Académique Documents

Professionnel Documents

Culture Documents

m c θ c θ c c: n vi li

Transféré par

Vanessa SimTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

m c θ c θ c c: n vi li

Transféré par

Vanessa SimDroits d'auteur :

Formats disponibles

CONDENSER DESIGN

Heat transferred from FFA,

c li li

where

=

Q

c vi

vi

m

ihfg,i +

is the mass flowrate of component i (kg/s)

is the vapour specific heat capacity of component i

c vi

(kJ/kg.K)

c li is the liquid specific heat capacity of component i

(kJ/kg.K)

vi is the difference in temperature with the operating

temperature and

boiling point for each component (K)

hfg,i is the latent heat of vaporization of component i (kJ/kg)

l,i is the difference in temperature of boiling point and

temperature FFA leaves the molecular distillation column

Cooling water flowrate,

/(

= Q

cw)

where w is the difference in temperature at inlet and outlet (K)

cw is the specific heat capacity of water (kJ/kg.K)

R=

t

( 1t 2)

(T 1T 2)

T

( 1t 1)

and S=

(t 1t 1)

The temperature correction factor, Ft is a function of R and S. The

correction factor can be found based on the chart.

T lm=

( vi li) w

( vi li )

ln

T m=T lm F t

The value of overall heat transfer coefficient, U is estimated from

the figure attached below :

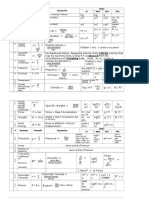

Figure 1. Estimation of overall heat transfer coefficient

Q

Provisional area, A=

U Tm

Tube size and type of pitch were chosen and the area was calculated

based on it.

Area of one tube = DL

Q

(

)

U Tm

Number of tubes =

DL

Cross-sectional area of one tube =

D2 / 4

D2

Total tube area =

Number of tubes

4

m

w

w Total tube area

is the density of water

Tube velocity for one pass=

where

Tube velocity, ut =Tube velocity for one pass number of passes

Since water is used in the tube side, the tube side coefficient is as

shown below.

Tube side coefficient, hi :

0.8

4200(1.35+0.02 t)u t

hi=

0.2

di

where hi is the inside coefficient of water (W/ m2 . )

is the inner diameter of the tube

t is the temperature of the water

di

Shell side coefficient,

h

L ( L v ) g 31

L v

h

where is the mean condensation coefficient

v is the vertical tube loading, condensate rate per unit tube

perimeter

Wc

For a tube bundle, v =

N l do

c =

4 v

L

Overall coefficient, U is found using the formula below :

do

d o ln ( )

di d o 1 d o 1

1

1 1

= + +

+ +

U o ho hod

2 kw

d i h id d i hi

where U o is the overall coefficient based on the outside area of

the tube

ho is the outside fluid film coefficient

hi is the inside fluid film coefficient

hod is the outside dirt coefficient

hid is the inside dirt coefficient

k w is the thermal conductivity of the tube wall material

d o is the outside tube diameter

d i is the inside tube diameter

If the overall coefficient calculated is not within 5 of the overall

coefficient found based on Figure 1, the calculation is repeated

using the new calculated value.

Pressure drop in shell side

(t d o ) D s I B

pt

where pt is the tube pitch

d o is the tube outside diameter

Ds is the shell inside diameter

I B is the baffle spacing

Cross flow area, A s =

Mass flow rate,

G s=

Condensed FFA flowrate

Cross flow area

Equivalent diameter for square pitch arrangement, d e =

p2t d 2o

4(

)

4

do

Equivalent diameter for triangular pitch arrangement, d e =

1.1 2

( pt 0.917 d 2o)

do

Re=

Gs de

where

is the vapour viscosity

Using the Figure below, the friction factor is found based on the

Reynolds number.

