Académique Documents

Professionnel Documents

Culture Documents

T Bolt Specs PDF

Transféré par

refaeTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

T Bolt Specs PDF

Transféré par

refaeDroits d'auteur :

Formats disponibles

T-HEAD BOLTS AND NUTS

WaterworksIndustries

1. Dimension B is unthreaded shank.

2. Dimension D is measured to face of nut run up finger-tight

*Indicates most common sizes stocked in T304 stainless steel.

Nominal

Size

A

0.05

B

+ 0.036

- 0.074

C

+ 0.25

- 0.06

J

+ 0.15

- 0.03

R

Max.

5/8 - 11

x3

1.50

0.625

3.0

1.50

0.625

+ 0.04

1.062

+ 0.00

0.625

-0.04

0.312

*3/4-10

x 3-1/2

1.75

0.750

3.5

1.50

0.750

+ 0.06

1.250

+ 0.00

0.750

-0.06

0.375

* 3/4-10

x4

1.75

0.750

4.0

2.25

0.750

0.06

1.250

+ 0.00

0.750

- 0.06

0.375

* 3/4-10

x 4-1/2

1.75

0.750

4.5

2.50

0.750

0.06

1.250

+ 0.00

0.750

-0.06

0.375

3/4-10

x5

1.75

0.750

5.0

3.00

0.750

0.06

1.250

+ 0.00

0.750

-0.06

0.375

1-8 x 6

2.25

1.000

6.0

3.75

1.000

0.08

1.625

+ 0.00

1.000

-0.08

0.500

1-1/4-7 x 6

2.50

1.250

6.0

3.75

1.000

0.08

1.625

+ 0.00

1.000

-0.08

0.500

Number of threads per inchCoarse-Thread Series (ANSI B1.1, Unified Standard for Screw Threads) Class 2A,

external fit UNCA2A and Class 2B, UNC2B (ANSI B1.2, Standard for Gages and Gaging).

Manufactured to specifications of American Water Works Association.

*Source: American Water Works Association

888.482.7323 708.482.7644 FAX 708.482.7795

waterworks@activescrew.com

WaterworksIndustries

INSTALLATION OF

MECHANICAL JOINTS

Notes on Installation of Mechanical Joints

The successful operation of the mechanical joint specified requires that the plain end be centrally located in the bell and

that adequate anchorage be provided where abrupt changes in direction and dead ends occur. The rubber gasket will

seal more effectively (particulary when sealing gas) if the surfaces with which it comes in contact are cleaned thoroughly

(for example, with a wire brush) just prior to assembly in ofer to remove all losse rust or foreign material. Lubrication and

additional cleaning should be provided by brushing both the gasket and the plain end with soapy water or pipe lubricant

as per Sec. 11-8.4 just prior to slipping the gasket into the plain end and assembling the joint.

For water and gas service, the normal range of bolt torques to be applied and the lengths of wrenches that should satisfactorily produce the ranges of torques are given in the following table:

Size

Bolt Size

Range of Torque

Length of Wrench*

in.

in.

mm

lblft

Nm

in.

mm

5/8

15.9

45-60

61-81

203

4-24

3/4

19.1

75-90

102-122

10

254

30-36

25.4

100-120

136-163

14

356

42-48

1-1/4

31.8

120-150

163-203

16

406

*The torque loads may be applied with torque-measuring or torque-indication wrenches, which may also be used to check the application of approximate torque loads applied by a man trained to give an average pull on a definite length of regular socket wrench.

When tightening bolts, it is essential that the gland be brought up toward the pipe flange evenly, maintaining approximately the same distance between the gland and the lace of the flange at all points around the socket. This may be

achieved by partially tightening the bottom bolt first; then, the top bolt; next, the bolts are within the range of torques

shown below. (In larger sizes [30-48 in.], as many as five repetitions may be required.) If effectively disassembled, thoroughly

cleaned, and reassembled. Overstressing of bolts to compensate for poor installation practice is to be avoided.

NOTE:

In assembling stainless steel T-Head Bolts and Nuts, it is essential that all surfaces are kept extremely clean and that an

anti-seize compound is applied to the surfaces of the threads.

ANSI/AWWA C111/A21.11-90 Mechanical Joint T-Bolt Technical Information

Nominal Pipe Size

Qty.

