Académique Documents

Professionnel Documents

Culture Documents

JSA NO 3-Pile Cap

Transféré par

knabpshoTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

JSA NO 3-Pile Cap

Transféré par

knabpshoDroits d'auteur :

Formats disponibles

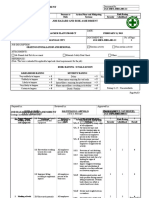

MITISA HOLDINGS SDN BHD

Jobs Safety Analysis

Revision No.

Page No.

Effective Date

0

of

15/01/09

JSA NO : 003 PILE CAP WORKS

Project Name:

Location:

Task/Activity: EXCAVATION OF PITS, PILE HACKING, PILE CAP PREPARATION AND

CONCRETING WORKS.

This SWMS/JSA has been developed and

approved by: ________________________

Duration:

Position: __________________ Date: _ / __ /

Resources Trades Involved:

Equipment Used: CRANE, EXCAVATOR, AIR COMPRESOR, VIBRATOR

Maintenance checks:

Materials Used:

Safety Legislation:

Code/s Of Practice (COP) Applicable To The Works

MITISA HOLDINGS SDN BHD

Revision No.

Page No.

Jobs Safety Analysis

Item

1

Job Steps

Pile cap setting out.

Pile cap setting out are marked on

the ground with steel bars as pegs

of length less than 150 mm by

surveyor.

Excavation

Risk

Category

Effect

1.Pierced by steel

bars.

Moderate

illness /Injury

Damage

Fatality/

Permanent

Disability

16

1. Buried services

Piled area will be excavated to form

pile groups to be later caste as pile

caps.

Effective Date

Hazards

Fatality/

Permanent

Disability

15/01/09

Controls

1.

Tie a brightly colored barrier tape

for easy identification to steel peg.

Responsible

Person

Surveyor

Chain man

2. Peg to be bent over at top to prevent risk

of being pierced if one falls on the peg.

1. Drawing to be reviewed to ensure

no buried services present in the

excavation area.

1.1 Operator and the workers to be

fully briefed on what to look for in

the ground during the excavation

works.E.g.

a) Marker tape

b) Changes in earth colour

c) Any bricks found in the

excavation.

d) PVC Conduits or pipes or

services

If any of the above are found the

works to stop and supervisor to

be notified.

2.collapseof

excavated soil due

to erosion.

0

of

12

2.1 Excavated soil to be placed at

minimum of 1 meter away from

the edge of the pit to ensure pit

does not cave in due to

excessive weight on top.

Site

Supervisor

Safety

Supervisor

Machine

operator

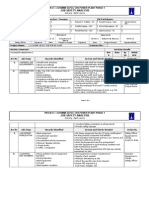

MITISA HOLDINGS SDN BHD

Revision No.

Page No.

Jobs Safety Analysis

Item

Job Steps

Hazards

Effective Date

Risk

Category

Effect

0

of

15/01/09

Controls

Responsible

Person

2.2 Installation of Polythene Sheet

(heavy duty) when excavation is

completed. The sheet is to be

installed into excavated trench

and weighted down by an earth

bund that double up as a

stoppage to surface water from

running into the excavated area.

2.3 Regular maintenance checks on the

Polythene sheet protection to the slope

to be carried out especially after a wet

weather.

3.

Access into excavation area

Hacking of pile to the required cut

off levels.

1. Falls

Serious

Illness /

Injury Major

Damage

1. Noise during

hacking works

Moderate

illness /Injury

Damage

Moderate

illness /Injury

Damage

2. Hand injuries

3. Eye injuries

Serious

Illness /

Injury Major

Damage

12

1. A safe designated access will be

provided into the pit. All workers to

use the access..

Site supervisor

1. Hackers to use Ear plug at all times

while hacking works are being

undertaken..

Site supervisor

2. Use hand gloves during fixing up.

Air breaker shall also be tied to the

existing pile heads to avoid slip

during hacking.

3. Safety goggles to be used while

Hacking.

Safety

supervisor

Pile hackers

MITISA HOLDINGS SDN BHD

Revision No.

Page No.

Jobs Safety Analysis

Item

6.

Job Steps

Hazards

Effective Date

Risk

Category

Effect

Controls

4.Struck by flying

hoses from air

compressor.

Minor

illness /injury

Minor

Damage

4. To prevent the possibility of

hoses coming free during the

hacking works from the compressor

it is necessary at all times to wire

the hoses together at the joints of

the hoses.

