Académique Documents

Professionnel Documents

Culture Documents

Applications of Microorganism in Food Biotechnology

Transféré par

Claudia MartinezCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Applications of Microorganism in Food Biotechnology

Transféré par

Claudia MartinezDroits d'auteur :

Formats disponibles

Indian Journal of Biotechnology

Vol 2, July 2003, pp 382-386

Applications of Microorganisms in Food Biotechnology

J S Pai*

Department of Food and Fermentation Technology, Institute of Chemical Technology, University of Bombay,

Matunga, Mumbai 400019, India

Received 28 November 2002; accepted 20 February 2003

Strain improvement of microorganisms in food products has been slow as isolation and mutation are timeconsuming and labour-intensive. Hybridization also is slow as unwanted traits have to be bred out. Applications with

food related enzymes were the first products of modern biotechnology, followed by organic acids and amino acid

production by microorganisms. Food fermentation applications such as fermented dairy products and alcoholic beverages have also shown good possibility for using GMOs for improved fermentation performance and resistance to

bacteriophages rather than yield improvement. Improvement in product characteristics including better nutritive

quality will be the driving force of future research in food biotechnology.

Keywords: genetically engineered microorganisms, acids, enzymes, dairy fermentation, alcoholic fermentation

Introduction

Microorganisms have been used for preparing food

products like bread, yoghurt or curd, alcoholic beverages, cheese, etc, for a long time without even knowing their involvement in fermentation. Louis Pasteur

showed the role of microorganisms in spoilage and

subsequent elucidation that fermentation also involves

microorganisms. Once this fact was established, the

scientists tried to isolate microorganisms, which were

more efficient in producing better products or improvement of processes. Some species are useful for

development of flavour unique to certain wines. Thus

traditionally certain microorganisms were used in

such fermented foods.

Need for Improved

Cultures

When large-scale commercialisation of such products occurred, there was a need to increase the production to meet the increasing demands. Microbial

techniques (selection, isolation of pure culture, mutation, protoplast fusion, etc.), well developed by middle of last century, were used advantageously in the

maximum output of the desired product with minimum by-product formation. These techniques, however, are slow in developing a microorganism having

the desirable traits and very few undesirable properties. Sometimes when protoplast fusion is carried out,

*Tel: 022-24145156; Fax: 022-24245156

E-mail: j spai @foodbio.udct.ernet.in

some undesirable properties are transferred, which

have to be slowly removed by further mutation. All

this takes a long time and the results are not precise as

much of the development is being performed empirically.

With the capabilities of modern biotechnology, the

scientists can now transfer desirable characteristics or

genes, without simultaneous transfer of other undesirable genes (Hui & Khachatourians, 1995). Cut and

paste techniques, developed in genetic engineering,

can incorporate only the desirable genes. Thus genetically modified organism takes only a few months

compared to a few years of laboratory work by traditional methods. This communication presents developments related to foods, wherein a review of genetically modified microorganisms useful in foods is

given. An attempt is also made to point out some desirable traits for commercial cultures, which might

prove useful in industrial food production and processing.

Organic Acids by Microorganisms

Citric acid is the most important organic acid produced by fermentation with an estimated annual production of about half a million tonnes with the value

more than half a billion dollars. It is primarily used in

foods. Some of the other acids produced in large

quantities by fermentation are gluconic acid, lactic

acid and ascorbic acid, each with production over

50,000 tonnes per annum.

PAl: APPLICATIONS

OF MICRO-ORGANISMS

Citric acid had been prepared from citrus fruits like

lemon but now it is mostly produced by fermentation

using Aspergillus niger, in large corrosion resistant

fermenters having stirrers. Some yeasts like Candida

have also been used to a smaller extent. A smaller

amount is also made by older technique with surface

fermenters. In submerged culture, when environmental conditions are controlled, organisms grow into

small pellets. Sugar from cane molasses is commonly

used in the medium, which needs to be controlled for

trace metals like iron, copper etc. Maintenance of

very low pH avoids by-products formation. High

aeration rate is needed for higher yields. Conversion

of glucose to product is high (70-90%) depending on

the strain, purity of carbohydrate raw material, and

environmental conditions. By-product formation of

oxalic or gluconic acid can be reduced by strict control of growth conditions (Roehr et al, 1996).

A. niger strains have been developed by mutagenesis and screening, for higher productivity and adaptability to industrial fermenters. Some studies have

been undertaken

on parasexual

recombination,

diploidization, and heterokaryon formation, etc. (Visser, 1991). Although recombinant DNA technology

has been reported for Aspergillus species, no reports

are available on using this technique for commercial

citric acid production. Genes cloned from A. niger for

pyruvate kinase and phosphofructokinase

will tremendously improve the commercial strains producing

citric acid.

