Académique Documents

Professionnel Documents

Culture Documents

Cooling Towers Clean

Transféré par

zeliteTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Cooling Towers Clean

Transféré par

zeliteDroits d'auteur :

Formats disponibles

ROWAN UNIVERSITY

Design Guide

2013

SECTION 236500 - COOLING TOWERS

1.0

All cooling towers shall have the following characteristics:

A.

B.

C.

D.

E.

F.

Modular cell, induced draft type with vertical discharge and counterflow arrangements.

Gear driven, direct drive fans. Belt drives are discouraged due to maintenance costs.

Provide a close coupled oil sight glass visible from the exterior of the tower.

Propeller type fans which are individually adjustable and replaceable.

Towers shall be of non-combustible construction with non-combustible or limited

combustible fill material; otherwise the A/E shall evaluate the requirement for sprinkler

protection. Towers that are Factory Mutual approved do not require sprinkler protection.

Fill, louvers and drift eliminators shall be constructed of 15 Mil PVC capable of service up

to 125oF and supported by hot-dipped galvanized structural tubing. Drift losses shall not

exceed 0.005% of the design GPM. Fill shall be elevated above the cooling tower basin

to permit cleaning. Dampers and linkages shall be stainless steel.

Basins (hot and cold), framework, casing, fan deck and fan cylinder shall be constructed

of one of the following options:

1.

2.

3.

G.

H.

I.

J.

K.

L.

M.

N.

O.

Concrete.

Fiberglass reinforced polyester, stainless steel and PVC.

Protruded fiberglass reinforced plastic (preferred choice).

Nominal design conditions shall be 78oF entering wet bulb, 95oF entering water

temperature, and a nominal 10 oF water temperature drop. The A/E should investigate

alternative entering and leaving conditions to determine the most economical and

efficient choice.

Access - Personnel shall be able to safely access all sections of the cooling tower

requiring service without danger of falling (all decking ladders and stairs shall be provided

to meet this requirement). Fan motors shall have a motor removal hoist provided.

Specify at a minimum a steel ladder, ladder extension, cell partitions, fan cylinder

extensions and hot water basin covers. Hot water basin covers shall be hinged to

facilitate access. All ladders shall have safety cages.

The cooling towers shall be located so that the hot water basin is the highest point in the

condenser water system. The difference in elevation between the condenser water pump

impeller and the cold water basin shall be such that the net positive suction head entering

the pump (available) will be greater than the pump requirements when using a fluid vapor

pressure of 14.7 psia.

Calculations shall not use a fluid vapor pressure corresponding to the maximum fluid

temperature (i.e. 95-100oF).

Cooling towers shall be located in areas that are fully accessible.

Tower efficiency shall not be reduced by cosmetic screening. For towers with screening,

and where screening is installed closer than cataloged minimum clearances, the A/E shall

submit the manufacturer's analysis for the tower rating at the specific conditions to the

Office of the University Engineer.

The location of the tower shall take into consideration the affects of tower noise and

plume upon adjacent occupied spaces, outside air intakes, and parking areas. The

location shall also give consideration to the building's wake and prevailing wind, etc.

The design and location of cooling towers must consider the effects of noise, aesthetics,

and service access. Some buildings on campus are listed in the Historical Register and

must conform to the requirements of such. On a project by project basis, exterior

installations of cooling towers shall be evaluated against local site noise level goals and

criteria. Refer to Part I, General Section XI. The A/E shall submit an acoustic report to

the University representative identifying any noise impacts.

Winter Protection Basin freeze protection shall be provided when towers are intended

COOLING TOWERS

236500 - 1

ROWAN UNIVERSITY

Design Guide

2013

for winter use.

1.

2.

3.

P.

Q.

R.

For factory fabricated package units, provide each cell with a basin electrical

heating package. The package shall include a control relay, control transformer,

low water cut-off electrode or float switch, thermostat with capillary and bulb

mount, magnetic contactors, and necessary immersion heaters to maintain the

basin water at 40 degrees F when the outside temperature is 0 degrees F with 15

mph winds. All outdoor equipment shall be in a NEMA 4X enclosure. The

package immersion heaters shall utilize 480-volt electrical power, and shall be

designed for intermittent service and be UL approved.

For field fabricated units consider alternate methods of basin heating such as

the use of an electric hot water boiler system or a compressed air bubbling

system.

Exterior piping (condenser water, fill and drain) shall be heat traced.

Variable speed drives shall be used for tower fans on all tower installations.

The A/E shall consider field performance testing for cooling tower installations. Review

specific applications with the University Engineering Department.

Specify that the tower, less motor, shall be warranted for five (5) years. The warranty

period shall commence following the Universitys acceptance of the tower(s) field

performance test(s) and when commissioning efforts are complete.