Lift and removal of unused

concrete pile heads for disposal by

1. Bodily injuries

Minor

illness /injury

Minor

Damage

1. Removal to be done by using lifting

machinery eg: crane or excavator.

crawler crane or excavator

2. Hit by

excavator bucket

2. Operator to ensure swinging radius

is clear

Fabrication of formwork as mould

for pile cap concreting

1. Bodily injuries

Placement of reinforcement bars in

to the mould prior to concreting

2. Stepping on nails

Cleaning of the area prior to

concreting works.

3. Flying of loose

objects

Serious

Illness /

Injury Major

Damage

Minor

illness /injury

Minor

Damage

Minor

illness /injury

Minor

Minor

illness /injury

Minor

Damage

1. Proper working clothes is required

to be worn while working in the

area.

2. All protruding nails to be bent.

3. Cleaning with pressurized air to be

done after all works are complete

in the pile cap area and no workers

to be present other than the

cleaning workers.

0

of

15/01/09

Responsible

Person

Supervisor

Machine

operator

Foreman

Safety

supervisor

Trade

Foreman

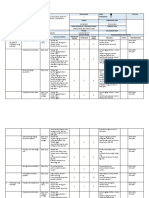

MITISA HOLDINGS SDN BHD

Revision No.

Page No.

Jobs Safety Analysis

Item

7

Job Steps

Concreting works for pile cap

Striping of pile cap formwork

Hazards

1. Falling into the

concreting area.

Effective Date

Risk

Category

Effect

Serious

Illness /

Injury Major

2. Hand injury

Serious

Illness /

Injury Major

12

1. Bodily injury

Moderate

illness /Injury

0

of

15/01/09

Controls

Responsible

Person

1. Standing platform to be placed on

top of rebars for workers to stand

and do concreting works for large

pile caps.

Supervisor

2. Concreters to use rubberized hand

gloves to avoid contemning their

hands with concrete.

Safety

Supervisor

1. Striping to be done by trained

carpenters.

Trade

Foreman

2. Protruding nails from formwork

stripped to be bent.

Safety

Supervisor

Trade

Foreman

3. All stripped formwork to be stacked

up in a safe manner in order to be

used later.

4

Personnel Protection

1. Personnel injury

Monitor Compliance

The Project Manager or the appointed

personal shall on a weekly basis audit this

procedure.

Records.

Copy of the JSA to be retain in the site

safety file by the contractor Project Manager

or appointed personal

Serious

Illness /

Injury Major

1. All site personnel shall at all times

wear the minimum Personnel

Protection Equipment

All Personnel

MITISA HOLDINGS SDN BHD

Jobs Safety Analysis

Revision No.

Page No.

Effective Date

Remarks / Precaution to be taken not captured in the JSA :

0

of

15/01/09

MITISA HOLDINGS SDN BHD

Revision No.

Page No.

Jobs Safety Analysis

Effective Date

Qualifications and experience required to complete the task:

Personnel, Duties and Responsibilities (Supervisory staff and

others):

1. Competent machinery operators

1. Safety Supervisor to ensure compliance to the

JSA at all times.

0

of

15/01/09

Training Required to Complete Work:

2. JSA to be briefed to all workers involved in the

activity and recorded.

Engineering Details/Certificates/Work cover Approvals:

This SWMS/JSA has been developed through consultation with our employees and has been read & signed by all employees undertaking the works:

Print Names

Signature

Date

Print Names

Signature

Date

RISK MATRIX.

Probability

Practically

Impossible

Not likely to Occur

Could occur i.e

heard of happening

Know To Occur i.e

Has Happened in The

Past.

Know To Be A Common

Or Repeating

Occurrence

Minor illness /injury Minor

Damage

Moderate illness /Injury

Damage

10

Serious Illness / Injury

Major Damage

12

15

Consequence

MITISA HOLDINGS SDN BHD

Revision No.

Page No.

