Académique Documents

Professionnel Documents

Culture Documents

HOW TO READ BORING BAR STANDARDS

Transféré par

Sơn ĐặngTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

HOW TO READ BORING BAR STANDARDS

Transféré par

Sơn ĐặngDroits d'auteur :

Formats disponibles

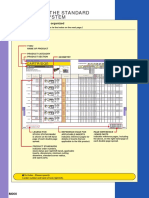

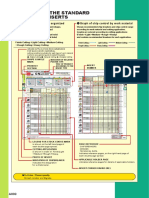

HOW TO READ THE STANDARD

OF BORING BARS

a How this section page is organized

zOrganized by product series.

(Refer to the index on the next page.)

FIGURE SHOWING THE TOOLING APPLICATION

uses illustrations and arrows to depict available

machining applications along with cutting edge

lead angles.

TYPE OF BORING BAR

indicates the initial letters for the order number,

as well as applicable insert types.

GEOMETRY

TITLE OF PRODUCT SERIES

PRODUCT SECTION

CHIP BREAKER BY

CUTTING APPLICATION

PRODUCT FEATURES

BORING BARS

DIMPLE BAR

FSCLC/P

a Excellent vibration resistance due to light dimple head.

a Chip disposal is improved by having two channels for chip evacuation.

a A laser printed scale on the side for easy installation (Steel shank).

a l/d is 3 to 5 times the diameter (Carbide shank is 7 to 8 times the diameter).

CCooinserts, CPooinserts FP

Finish

Finish

(06,09)

Medium

95

Light

FM

MP

Light

LP

LM

(06,09)

(06,09)

Medium

PCD/CBN

FSTUP

TPooinserts

Finish

(06,09)

SV

(08,09)

Medium

MV

(08,09,11,16) (08,09,11,16)

PCD

93

MM

Light

FV

CBN

R/L-F

FSCLC1008R/L-06S=1

BORING

R L

FSCLC1008R/L-06S

a a

FSCLP1210R/L-08S

a a

FSCLP1412R/L-08S

a a

FSCLP1612R/L-09S

a a

FSCLP1816R/L-09S

a a

FSCLP2220R/L-09S

FSCLP3025R/L-09S

(06,09)

(06,09)

DCON

LF

LDRED WF

Right hand tool holder shown.

(06,08,09)

Dimensions(mm)

Insert Number

GAMF DMIN

RE

Maximum

recommendation

l/d

ratio Clamp

Order Number

(08,09,11,16)

GAMF DMIN

RE

Maximum

recommendation

l/d

ratio Clamp

Screw

Wrench

TKY06F

125 18

7.2 12

10

0.4

TS253 TKY08F

FSTUP1008R/L-08S

a a

0802pp

125

18

7.2

10

10

0.4

TS2D

150 22.5

12

0.4

3.5

TS3D

TKY10F

FSTUP1210R/L-09S

a a

0902pp

10

150

22.5

12

0.4

3.5

TS25D TKY08F

0802pp

12

150 27

11

14

0.4

TS3D

TKY10F

FSTUP1412R/L-09S

a a

0902pp

12

150

27

11

14

0.4

TS25D TKY08F

0903pp

12

150 30

11

16

0.4

TS4D

TKY15F

FSTUP1210R/L-11S

a a

1103pp

10

150

22.5

12

0.4

3.5

TS31D TKY10F

0903pp

16

180 36

15

3.5

18

0.4

TS4D

TKY15F

FSTUP1412R/L-11S

a a

1103pp

12

150

27

11

14

0.4

TS31D TKY10F

a a

0903pp

20

220 45

11

19

22

0.4

TS4D

TKY15F

FSTUP1816R/L-11S

a a

1103pp

16

180

36

15

18

0.4

TS31D TKY10F

a a

0903pp

25

250 56.3

15

23.4

30

0.4

TS4D

TKY15F

FSTUP2220R/L-11S

a a

1103pp

20

220

45

11

19

22

0.4

TS31D TKY10F

FSTUP3225R/L-16S

a a

1603pp

25

270

56.3

16

23.4

32

0.8

TS4D

CPMH

NP-CPGB

NP-CPMB

NP-CPMH

Carbide shank

with coolant hole

CCooinserts, CPooinserts

Finish

FP

Finish

Light

FM

Light

LP

LM

(06,09)

(06,09)

(06,09)

Medium

Medium

PCD/CBN

MP

(06,09)

Right hand tool holder shown.

Stock

FSCLC1008R/L-06E

a a

FSCLC1008R-06E-2/3

(06,09)

DCON

LF

LDRED WF

FSTUP-E

Carbide shank

with coolant hole

TPooinserts

Finish

RE

Maximum

recommendation

l/d

ratio Clamp

Screw

Right hand tool holder shown.