Lactic acid is another important acid produced by

fermentation, although an equal amount is also

chemically synthesised. The acid is mostly used for

the manufacture of emulsifiers and as additives in

food industry. It has two enantiomers, L( +)- and D(-)lactic acid. The L-lactic acid is involved in normal

human metabolism which can selectively be produced

by fermentation and this is used in food applications,

whereas the chemical synthesis produces DL-lactic

acid.

Strains of Lactobacillus delbruckii, L. casei, L.

helveticus and L. acidophilus, employed in commercial fermentation, can ferment a medium containing

12-15% sugar in 2 to 4 days with more than 90%

yield (Kascak et al, 1996). Most lactobacilli cannot

use starch. L. amylophilus and L. amylovorus are able

to ferment starch to lactic acid (Zhang & Chery an,

1991). The production of lactic acid or products like

ethanol, acetic acid, etc. depends on the strains as well

as the substrate and environmental conditions (Cheng

IN FOOD BIOTECHNOLOGY

383

et al, 1991). Lactobacilli are very fastidious and require many nutrients including nucleotides, amino

acids and vitamins provided by yeast extract or peptone.

Mutants can be generated spontaneously or by

mutagenic agents to give higher conversion or concentration of lactic acid. For commercial and economical production of lactic acid, the further improvements will expand substrate range, improve

product tolerance, use of simpler nitrogen, increase

disease resistance and control LID isomer ratio

(Demirci & Pometto, 1992).

Gluconic acid is prepared by fermentation using

mostly A. niger and less commonly Acetobacter (Gluconobacter) suboxidans and some Penicillium species(Milsom & Meers, 1985). A. niger produces acid

at high levels(97 -99%) with negligible by-products

when the trace elements are controlled and sufficient

manganese is present. Glucose is converted to glucono delta-lactone by glucose oxidase enzyme. The

lactone hydrolyses to gluconate. Fermentation conditions are designed to maintain high levels of this enzyme. Medium contains glucose with low levels of

phosphate and nitrogen to prevent excess growth.

High aeration, temperature about 30C and mildly

acidic pH produces gluconate rapidly. The pH is

maintained by adding CaC03 to produce calcium gluconate whereas NaOH gives sodium gluconate. A.

niger gene for glucose oxidase has been cloned into S.

cerevisiae, A. niger and A. nidulans to yield improved

organisms and fermentation (Kopetzski et al, 1989).

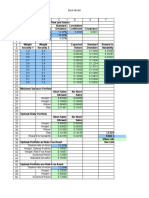

Microbial Enzymes in Food Industry

Enzymes have been used in foods such as leavening of bread, fermentation of fruit juices or malt, clotting of milk for cheese, etc. Purified enzymes are being used mostly in food industry although some still

use live cells as in leavening of bread and alcoholic

fermentation (Godfrey & West, 1996). World market

for enzymes, mostly microbial enzymes, is over 1.5

billion dollars. Newer applications for enzymes are in

detergents, textiles, paper & pulp, chemical industry,

etc. However, the largest application (over 45% of the

total enzyme produced), mostly bulk enzymes, is used

in foods (Ratledge & Kristiansen, 2001). Largest

market is for rennet (25%) followed by glucoamylase

(20%), a-amylase (16%) and glucose isomerase

(15%). Bulk enzymes normally cost less (Rs2351400/kg) whereas speciality enzymes may cost Rs

2,35,000 or more per kg.

384

INDIAN J BIOTECHNOL, JULY 2003

Cheese is traditionally prepared using calf rennet, a

protease. In 60s and 70s, due to severe shortage of

calf rennet, several substitutes from microorganisms,

Rhizomucor miehei, Endothia parasitica and Rhizomucor pusillus, were chosen by mutation and selection method. Recently, several genetically modified

microorganisms(E. coli, K. lac tis, A. niger), which

contain calf rennet gene, have been developed. Chymosin gene coding for calf rennet was taken from calf

stomach cells and inserted into a plasmid, which was

inserted into microbial cells. The microorganisms

started producing calf rennet (Madden, 1995). These

rennets by GMOs have been commercially produced

since 1980s and, in India, only the microbial rennet is

being used since the ban on calf rennet.

acting types. The industrially

important

exopeptidases are classified as per their catalytic mechanisms: serine, cysteine (thiol), metallo- and aspartic

(carboxyl) proteases. The serine proteases (PH, 9-11)

have no metal ion requirement and are resistant to

high temperature and oxidising agents. Such properties are further enhanced by protein engineering

making them useful in laundry detergents. They are

useful in production of fish-meal and protein hydrolysates from fish. Acid proteases, useful in cheese industry, are found less in bacteria than in moulds such

as Mucor from which commercial microbial rennet is

prepared. Similarly thiol proteases like papain are not

common in bacilli.

Bacillus spp., mostly extracellular, are important

source of stable enzymes for use in food industry.

These degrade substrate into smaller molecules,

which are easily absorbed by the bacteria. Some industrial enzymes produced by Bacillus sp. are Pullulanase by B. acidopullulyticus, a-amylase by B. amyloliquefaciens and B. licheniformis, glucose isomerase

by B. coagulans, ~-glucanase by B. subtilis, etc. (Cocconcelli et al, 1991).

