Académique Documents

Professionnel Documents

Culture Documents

Test Criteria For MV Cables PDF

Transféré par

Mohamad Aboelsoud HessenTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Test Criteria For MV Cables PDF

Transféré par

Mohamad Aboelsoud HessenDroits d'auteur :

Formats disponibles

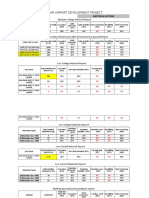

CABLE DESIGN, MATERIAL AND

PROCESSING

SCHEDULE OF TESTS - MEDIUM VOLTAGE CABLES

Test

1 Conductor

Conductor examination and

electrical resistance

2 Conductor screen

(a) Volume resistivity of

extruded screen

Criteria

Category of test

The Conductor form, material and resistance shall

comply with appropriate requirements of IEC 228.

Routine

Max.volume resistivity at 90 + 2oC: 500 .m

Type

(b) Thickness of extruded

Screen

Minimum thickness at any point: 0.3 mm or as

specified and as appropriate.

Special

(c) Elongation at rupture on

Laboratory prepared

sample of extruded

material, after ageing in

an air oven

After 168 h at 100 + 3oC, minimum elongation at

rupture: 100%

Type

Any projections or irregularities at the conductor

screen/insulation interface, shall not protrude more

than 0.25 mm into the insulation.

Special

The minimum average thickness and the minimum

thickness at any point, shall comply with the

requirements and as appropriate.

After 1 h at 130 + 3oC, maximum shrinkage: 4%

Special

(d) Projection or

irregularities

at conductor screen/

insulation interface

3 Insulation

(a) Thickness

(b) Shrinkage

(c) Determination of

(i) size of voids;

(ii) size of contaminants

iii) size of discoloured

translucents, XLPE

only;

(iv) number of voids;

and

(v) number of

contaminants

Voids: < 0.08 mm

Contaminants: < 0.15 mm

Special

Special

Discoloured translucents: < 1.25 mm

Voids: < 30 per 16 cm3

Contaminants: < 15 per 16 cm3

(d) Mechanical tests without

ageing:

(i) Tensile strength

Type

Minimum tensile strength: 12.5 N/mm2

(ii) Elongation

(e) Mechamical tests after

ageing in an air oven:

(i) Tensile strength

(ii) Elongation

Minimum elongation at rupture: 200%

After 168 h at 135 + 3oC, minimum percentage of

values found in the unaged specimens:

XLPE: 75

XLPE: 75

PDF created with pdfFactory Pro trial version www.pdffactory.com

Type

CABLE DESIGN, MATERIAL AND

PROCESSING

Test

(f) Hot set test:

Duration

Temperature

Load:

(i) Elongation under load

(ii) Residual elongation

after cooling

(g) Insulation resistance

4 Insulation screen

(a) Volume resistivity of

extruded screen

(b) Strippable of handstrippable extruded screen

(c) Adhesion of hand

strippable extruded screen

(d) Thickness

5 Individual or collective

screen

(a) Diameter of wires

(b) Cross-sectional area

6 Separation and non-metallic

sheath

(a) Thickness

(b) Mechanical tests without

ageing:

(i) Tensile strength

(ii) Elongation

Criteria

15 min

XLPE: 200 + 3oC

Category of test

Special

20 N/mm2

Maximum:175%

Maximum 15%

Minimum insulation resistance constant (ki)

at 20oC XLPE: 40 000 G.m

at 90oC XLPE: 40 G.m

Type

Maximum volume resistivity at 90 + 2oC: 500 .m

Type

Semiconductive material shall peel cleanly from

insulation for 300 mm without tearing

Special

Required force to remove 10 mm wide strips shall

be 4 to 45 N

The screen shall be removable without damaging

the insulation, leaving no semiconductive material

which cannot be readily removed

Special

As specified and as appropriate

As specified and as appropriate

Special

Special

As specified and as appropriate

Special

The minimum average thickness, and the minimum

thickness at any point, shall comply with the

requirements and as appropriate

Special

Type

Minimum tensile strength:

PVC: 12.5 MPa

HDPE: 22.0 MPa

Minimum elongation at rupture:

PVC: 150%

HDPE: 400%

PDF created with pdfFactory Pro trial version www.pdffactory.com

CABLE DESIGN, MATERIAL AND

PROCESSING

Test

(c) Mechanical tests after

ageing in an air oven:

(i)Tensile strength, PVC

only.