Jobs Safety Analysis

Fatality/Permanent

Disability

Low ( L:1-3 )

Effective Date

12

20

High ( H:9-20 )

H

Minor illness /injury Minor Damage

Required first Aid Treatment : repairable / immediate replacement

Moderate illness /Injury Damage

Out patient / 4 days and less MC: repairable but limited workdays

Serious Illness / Injury Major Damage

Warded / temporary disability / more than 4 days MC irreparable / total lost

Fatality/Permanent Disability

Fatality within 1 year /Permanent disability

15/01/09

16

Medium ( M:4-8 )

M

0

of

Vous aimerez peut-être aussi

- RAM - Pile CroppingDocument14 pagesRAM - Pile CroppingDaniel Cryer0% (1)

- Dental Hygienist Learning Outcomes Form v1.2Document32 pagesDental Hygienist Learning Outcomes Form v1.2Karman Deep Singh100% (1)

- JSA Erection of Gathering TentDocument12 pagesJSA Erection of Gathering TentMuhammad Tariq100% (2)

- Rapid P20ai Jsa Box CulvertDocument10 pagesRapid P20ai Jsa Box CulvertChung May Lynn100% (2)

- Rmdjv-pj74-Hiradc-subc 10 (Turfing & Landscaping)Document2 pagesRmdjv-pj74-Hiradc-subc 10 (Turfing & Landscaping)myn maliQue100% (1)

- Comprehensive Soup ProjectDocument98 pagesComprehensive Soup ProjectSachin Soni63% (8)

- Land ClearingDocument9 pagesLand ClearingAzmi Fauzi100% (2)

- SWP BackfillDocument1 pageSWP BackfillMohamed Zied ChaariPas encore d'évaluation

- ULSADO-JSA - Installation of Temporary Fence GateDocument2 pagesULSADO-JSA - Installation of Temporary Fence GateKelvin TanPas encore d'évaluation

- Job Hazard Analysis: Task Excavation and Laying of Cable From A8 To A9Document4 pagesJob Hazard Analysis: Task Excavation and Laying of Cable From A8 To A9OGBONNAYA MARTINSPas encore d'évaluation

- JSA NO 8-Roof WorkDocument6 pagesJSA NO 8-Roof WorkknabpshoPas encore d'évaluation

- LGT - SWMS - Bored Pile WorksDocument9 pagesLGT - SWMS - Bored Pile WorkssinthianPas encore d'évaluation

- Agtes New PDFDocument4 pagesAgtes New PDFSaravanan RasayaPas encore d'évaluation

- Ws - Mea Millennium Ecosystem AssessmentDocument3 pagesWs - Mea Millennium Ecosystem Assessmentapi-305791685Pas encore d'évaluation

- Vendor Security ChecklistDocument11 pagesVendor Security ChecklistHarisPas encore d'évaluation

- Block Work MS (Sample)Document18 pagesBlock Work MS (Sample)jones100% (1)

- JGS SHES JHRA 001 13 Grating Installation and RemovalDocument2 pagesJGS SHES JHRA 001 13 Grating Installation and Removalarnel sungkip100% (2)

- Wall Painting Risk AssesmentDocument3 pagesWall Painting Risk AssesmentJacob ChirayilPas encore d'évaluation

- Trial Pit During ExcavationDocument3 pagesTrial Pit During Excavationmujahid1137Pas encore d'évaluation

- Job Safety Analysis - Piling WorkDocument11 pagesJob Safety Analysis - Piling WorkAhmad MensaPas encore d'évaluation

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety AnalysisDocument4 pagesProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety AnalysisJohn100% (1)

- JACK IN Piling WorkDocument9 pagesJACK IN Piling WorkShaheed AzharPas encore d'évaluation

- Risk AssessmentDocument3 pagesRisk AssessmentSam HodgsonPas encore d'évaluation

- Children & Young People's Services RISK ASSESSMENTDocument2 pagesChildren & Young People's Services RISK ASSESSMENThaziq ziqPas encore d'évaluation

- JsaDocument7 pagesJsaAnees TPas encore d'évaluation

- Lim Meng Heck (SR - Operation Manager) : ISK Ssessment ORMDocument2 pagesLim Meng Heck (SR - Operation Manager) : ISK Ssessment ORMVaradaraju ThirunavukkarasanPas encore d'évaluation

- Rapid P20ai Jsa Box CulvertDocument8 pagesRapid P20ai Jsa Box Culvertfadli.lpgPas encore d'évaluation

- Hazard Risk Assessment of Jack HammerDocument14 pagesHazard Risk Assessment of Jack HammerAkhtar BahramPas encore d'évaluation

- JSA Demolish Existing Concrete Foundation EDGDocument1 pageJSA Demolish Existing Concrete Foundation EDGWidya PrasetyaPas encore d'évaluation

- ISC-JSA Grouting Works For Shared FenceDocument4 pagesISC-JSA Grouting Works For Shared FenceSameer AlmahboubPas encore d'évaluation

- RS Concrete Pumping Risk AssessmentDocument8 pagesRS Concrete Pumping Risk AssessmentLito PanchoPas encore d'évaluation