Fermentative Production of Amino Acids

Amylases and related enzymes are mostly obtained

from Bacillus species (Svensson et al, 1991). The aamylase, that hydrolyse internal 1-4 a-bonds of starch

resulting in rapid reduction of viscosity of the substrate, is called liquefying enzyme and produces

mostly maltohexaose or maltopentaose. This enzyme

from B. licheniformis is exceptionally thermostable

and is used in starch processing. The enzyme from B.

subtilis is referred to as saccharifying ~-amylase as it

predominantly produces maltose and glucose from

starch. It shares limited sequence homology with the

liquefying enzymes and is less thermostable. The cyclodextrin glucanotransferases catalyse the hydrolysis

of amylose to cyclic dextrins, a-, ~- and ycyclodextrins, which have useful properties in food

industry for stabilisation of volatile flavours, enhancers, etc. These are also produced by a number of

Bacillus sp. While amylases hydrolyse 1-4 linkages,

pullulanase hydrolyse 1-6 a-linkages in pullulan and

amylopectin. Whereas saccharifying amylases yield

mostly maltose, glucoamylase produces glucose.

These are commercially produced mostly by fungal

cultures but a few Bacillus species are also used (Cole

et al, 1988).

The bacilli also produce proteases useful in food

industry. Proteases are divided into exo- and endo-

Many amino acids are used in food industry

(Leuchtenberger, 1996), L-glutamate as flavour enhancer, glycine as sweetener, lysine and methionine

as food and feed additives, aspartate and phenylalanine for aspartame, an low-calorie sweetener, etc. The

total commercial production of all the amino acids

(chemical and enzymatic) is over 1.6 million tonnes,

of which glutamate is almost 1 million tonnes, followed by lysine and methionine with each about

350,000 tonnes. The market is steadily growing at a

rapid rate of 5-10% per year. Amino acids produced

in larger quantities are cheaper, glutamate being the

cheapest followed by methionine and lysine. All three

cost less than Rs400 per kg. The two amino acids, not

needed in optically pure forms, are prepared by

chemical synthesis. Methionine can be utilised in dlor racemic form and glycine does not have d- and 1forms. Others are prepared either by fermentation or

by enzymatic catalysis.

Corynebacterium glutamicum is the most versatile

organism used commercially to prepare glutamate,

lysine, threonine, phenylalanine, etc. Escherichia,

Serratia, Bacillus, Hansenula, Candida, and Saccharomyces are also used in amino acid production, some

of them are genetically modified. Bacteria normally

do not accumulate large amounts of amino acids because of regulatory control over their synthesis. Mutants have to be prepared by laborious mutagenesis

and selecting the mutant producing highest amount.

By using recombinant DNA technology, new producers can be developed rapidly by increasing limiting

enzyme activities, etc. (Eggeling & Sahm, 1999).

The genome analysis of producer strains is now becoming a useful tool. Entire sequence of the chromo-

PAl: APPLICA nONS

OF MICRO-ORGANISMS

somes of C. glutamicum and E. coli is available. It is

possible to compare mutants and identify mutations

necessary for overproduction of metabolites (Eikmanns et ai, 1991; Miwa et ai, 1983). Genetic manipulations including transduction, transformation and

conjugation have been used in genetic study of these

bacteria. This has led to the understanding of regulatory mechanism for microbial metabolism at genes

level. Genetic engineering modification aimed at improving amino acid production by these organisms

has not yet resulted in substantial increase in amino

acid production (Aiba et ai, 1980). Amplification of

genes coding for limiting enzymes might result in increased amino acid production and is carried out by

multiple copy plasmids. There are problems of maintaining stability unless selective pressure is exerted by

adding antibiotics in the media. A new system with

Mu recombinant phages can integrate several copies

into the host chromosomes showing stable accumulation without antibiotic selection pressure.

Biotechnology of Dairy Products

Lactic acid bacteria (Lactobacillus,

Leuconostoc,

Pediococcus,

Bifidobacterium,

and Lactococcus) have

been used to improve the flavour, texture, preservation and nutritive value of dairy as well as vegetable,

cereal and legume fermentation products including

yoghurt, buttermilk, cheese, pickled vegetables, idli,

etc. (Luchansky et ai, 1988; Wood, 1992). In addition,

some are even used as probiotics, which contribute to

the overall health of the user. In milk, the lactic acid

bacteria ferment lactose and other sugars. Some proteases play role in the process along with the sugar

metabolising enzymes. Formation of these products as

well as compounds affecting flavour and texture gives

the typical pleasant aroma, taste and body to the

product. The metabolic activity also forms some useful vitamins. Many lactic acid bacteria like L. acidophilus and L. sake produce antimicrobial bacteriocins, which help in controlling unwanted microorganisms. Molecular strategies are being studied. Genetically engineered lactics with better fermentation

efficiency, better shelf-life, nutritional and sensory

properties for the product, etc. will be the target of

these studies (Lin & Savage, 1986).