(ii) Elongation

(d) Loss of mass, PVC only

Criteria

Category of test

Type

After 168 h at 100 + 2oC, minimum 75% of the

value found in an unaged specimen

PVC: After 168 h at 100 + 2oC, minimum 75% of

the value found in an unaged specimen

HDPE: After 336 h at 110 + 3oC, min 300%

The median loss of mass related to specimen

surface: maximum 1.5 mg/cm2

Type

(e) Pressure test at elevated

temperature, PVC only

Maximum indentation at 90 + 2oC: 50%

Type

(f) Heat shock, PVC only

The sheath shall show no signs of cracking or

flaking either when initially wound on the mandrel

or after the test

Special

(g) Melt flow index, HDPE

only

Maximum 0.4 g/600 s

Type

(h) Environmental stress crack

resistance, HDPE only, on

specimens 1.75 2.00 mm

thickness, with notch

depth of 0.30-0.40 mm

After 250 h immersion in the reagent, there shall

be no sign of failure in any of the 10 specimens

Type

(i) Carbon black content,

HDPE only

(j) Compatibility test for

PVC/HDPE combination only

7 Metal sheath thickness

Minimum carbon black 2%

Type

Under consideration

Type

The minimum average thickness, and the minimum

thickness at any point, shall comply with specified

requirements and as appropriate.

The nominal diameter of armour wires shall comply

with the requirements and as appropriate

Special

The magnitude of discharge shall not exceed 10pC

Routine

No breakdown of the insulation shall occur

Routine

No breakdown of the sheath shall occur, when

applying 3.5 kV between the adjacent metallic

layers separated by the sheath

Routine

8 Armour wire diameter

9 Cable

(a) Partial distance test (See

Note 1)

(b) High voltage a.c. test for

5 min.

(c) High voltage a.c. test for

1 min, on separation

sheath

PDF created with pdfFactory Pro trial version www.pdffactory.com

Special

CABLE DESIGN, MATERIAL AND

PROCESSING

Test

Criteria

Category of test

(d) Partial discharge test

after bending

The magnitude of discharge shall not exceed 5 pC.

Type

(e) DDF (tan )

measurement as a

function of the voltage at

ambient temperature

Maximum tan at Uo:

XLPE insulated cable: 40 x 10-4

Maximum increment of tan between 0.5 and

2 Uo: 20 x 10-4

Type

(f) DDF (tan )

measurement as a

function of the

temperature at 2 kV a.c.

Maximum tan at ambient temperature:

XLPE insulated cable: 40 x 10-4

Type

Maximum tan at 90 + 3oC:

XLPE insulated cable: 80 x 10-4

(g) Partial discharge test

after heat cycling

The magnitude of discharge shall not exceed 5 pC.

Type

(h) Impulse withstand test

followed by a high

voltage a.c. test for 15

min.