- JSA - Anchor Bolt and Template Lifting From Ground To Elevated Work PlatformDocument6 pagesJSA - Anchor Bolt and Template Lifting From Ground To Elevated Work PlatformRaju KhalifaPas encore d'évaluation

- Cutting WorkDocument1 pageCutting WorkGudduPas encore d'évaluation

- 5-Risk Assessment For Excavation & Backfilling and Compaction WorksDocument15 pages5-Risk Assessment For Excavation & Backfilling and Compaction WorksAmran HossainPas encore d'évaluation

- Hirarc CRDocument76 pagesHirarc CRNazri100% (1)

- Jsa006-Construction of Retaining WallDocument5 pagesJsa006-Construction of Retaining WallWan Muhammad Faiz100% (1)

- Tool Box Talk - MK - Emergency Response ProceduresDocument2 pagesTool Box Talk - MK - Emergency Response ProceduresPaul McGahanPas encore d'évaluation

- Risk Assessment - Erection of Temporary Shoring System at Valve Chamber No. 1 & No. 2rev1.1Document14 pagesRisk Assessment - Erection of Temporary Shoring System at Valve Chamber No. 1 & No. 2rev1.1Pang Lee ChingPas encore d'évaluation

- Demolition JhaDocument2 pagesDemolition JhaElvyn Fabellore HerreraPas encore d'évaluation

- 9 Use of Hand Roller Compactor SafetyDocument2 pages9 Use of Hand Roller Compactor SafetyarchiePas encore d'évaluation

- JSA NO 2-Piling WorkDocument3 pagesJSA NO 2-Piling WorkKarthik GanesanPas encore d'évaluation

- Health, Safety, & Environment Manual: Piling WorksDocument12 pagesHealth, Safety, & Environment Manual: Piling Worksrizal azizanPas encore d'évaluation

- Hirarc ExcavationDocument6 pagesHirarc ExcavationKalai Arasan100% (1)

- Operational Control Procedure For Excavation.: 1.0 PurposeDocument3 pagesOperational Control Procedure For Excavation.: 1.0 Purposebabu541Pas encore d'évaluation

- Jsa No: 00 - Piling WorksDocument4 pagesJsa No: 00 - Piling WorksUMUTPas encore d'évaluation

- Risk Assessment Sheet For Floor Screed Works: China Harbour Engineering Co.L.L.CDocument5 pagesRisk Assessment Sheet For Floor Screed Works: China Harbour Engineering Co.L.L.CYash SharmaPas encore d'évaluation

- Excavations JSA Final 2015Document5 pagesExcavations JSA Final 2015jithin shankarPas encore d'évaluation

- 10 JSA Excavation, Lowering, Back FillingDocument8 pages10 JSA Excavation, Lowering, Back FillingYosua SitumorangPas encore d'évaluation

- Petrochina International Jabung Ltd. Job Safety Analysis: Put On Ppe Required For A Safe JobDocument3 pagesPetrochina International Jabung Ltd. Job Safety Analysis: Put On Ppe Required For A Safe JobYosua SitumorangPas encore d'évaluation

- Earth Works JSADocument4 pagesEarth Works JSARen SalazarPas encore d'évaluation

- cONSTRUCTION WORK JSADocument21 pagescONSTRUCTION WORK JSAMohammed AlshehhiPas encore d'évaluation

- JSO Cable Drum (02 Sept.'07)Document2 pagesJSO Cable Drum (02 Sept.'07)Francis Enriquez TanPas encore d'évaluation

- Risk Assessment What Work Excavation Work With Help of JCB Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDDocument2 pagesRisk Assessment What Work Excavation Work With Help of JCB Location PM Warehouse Area Contractor Company-Aalanna Project PVT LTDhemant yadav0% (1)

- HSE-F-314 Passenger-Material Hoist Monthly ChecklistDocument1 pageHSE-F-314 Passenger-Material Hoist Monthly ChecklistAhmad RazaPas encore d'évaluation

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument6 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagya100% (1)

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDocument5 pagesJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagyaPas encore d'évaluation

- Risk Assessment DAWRA001R4 Loading Unloading Vehicles 090621Document2 pagesRisk Assessment DAWRA001R4 Loading Unloading Vehicles 090621Danny100% (1)

- Hirac (Small Power Installation)Document4 pagesHirac (Small Power Installation)tanaPas encore d'évaluation

- DemolitionDocument2 pagesDemolitionGanga Daran100% (1)