Vous aimerez peut-être aussi

- Heat Exchanger-Design and ConstructionDocument46 pagesHeat Exchanger-Design and ConstructionMohd Jamal Mohd Moktar100% (2)

- Double Pipe HXDocument67 pagesDouble Pipe HXKendin Yap Fikirleri Diy0% (1)

- Heat Exchanger DesignDocument22 pagesHeat Exchanger DesignRupack HalderPas encore d'évaluation

- Design HeatexchangerDocument15 pagesDesign HeatexchangerMayurMahajan100% (1)

- Pipe Heat Loss CalculationDocument10 pagesPipe Heat Loss Calculationingemarquintero67% (3)

- 1 For ProjectDocument60 pages1 For ProjectGhazanfer AliPas encore d'évaluation

- Jacketed VesselsDocument9 pagesJacketed VesselsParikshit Shahane67% (3)

- Process Heat TransferDocument21 pagesProcess Heat TransferFarhad MalikPas encore d'évaluation

- Shell and Tube Heat Exchanger DesignDocument50 pagesShell and Tube Heat Exchanger DesignAsmaa HarrazPas encore d'évaluation

- Design of Heat ExchangersDocument23 pagesDesign of Heat ExchangersKhalid Turki100% (2)

- Compiled Correlation For Shell Side Heat Transfer CoefficientDocument20 pagesCompiled Correlation For Shell Side Heat Transfer Coefficientscranderi100% (1)

- Air Cooled Heat ExchangerDocument35 pagesAir Cooled Heat ExchangerNAGARAJAN A R [CB.EN.U4CHE17035]Pas encore d'évaluation

- Vertical ConderDocument9 pagesVertical Condermanoj kumarPas encore d'évaluation

- Calculations Involved in Hydraulic Fracturing Design: Fracture GeometryDocument8 pagesCalculations Involved in Hydraulic Fracturing Design: Fracture GeometryAbdullah IshaqPas encore d'évaluation

- Line SizingDocument20 pagesLine SizingAhmed HassanPas encore d'évaluation

- Heat and Mass Transfer Calculation of The Intercooler With SprayiDocument6 pagesHeat and Mass Transfer Calculation of The Intercooler With SprayiBertalan Gyuszi Kristóf0% (1)

- Chapter 10 Heat TransferDocument14 pagesChapter 10 Heat TransferaimanrslnPas encore d'évaluation

- Lecture 04c - Shortcut Exchanger Design ProcedureDocument47 pagesLecture 04c - Shortcut Exchanger Design Proceduresds0% (1)

- Chapter - 3 Forced ConvectionDocument63 pagesChapter - 3 Forced ConvectionRenu Sekaran100% (2)

- Design of LPG Refigeration System: 1. Copper TubesDocument20 pagesDesign of LPG Refigeration System: 1. Copper TubesJeevan Landge PatilPas encore d'évaluation

- Standard Sizes of Pipes (After Changing)Document45 pagesStandard Sizes of Pipes (After Changing)Muhammad AliPas encore d'évaluation

- Assignment 1: R Z C D Z Uc T CDocument12 pagesAssignment 1: R Z C D Z Uc T CCesar Augusto GarechPas encore d'évaluation

- Ethyleneglycol Design 2520of 2520equipmentsDocument41 pagesEthyleneglycol Design 2520of 2520equipmentsHardik Gandhi100% (1)

- Design of Shell and Tube Heat ExchangerDocument42 pagesDesign of Shell and Tube Heat Exchanger3004 Divya Dharshini. MPas encore d'évaluation

- Heat Transfer in Olga 2000Document11 pagesHeat Transfer in Olga 2000Akin MuhammadPas encore d'évaluation

- Heat Chap08 001Document30 pagesHeat Chap08 001Kerem GöncePas encore d'évaluation

- Heat Exchanger DesignDocument19 pagesHeat Exchanger DesignMohawk Chavanant Roongchao100% (2)

- Daftar Simbol: Baffle Spacing Pitch TubeDocument2 pagesDaftar Simbol: Baffle Spacing Pitch TubeAnonymous mZEUquPas encore d'évaluation

- Chapter SM 1 Heat Exchangers For Heating Applications: SurfaceDocument6 pagesChapter SM 1 Heat Exchangers For Heating Applications: SurfaceJaved Ahmad ChatthaPas encore d'évaluation

- Pin Fin Apparatus - UpdatedDocument10 pagesPin Fin Apparatus - UpdatedVignesh MallyaPas encore d'évaluation

- 84 Picon NunezDocument6 pages84 Picon Nunez1940LaSallePas encore d'évaluation

- Determine Heat LoadDocument3 pagesDetermine Heat LoadBhawani Pratap Singh PanwarPas encore d'évaluation