No breakdown of the insulation shall occur

Type

(i) High voltage a.c. test for

4 hour

No breakdown of the insulation shall occur

Type

(j) Spark test of nonmetallic sheath

No breakdown of the sheath shall occur

Routine

(k) Water-blocking test

There shall be no evidence of water leakage at the

(applicable only to cables cable ends

incorporating waterblocking measures)

NOTES:

1) Applicable to XLPE cables of designated voltage above 1.9/3.3 (3.6) kV

2 ) Applicable to cables of designated voltage above 3.8/6.6 (7.2) kV

PDF created with pdfFactory Pro trial version www.pdffactory.com

Type

Vous aimerez peut-être aussi

- HSE Hazards and Effects Management for Wood Cutting MachinesDocument7 pagesHSE Hazards and Effects Management for Wood Cutting Machinessaravana.bPas encore d'évaluation

- Job Safety Analysis (Jsa) : CONTRACT N° .Document1 pageJob Safety Analysis (Jsa) : CONTRACT N° .ghazi kallelPas encore d'évaluation

- Contractor Ehs Risk Assessment For NDT TestingDocument6 pagesContractor Ehs Risk Assessment For NDT TestingBernard PenuliarPas encore d'évaluation

- Penguard ZP AO - English (Uk) - Issued.06.12.2007Document3 pagesPenguard ZP AO - English (Uk) - Issued.06.12.2007Mohamed FaragPas encore d'évaluation

- HSE Operational Control Procedure For Electrical WorkDocument3 pagesHSE Operational Control Procedure For Electrical Workalit2Pas encore d'évaluation

- Larsen & Toubro Limited Buildings and Factories Independent CompanyDocument5 pagesLarsen & Toubro Limited Buildings and Factories Independent CompanyabbasPas encore d'évaluation

- CSHP Checklist 2011Document2 pagesCSHP Checklist 2011JenniferValle0% (1)

- Earth Pit Maintenance Instructions MBCDocument2 pagesEarth Pit Maintenance Instructions MBCdilipgmPas encore d'évaluation

- PM 01 Hira For Excavation of Boiler FoundationDocument3 pagesPM 01 Hira For Excavation of Boiler FoundationSyed Shariq Hassan100% (1)

- Safety Check (Please Put Tick ( ) Mark in The Appropriate BoxDocument8 pagesSafety Check (Please Put Tick ( ) Mark in The Appropriate BoxAntony JebarajPas encore d'évaluation

- WAH - Working On Roofs - 0Document13 pagesWAH - Working On Roofs - 0Rizki DarmawanPas encore d'évaluation

- Release Notes: RDL-3000 XP Edge v3.9Document8 pagesRelease Notes: RDL-3000 XP Edge v3.9alex BecerraPas encore d'évaluation

- Ms For Tele Tower ErectionDocument12 pagesMs For Tele Tower ErectionSahabzada AamirPas encore d'évaluation

- Expectations and Deliverables HSE Excellence AwardDocument4 pagesExpectations and Deliverables HSE Excellence AwardOki EriandiPas encore d'évaluation

- Chemical Manifest and Hazardous Chemical Substance List KathuDocument13 pagesChemical Manifest and Hazardous Chemical Substance List KathuVictorPas encore d'évaluation

- Risk Assessment - Hot Water BoilersDocument4 pagesRisk Assessment - Hot Water BoilersUgonnaPas encore d'évaluation

- Electrical Maintenance & Testing Hazard IdentificationDocument10 pagesElectrical Maintenance & Testing Hazard IdentificationRavi ValiyaPas encore d'évaluation

- 38 Through Installation Job Safe Practice Ladder and Rack InstallationDocument1 page38 Through Installation Job Safe Practice Ladder and Rack InstallationsalmanPas encore d'évaluation

- Nitoproof 230Document2 pagesNitoproof 230Balasubramanian Ananth50% (2)

- Msds 0864 Aquafill Wallfiller Fine en 1Document10 pagesMsds 0864 Aquafill Wallfiller Fine en 1baseet gazaliPas encore d'évaluation

- Earth Mat Risk AssessmentDocument1 pageEarth Mat Risk Assessmentakshaf10Pas encore d'évaluation

- uJJ O: J.illDocument3 pagesuJJ O: J.illEngr.Syed AmjadPas encore d'évaluation

- Risk Ass - ProcessDocument4 pagesRisk Ass - ProcessBalakrishnan Sivagnanam SPas encore d'évaluation

