Académique Documents

Professionnel Documents

Culture Documents

Ce422l E1 4eg2

Transféré par

Christine Joyce A. CortezTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Ce422l E1 4eg2

Transféré par

Christine Joyce A. CortezDroits d'auteur :

Formats disponibles

EXPERIMENT NO.

1

DETERMINATION OF ORIFICE COEFFICIENTS

Year and Section:

Group Number:

Group Members:

4CE-E

2

CORTEZ, CHRISTINE JOYCE A.

Date Started:

Date Finished:

Date Submitted:

February 4, 2016

February 4, 2016

February 10, 2016

DATILES, JUAN CARLOS C.

CRUZ, RALEIGH MAE DR.

CUEVAS, MICHAEL GERARD L.

DANAN, JEREMIAH M.

1. OBJECTIVE/S

This activity aims to obtain data on the individual character of the orifice.

2. APPARATUS AND SUPPLIES

Orifice Apparatus

Set of Orifices

Hydraulics Bench

Stop Watch

3. PROCEDURE

1. Set up the orifice tank fitted with the 5 mm. orifice plug in the horizontal position and the

discharge profile gauge fitted.

2. Start the pump.

3. Regulate the flow rate by means of the delivery valve to maintain the water level at

maximum height. Care should be taken to ensure that this level is steady.

4. When this has been achieved, record the flow rate on the test sheet together with that of

the water level.

5. Set the needle and the profile gauge to just reach the discharge steam and clamp in

position.

6. Measure the horizontal distance from the orifice to the lowest needle and the vertical

distance from the orifice center line to the tip of the needle point.

7. Repeat Test 3 to 6 for several values of water level.

8. Close the valve and switch off the pump.

9. Change the orifice to 8 mm. diameter and repeat steps 2 to 8.

CE 422L: Hydraulics Laboratory | Experiment No. 1: Determination of Orifice

Coefficients

4. DATA AND RESULTS

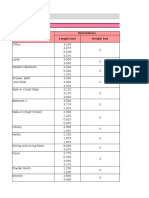

Table 8.1 Determination of Orifice Coefficients

Orifice

Diameter

5-mm

8-mm

Vt

Va

Qt

Qa

Cv

Cc

0.353

2.632

0.1635

0.019

2.627

1.860

x10-5

1.450

x10-5

0.998

0.780

0.782

0.353

2.632

0.2635

0.053

2.535

1.860

x10-5

1.450

x10-5

0.963

0.780

0.810

0.353

2.632

0.3635

0.096

2.598

1.860

x10-5

1.450

x10-5

0.987

0.780

0.790

0.355

2.639

0.1635

0.019

2.627

7.462

x10-5

5.925

x10-5

0.995

0.794

0.798

0.355

2.639

0.2635

0.057

2.584

7.462

x10-5

5.925

x10-5

0.979

0.794

0.811

0.355

2.639

0.3635

0.095

2.612

7.462

x10-5

5.925

x10-5

0.990

0.794

0.802

5. FORMULAS AND COMPUTATIONS

CE 422L: Hydraulics Laboratory | Experiment No. 1: Determination of Orifice

Coefficients

6. FIGURES/DIAGRAMS/GRAPHS

Figure 1.1 Adjusting water level

marking needles

Figure 1.2 Adjusting and

CE 422L: Hydraulics Laboratory | Experiment No. 1: Determination of Orifice

Coefficients

Figure 1.3 Measuring actual discharge

Figure 1.4 Volume of

water over 10 seconds

7. SOURCES OF ERRORS

Sources of error may occur due to inaccuracy of work, these events may have likely aroused

from the measurements and readings. Probable one would be human error, due to limitation of the

eyes, inaccurate measurements would most likely occur. Other errors would be the temperature, which

gives a minimal effect in the unit weight of water and instrument error.

8. CONCLUSIONS AND REMARKS

The experiment that has been conducted showed that the bigger the diameter of the orifice,

the bigger the discharge or flow rate. The results show that the values for the coefficients are less than

one, which means that the values are reliable despite the small discrepancies encountered while

performing the experiment.