Size

Length

Recommeded Torque

5/8

45-60

3/4

3-1/2

75-90

3/4

3-1/2

75-90

3/4

75-90

10

3/4

75-90

12

3/4

75-90

14

10

3/4

4-1/2

75-90

16

12

3/4

4-1/2

75-90

18

12

3/4

4-1/2

75-90

20

14

3/4

4-1/2

75-90

24

16

3/4

75-90

30

20

100-120

36

24

100-120

Size and length are in inches. Torque is in ft.lbs. Source: American Water Works Association

888.482.7323 708.482.7644 FAX 708.482.7795

waterworks@activescrew.com

Vous aimerez peut-être aussi

- Caterpillar 3208 Diesel Engine SM Manual Copy OneDocument350 pagesCaterpillar 3208 Diesel Engine SM Manual Copy Oneswoods71588% (25)

- How To Specify Fasteners: 3/4 - 10 X 5 Hex Cap Screw Grade 5 Zinc 3/4 - 16 X 5 Hex Cap Screw Grade 5 ZincDocument15 pagesHow To Specify Fasteners: 3/4 - 10 X 5 Hex Cap Screw Grade 5 Zinc 3/4 - 16 X 5 Hex Cap Screw Grade 5 ZincAndré BuysPas encore d'évaluation

- Geometrical TolerancingDocument12 pagesGeometrical TolerancingItalo Venegas100% (1)

- Conveyor Pulley DesignDocument2 pagesConveyor Pulley DesignZoebair100% (1)

- Catalog HRC Jaw CouplingsDocument8 pagesCatalog HRC Jaw CouplingsMadan Yadav100% (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceD'EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenancePas encore d'évaluation

- Valvulas de Bola - JAMESBURYDocument4 pagesValvulas de Bola - JAMESBURYcasv9Pas encore d'évaluation

- Chainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosD'EverandChainsaw Carving for Beginners: Patterns and 250 Step-by-Step PhotosPas encore d'évaluation

- 2015 Installation GuideDocument6 pages2015 Installation Guidealif suryantoPas encore d'évaluation

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementD'EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementPas encore d'évaluation

- Power Stream Couplings-Specn SheetsDocument6 pagesPower Stream Couplings-Specn SheetsAmol PatkiPas encore d'évaluation

- Off-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderD'EverandOff-Road Welding: Advanced Techniques on How to Become a True Off-Road WelderÉvaluation : 5 sur 5 étoiles5/5 (2)

- Torque SpecsDocument2 pagesTorque SpecsMirnal MungraPas encore d'évaluation

- Steel SAE O-Rings AdaptersDocument3 pagesSteel SAE O-Rings Adaptersgeav25653855Pas encore d'évaluation

- Fits & TolerancesDocument6 pagesFits & Tolerancessuperman92makPas encore d'évaluation

- Machine Screw ThreadsDocument2 pagesMachine Screw ThreadsMoaed KanbarPas encore d'évaluation

- Bolt Sizes and DimensionsDocument1 pageBolt Sizes and DimensionsgilbnyPas encore d'évaluation

- HALFEN ConectoriDocument12 pagesHALFEN ConectoriSárközi Pál-ZoltánPas encore d'évaluation

- Rivets AluminumDocument12 pagesRivets AluminumantblyPas encore d'évaluation

- Procedures For Rotational Capacity Testing of Galvanized ASTM A325 ..Document14 pagesProcedures For Rotational Capacity Testing of Galvanized ASTM A325 ..Sayed Diab AlsayedPas encore d'évaluation

- ISO Bar TolerancesDocument1 pageISO Bar TolerancesBaziPas encore d'évaluation

- Basic Electronics - IC's - Finished - Kev 3 Feb 2014Document37 pagesBasic Electronics - IC's - Finished - Kev 3 Feb 2014Suman BajracharyaPas encore d'évaluation

- PIX Belts Product CatalogueDocument66 pagesPIX Belts Product Cataloguevideo1233% (3)

- G3516e Service Manual (Gas)Document753 pagesG3516e Service Manual (Gas)Сергей Шевченко88% (17)

- Serie 60 Informacion AdicionalDocument51 pagesSerie 60 Informacion AdicionalMauricio Campos QuirosPas encore d'évaluation

- Bore and Keyway TolerancesDocument8 pagesBore and Keyway TolerancesIgor San Martín PeñalozaPas encore d'évaluation