- ARA - For Emergency Diesel GeneratorDocument4 pagesARA - For Emergency Diesel GeneratorShaikh AftabPas encore d'évaluation

- Kta Alliance Spray /touch Up Painting of Project Materials: Job Safety Analysis (JSA)Document3 pagesKta Alliance Spray /touch Up Painting of Project Materials: Job Safety Analysis (JSA)Ogunwa EmmanuelPas encore d'évaluation

- Installation of AMI/AMR CablesDocument9 pagesInstallation of AMI/AMR Cablessalman100% (1)

- Experienced Instrument Engineer CVDocument4 pagesExperienced Instrument Engineer CVfahad fahadPas encore d'évaluation

- Part Submission WarrantDocument4 pagesPart Submission WarrantSam AnuPas encore d'évaluation

- ECO - Electrical Shock Emergency Mock DrillDocument4 pagesECO - Electrical Shock Emergency Mock DrillBoluwatife Elisha100% (1)

- TRA Cable Laying & Allied WorkDocument3 pagesTRA Cable Laying & Allied WorkswathishPas encore d'évaluation

- Weekly Tower Light Check ListDocument1 pageWeekly Tower Light Check ListpjosesmPas encore d'évaluation

- Site Access Request Form (ACBA - 0105 (BGW00174) )Document1 pageSite Access Request Form (ACBA - 0105 (BGW00174) )Maijul Islam Sarkar JituPas encore d'évaluation

- Air Curtain InstallDocument16 pagesAir Curtain InstallSherif Mohamed KhattabPas encore d'évaluation

- Risk Assessment - Mobile Crane Operations - 2021Document3 pagesRisk Assessment - Mobile Crane Operations - 2021Asakundwi MukhwaPas encore d'évaluation

- Risk Assesment For Electrical Conducting & Installation WorkDocument2 pagesRisk Assesment For Electrical Conducting & Installation WorkAjay kumarPas encore d'évaluation

- SS JSP - 013 Foundation and Ground Shuttering Forms and Rebar WorksDocument6 pagesSS JSP - 013 Foundation and Ground Shuttering Forms and Rebar WorksFarhat SetharPas encore d'évaluation

- CamScanner 03-22-2023 07.44Document2 pagesCamScanner 03-22-2023 07.44Umar AliPas encore d'évaluation

- SSR Competency Assurance Guidance Booklet SummaryDocument8 pagesSSR Competency Assurance Guidance Booklet SummarywavehayiathPas encore d'évaluation

- Delfix 8-10Document2 pagesDelfix 8-10FAIYAZ AHMEDPas encore d'évaluation

- Hazard Identification FormDocument1 pageHazard Identification Formabdulrazzaq hatem100% (1)

- EXHIBIT O.site Safety and Health Plan - SHP 098 00. 20150615Document31 pagesEXHIBIT O.site Safety and Health Plan - SHP 098 00. 20150615safetydmrcPas encore d'évaluation

- List of Madarsa Programs Approved by The University For Admissions PDFDocument13 pagesList of Madarsa Programs Approved by The University For Admissions PDFsaddam husainPas encore d'évaluation

- Mom For Table To Drill MeetingDocument2 pagesMom For Table To Drill MeetingChaudhary Wasim MurtazaPas encore d'évaluation

- EHS October 2019 Calendar Safety Training AuditsDocument1 pageEHS October 2019 Calendar Safety Training AuditsSiddharth RanaPas encore d'évaluation

- Kedar - MMUP Engineering License Exam DTD 08th December 2014Document4 pagesKedar - MMUP Engineering License Exam DTD 08th December 2014Abdul Rahman A RPas encore d'évaluation

- Safe Work Method For Peb Work: Procedure Possible Hazards Control MeasuresDocument35 pagesSafe Work Method For Peb Work: Procedure Possible Hazards Control Measuressandip patilPas encore d'évaluation

