated Drug Delivery System For OrniadazoleBaru Chandrasekhar RaoPas encore d'évaluation

- Development of Cell Culture System From Selected Tissues of Pangaius HypopthalmusDocument6 pagesDevelopment of Cell Culture System From Selected Tissues of Pangaius HypopthalmusBaru Chandrasekhar RaoPas encore d'évaluation

- Analytical Method Development and Validation of Stability Indicating RP-HPLC Method For Estimation of Lercanidipine Hydrochloride and Enalapril Maleate in CombinationDocument8 pagesAnalytical Method Development and Validation of Stability Indicating RP-HPLC Method For Estimation of Lercanidipine Hydrochloride and Enalapril Maleate in CombinationBaru Chandrasekhar RaoPas encore d'évaluation

- Knowledge On Antibiotics Use and Its Storage Among Saudi Arabia Residents: A Cross Sectional StudyDocument8 pagesKnowledge On Antibiotics Use and Its Storage Among Saudi Arabia Residents: A Cross Sectional StudyBaru Chandrasekhar RaoPas encore d'évaluation

- Simultaneous Estimation of Rosuvastatin Calcium and Ezetimibe As Bulk Drug and in Tablet Dosage Form by RP-HPLC MethodDocument6 pagesSimultaneous Estimation of Rosuvastatin Calcium and Ezetimibe As Bulk Drug and in Tablet Dosage Form by RP-HPLC MethodBaru Chandrasekhar RaoPas encore d'évaluation

- Review On: Inventory ManagementDocument8 pagesReview On: Inventory ManagementBaru Chandrasekhar RaoPas encore d'évaluation

- Association of Socioeconomic Status, Hypertension and Treatment Modality With Diabetic Amputation - A Case Control StudyDocument4 pagesAssociation of Socioeconomic Status, Hypertension and Treatment Modality With Diabetic Amputation - A Case Control StudyBaru Chandrasekhar RaoPas encore d'évaluation

- Preparation of Silver Nanoparticles From Herbal PlantDocument9 pagesPreparation of Silver Nanoparticles From Herbal PlantBaru Chandrasekhar RaoPas encore d'évaluation

- Non-Adherence in Hyppertensive Patients of Peshawar, PakistanDocument13 pagesNon-Adherence in Hyppertensive Patients of Peshawar, PakistanBaru Chandrasekhar RaoPas encore d'évaluation

- A Brief Review On YawsDocument7 pagesA Brief Review On YawsBaru Chandrasekhar RaoPas encore d'évaluation

- Gastroprotective Activity of Methanolic Extract of Phyllanthus Acidus Fruit Against Indomethacin-Induced Gastric Ulcers in RatsDocument7 pagesGastroprotective Activity of Methanolic Extract of Phyllanthus Acidus Fruit Against Indomethacin-Induced Gastric Ulcers in RatsBaru Chandrasekhar RaoPas encore d'évaluation

- The Bordering Areas (Nine Areas of Panjgur District) Issue of Pakistan About Human Malaria Prevalence: A Cross-Sectional Research of Malaria Parasites Identification in Blood SlidesDocument8 pagesThe Bordering Areas (Nine Areas of Panjgur District) Issue of Pakistan About Human Malaria Prevalence: A Cross-Sectional Research of Malaria Parasites Identification in Blood SlidesBaru Chandrasekhar RaoPas encore d'évaluation

- Nephroprotective Activityof Acorus Calamus Leaves Extract Against Lithium Induced Nephrotoxicity in Wistar RatsDocument12 pagesNephroprotective Activityof Acorus Calamus Leaves Extract Against Lithium Induced Nephrotoxicity in Wistar RatsBaru Chandrasekhar RaoPas encore d'évaluation

- Role of Simvastatin in Addition To Metformin in Polycystic Ovarian Syndrome Patients, A Randomized Controlled Trial On Pakistani WomenDocument4 pagesRole of Simvastatin in Addition To Metformin in Polycystic Ovarian Syndrome Patients, A Randomized Controlled Trial On Pakistani WomenBaru Chandrasekhar RaoPas encore d'évaluation

- An Incidence of Hypertension Among People and Its Association To Consumption of Hard Water: A Cross-Sectional ResearchDocument6 pagesAn Incidence of Hypertension Among People and Its Association To Consumption of Hard Water: A Cross-Sectional ResearchBaru Chandrasekhar RaoPas encore d'évaluation

- Pharmaceutical Sciences: IAJPS 2018, 05 (04), 3075-3081 Aneeqa Ali RaoDocument7 pagesPharmaceutical Sciences: IAJPS 2018, 05 (04), 3075-3081 Aneeqa Ali RaoBaru Chandrasekhar RaoPas encore d'évaluation

- Relationship of Testosterone With Body Mass Index in Infertile Males in Local CommunityDocument4 pagesRelationship of Testosterone With Body Mass Index in Infertile Males in Local CommunityBaru Chandrasekhar RaoPas encore d'évaluation

- An Exploratory Review of The Myths and Common Beliefs About Acne and Its TreatmentDocument6 pagesAn Exploratory Review of The Myths and Common Beliefs About Acne and Its TreatmentBaru Chandrasekhar RaoPas encore d'évaluation

- Descriptive Study Knowing The Patients Load in The Neonatal Icu at The Tertiary Care Hospital LahoreDocument4 pagesDescriptive Study Knowing The Patients Load in The Neonatal Icu at The Tertiary Care Hospital LahoreBaru Chandrasekhar RaoPas encore d'évaluation

- C-Reactive Protein Levels Preoperatively and Postoperatively Effect On Cardiovascular Surgery ComplicationsDocument5 pagesC-Reactive Protein Levels Preoperatively and Postoperatively Effect On Cardiovascular Surgery ComplicationsBaru Chandrasekhar RaoPas encore d'évaluation