- 35-Duct Weight Calculation SheetDocument11 pages35-Duct Weight Calculation SheetAnanth Ganesan100% (1)

- Service SpecificationDocument95 pagesService SpecificationLoc TruongPas encore d'évaluation

- Standard Bolt Specifications and Torque ValuesDocument72 pagesStandard Bolt Specifications and Torque Valuesdgc513Pas encore d'évaluation

- Tri Clamp CatalogueDocument25 pagesTri Clamp CatalogueNenad PetrovicPas encore d'évaluation

- Type U Hammer Drive Technical DataDocument1 pageType U Hammer Drive Technical Datamarcinek77Pas encore d'évaluation

- External Threads For Machine Screws and SEMSDocument2 pagesExternal Threads For Machine Screws and SEMSez1010Pas encore d'évaluation

- Din 2095Document42 pagesDin 2095Eduardo ValenciaPas encore d'évaluation

- Drill Stem Components GuideDocument28 pagesDrill Stem Components Guidechonubobby100% (1)

- Schnorr Disc SpringsDocument8 pagesSchnorr Disc SpringsSean PorterPas encore d'évaluation

- Standard Belt Cross SectionsDocument26 pagesStandard Belt Cross Sectionsagung badoPas encore d'évaluation

- Tabelas Normativas DinDocument2 pagesTabelas Normativas DinDeimos PhobosPas encore d'évaluation

- Elastomer Bellows Seal: Applications Non-Concurrent Operating ConditionsDocument6 pagesElastomer Bellows Seal: Applications Non-Concurrent Operating ConditionsAdhie_ginthinkPas encore d'évaluation

- 459-475 Hose AssembliesDocument17 pages459-475 Hose Assembliesrobertito101Pas encore d'évaluation

- 03-Senr3130!08!01-All Torque SpecificationsDocument16 pages03-Senr3130!08!01-All Torque Specificationsgustavoespinosam100% (1)

- Style 77 Standard Flexible Coupling: Product DescriptionDocument0 pageStyle 77 Standard Flexible Coupling: Product DescriptionAnibal MoralesPas encore d'évaluation

- V-belt drive design factorsDocument12 pagesV-belt drive design factorsPeter IyerePas encore d'évaluation

- Proper Belt Tensioning Guidelines for Registration Critical DrivesDocument4 pagesProper Belt Tensioning Guidelines for Registration Critical DrivesMaulik Trivedi100% (1)

- Thread Height Gage Standards and Contact PointsDocument1 pageThread Height Gage Standards and Contact PointsCarlos Enrique Guzman CastellonPas encore d'évaluation

- MachiningDocument63 pagesMachiningAnonymous LU3Dz3TKtVPas encore d'évaluation

- Unbalanced and Pressure-Balanced Trim: Sizing & SelectionDocument6 pagesUnbalanced and Pressure-Balanced Trim: Sizing & SelectionPratik134Pas encore d'évaluation

- Saej 1459Document6 pagesSaej 1459Nicole KeithPas encore d'évaluation

- Breaking and Yield Loads for FastenersDocument6 pagesBreaking and Yield Loads for FastenersJamesPas encore d'évaluation

- Guidelines For Collect DesignDocument24 pagesGuidelines For Collect DesignArun LelePas encore d'évaluation

- Pipe Threads, General Purpose (Inch) : ASME B1.20.1-2013Document4 pagesPipe Threads, General Purpose (Inch) : ASME B1.20.1-2013NavafPas encore d'évaluation

- Tightening TorqueDocument6 pagesTightening TorqueShirish100% (1)

- TSKDocument4 pagesTSKar174_569868987Pas encore d'évaluation

- IADC Dull Grading - Roller Cone BitsDocument2 pagesIADC Dull Grading - Roller Cone BitsYasir IrfanPas encore d'évaluation

- Dobladores de TubingDocument19 pagesDobladores de TubingJuan Chan CanulPas encore d'évaluation

- Sae and Din HosesDocument5 pagesSae and Din Hosesapi-247972389Pas encore d'évaluation

- The Test of English For Academic Purposes (TEAP) Impact Study: Report 1 - Preliminary Questionnaires To Japanese High School Students and TeachersDocument47 pagesThe Test of English For Academic Purposes (TEAP) Impact Study: Report 1 - Preliminary Questionnaires To Japanese High School Students and TeachersrefaePas encore d'évaluation