When cheese, yoghurt, etc. are made, undesirable

contaminants can lead to poor flavour, low yield and

food poisoning. Lactic acid bacteria can be genetically engineered to grow faster than the contaminants,

as well as inhibit and destroy the growth of the contaminants including pathogens by producing antimi-

IN FOOD BIOTECHNOLOGY

385

crobial agents. The starter cultures have been modified to produce an antimicrobial agent, which destroys

cell walls of Listeria monocytogenes.

Similar modification can also be carried out to protect against organisms like Salmonella.

Alcoholic Fermentation using Improved Cultures

Yeast strain used in beer brewing is selected on the

basis of flavour and aroma, imparted by the strain

during fermentation. Flocculation, fermentation rate,

ethanol tolerance, osmotolerance, and oxygen requirements are other important factors in considering

different strains. For commercial beer production,

mostly S. uvarum and S. cerevisiae have been commonly used. Earlier protoplast fusion, which used to

produce a fusion product from S. uvarum and S. diastaticus, was not only more rapid in fermenting but

utilised available sugars more completely. Many of

the desirable properties can be incorporated by genetic modification (GMO). Though GMOs are not

being used commercially for brewing beer, but with

better understanding of genes controlling the properties of brewer's yeast and application of genetic engineering, increasing efficiency and productivity at

minimum cost without affecting adversely the beer

quality will soon become a reality. Some work is also

carried out to develop zymocide resistant strain.

The studies to improve the distiller's yeast strain

include manipulation of alcohol dehydrogenase promoter gene, leading to increased production of uamylase in S. cerevisiae (Ruohonen et ai, 1991),

cloning of regulatory genes into S. cerevisiae resulting in higher maltase activity thereby improved conversion to ethanol (Rodicio & Zimmermann, 1985),

transforming amylase genes from S. diastaticus into S.

cerevisiae to enable latter to utilise dextrins, incorporating glucoamylase genes from R. oryzae and A.

awamori(Ashikari

et ai, 1989). Most of the efforts

were directed towards faster and more complete conversion of carbohydrates to ethanol.

Miscellaneous Microbial Products

Candida utilis has been used industrially in the

production of SCP for food and fodder, waste treatment and the production of fine chemicals used as

flavour enhancers (Boze et ai, 1992). Among the

products useful in foods, besides SCP, are 5' -GMP &

5' -IMP, ethanol, ethylacetate, acetylaldehyde, amino

acids like serine, histidine, glutamic acid and lysine,

xylitol, etc. C. utilis does not possess enzymes to hydrolyse starch, cellulose or pectic substrates. Two-

386

INDIAN J BIOTECHNOL, JULY 2003

step dual fermentation can be carried out using C.

utilis with organisms like S. fibuliger, which produces

amylases and can be used in starch wastes, and T.

reesei, which has cellulases and can be used in cellulosic waste. Molecular genetics of C. utilis is not adequately studied. Although some transformations have

been successfully carried out, no commercial strain

has been developed by GMO including protoplast

fusion. Since some of the enzymes are lacking in this

organisms, incorporation of genes encoding these enzymes would produce a desirable modified organism

with application in food industry.

Bacillus species have provided traditional biotech

products such as extracellular enzymes and insect

toxins. B. thuringiensis strains with toxicities against

a variety of pests have been exploited to the extent of

getting the genes inserted into food crops for successful development of resistance against these pests.

Protein engineering and molecular technologies will

slowly replace screening programmes.

Future Applications of Biotechnology in Foods

At present, the large amounts of Genetically Modified (GM) Foods including soya beans, corn, tomatoes, etc. as well as ingredients from GM organisms

are being used in most parts of the world. With wide

acceptance to biotechnology in food applications,

commercial interest would stimulate research in the

area. With genetic engineering techniques being used

to develop improved cultures, there will be marked

improvement in production and quality in addition to

many new applications of microorganisms.

References

Aiba S et al, 1980. Enhancement of tryptophan production by

Escherichia coli as an application of genetic engineering.

Biotechnol Leu, 2, 525-530.

Ashikari T et al, 1989. Direct fermentation of raw corn to ethanol

by yeast transformants containing a modified Rhizopus glucoamylase gene. Appl Microbiol Biotechnol, 32, 129-133.

Boze H et al, 1992. Production of food and fodder yeasts. Crit

Rev Biotechnol, 12, 65-86.

Cheng P et al, 1991. Lactic acid production from enzyme-thinned

corn starch using Lactobacillus amylovorus. J Ind Microbiol,

7,27-34.

Cocconcelli P Set al, 1991. Single-stranded DNA plasmid, vector

construction and cloning of Bacillus stearothermophilus aamylase in Lactobacillus. Res Microbiol, 142,643-652.

Cole G E P et al, 1988. Stable expression of Aspergillus awamori

glucoamylase in distiller's yeast. Bioffechnology,

6, 417421.