COOLING TOWERS

236500 - 2

Vous aimerez peut-être aussi

- !-Bab 02 Moulded Case Circuit Breaker (MCCB)Document38 pages!-Bab 02 Moulded Case Circuit Breaker (MCCB)zelitePas encore d'évaluation

- 002 Ac Thermal Load Calculation (Substation)Document1 page002 Ac Thermal Load Calculation (Substation)Faouzi TlemcenPas encore d'évaluation

- !-Bab 03 Air Circuit Breaker (ACB)Document20 pages!-Bab 03 Air Circuit Breaker (ACB)zelitePas encore d'évaluation

- 10KV & Low Inst. DrawingsDocument546 pages10KV & Low Inst. DrawingszelitePas encore d'évaluation

- QFSS-1.02 - Substations & Switch Gear Rooms Rev ADocument2 pagesQFSS-1.02 - Substations & Switch Gear Rooms Rev ARotsapNayrbPas encore d'évaluation

- QFSS-1.02 - Substations & Switch Gear Rooms Rev ADocument2 pagesQFSS-1.02 - Substations & Switch Gear Rooms Rev ARotsapNayrbPas encore d'évaluation

- LV Switchs and EquipmentsDocument195 pagesLV Switchs and EquipmentszelitePas encore d'évaluation

- Voltage Reference Selection BasicsDocument11 pagesVoltage Reference Selection Basicstonyariel100% (2)

- UE12MK03EN (Web) PDFDocument12 pagesUE12MK03EN (Web) PDFzelitePas encore d'évaluation

- Low Voltage Selectivity With ABB Circuit Breakers (1SDC007100G0202)Document56 pagesLow Voltage Selectivity With ABB Circuit Breakers (1SDC007100G0202)Eduardo ZapataPas encore d'évaluation

- TP21 - BEC - DT - 0402 MAS For 11 KV Chiller Starter Panel PDFDocument139 pagesTP21 - BEC - DT - 0402 MAS For 11 KV Chiller Starter Panel PDFzelitePas encore d'évaluation

- Hvac Method StatementDocument74 pagesHvac Method StatementnafoukhPas encore d'évaluation

- 01 Fault at FCO 5D-30 (Well 5D-93 & 5D-83) - Substation 5B Feeder 02 - Crew 01-14-07-2014Document1 page01 Fault at FCO 5D-30 (Well 5D-93 & 5D-83) - Substation 5B Feeder 02 - Crew 01-14-07-2014zelitePas encore d'évaluation

- Training Courses Descriptions Full PDFDocument6 pagesTraining Courses Descriptions Full PDFzelitePas encore d'évaluation

- TP21 - BEC - DT - 0316 Rev-4 LVMCC Panel PDFDocument81 pagesTP21 - BEC - DT - 0316 Rev-4 LVMCC Panel PDFzelitePas encore d'évaluation

- YF-01-04 HVAC Overlay PDFDocument1 pageYF-01-04 HVAC Overlay PDFzelitePas encore d'évaluation

- Voltage Drop Calculation$ PDFDocument1 pageVoltage Drop Calculation$ PDFzelitePas encore d'évaluation

- Visual Test 20kv Panel Cubicle PDFDocument7 pagesVisual Test 20kv Panel Cubicle PDFzelitePas encore d'évaluation

- Wearing of BSP Uniform and Office Attire PDFDocument1 pageWearing of BSP Uniform and Office Attire PDFzelitePas encore d'évaluation

- CPTG003 en PDFDocument24 pagesCPTG003 en PDFbyyramPas encore d'évaluation

- VG-01-05 HVAC Overlay PDFDocument1 pageVG-01-05 HVAC Overlay PDFzelitePas encore d'évaluation

- TP21 - BEC - DT - 0402 MAS For 11 KV Chiller Starter Panel Rev - 3 PDFDocument127 pagesTP21 - BEC - DT - 0402 MAS For 11 KV Chiller Starter Panel Rev - 3 PDFzelitePas encore d'évaluation

- The Mosque and The Modern World LowDocument248 pagesThe Mosque and The Modern World LowzelitePas encore d'évaluation

- Plumbing & Fire Protection Piping Systems CleanDocument7 pagesPlumbing & Fire Protection Piping Systems CleanzelitePas encore d'évaluation

- Rowan University Design Guide 2013Document4 pagesRowan University Design Guide 2013zelitePas encore d'évaluation

- TG MCC Room General Arrangement PDFDocument1 pageTG MCC Room General Arrangement PDFzelitePas encore d'évaluation

- Total Low PDFDocument16 pagesTotal Low PDFzelitePas encore d'évaluation

- Fire Suppression Systems CleanDocument4 pagesFire Suppression Systems CleanzelitePas encore d'évaluation