- Trench & Shoring Inspection Checklist: Manifa Temporary Office and Camp FacilityDocument2 pagesTrench & Shoring Inspection Checklist: Manifa Temporary Office and Camp FacilityMunawwar KhanPas encore d'évaluation

- Oxy-Acetylene Welding SafetyDocument4 pagesOxy-Acetylene Welding SafetyBajaj NitinPas encore d'évaluation

- Safety Notice BoardDocument2 pagesSafety Notice Boardkalyan1990Pas encore d'évaluation

- Job Safety Analysis Sheet: Manual ExcavationDocument1 pageJob Safety Analysis Sheet: Manual ExcavationSafety ProfessionalPas encore d'évaluation

- GE PTW Confined SpacesDocument2 pagesGE PTW Confined SpacesKural MurugesanPas encore d'évaluation

- Camp Cleaning ScheduleDocument4 pagesCamp Cleaning Schedulerashid zamanPas encore d'évaluation

- JHA For Installation 2 Inch Nozzle..Document6 pagesJHA For Installation 2 Inch Nozzle..arnolhari100% (1)

- Work at Height ProcedureDocument36 pagesWork at Height ProcedureShams JogPas encore d'évaluation

- ExcavcklDocument5 pagesExcavcklvg1900Pas encore d'évaluation

- Guidelines for Swimming Pool ApprovalDocument5 pagesGuidelines for Swimming Pool ApprovalNiel Brian VillarazoPas encore d'évaluation

- Confined Space PermitDocument1 pageConfined Space PermitNethiyaaRajendranPas encore d'évaluation

- 11 KV 120 SQMM AAA Covered Conductor TSDocument7 pages11 KV 120 SQMM AAA Covered Conductor TSabhishekPas encore d'évaluation

- ZTT Technical Spec for Duct & Direct Buried Optical CableDocument8 pagesZTT Technical Spec for Duct & Direct Buried Optical CableEnzo del PradoPas encore d'évaluation

- PAL Polyurethane Panel Spec 31102008Document4 pagesPAL Polyurethane Panel Spec 31102008Mohd Fahmie Bin MustapaPas encore d'évaluation

- Amadrainer201..Product PresentationDocument2 pagesAmadrainer201..Product PresentationMohamad Aboelsoud HessenPas encore d'évaluation

- Abb TmaxDocument382 pagesAbb TmaxMohammed AbdelsalamPas encore d'évaluation

- Ama Drainer301 Op Manual1Document16 pagesAma Drainer301 Op Manual1Mohamad Aboelsoud HessenPas encore d'évaluation

- Fa MirDocument1 pageFa MirMohamad Aboelsoud HessenPas encore d'évaluation

- Capacitors 2Document8 pagesCapacitors 2chinith100% (1)

- Amadrainer A..pump CatalogueDocument16 pagesAmadrainer A..pump CatalogueMohamad Aboelsoud HessenPas encore d'évaluation

- International Standard: Sound System Equipment - Objective Rating of Speech Intelligibility by Speech Transmission IndexDocument6 pagesInternational Standard: Sound System Equipment - Objective Rating of Speech Intelligibility by Speech Transmission IndexMohamad Aboelsoud HessenPas encore d'évaluation

- High Voltage Testing of GeneratorDocument28 pagesHigh Voltage Testing of GeneratorbuntysuratPas encore d'évaluation

- International Standard: Sound System Equipment - MicrophonesDocument8 pagesInternational Standard: Sound System Equipment - MicrophonesMohamad Aboelsoud HessenPas encore d'évaluation

- Fa MirDocument1 pageFa MirMohamad Aboelsoud HessenPas encore d'évaluation

- Electrical Works 26 ReportDocument5 pagesElectrical Works 26 ReportMohamad Aboelsoud HessenPas encore d'évaluation