Demirci A & Pometto III A L, 1992. Enhanced production of D

(- j-Iactic acid by mutants of Lactobacillus delbrueckii

ATCC9649. J Ind Microbiol, 11,23-28.

Eggeling L & Sahm H, 1999. L-glutamate and L-Iysine: tradi-

tional products with impetuous developments. Appl Microbioi Biotechnol, 52, 146-153.

Eikmanns B J et al, 1991, Amplification of three threonine biosynthesis genes in Corynebacterium glutamicum and its infuence on carbon flux in different strains. Appl Microbiol

Biotechnol, 34, 617-622.

Godfrey T & West S, 1996. Industrial Enzymology, 2nd edn.

Macmillan Press, London

Hui Y H & Khachatourians G G, 1995. Food Biotechnology: Microorganisms. VCH Publishers, Inc, N Y.

Kascak K et al, 1996. Lactic acid. in Biotechnology, edited by H J

Rehm & G Reed, 2nd edn, Vol. VI, Products of Primary Metabolism. Verlag Chemie, Weinheim. Pp 294-306.

Kopetzski E et al, 1989. Cloning and characterisation of baker's

yeast a-glucosidase: Over-expression in a yeast strain devoid

ofvacuolarproteinases.

Yeast,S, 11-24.

Leuchtenberger W, 1996. Amino acids, technical production and

use. in Biotechnology, edited by H J Rehm & G Reed, 2nd

edn, Vol. VI, Products of Primary Metabolism. Verlag

Chemie, Weinheim. Pp 455-502.

Lin J H-C & Savage 0 C, 1986. Genetic transformation of rifampicin resistance in Lactobacillus acidophilus. J Gen Microbioi, 132, 2107-2111.

Luchansky J B et al, 1988. Application of eiectroporation for

transfer of plasmid DNA to Lactobacillus, Lactococcus, Leuconostoc, Listeria, Pediococcus, Bacillus, Staphylococcus,

Enterococcus and Propionibacterium.

Mol Microbiol, 2,

637-646.

Madden D, 1995. Food Biotechnology, ILSI Press, Washington,

D.C.

Milsom P E & Meers J L, 1985. Gluconic and itaconic acids. in

Comprehensive Biotechnology: The Principles, Applications,

and Regulations of Biotechnology in Industry, Agriculture

and Medicine, edited by H W Blanch, S Drew & D I C

Wang, Vol. III. Pergamon Press, Oxford. Pp 681-700.

Miwa K et al, 1983. Construction of L-threonine overproducing

strains of Escherichia coli K-12 using recombinant DNA

technique. Agric Bioi Chem, 47, 2329-2334.

Ratledge C & Kristiansen B, 2001. Basic Biotechnology, 2nd edn.

Cambridge Univ Press, UK.

Rodicio, R & Zimmermann F K, 1985. Cloning of maltase regulatory genes in S. cerevisiae. Curr Genet, 9, 539-551.

Roehr Met al, 1996. Citric acid. in Biotechnology, edited by H J

Rehm & G Reed, 2nd edn, Vol. VI, Products of Primary Metabolism. Verlag Chemie, Weinheim. Pp 308-345.

Ruohonen L et al, 1991. Optimisation of Bacillus a-amylase production by S. cerevisiae. Yeast, 7, 337-346.

Svensson B et al, 1991. Structure function relationships in amylases. in Biotechnology of Amylodextrin Oligo saccharides,

edited by R B Friedman. American Chemical Society,

Washington, DC. Pp 28-43.

Visser J, 1991. Biochemical and molecular approaches in understanding carbohydrate metabolism in Aspergillus niger. J

Chem Technol Biotechnol, 50, 111-113.

Wood B J B, 1992. The Lactic Acid Bacteria in Health and Disease. Elsevier Science Publ, London.

Zhang D X & Cheryan M, 1991. Direct fermentation of starch to

lactic acid by Lactobacillus amylovorus. Biotechnol Leu, 13,

733-738.

Vous aimerez peut-être aussi

- CARBOWAX™ Polyethylene Glycol (PEG) 1000Document2 pagesCARBOWAX™ Polyethylene Glycol (PEG) 1000Anonymous vJPniV7Pas encore d'évaluation

- 7 - BP Khaswar - Single Cell Protein and Its ApplicationDocument35 pages7 - BP Khaswar - Single Cell Protein and Its ApplicationRendy CisaraPas encore d'évaluation

- Advances in Dairy ProductsD'EverandAdvances in Dairy ProductsFrancesco ContoPas encore d'évaluation

- SA 8000 Audit Check List VeeraDocument6 pagesSA 8000 Audit Check List Veeranallasivam v92% (12)

- Industrial MicrobiologyDocument0 pageIndustrial Microbiologymmoradi55100% (2)

- Hodgkin LymphomaDocument44 pagesHodgkin LymphomaisninePas encore d'évaluation

- 15 Yeast in BiotechnologyDocument6 pages15 Yeast in BiotechnologyMichael Vincent MonteroPas encore d'évaluation