- Job Safety Analysis For Pump Installation in Ts3 Area: Hcu & Lobs Revamp ProjectDocument5 pagesJob Safety Analysis For Pump Installation in Ts3 Area: Hcu & Lobs Revamp ProjectShilpiengg SafetyPas encore d'évaluation

- HIRADC Installation PipeDocument4 pagesHIRADC Installation PipeamizanPas encore d'évaluation

- Anchor Bolt Setting - Rev 01Document26 pagesAnchor Bolt Setting - Rev 01Geherson AbustanPas encore d'évaluation

- JSA NO 3-Pile CapDocument8 pagesJSA NO 3-Pile Capknabpsho50% (2)

- JSA Piling WorkDocument6 pagesJSA Piling WorkAhmad 'mat' Rahmat100% (2)

- Building Construction I - REPORTDocument46 pagesBuilding Construction I - REPORTMuhammad NazmiPas encore d'évaluation

- I1 Staff ResponsibilitiesDocument1 pageI1 Staff ResponsibilitiesknabpshoPas encore d'évaluation

- Factories and Machinery Act 1967 (Revised - 1974) (Acts 139) Ve - Acts139Document39 pagesFactories and Machinery Act 1967 (Revised - 1974) (Acts 139) Ve - Acts139Exsan OthmanPas encore d'évaluation

- Todd Conklin - HPIDocument44 pagesTodd Conklin - HPIknabpshoPas encore d'évaluation

- Hazid and HazanDocument17 pagesHazid and HazanMarwan MalekPas encore d'évaluation

- 10 Continuous Improvement Strategies That Work 130412165110 Phpapp01Document42 pages10 Continuous Improvement Strategies That Work 130412165110 Phpapp01knabpshoPas encore d'évaluation

- Stop Work Authority: Energy Isolation Safe Lifting OperationsDocument28 pagesStop Work Authority: Energy Isolation Safe Lifting OperationsknabpshoPas encore d'évaluation

- Millercatalog Digital FinalDocument14 pagesMillercatalog Digital FinalknabpshoPas encore d'évaluation

- 3D Pyramid Chart For Powerpoint: Sample Text Sample TextDocument3 pages3D Pyramid Chart For Powerpoint: Sample Text Sample TextknabpshoPas encore d'évaluation

- Potential Environmental Aspects & Impact Master Checklist: Masterlist of Aspect & ImpactDocument9 pagesPotential Environmental Aspects & Impact Master Checklist: Masterlist of Aspect & ImpactknabpshoPas encore d'évaluation

- Promoting A Positive CultureDocument16 pagesPromoting A Positive CultureebiyabolawsonPas encore d'évaluation

- DOSH Contract Management 2015 13Document1 pageDOSH Contract Management 2015 13alexcus1539Pas encore d'évaluation

- MHSB-Std-01 Document Drawing TransmittalDocument1 pageMHSB-Std-01 Document Drawing TransmittalknabpshoPas encore d'évaluation

- B-Location PlanDocument1 pageB-Location PlanknabpshoPas encore d'évaluation

- Almacenamiento de LubricantesDocument2 pagesAlmacenamiento de LubricantesRicardo BenitezPas encore d'évaluation

- Oil Drum 1471065260Document17 pagesOil Drum 1471065260knabpshoPas encore d'évaluation

- Millercatalog Digital FinalDocument103 pagesMillercatalog Digital FinalBoris VukasinovicPas encore d'évaluation

- Sds - Cat Deo 15w-40 Engine Oil (2014)Document10 pagesSds - Cat Deo 15w-40 Engine Oil (2014)MichaelPas encore d'évaluation

- SafeStart PPE Guide PDFDocument15 pagesSafeStart PPE Guide PDFSebastian iacopi100% (1)

- Business Action PlanDocument2 pagesBusiness Action PlanknabpshoPas encore d'évaluation

- MHSB-STD-14 Defect Good ChecklistDocument2 pagesMHSB-STD-14 Defect Good ChecklistknabpshoPas encore d'évaluation

- MHSb-Std-11 Request For InformationDocument1 pageMHSb-Std-11 Request For InformationknabpshoPas encore d'évaluation

- MHSB STD 08 Site MemoDocument1 pageMHSB STD 08 Site MemoknabpshoPas encore d'évaluation

- Business Action PlanDocument1 pageBusiness Action PlanknabpshoPas encore d'évaluation

- ESH Risk Management MotorDocument2 pagesESH Risk Management MotorknabpshoPas encore d'évaluation