CE 422L: Hydraulics Laboratory | Experiment No. 1: Determination of Orifice

Coefficients

Vous aimerez peut-être aussi

- Planning For The Dist of Reclaimed WaterDocument117 pagesPlanning For The Dist of Reclaimed WaterChristine Joyce A. CortezPas encore d'évaluation

- Estimation For Masonry: Designation Dimensions Length (M) Height (M)Document8 pagesEstimation For Masonry: Designation Dimensions Length (M) Height (M)Christine Joyce A. CortezPas encore d'évaluation

- Water Conservation ProgramsDocument161 pagesWater Conservation ProgramsChristine Joyce A. CortezPas encore d'évaluation

- My - Korean.1.2nd - Ed Monash UniversityDocument471 pagesMy - Korean.1.2nd - Ed Monash UniversityJimMeyer80% (5)

- Initiation Into Their CircleDocument1 pageInitiation Into Their CircleChristine Joyce A. CortezPas encore d'évaluation

- For PVC CoatDocument1 pageFor PVC CoatChristine Joyce A. CortezPas encore d'évaluation

- Cortez - Report (Types of Ceeramics)Document2 pagesCortez - Report (Types of Ceeramics)Christine Joyce A. CortezPas encore d'évaluation

- Script For Chapter 2Document6 pagesScript For Chapter 2Christine Joyce A. CortezPas encore d'évaluation

- Energy Loss Factors for Pipe FittingsDocument5 pagesEnergy Loss Factors for Pipe FittingsChristine Joyce A. CortezPas encore d'évaluation

- What Is Consolidation?Document1 pageWhat Is Consolidation?Christine Joyce A. CortezPas encore d'évaluation

- The Need For Consolidation Theory: Magnitude and The Rate ofDocument2 pagesThe Need For Consolidation Theory: Magnitude and The Rate ofChristine Joyce A. CortezPas encore d'évaluation

- Determine Orifice Coefficients in Hydraulics Lab ExperimentDocument4 pagesDetermine Orifice Coefficients in Hydraulics Lab ExperimentChristine Joyce A. CortezPas encore d'évaluation

- Experiment No. 6 Energy Losses Across A Gate Valve Year and Section: Date Started: Group Number: Date Finished: Group Members: Date SubmittedDocument5 pagesExperiment No. 6 Energy Losses Across A Gate Valve Year and Section: Date Started: Group Number: Date Finished: Group Members: Date SubmittedChristine Joyce A. CortezPas encore d'évaluation

- Slex (South Luzon Expressway) &: It Cuts SouthwardDocument5 pagesSlex (South Luzon Expressway) &: It Cuts SouthwardChristine Joyce A. CortezPas encore d'évaluation

- South Luzon Tollway Rehabilitation ProjectDocument6 pagesSouth Luzon Tollway Rehabilitation ProjectChristine Joyce A. CortezPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (72)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Converting Polyurethane Foam PlantsDocument8 pagesConverting Polyurethane Foam PlantsSiavashPas encore d'évaluation

- High Pressure System Boiler Water Chemical Dosing Calculations (Coal F - Industrial Professionals - CheresourcesDocument3 pagesHigh Pressure System Boiler Water Chemical Dosing Calculations (Coal F - Industrial Professionals - Cheresourcescepong89Pas encore d'évaluation

- Optimal Control of A CSTR ProcessDocument14 pagesOptimal Control of A CSTR ProcessYahya ZabenPas encore d'évaluation

- Laboratory Study On Pore Pressure Generation and Liquefaction of Low-Plasticity Silty Sandy Soils During The 2012 Earthquake in ItalyDocument10 pagesLaboratory Study On Pore Pressure Generation and Liquefaction of Low-Plasticity Silty Sandy Soils During The 2012 Earthquake in ItalyPinak RayPas encore d'évaluation

- ELE515 Power System Protection CourseDocument2 pagesELE515 Power System Protection CourseSanjesh ChauhanPas encore d'évaluation

- Assignment 2Document4 pagesAssignment 2王俞文Pas encore d'évaluation

- WS Calipers and MicrometersDocument2 pagesWS Calipers and MicrometersEster Fatmawati100% (1)