- International Standard: Sound System Equipment - MicrophonesDocument8 pagesInternational Standard: Sound System Equipment - MicrophonesMohamad Aboelsoud HessenPas encore d'évaluation

- International Standard: Sound System Equipment - MicrophonesDocument8 pagesInternational Standard: Sound System Equipment - MicrophonesMohamad Aboelsoud HessenPas encore d'évaluation

- International Standard: Sound System Equipment - MicrophonesDocument8 pagesInternational Standard: Sound System Equipment - MicrophonesMohamad Aboelsoud HessenPas encore d'évaluation

- التحكم الصناعي و الألي 2Document125 pagesالتحكم الصناعي و الألي 2MohammadAbuRayyaPas encore d'évaluation

- Electrical Works 35 ReportDocument6 pagesElectrical Works 35 ReportMohamad Aboelsoud HessenPas encore d'évaluation

- 2 Structured Cabling SystemDocument9 pages2 Structured Cabling Systemmd Betab alamPas encore d'évaluation

- Assuco Drawings0506Document487 pagesAssuco Drawings0506Mohamad Aboelsoud HessenPas encore d'évaluation

- Huihong International Limited: E2000 ConnectorDocument0 pageHuihong International Limited: E2000 ConnectorRafael PachecoPas encore d'évaluation

- New Microsoft Office PowerPoint PresentationDocument18 pagesNew Microsoft Office PowerPoint PresentationMohamad Aboelsoud HessenPas encore d'évaluation

- Daily field report for Zuhair Fayez Partnership projectDocument2 pagesDaily field report for Zuhair Fayez Partnership projectMohamad Aboelsoud HessenPas encore d'évaluation

- SOLVSAMPDocument15 pagesSOLVSAMPcoldblood22Pas encore d'évaluation

- New Microsoft Office PowerPoint PresentationDocument18 pagesNew Microsoft Office PowerPoint PresentationMohamad Aboelsoud HessenPas encore d'évaluation

- التحكم الصناعي و الألي 1Document138 pagesالتحكم الصناعي و الألي 1ايهاب غزالةPas encore d'évaluation

- Access Route 1Document1 pageAccess Route 1Mohamad Aboelsoud HessenPas encore d'évaluation

- PDFSig QFormal RepDocument1 pagePDFSig QFormal RepcarloschmPas encore d'évaluation

- Vac AppDocument1 pageVac AppMohamad Aboelsoud HessenPas encore d'évaluation

- Font MapDocument5 pagesFont MapFuat ArslanPas encore d'évaluation

- Lawatherm Furnace Private Limited Delhi IndiaDocument10 pagesLawatherm Furnace Private Limited Delhi IndiaLawatherm Furnace Private LimitedPas encore d'évaluation

- Problems On Insulators (Power Systems) EEEDocument7 pagesProblems On Insulators (Power Systems) EEEAditya JhaPas encore d'évaluation

- 150 KV Surge ArresterDocument112 pages150 KV Surge ArresterAhmadBintangNegoroPas encore d'évaluation

- Deskline Dl12 Db12 Dl14 Db14 Dl17 User Manual EngDocument36 pagesDeskline Dl12 Db12 Dl14 Db14 Dl17 User Manual EngJorge Manuel Perez RodriguezPas encore d'évaluation

- The ABCs of Construction SafetyDocument68 pagesThe ABCs of Construction SafetytariqPas encore d'évaluation

- TransformersDocument15 pagesTransformersAnonymous GRXy0TPas encore d'évaluation

- Multimode Relay MT: 2 / 3 Pole 10 A, DC-or AC-coilDocument4 pagesMultimode Relay MT: 2 / 3 Pole 10 A, DC-or AC-coilgoo glePas encore d'évaluation