- Heat Exchanger PerformanceDocument31 pagesHeat Exchanger PerformanceFA AyPas encore d'évaluation

- Muhammad Nauman Abbas: Equipment: Heat ExchangerDocument8 pagesMuhammad Nauman Abbas: Equipment: Heat ExchangerNauman KhanPas encore d'évaluation

- Me 2204 Fluid Mechanics and Machinery LiDocument8 pagesMe 2204 Fluid Mechanics and Machinery LiSheryll de GuzmanPas encore d'évaluation

- 414CC3 Excel Template Prelim Shell and Tube Heat Exchanger Design Si UnitsDocument3 pages414CC3 Excel Template Prelim Shell and Tube Heat Exchanger Design Si UnitsGuruh Mehra MulyanaPas encore d'évaluation

- Design of CondenserDocument2 pagesDesign of CondenserEngr Renato Arriola0% (1)

- Shell & TubeDocument9 pagesShell & TubeRanjith Kumar PPas encore d'évaluation

- A New Optimization Method For Evaluating Thermal Parameters in A Single Segmental Shell and Tube Heat ExchangerDocument8 pagesA New Optimization Method For Evaluating Thermal Parameters in A Single Segmental Shell and Tube Heat Exchangertotok89Pas encore d'évaluation

- Convection SummaryDocument10 pagesConvection SummarycacafaruqPas encore d'évaluation

- Steps For Design of Heat ExchangerDocument10 pagesSteps For Design of Heat ExchangerBHAVINPas encore d'évaluation

- Heat Exchanger Design - Part 2Document15 pagesHeat Exchanger Design - Part 2Siddhant SoymonPas encore d'évaluation

- Duct Designing: Laminar and Turbulent Flow in TubesDocument18 pagesDuct Designing: Laminar and Turbulent Flow in TubesMuhammad Hassan MaqsoodPas encore d'évaluation

- 4.1.3 Step-by-Step CalculationDocument11 pages4.1.3 Step-by-Step Calculationmohamed nizal100% (1)

- Design of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateDocument7 pagesDesign of Shell Tube Heat Exchanger by Kern Method 2 57 Excel TemplateAnonymous xrBCp9Ej50% (4)

- STEP 7. Specification of Shell and Bundle Diameter.: D 0.689 M Zero Point Six Hundred Eighty NineDocument4 pagesSTEP 7. Specification of Shell and Bundle Diameter.: D 0.689 M Zero Point Six Hundred Eighty Ninemmmd.krmv.00Pas encore d'évaluation

- Información Diseño de Intercambiadores Shell and TubeDocument16 pagesInformación Diseño de Intercambiadores Shell and Tubejenny pereaPas encore d'évaluation

- CPE533 Shell and Tube Heat Exchanger Full Lab ReportDocument28 pagesCPE533 Shell and Tube Heat Exchanger Full Lab ReportJonnah Faye MojaresPas encore d'évaluation

- Heat Transfer FundamentalsDocument6 pagesHeat Transfer FundamentalsMuhammad FahadPas encore d'évaluation

- C*-Algebra Extensions and K-Homology. (AM-95), Volume 95D'EverandC*-Algebra Extensions and K-Homology. (AM-95), Volume 95Pas encore d'évaluation

- Southern Marine Engineering Desk Reference: Second Edition Volume ID'EverandSouthern Marine Engineering Desk Reference: Second Edition Volume IPas encore d'évaluation

- Plant Design ChaptersDocument60 pagesPlant Design ChaptersIan Jasper Sabordo100% (1)

- Aoac 915.03 PDFDocument1 pageAoac 915.03 PDFAngie Cerinza Acosta0% (1)

- Astm D36Document5 pagesAstm D36Oscar Mauricio Santos M80% (5)

- Particulars Inwards Opening Balance: 1-May-2022 To 20-May-2022Document24 pagesParticulars Inwards Opening Balance: 1-May-2022 To 20-May-2022kush mishraPas encore d'évaluation

- Ench3mt Main Nov 2015 Section A QuestionsDocument5 pagesEnch3mt Main Nov 2015 Section A QuestionsWendellReeceFrankPas encore d'évaluation

- Methods of SeparationDocument8 pagesMethods of SeparationJayson DayaoPas encore d'évaluation