- MHSB-Std-01 Document Drawing TransmittalDocument1 pageMHSB-Std-01 Document Drawing TransmittalknabpshoPas encore d'évaluation

- MHSB-Std-09 Request For InspectionDocument1 pageMHSB-Std-09 Request For InspectionknabpshoPas encore d'évaluation

- MHSB-Std-07 Fax Transmission SheetDocument1 pageMHSB-Std-07 Fax Transmission SheetknabpshoPas encore d'évaluation

- MHSB-Std-03 Technical Query SheetDocument2 pagesMHSB-Std-03 Technical Query SheetknabpshoPas encore d'évaluation

- MHSB-Std-04 Joint Measurement SheetDocument2 pagesMHSB-Std-04 Joint Measurement SheetknabpshoPas encore d'évaluation

- Clay Analysis - 1Document55 pagesClay Analysis - 1JCSPas encore d'évaluation

- Philosophy For Management and DisciplineDocument8 pagesPhilosophy For Management and Disciplineapi-300120362Pas encore d'évaluation

- Bandura Social Cognitive TheoryDocument93 pagesBandura Social Cognitive TheoryВикторияPas encore d'évaluation

- Seed PrimingDocument4 pagesSeed PrimingbigbangPas encore d'évaluation

- Yume Beauty Price ListDocument1 pageYume Beauty Price ListjessicaelaPas encore d'évaluation

- Assessment in The Affective DomainDocument19 pagesAssessment in The Affective DomainChano MorenoPas encore d'évaluation

- Government of Canada Gouvernement Du CanadaDocument17 pagesGovernment of Canada Gouvernement Du CanadaSaman BetkariPas encore d'évaluation

- FPSB 2 (1) 56-62oDocument7 pagesFPSB 2 (1) 56-62ojaouadi adelPas encore d'évaluation

- What Is Nursing?: What Exactly Do Nurses Do?Document3 pagesWhat Is Nursing?: What Exactly Do Nurses Do?mabel yapuraPas encore d'évaluation

- LabExercise2 PoriferaDocument13 pagesLabExercise2 PoriferaMarvin I. Delos SantosPas encore d'évaluation

- Solid Dosage Form Part 1Document48 pagesSolid Dosage Form Part 1Claire Marie AlvaranPas encore d'évaluation

- Practice Questions Human Nutrition Part 1Document4 pagesPractice Questions Human Nutrition Part 1PeiYi TanPas encore d'évaluation

- A - S-2W & B - S-2W Series: 2W, Fixed Input, Isolated & Unregulated Dual/Single Output DC-DC ConverterDocument5 pagesA - S-2W & B - S-2W Series: 2W, Fixed Input, Isolated & Unregulated Dual/Single Output DC-DC ConverteranonbeatPas encore d'évaluation

- ComFlor 80 Load Span Tables PDFDocument4 pagesComFlor 80 Load Span Tables PDFAkhil VNPas encore d'évaluation

- Cardiac AmyloidosisDocument3 pagesCardiac AmyloidosisPrasad SrbPas encore d'évaluation

- FCE Writing 14 - ArticleDocument4 pagesFCE Writing 14 - Articlepingu70Pas encore d'évaluation

- OSCE Pediatric Dentistry Lecture-AnswersDocument40 pagesOSCE Pediatric Dentistry Lecture-AnswersR MPas encore d'évaluation

- Steel Scrap Recycling Policy 06.11.2019 PDFDocument31 pagesSteel Scrap Recycling Policy 06.11.2019 PDFAnshul SablePas encore d'évaluation

- Manual L W26Document436 pagesManual L W26Taufan ArifPas encore d'évaluation

- Osteoarthritis DissertationDocument8 pagesOsteoarthritis DissertationPaperHelpJackson100% (1)

- Goat AnatomyDocument8 pagesGoat AnatomyLochi GmPas encore d'évaluation

- Consumer ReportsDocument64 pagesConsumer ReportsMadalina Pilipoutanu100% (1)

- Pre-Feasibility Report: at Plot No. 15/B-3, Jigani Industrial Area Anekal Taluk, Bangalore South District Karnataka byDocument41 pagesPre-Feasibility Report: at Plot No. 15/B-3, Jigani Industrial Area Anekal Taluk, Bangalore South District Karnataka by12mchc07Pas encore d'évaluation

- Astm c126 Jtvo9242Document5 pagesAstm c126 Jtvo9242Nayth Andres GalazPas encore d'évaluation