- Lactic Acid Industrial ProductionDocument20 pagesLactic Acid Industrial Productiondorei100% (1)

- Applied and Industrial MicrobiologyDocument57 pagesApplied and Industrial MicrobiologyWinstonSwaby100% (1)

- Postoperative Care in Thoracic Surgery A Comprehensive GuideDocument397 pagesPostoperative Care in Thoracic Surgery A Comprehensive GuideΑΘΑΝΑΣΙΟΣ ΚΟΥΤΟΥΚΤΣΗΣ100% (1)

- Fermentative Production of Lactic Acid FDocument11 pagesFermentative Production of Lactic Acid FDHENADAPas encore d'évaluation

- Production of Metabolites, Industrial Enzymes, AminoDocument50 pagesProduction of Metabolites, Industrial Enzymes, AminoInuyashayahooPas encore d'évaluation

- General Process For The Preparation of Single Cell ProteinsDocument19 pagesGeneral Process For The Preparation of Single Cell ProteinsNikita BatraPas encore d'évaluation

- Starter Cultures in Food ProductionD'EverandStarter Cultures in Food ProductionBarbara SperanzaPas encore d'évaluation

- Jurnal MikrobiologiDocument14 pagesJurnal MikrobiologiWita RismaPas encore d'évaluation

- Growth Studies of Potentially Probiotic Lactic Acid Bacteria in Cereal-Based SubstratesDocument9 pagesGrowth Studies of Potentially Probiotic Lactic Acid Bacteria in Cereal-Based SubstratesSjjshahaPas encore d'évaluation

- MTP NewDocument23 pagesMTP Newhalewat AbebePas encore d'évaluation

- InTech-Gel Electrophoresis For Investigating Enzymes With Biotechnological ApplicationDocument15 pagesInTech-Gel Electrophoresis For Investigating Enzymes With Biotechnological Applicationchavi1310Pas encore d'évaluation

- Artículo PDFDocument7 pagesArtículo PDFEric Adiel Lona GaribayPas encore d'évaluation

- Food IndustryDocument8 pagesFood IndustrySabnam HossainPas encore d'évaluation

- Name: Nityantini D/O Nadeson REG NUMBER: 33DFO1E8F1009 Subject: Biotechnology (Tutorial Assessment) Lect Name: Miss Dina IzzatyDocument8 pagesName: Nityantini D/O Nadeson REG NUMBER: 33DFO1E8F1009 Subject: Biotechnology (Tutorial Assessment) Lect Name: Miss Dina IzzatynityaPas encore d'évaluation

- FermentationDocument3 pagesFermentationbretz.andreiPas encore d'évaluation

- Production of Lactic Acid From Starchy-Based Food SubstratesDocument9 pagesProduction of Lactic Acid From Starchy-Based Food SubstratesYoali HdezPas encore d'évaluation

- Teff Type-I Sourdough To ProduDocument21 pagesTeff Type-I Sourdough To ProdudanaPas encore d'évaluation

- Food Preservation Processing: NT30903. andDocument47 pagesFood Preservation Processing: NT30903. andAhmad Syamil Muhamad ZinPas encore d'évaluation

- A Novel Application of Solid State Culture Production of Lipases byDocument5 pagesA Novel Application of Solid State Culture Production of Lipases byasep muhamadPas encore d'évaluation

- Yeast Transgenic PlantsDocument5 pagesYeast Transgenic PlantsTooba Iqbal67% (6)

- (Honorato Et Al., 2007) Fermentation of Cashew Apple Juice To Produce High Added Value ProductsDocument7 pages(Honorato Et Al., 2007) Fermentation of Cashew Apple Juice To Produce High Added Value ProductsRosane CavalcantePas encore d'évaluation

- Food Biotechnology NotesDocument42 pagesFood Biotechnology NotesThirulogaSundhar BalakamatchiPas encore d'évaluation

- SCP CompleteDocument13 pagesSCP Completeviveka_vgo182471100% (3)

- 25 LSA Jakathi PDFDocument4 pages25 LSA Jakathi PDFLife Science ArchivesPas encore d'évaluation

- 10 1097@sga 000000000000036833Document12 pages10 1097@sga 000000000000036833khawla 2020Pas encore d'évaluation

- Z Biotech - RevisedDocument51 pagesZ Biotech - Revisedrani padamavathiPas encore d'évaluation

- Food and Beverage BiotechnologyDocument10 pagesFood and Beverage BiotechnologyHayderPas encore d'évaluation

- Lactic Acid Industrial ProductionDocument20 pagesLactic Acid Industrial ProductionJossePas encore d'évaluation

- Applications of Biotechnology in Food and AgricultureDocument2 pagesApplications of Biotechnology in Food and AgriculturekingsleyesedebePas encore d'évaluation

- Introduction of LipaseDocument38 pagesIntroduction of LipaseRamneet RanaPas encore d'évaluation