- Extraction Methods of Essential OilDocument44 pagesExtraction Methods of Essential OilMOHAMMAD HISYAM RISYADPas encore d'évaluation

- JEE Advance Practice Test - 01 (Paper-2) - Chemistry - Lakshya JEE 2024Document3 pagesJEE Advance Practice Test - 01 (Paper-2) - Chemistry - Lakshya JEE 2024everythingisrelative21Pas encore d'évaluation

- Refinery All Lectures PDFDocument64 pagesRefinery All Lectures PDFHelin HassanPas encore d'évaluation

- PHYSICAL CHEMISTRY-phase Diagram 2 Component L-L and L-V (For Student)Document27 pagesPHYSICAL CHEMISTRY-phase Diagram 2 Component L-L and L-V (For Student)Muhammad YanuarPas encore d'évaluation

- Zero1 20070126175851Document4 pagesZero1 20070126175851Omer Altimimi OmerPas encore d'évaluation

- Processes 11 01325 v2Document15 pagesProcesses 11 01325 v2Món Quà Vô GiáPas encore d'évaluation

- Ponchon SavaritDocument1 pagePonchon SavaritDavid GarcíaPas encore d'évaluation

- JimMurray WhiskeyBible2015 FinalDocument196 pagesJimMurray WhiskeyBible2015 Finalsirion100% (1)

- Chemistry Project: Dry Distillation of Jeera, Ajwain and Fruit PeelsDocument10 pagesChemistry Project: Dry Distillation of Jeera, Ajwain and Fruit PeelsSiddharth TyagiPas encore d'évaluation

- Death and Co. Modern Classic Cocktails (Categories) PDFDocument1 pageDeath and Co. Modern Classic Cocktails (Categories) PDFJoshua Leiva MuñozPas encore d'évaluation

- Lab Report 1 2Document26 pagesLab Report 1 2Noah Patrick LesacaPas encore d'évaluation

- Comparison of Extractive Distillation and Pressure-Swing Distillation For Acetone - Chloroform SeparationDocument7 pagesComparison of Extractive Distillation and Pressure-Swing Distillation For Acetone - Chloroform SeparationFelipe Paéz BotiaPas encore d'évaluation

- Chapter 06 Phase EquilibriaDocument77 pagesChapter 06 Phase Equilibriaakimarf60% (5)

- Test 02 PDFDocument5 pagesTest 02 PDFMamta GhunashamPas encore d'évaluation

- Concentration of Fruit Juices by Vacuum Membrane Distillation: A ReviewDocument6 pagesConcentration of Fruit Juices by Vacuum Membrane Distillation: A ReviewAnkur murarkaPas encore d'évaluation

- Instrumentation FOR P&ID'sDocument51 pagesInstrumentation FOR P&ID'sEvando Pereira dos SantosPas encore d'évaluation

- Separating MixturesDocument8 pagesSeparating MixturesKes DimapilisPas encore d'évaluation

- An Overview of Essential Oil Bearing Plants of NepalDocument7 pagesAn Overview of Essential Oil Bearing Plants of NepalKhilendra Gurung100% (3)

- Determination of Moisture Content or Total SolidsDocument12 pagesDetermination of Moisture Content or Total SolidsfikerykPas encore d'évaluation

- Presentation On: Fundamentals of Refinery ProcessesDocument110 pagesPresentation On: Fundamentals of Refinery ProcessesTushar VermaPas encore d'évaluation

- Benzene - It'S Characteristics and Safety in Handling, Storing & TransportationDocument6 pagesBenzene - It'S Characteristics and Safety in Handling, Storing & TransportationEhab SaadPas encore d'évaluation

- Official Report Practicum of Chemical Separation Principles Fracsination DestilationDocument22 pagesOfficial Report Practicum of Chemical Separation Principles Fracsination DestilationFitriyah AbidinPas encore d'évaluation

- Asphaltene Precipitation From Crude Oil Blends, Conventional Oils, and Oils With Emulsified Water by Asok Kumar TharanivasanDocument211 pagesAsphaltene Precipitation From Crude Oil Blends, Conventional Oils, and Oils With Emulsified Water by Asok Kumar TharanivasanHenry Reynolds DarcyPas encore d'évaluation

- Sheet 1Document2 pagesSheet 1Mohamed SalahPas encore d'évaluation