- The Test of English For Academic Purposes (TEAP) Impact Study: Report 1 - Preliminary Questionnaires To Japanese High School Students and TeachersDocument47 pagesThe Test of English For Academic Purposes (TEAP) Impact Study: Report 1 - Preliminary Questionnaires To Japanese High School Students and TeachersrefaePas encore d'évaluation

- Questions and Answers Parents English PDFDocument20 pagesQuestions and Answers Parents English PDFrefaePas encore d'évaluation

- Ilecsample PDFDocument51 pagesIlecsample PDFrefaePas encore d'évaluation

- Bulats Sample Paper - En001Document32 pagesBulats Sample Paper - En001mome85Pas encore d'évaluation

- Sample Aptitude Test of MBA Karachi UniversityDocument8 pagesSample Aptitude Test of MBA Karachi Universityzeb593100% (6)

- SEPT Format English June 2011Document2 pagesSEPT Format English June 2011M Fahrudin MunaPas encore d'évaluation

- SEPT Format English June 2011Document2 pagesSEPT Format English June 2011M Fahrudin MunaPas encore d'évaluation

- Reading Comprehension PracticeDocument14 pagesReading Comprehension PracticeVasantha Mallar60% (5)

- Ket Handbook2007Document54 pagesKet Handbook2007hugoysamy29Pas encore d'évaluation

- Testas: Sample QuestionsDocument72 pagesTestas: Sample QuestionsrefaePas encore d'évaluation

- gr7 Reading PT PDFDocument19 pagesgr7 Reading PT PDFrefae100% (2)

- TEA Guide For Students 2016Document10 pagesTEA Guide For Students 2016Crashed FailedPas encore d'évaluation

- ExamEssentials Advanced1 SampleTest 0 PDFDocument2 pagesExamEssentials Advanced1 SampleTest 0 PDFrefaePas encore d'évaluation

- FDA General EnglishDocument13 pagesFDA General EnglishAshwin GowdaPas encore d'évaluation

- EP Rtep Qa PDFDocument2 pagesEP Rtep Qa PDFrefaePas encore d'évaluation

- G9a PDFDocument14 pagesG9a PDFrefaePas encore d'évaluation

- English Language Exam - A2-B1Document10 pagesEnglish Language Exam - A2-B1dule8350% (2)

- English II EOC 2015 Release Test PDFDocument48 pagesEnglish II EOC 2015 Release Test PDFrefae0% (1)

- Ela PDFDocument35 pagesEla PDFrefaePas encore d'évaluation

- EOC English 2 Pretest Session 1 PDFDocument29 pagesEOC English 2 Pretest Session 1 PDFrefaePas encore d'évaluation

- CAE TestDocument16 pagesCAE TestLuB.100% (3)

- English Language Exam - A2-B1Document10 pagesEnglish Language Exam - A2-B1dule8350% (2)

- LAU English Entrance Exam Preparation GuideDocument12 pagesLAU English Entrance Exam Preparation GuidexiaomiredmiPas encore d'évaluation

- Level 2 Sample Assessment Materials PDFDocument31 pagesLevel 2 Sample Assessment Materials PDFrefaePas encore d'évaluation

- Ela6 - Released 2009 English PDFDocument27 pagesEla6 - Released 2009 English PDFrefaePas encore d'évaluation

- NSW, Australia Driver Knowledge Test Questions CarDocument94 pagesNSW, Australia Driver Knowledge Test Questions Carmesssi269Pas encore d'évaluation

- Cbest Practice Test: California Basic Educational Skills TestDocument36 pagesCbest Practice Test: California Basic Educational Skills Testross DowninPas encore d'évaluation

- ACTprep2013 2014 PDFDocument64 pagesACTprep2013 2014 PDFrefae100% (1)

- ADI Two-Step Austempering StudyDocument26 pagesADI Two-Step Austempering StudyartikscindianPas encore d'évaluation

- Materials AlturasDocument66 pagesMaterials AlturasDonald ToledoPas encore d'évaluation

- XL 40 Bronze EDocument1 pageXL 40 Bronze EJacqueline JonesPas encore d'évaluation

- Failure of Jigs & FixtureDocument27 pagesFailure of Jigs & FixtureTooling ganeshPas encore d'évaluation

- Tuttle Original SpecificationDocument3 pagesTuttle Original SpecificationMichel CotePas encore d'évaluation