- NBECT Handout 12 INDUSTRIAL BIOTECHNOLOGYDocument16 pagesNBECT Handout 12 INDUSTRIAL BIOTECHNOLOGYAlliana EclarinalPas encore d'évaluation

- Bioresource Technology: Contents Lists Available atDocument7 pagesBioresource Technology: Contents Lists Available atAtchaya அட்சயாPas encore d'évaluation

- Production and Partial Characterization of Extracellular Amylase Enzyme From Bacillus Amyloliquefaciens P-001Document12 pagesProduction and Partial Characterization of Extracellular Amylase Enzyme From Bacillus Amyloliquefaciens P-001Matache GabrielaPas encore d'évaluation

- Why Inspection Microbial EnzymesDocument3 pagesWhy Inspection Microbial EnzymesAbdel Azim MohamedPas encore d'évaluation

- Food Biotechnology: Tahir Zahoor, Muhammad Saeed, Salim-ur-Rehman and Nazia KhalidDocument17 pagesFood Biotechnology: Tahir Zahoor, Muhammad Saeed, Salim-ur-Rehman and Nazia KhalidM SPas encore d'évaluation

- Evaluation of A Novel Low-Cost Culture MediumDocument8 pagesEvaluation of A Novel Low-Cost Culture MediumRosita HandayaniPas encore d'évaluation

- Algal BiotechDocument32 pagesAlgal BiotechKezhakkekarammal Puthiyedattu SandeepPas encore d'évaluation

- Azaizeh2020 - Production of Lactic Acid From Carob, Banana and Sugarcane Lignocellulose Biomass.Document14 pagesAzaizeh2020 - Production of Lactic Acid From Carob, Banana and Sugarcane Lignocellulose Biomass.Caitlyn Danielle Ogay SeePas encore d'évaluation

- Biotechnology in Microbial ProcessesDocument13 pagesBiotechnology in Microbial Processesolamicro50% (2)

- CAL A Expression in Picia PastorisDocument8 pagesCAL A Expression in Picia PastorisankurnewaskerPas encore d'évaluation

- 1.1the Role of Biotechnology in Food Production and ProcessingDocument12 pages1.1the Role of Biotechnology in Food Production and ProcessingJavierPas encore d'évaluation

- Bridging Biotechnology and Nanomedicine To Produce Biogreen Whey-Nanovesicles For Intestinal Health PromotionDocument47 pagesBridging Biotechnology and Nanomedicine To Produce Biogreen Whey-Nanovesicles For Intestinal Health PromotionTeresita CamachoPas encore d'évaluation

- Selection of Micro-OrganismsDocument9 pagesSelection of Micro-OrganismsNizar MousaPas encore d'évaluation

- Large Scale Production of Enzymes - Gaurav - ShresthaDocument22 pagesLarge Scale Production of Enzymes - Gaurav - ShresthaShivam AnandPas encore d'évaluation

- Metabolic EngineeringDocument9 pagesMetabolic EngineeringArup ChakrabortyPas encore d'évaluation

- Fermentation 1Document18 pagesFermentation 1MD. FOYSAL SIKDERPas encore d'évaluation

- Citric Acid Production From Molasses Use Biosynthesis Aspergillus NigerDocument4 pagesCitric Acid Production From Molasses Use Biosynthesis Aspergillus NigerManasa Sai AllavarapuPas encore d'évaluation

- Single Cell ProteinDocument3 pagesSingle Cell ProteinIamPankajPas encore d'évaluation

- Microbial Biomass ProductionDocument32 pagesMicrobial Biomass Productionpramudita nadiahPas encore d'évaluation

- Isolation of Lactic Acid Producing Bacteria and Production of Lactic Acid From IsolatesDocument6 pagesIsolation of Lactic Acid Producing Bacteria and Production of Lactic Acid From IsolatesNIET Journal of Engineering & Technology(NIETJET)Pas encore d'évaluation

- 15 TH PPT of Foods and Industrial MicrobiologyCourse No. DTM 321Document24 pages15 TH PPT of Foods and Industrial MicrobiologyCourse No. DTM 321Gounder KirthikaPas encore d'évaluation

- Module-9 (Theory) Media FormulationDocument4 pagesModule-9 (Theory) Media FormulationriyaPas encore d'évaluation

- Rhizopus Oryzae: Production of L-Lactic Acid From Starch and Food Waste by Amylolytic MTCC 8784Document11 pagesRhizopus Oryzae: Production of L-Lactic Acid From Starch and Food Waste by Amylolytic MTCC 8784Christin SimamoraPas encore d'évaluation

- Yeast Biomass Production: A New Approach in Glucose-Limited Feeding StrategyDocument8 pagesYeast Biomass Production: A New Approach in Glucose-Limited Feeding StrategyJoão Luis Bortolussi RodriguesPas encore d'évaluation