- Svs College of Engineering: COIMBATORE 642 109Document34 pagesSvs College of Engineering: COIMBATORE 642 109agkacdm1163100% (1)

- Wind Tunnel SystemsDocument3 pagesWind Tunnel SystemsArjun SharmaPas encore d'évaluation

- My Notes On TensorsDocument5 pagesMy Notes On Tensorschandan ChaudharyPas encore d'évaluation

- BIEE 2nd Yr. Fundamentals of Instrumentation Class Test I 2019Document2 pagesBIEE 2nd Yr. Fundamentals of Instrumentation Class Test I 2019Sudden leePas encore d'évaluation

- Gear Box Selection in Gate ValveDocument24 pagesGear Box Selection in Gate ValvemudrijasmPas encore d'évaluation

- Ventilation and Indoor Air Quality in Part F 2006 HomesDocument67 pagesVentilation and Indoor Air Quality in Part F 2006 HomesskamingPas encore d'évaluation

- Light and Architectural Lighting SystemsDocument17 pagesLight and Architectural Lighting SystemsCrystal Kaye CortezPas encore d'évaluation

- Pulp SynopsisDocument12 pagesPulp SynopsisnaiduPas encore d'évaluation

- Development of Geodynamic Model of Bangladesh - 2012Document48 pagesDevelopment of Geodynamic Model of Bangladesh - 2012CDMP BangladeshPas encore d'évaluation

- Experimental Analysis and Computational-Fluid-Dynamics Modeling of Pilot-Scale Three-Phase SeparatorsDocument15 pagesExperimental Analysis and Computational-Fluid-Dynamics Modeling of Pilot-Scale Three-Phase Separators기계공학과/김수빈Pas encore d'évaluation

- EimDocument3 pagesEim4thidiotPas encore d'évaluation

- En 12517Document15 pagesEn 12517Nguyen Huu TriPas encore d'évaluation

- Asme Sec V A-2 PDFDocument41 pagesAsme Sec V A-2 PDFarlyPas encore d'évaluation

- Chemical Ecology in Aquatic Systems An Introduction PDFDocument301 pagesChemical Ecology in Aquatic Systems An Introduction PDFmoshroom914100% (1)

- Meo CL 2 Ekg QusetionsDocument17 pagesMeo CL 2 Ekg QusetionsAurvin SinghPas encore d'évaluation

- Chemrite PP FibreDocument2 pagesChemrite PP FibreghazanfarPas encore d'évaluation

- Mediciòn de La Calidad Educativa A Partir Del Calculo Del Rendimiento Academico en Un Programa Universitario en Una Universidad EmergenteDocument6 pagesMediciòn de La Calidad Educativa A Partir Del Calculo Del Rendimiento Academico en Un Programa Universitario en Una Universidad EmergenteRICRA CHAUCA YORDIN KENEDYPas encore d'évaluation

- (Assumptions Leading To This?) : Summary of Last LectureDocument23 pages(Assumptions Leading To This?) : Summary of Last LectureUtkarsh VermaPas encore d'évaluation

- Autonic SensorDocument4 pagesAutonic SensorcaskololoPas encore d'évaluation

- Model Question: Third Semester M.Sc. (Physics)Document1 pageModel Question: Third Semester M.Sc. (Physics)Sagar RawalPas encore d'évaluation

- ENVI Classic Tutorial: Target DetectionDocument18 pagesENVI Classic Tutorial: Target DetectionGualberto Machaca MendietaPas encore d'évaluation

- High-Entropy Metal Diborides: A New Class of High-Entropy Materials and A New Type of Ultrahigh Temperature CeramicsDocument10 pagesHigh-Entropy Metal Diborides: A New Class of High-Entropy Materials and A New Type of Ultrahigh Temperature CeramicschaddiPas encore d'évaluation

- Brochure Trasmission 132kV - 400kV - Per StampaDocument8 pagesBrochure Trasmission 132kV - 400kV - Per StampaaakashPas encore d'évaluation