- General CableDocument57 pagesGeneral CableelmerbarrerasPas encore d'évaluation

- Unigear 550: 12 - 17.5 KV, Arc-Proof, Air Insulated Switchgear For Power ApplicationsDocument48 pagesUnigear 550: 12 - 17.5 KV, Arc-Proof, Air Insulated Switchgear For Power ApplicationsMohd Nawawi Ab AzizPas encore d'évaluation

- Draft Spec. For Set of Panels For LHB Non AC EOG Coaches PDFDocument27 pagesDraft Spec. For Set of Panels For LHB Non AC EOG Coaches PDFVishal Kinikar0% (1)

- Catalogo Fire Alarm Cables BeldenDocument8 pagesCatalogo Fire Alarm Cables BeldenCesar Muñoz BonettPas encore d'évaluation

- Counter Module XI/ON ECO, 24 V DC, 2 Channels Part No. Xne-2Cnt-2Pwm Catalog No. 140038 EL-Nummer (Norway) 4520603Document4 pagesCounter Module XI/ON ECO, 24 V DC, 2 Channels Part No. Xne-2Cnt-2Pwm Catalog No. 140038 EL-Nummer (Norway) 4520603dachinicuPas encore d'évaluation

- Building Utilities 2: Casulla, Cristine T. Bs in Architecture 3 University of LuzonDocument20 pagesBuilding Utilities 2: Casulla, Cristine T. Bs in Architecture 3 University of LuzonEreca NavarroPas encore d'évaluation

- Uputstvo Za Argonski Aparat LJ 490732 LDocument102 pagesUputstvo Za Argonski Aparat LJ 490732 LjmunjaPas encore d'évaluation

- Pre Test and Post TestDocument12 pagesPre Test and Post TestKathleen OlaloPas encore d'évaluation

- Owner'S Manual: Operation Maintenance Parts ListDocument94 pagesOwner'S Manual: Operation Maintenance Parts ListDmitryPas encore d'évaluation

- Electrical System of BuildingDocument86 pagesElectrical System of BuildingCatherinePas encore d'évaluation

- Chainflex CatalogDocument290 pagesChainflex CatalogTapelea CristianPas encore d'évaluation

- Lightning Over Voltage Performance of 132kV GIS Substation in MalaysiaDocument7 pagesLightning Over Voltage Performance of 132kV GIS Substation in MalaysiaboopelectraPas encore d'évaluation

- O&m Manual For Landscapeing LightDocument104 pagesO&m Manual For Landscapeing Lightmukilanarul12Pas encore d'évaluation

- Motors A Performance Opportunity RoadmapDocument18 pagesMotors A Performance Opportunity RoadmapAtiq_2909Pas encore d'évaluation

- Samsung ht-f4550 en PDFDocument65 pagesSamsung ht-f4550 en PDFMartin Calci EdwardPas encore d'évaluation

- 20-05-15-A1-CR01 - Manual TruDisk4002 (2C) enDocument314 pages20-05-15-A1-CR01 - Manual TruDisk4002 (2C) enshrus100% (1)

- 227 IEC 05 BV WireDocument1 page227 IEC 05 BV WireZAHID IQBALPas encore d'évaluation

- DNV RP F401Document23 pagesDNV RP F401Christopher BlevinsPas encore d'évaluation

- DR As NZS 4836 2022Document94 pagesDR As NZS 4836 2022Consultindo TechnicalPas encore d'évaluation

- AutomotiveDocument32 pagesAutomotiveMos CraciunPas encore d'évaluation

- 3m Arc Proof Tape 77Document4 pages3m Arc Proof Tape 77shubham pandeyPas encore d'évaluation

- SE Minera GMX Oil Transformer Installation O&M ManualDocument20 pagesSE Minera GMX Oil Transformer Installation O&M ManualnooruddinkhanPas encore d'évaluation

- ENG DS RT1 Bistable 0613 RT1 BistableDocument3 pagesENG DS RT1 Bistable 0613 RT1 BistablePredrag MarkovicPas encore d'évaluation