- Residual Yoghurt Whey For Lactic Acid ProductionDocument8 pagesResidual Yoghurt Whey For Lactic Acid ProductionJuan Daniel GuaquetaPas encore d'évaluation

- Micro-Algae Assisted Bioremediation of Simulated Dairy Effluent and ValorizationDocument227 pagesMicro-Algae Assisted Bioremediation of Simulated Dairy Effluent and ValorizationImane GadiPas encore d'évaluation

- A Compilation of Ligno-Cellulose Feedstock and Related Research for Feed, Food and EnergyD'EverandA Compilation of Ligno-Cellulose Feedstock and Related Research for Feed, Food and EnergyPas encore d'évaluation

- SSP 465 12l 3 Cylinder Tdi Engine With Common Rail Fuel Injection SystemDocument56 pagesSSP 465 12l 3 Cylinder Tdi Engine With Common Rail Fuel Injection SystemJose Ramón Orenes ClementePas encore d'évaluation

- Gay Costa Del Sol - 2010Document2 pagesGay Costa Del Sol - 2010gayinfospainPas encore d'évaluation

- f2607-#### f2607 20191203 111644Document2 pagesf2607-#### f2607 20191203 111644คุณชายธวัชชัย เจริญสุขPas encore d'évaluation

- Microsoft Security Intelligence Report Volume 21 EnglishDocument180 pagesMicrosoft Security Intelligence Report Volume 21 EnglishAlejandro CadarsoPas encore d'évaluation

- Paterno Report: Dr. Fred S. Berlin, M.D., PH.D Final Report 2-7-2013Document45 pagesPaterno Report: Dr. Fred S. Berlin, M.D., PH.D Final Report 2-7-2013The Morning CallPas encore d'évaluation

- Coarse DispersionsDocument35 pagesCoarse Dispersionsraju narayana padala0% (1)

- Essay 31 - Permissive ParentingDocument2 pagesEssay 31 - Permissive Parentingqbich37Pas encore d'évaluation

- Tcu Module Pe1 Lesson 1Document7 pagesTcu Module Pe1 Lesson 1Remerata, ArcelynPas encore d'évaluation

- PV2R Series Single PumpDocument14 pagesPV2R Series Single PumpBagus setiawanPas encore d'évaluation

- Brochure - ILLUCO Dermatoscope IDS-1100Document2 pagesBrochure - ILLUCO Dermatoscope IDS-1100Ibnu MajahPas encore d'évaluation

- My Public Self My Hidden Self My Blind Spots My Unknown SelfDocument2 pagesMy Public Self My Hidden Self My Blind Spots My Unknown SelfMaria Hosanna PalorPas encore d'évaluation

- EB Research Report 2011Document96 pagesEB Research Report 2011ferlacunaPas encore d'évaluation

- Family Stress TheoryDocument10 pagesFamily Stress TheoryKarina Megasari WinahyuPas encore d'évaluation

- Ancon Tension Systems March 2008Document16 pagesAncon Tension Systems March 2008Slinky BillPas encore d'évaluation

- Amul Amul AmulDocument7 pagesAmul Amul Amulravikumarverma28Pas encore d'évaluation

- LECTURE NOTES-EAT 359 (Water Resources Engineering) - Lecture 1 - StudentDocument32 pagesLECTURE NOTES-EAT 359 (Water Resources Engineering) - Lecture 1 - StudentmusabPas encore d'évaluation

- Chapter 8 - Lipids and Proteins Are Associated in Biological Membranes - Part 1Document44 pagesChapter 8 - Lipids and Proteins Are Associated in Biological Membranes - Part 1Tommy RamazzottoPas encore d'évaluation

- Electric Field Summary NotesDocument11 pagesElectric Field Summary NotesVoyce Xavier PehPas encore d'évaluation

- White Vaseline: Safety Data SheetDocument9 pagesWhite Vaseline: Safety Data SheetHilmi FauziPas encore d'évaluation

- Dwnload Full Fundamentals of Nursing 1st Edition Yoost Test Bank PDFDocument35 pagesDwnload Full Fundamentals of Nursing 1st Edition Yoost Test Bank PDFdetonateousellslbc100% (11)

- BKM 10e Ch07 Two Security ModelDocument2 pagesBKM 10e Ch07 Two Security ModelJoe IammarinoPas encore d'évaluation

- 10.1.polendo (Additional Patent)Document11 pages10.1.polendo (Additional Patent)Rima AmaliaPas encore d'évaluation

- Public Conveyances: Environments in Public and Enclosed Places"Document1 pagePublic Conveyances: Environments in Public and Enclosed Places"Jesse Joe LagonPas encore d'évaluation

- CP 1Document22 pagesCP 1api-3757791100% (1)

- TCJ Series: TCJ Series - Standard and Low Profile - J-LeadDocument14 pagesTCJ Series: TCJ Series - Standard and Low Profile - J-LeadgpremkiranPas encore d'évaluation

- Team SportsDocument143 pagesTeam SportsYashPas encore d'évaluation