- Summer Training Report of Forging Processes.Document12 pagesSummer Training Report of Forging Processes.बृज भूषण सिंह100% (1)

- TB-10001585 NPT Ring & Plug Gauge Operation Procedure - 4347652 - 01Document2 pagesTB-10001585 NPT Ring & Plug Gauge Operation Procedure - 4347652 - 01Anton SusiloPas encore d'évaluation

- Lead Screw Lead Screw: Lead Screws - Overview Lead Screw Specifications / Technical CalculationsDocument1 pageLead Screw Lead Screw: Lead Screws - Overview Lead Screw Specifications / Technical CalculationsMyint Myat NaingPas encore d'évaluation

- Welding Technology InspectionDocument32 pagesWelding Technology InspectionChaitanya Sai T100% (1)

- Bibliography of Resistance Welding, Compiled For The PDFDocument46 pagesBibliography of Resistance Welding, Compiled For The PDFdhruvaPas encore d'évaluation

- Audio Speaker BOM and Assembly DrawingsDocument11 pagesAudio Speaker BOM and Assembly DrawingsHenrique VianaPas encore d'évaluation

- Proposed Changes to IRS-T-29-2000 CMS Crossing Manufacturing StandardsDocument11 pagesProposed Changes to IRS-T-29-2000 CMS Crossing Manufacturing StandardsShipra MishraPas encore d'évaluation

- Mechanical Engineering Course on Unconventional Machining ProcessesDocument2 pagesMechanical Engineering Course on Unconventional Machining ProcessesN Dhanunjaya Rao BorraPas encore d'évaluation

- Single Station Manufacturing (CH.13 & 14 of Groover Book)Document70 pagesSingle Station Manufacturing (CH.13 & 14 of Groover Book)Khurram ShahzadPas encore d'évaluation

- Welding Procedure Specification (WPS) : Code: Asme-IxDocument2 pagesWelding Procedure Specification (WPS) : Code: Asme-IxAnonymous 4WzixLwupPas encore d'évaluation

- GANESH Precision GT-1340 Geared-Head Engine Lathe: 13" Swing Over Bedways, 40" Center DistanceDocument3 pagesGANESH Precision GT-1340 Geared-Head Engine Lathe: 13" Swing Over Bedways, 40" Center DistancemattnificentPas encore d'évaluation

- Unit VDocument26 pagesUnit VSabik NainarPas encore d'évaluation

- Is 3601.2006Document21 pagesIs 3601.2006kprasad_56900Pas encore d'évaluation

- Eye Bolt 1Document1 pageEye Bolt 1Adi SutardiPas encore d'évaluation

- JDM A17.1 - Rev. 11-2013Document10 pagesJDM A17.1 - Rev. 11-2013Romulo EduardoPas encore d'évaluation

- Iso 898 7 1992Document8 pagesIso 898 7 1992Quality & EngineeringPas encore d'évaluation

- Jigs ElementsDocument14 pagesJigs ElementsNur Nabila HudaPas encore d'évaluation

- PQR FormDocument2 pagesPQR Formpokok assamPas encore d'évaluation

- Hand Tools AMTDocument102 pagesHand Tools AMTboomscud33Pas encore d'évaluation

- Vertical Milling AttachmentDocument52 pagesVertical Milling Attachmentpramo_dassPas encore d'évaluation

- 1-Mechanics of Orthogonal CuttingDocument31 pages1-Mechanics of Orthogonal CuttingOKELLO JOB LAZARUSPas encore d'évaluation

- Reducing Gear Distortion with Simple FixtureDocument7 pagesReducing Gear Distortion with Simple FixtureVireshVerma100% (1)

- List of Some Necessary Iso Standards For Welding WorkDocument1 pageList of Some Necessary Iso Standards For Welding Workloboandi100% (1)

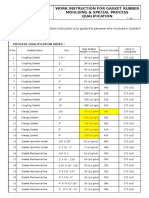

- Work Instruction For Gasket Rubber Moulding & Special Process QualificationDocument4 pagesWork Instruction For Gasket Rubber Moulding & Special Process Qualificationanant_z12Pas encore d'évaluation

- Engineering Technical Report of The v12 Engine and Related Assignments at Tipco IncDocument36 pagesEngineering Technical Report of The v12 Engine and Related Assignments at Tipco Incapi-244817040Pas encore d'évaluation