- Plumbing Systems CleanDocument6 pagesPlumbing Systems CleanzelitePas encore d'évaluation

- Plumbing Fixtures CleanDocument2 pagesPlumbing Fixtures CleanzelitePas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- 11 - Chemical ThermodynamicsDocument55 pages11 - Chemical ThermodynamicsGebre Tensay100% (1)

- Engine Motorcycle Parts Diagram - Google Search-1 PDFDocument1 pageEngine Motorcycle Parts Diagram - Google Search-1 PDFAlejandro ReyesPas encore d'évaluation

- General Physics - Worksheet II (2024)Document3 pagesGeneral Physics - Worksheet II (2024)merrymesfin87Pas encore d'évaluation

- FR20 5 Cablage ENDocument30 pagesFR20 5 Cablage ENEdmond MarkovitsPas encore d'évaluation

- Omm D8RDocument4 pagesOmm D8RRudi Abu ZahraPas encore d'évaluation

- Massabo-Richiami FratturaDocument53 pagesMassabo-Richiami FratturaTan ChingPas encore d'évaluation

- XT125R 2007Document57 pagesXT125R 2007Oren BuskilaPas encore d'évaluation

- Katalog en StandaradaDocument78 pagesKatalog en Standaradahebasignal100% (1)

- QYJ1000 Chocolate ConcheDocument9 pagesQYJ1000 Chocolate ConcheMajikates Service MaintenancePas encore d'évaluation

- WL 835H Liugong Heavy DutyDocument13 pagesWL 835H Liugong Heavy Dutyrusydi raushan fikriPas encore d'évaluation

- Service Repair Manual: English All Language: Geographic Region: Serial Number RangeDocument83 pagesService Repair Manual: English All Language: Geographic Region: Serial Number RangeAnne S. Sokolovska100% (1)

- Wiring Ecu CalyaDocument22 pagesWiring Ecu Calyakurnia wan100% (4)

- Eriksson Stability of Girders Presentation Aug 2015 DistibutionDocument36 pagesEriksson Stability of Girders Presentation Aug 2015 DistibutionsamPas encore d'évaluation

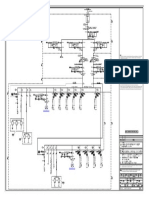

- Electrical SLDDocument1 pageElectrical SLDsusovan bIswasPas encore d'évaluation

- Re 040921Document3 pagesRe 040921francis puthuserilPas encore d'évaluation

- 12000TechnequipValveBrochureENGLISH332016EM PDFDocument20 pages12000TechnequipValveBrochureENGLISH332016EM PDFDaniel SanPas encore d'évaluation

- Biland Sa-250: Technical SpecificationsDocument4 pagesBiland Sa-250: Technical SpecificationsNofriagara Davit HarnawanPas encore d'évaluation

- MDDocument15 pagesMDRakesh Kumar Singh (Phase 1B)Pas encore d'évaluation

- TP6551 MobileOperationDocument48 pagesTP6551 MobileOperationAnonymous M0OEZEKoGiPas encore d'évaluation

- Workshop Manual: Downloaded From Manuals Search EngineDocument88 pagesWorkshop Manual: Downloaded From Manuals Search EngineRicky WrightPas encore d'évaluation

- British Steel Universal Beams Ub Datasheet PDFDocument6 pagesBritish Steel Universal Beams Ub Datasheet PDFLavanyan SatchithananthanPas encore d'évaluation

- Pump and Gas Moving EquipmentDocument13 pagesPump and Gas Moving EquipmentM.Ghulam Al-AyubiPas encore d'évaluation

- Membrane Pressure Relief Valves: VHS-CDocument4 pagesMembrane Pressure Relief Valves: VHS-C88jdccPas encore d'évaluation

- Bell B40DDocument15 pagesBell B40DAndy LiputoPas encore d'évaluation

- Especificaciones Acumulador de Direccion CAT789C Prueba y CargaDocument8 pagesEspecificaciones Acumulador de Direccion CAT789C Prueba y CargaRafael RodriguezPas encore d'évaluation

- Psych Rome TryDocument13 pagesPsych Rome TryAmira BagumbaranPas encore d'évaluation

- Kode Eror Berbagai Macam MerkDocument16 pagesKode Eror Berbagai Macam Merkikhsan centralacPas encore d'évaluation

- Private Admission Launch 2022 - 2023Document4 pagesPrivate Admission Launch 2022 - 2023YannickPas encore d'évaluation

- Tanks: Dosing Tank and AccessoriesDocument10 pagesTanks: Dosing Tank and AccessoriesNaji OmarPas encore d'évaluation

- Thermoplastic Tubing: Catalogue 5210/UKDocument15 pagesThermoplastic Tubing: Catalogue 5210/UKGeo BuzatuPas encore d'évaluation