- A Cross Sectional Survey Information About Weaning Process Among Mothers of Infants Above 6 Months of Age in Opd Pediatrics at Kishwer Fazal Teaching Hospital LahoreDocument8 pagesA Cross Sectional Survey Information About Weaning Process Among Mothers of Infants Above 6 Months of Age in Opd Pediatrics at Kishwer Fazal Teaching Hospital LahoreBaru Chandrasekhar RaoPas encore d'évaluation

- Study of Clinical Profile of Transfused Thalassemic Childrens With Special Reference To Hepatitis B Profile and Liver Function.Document6 pagesStudy of Clinical Profile of Transfused Thalassemic Childrens With Special Reference To Hepatitis B Profile and Liver Function.Baru Chandrasekhar RaoPas encore d'évaluation

- Isolation and Identification of Clostridium Perfringens Causing Enterotoxaemia in Bovine of Kacchi District Balochistan.Document8 pagesIsolation and Identification of Clostridium Perfringens Causing Enterotoxaemia in Bovine of Kacchi District Balochistan.Baru Chandrasekhar RaoPas encore d'évaluation

- An Epidemiological Survey About The Infections Caused by Dengue in The Perspective of Hematological, Clinical and Demographic Risk FactorsDocument6 pagesAn Epidemiological Survey About The Infections Caused by Dengue in The Perspective of Hematological, Clinical and Demographic Risk FactorsBaru Chandrasekhar RaoPas encore d'évaluation

- After Acute Myocardial Infarction End Result of Cardiogenic Shock in Hospitalized PatientsDocument4 pagesAfter Acute Myocardial Infarction End Result of Cardiogenic Shock in Hospitalized PatientsBaru Chandrasekhar RaoPas encore d'évaluation

- Oppertunistic Hypertension Screening in Rural Health Population of Umar Abad Tehsil Kharezat Disrtrict Pishin Balochistan. A Cross Sectional StudyDocument10 pagesOppertunistic Hypertension Screening in Rural Health Population of Umar Abad Tehsil Kharezat Disrtrict Pishin Balochistan. A Cross Sectional StudyBaru Chandrasekhar RaoPas encore d'évaluation

- Philippine Variation Guidelines V.1.0 With Fees and ChargesDocument83 pagesPhilippine Variation Guidelines V.1.0 With Fees and Chargesultimate_2226252Pas encore d'évaluation

- Nhis Medicines Price List (2021 Ed)Document47 pagesNhis Medicines Price List (2021 Ed)E.P.O0% (1)

- Course Structure of D.pharmDocument81 pagesCourse Structure of D.pharmRajesh GuptaPas encore d'évaluation

- Jacobus Pharmaceutical Company Inc. Plainsboro NJ EIR For Inspection Conducted 3 28 2012 4 16 2012Document38 pagesJacobus Pharmaceutical Company Inc. Plainsboro NJ EIR For Inspection Conducted 3 28 2012 4 16 2012vinayPas encore d'évaluation

- TABlet PDFDocument39 pagesTABlet PDFRania HamamPas encore d'évaluation

- Tablet Tooling: Advantages of Standard ToolingDocument11 pagesTablet Tooling: Advantages of Standard ToolingByunghoon LeePas encore d'évaluation

- Namibia Current Medicines RegisterDocument382 pagesNamibia Current Medicines RegisterportosinPas encore d'évaluation

- Baclofen 2007Document3 pagesBaclofen 2007panda louis100% (1)

- PHA17-1008 - Ferronyl - Iron - Supplement SellSheet - A4 - 050418 - A4 - DigitalDocument4 pagesPHA17-1008 - Ferronyl - Iron - Supplement SellSheet - A4 - 050418 - A4 - DigitalBrolie BarsebaPas encore d'évaluation

- Pravin B. Awate (M. Pharm Pharmaceutics) Assistant Professor Rdcop, BhorDocument27 pagesPravin B. Awate (M. Pharm Pharmaceutics) Assistant Professor Rdcop, BhorPravin AwatePas encore d'évaluation

- Jchps 6 (4) 15 Page 286-292 MsreddyDocument7 pagesJchps 6 (4) 15 Page 286-292 MsreddydwahyusafriPas encore d'évaluation

- Cleaning Validation PDFDocument27 pagesCleaning Validation PDFRifaat AlarakiPas encore d'évaluation

- Floris - Company PresentationDocument23 pagesFloris - Company PresentationmvbPas encore d'évaluation

- Scale - Up of Film Coating ProcessDocument17 pagesScale - Up of Film Coating ProcessshrikantmsdPas encore d'évaluation

- Rhodia Pharma Flyers 2 enDocument8 pagesRhodia Pharma Flyers 2 enTuePas encore d'évaluation

- Pharmaceutical AnalysisDocument73 pagesPharmaceutical AnalysisChristinaPas encore d'évaluation

- Formulation Development and Evaluation of Orodispersible Tablet of Cinnarizine Solid DispersionDocument16 pagesFormulation Development and Evaluation of Orodispersible Tablet of Cinnarizine Solid DispersionBaru Chandrasekhar RaoPas encore d'évaluation

- Progressive Price ListDocument21 pagesProgressive Price ListJhasper ManagyoPas encore d'évaluation

- Bosch Academy Training Program 2019 enDocument48 pagesBosch Academy Training Program 2019 enDeparted MoonPas encore d'évaluation

- Tablet BPR Template With SPCDocument14 pagesTablet BPR Template With SPCvikram chhabraPas encore d'évaluation

- Pharmatest 41-03000 - PTGS3 - 09.1.0EDocument6 pagesPharmatest 41-03000 - PTGS3 - 09.1.0EDavid SRPas encore d'évaluation