Wrench

0602pp

CCGH

CCMH

0602pp

NP-CCGT

NP-CCGW 0602pp

140

13.8

7.2 12

10

0.4

TS253 TKY08F

90

13.8

7.2 12

10

0.4

TS253 TKY08F

Order Number

Light

FV

SV

Medium

MV

(08,09)

(08,09,11)

PCD

CBN

(08,09,11)

R/L-F

(06,08,09)

GAMF DMIN

TKY15F

* Clamp Torque (N m) : TS2D=0.6, TS25D=1.0, TS31D=2.5, TS4D=3.5

93

(06,09)

Dimensions(mm)

Insert Number

R L

TPGH

TPMH

NP-TPGB

NP-TPMB

NP-TPMH

MM

FSCLC1008R/L-06E (-2/3, -1/2)=1

Stock

(08,09,11)

DCON

R L

LF

LDRED WF

(08,09,11)

Dimensions(mm)

Insert Number

GAMF DMIN

RE

Maximum

recommendation

l/d

ratio Clamp

Screw

Wrench

a a

0802pp

140

13.8

7.2

10

10

0.4

TS2D

TKY06F

90

13.8

7.2

10

10

0.4

TS2D

TKY06F

TKY06F

FSCLC1008R-06E-1/2

70

13.8

7.2 12

10

0.4

TS253 TKY08F

FSTUP1008R/L-08E

FSCLP1210R/L-08E

a a

0802pp

10

160

16.0

12

0.4

7.5

TS3D

TKY10F

FSTUP1008R-08E-2/3

0802pp

FSCLP1210R-08E-2/3

0802pp

10

105

16.0

12

0.4

7.5

TS3D

TKY10F

FSTUP1008R-08E-1/2

0802pp

70

13.8

7.2

10

10

0.4

TS2D

FSCLP1210R-08E-1/2

0802pp

10

80

16.0

12

0.4

7.5

TS3D

TKY10F

FSTUP1210R/L-09E

a a

0902pp

10

160

16.0

12

0.4

7.5

TS25D TKY08F

FSCLP1412R/L-08E

a a

0802pp

12

180

17.8

11

14

0.4

TS3D

TKY10F

FSTUP1210R-09E-2/3

0902pp

10

105

16.0

12

0.4

7.5

TS25D TKY08F

FSCLP1412R-08E-2/3

0802pp

12

120

17.8

11

14

0.4

TS3D

TKY10F

FSTUP1210R-09E-1/2

0902pp

10

80

16.0

12

0.4

7.5

TS25D TKY08F

FSCLP1412R-08E-1/2

0802pp

12

90

17.8

11

14

0.4

TS3D

TKY10F

FSTUP1412R/L-09E

a a

0902pp

12

180

17.8

11

14

0.4

TS25D TKY08F

FSCLP1816R/L-09E

a a

0903pp

16

220

21.8

15

3.5

18

0.4

TS4D

TKY15F

FSTUP1412R-09E-2/3

0902pp

12

120

17.8

11

14

0.4

TS25D TKY08F

0902pp

12

90

17.8

11

14

0.4

TS25D TKY08F

CPMH

NP-CPGB

NP-CPMB

NP-CPMH

TPGH

TPMH

NP-TPGB

NP-TPMB

NP-TPMH

FSCLP1816R-09E-2/3

0903pp

16

145

21.8

15

3.5

18

0.4

TS4D

TKY15F

FSTUP1412R-09E-1/2

FSCLP1816R-09E-1/2

0903pp

16

110

21.8

15

3.5

18

0.4

TS4D

TKY15F

FSTUP1816R/L-11E

a a

1103pp

16

220

21.8

15

18

0.4

TS31D TKY10F

FSCLP2220R/L-09E

a a

0903pp

20

250

24.0

11

19

22

0.4

TS4D

TKY15F

FSTUP1816R-11E-2/3

1103pp

16

145

21.8

15

18

0.4

TS31D TKY10F

FSCLP2220R-09E-2/3

0903pp

20

165

24.0

11

19

22

0.4

TS4D

TKY15F

FSTUP1816R-11E-1/2

1103pp

16

110

21.8

15

18

0.4

TS31D TKY10F

FSCLP2220R-09E-1/2

0903pp

20

125

24.0

11

19

22

0.4

TS4D

TKY15F

FSTUP2220R/L-11E

a a

1103pp

20

250

24.0

11

19

22

0.4

TS31D TKY10F

FSTUP2220R-11E-2/3

1103pp

20

165

24.0

11

19

22

0.4

TS31D TKY10F

FSTUP2220R-11E-1/2

1103pp

20

125

24.0

11

19

22

0.4

TS31D TKY10F

Clamp Torque (N m) : TS253=1.0, TS3D=2.5, TS4D=3.5

(Note 1) The insert photos are only examples. The letters refer to the chip breaker and the dimension refers to the inscribed circle.

(Note 2) When using insert with right and left hand chip breaker, please use left hand

insert for right hand holder and right hand insert for left hand holder.

CCpp type inserts

A126 A130

a : Inventory maintained in Japan.

CPpp type inserts

A131

CBN & PCD inserts

B039 B042, B059

* Clamp Torque (N m) : TS2D=0.6, TS25D=1.0, TS31D=2.5

LEGEND FOR STOCK

STATUS MARK

REFERENCE PAGE

FOR APPLICABLE INSERTS

is shown on the left hand page

of each double-page spread.

indicates reference pages for

details of inserts that are

applicable to the title product.

PRODUCT STANDARDS

indicates order numbers,

stock status (per right/left hand),

applicable inserts, dimensions,

minimum cutting diameters,

standard corner radius,

recommended l/d ratios,

and spare parts.

MIN. CUTTING DIAMETER

is colour-coded to let you find, at a

glance, the maximum / minimum cutting

diameters for internal machining.

a To Order : Please specify

zorder number and hand of tool (right/left).

E000

LDRED WF

10

95

E006

LF

0602pp

FSCLC/P-E

DCON

0802pp

* Clamp Torque (N m) : TS253=1.0, TS3D=2.5, TS4D=3.5

Order Number

Insert Number

R L

Wrench

Screw

CCG/MH

NP-CCGT

NP-CCGW

(08,09,11)

Dimensions(mm)

Stock

BORING

Right hand tool holder shown.

Stock

Order Number

CUTTING CONDITIONS

TPpp type inserts

CBN & PCD inserts

A145 A147

B046, B062

SPARE PARTS

TECHNICAL DATA

E012

P001

Q001

E007

PAGE REFERENCE

SPARE PARTS

TECHNICAL DATA

indicates reference pages, including

the above, on the right hand page of

each double-page spread.

TURNING TOOLS

BORING BARS

CLASSIFICATION OF BORING TOOLS .......... E002

IDENTIFICATION .............................................. E004

STANDARD BORING BARS

FEATURES OF DIMPLE BAR ...................... E005

DIMPLE BAR................................................. E006

DOUBLE CLAMP DIMPLE BAR................... E013

MICRO-DEX BORING BARS ........................ E016

MICRO-MINI TWIN BORING BARS ............. E019

MICRO-MINI BORING BARS........................ E022

F TYPE BORING BARS ................................ E025

S TYPE BORING BARS................................ E028

P TYPE BORING BARS................................ E035

D TYPE BORING HEAD ............................... E039

AL TYPE BORING BARS ............................. E042

Arranged by Alphabetical order

*E013

E017 CpppSTUC

Appp-DCLN

E013

E014

E014

E015

E015

E036

E037

E036

E038

E035

E035

E037

E022

E016

E030

E031

E029

E028

Appp-DDUN

Appp-DSKN

Appp-DTFN

Appp-DVUN

Appp-DWLN

ApppPCLN

ApppPDQN

ApppPDUN

ApppPDZN

ApppPSKN

ApppPTFN

ApppPWLN

Cpppp-BLS

CpppSCLC

CpppSCLC

CpppSDQC

CpppSDUC

CpppSTFC

E032

E016

E019

E020

E040

E040

E039

E039

E041

E026

E026

E006

E009

E008

E025

E025

E007

E012

CpppSVQC

CpppSWUB

CB

CR

DPCL

DPDH

DPDU

DPTF

DPVP

FCTU1

FCTU2

FSCLC/P

FSDQC

FSDUC

FSTU1

FSTU2

FSTUP

FSVJB/C

E011

E011

E027

E027

E010

E018

E023

E030

E034

E031

E029

E033

E028

E042

E032

E033

E024

FSVPB/C

FSVUB/C

FSWL1

FSWL2

FSWUB/P

RBH

RBH

SpppSCLC

SpppSCZC

SpppSDQC

SpppSDUC

SpppSSKC

SpppSTFC

SpppSTFE

SpppSVQC

SpppSVUC

SBH

E001

BORING BARS

CLASSIFICATION

KAPR=75 KAPR=91

Name of Tool Holder

DIMPLE BAR

Features

a

a

a

a

BORING

DOUBLE CLAMP

DIMPLE BAR

a

a

a

a

F Type Boring Bars

a

a

a

a

a

S Type Boring Bars

a

a

a

a

a

P Type Boring Bars

a

a

a

a

a

D Type Boring Head

a

a

a

a

The minimum cutting diameter is

from &10.

5, 7, 11 positive insert.

Excellent vibration resistance due

to a light dimple head.

l/d is 3 to 5 times the diameter

(Carbide shank is 7 to 8 times the

diameter).

The minimum cutting diameter is

from &32.

Economical negative insert.

Single action type.

Excellent vibration resistance due

to a light dimple head.

(With coolant hole.)

l/d is 3 to 4 times the diameter.

KAPR

KAPR

^ E007

DSKN

^ E014

DTFN

^ E014

a

a

a

a

a

a

MICRO-DEX

Boring Bars

(Carbide Shank)

a

a

^ E033

The minimum cutting diameter is

from &25.

ISO standard.

Economical negative insert.

Lever lock type, and pin lock type.

l/d is 3 times the diameter.

^ E035

a

a

a

a

MICRO-MINI TWIN

Boring Bars

a

a

a

a

MICRO-MINI

Boring Bars

a

a

a

a

The minimum cutting diameter is from &5.

7positive insert.

Carbide shank type.

Easy-to-use tool geometries.

Suitable for small workpieces.

l/d is 5 times the diameter.

^ E013

FSTU

The minimum cutting diameter is from &11.

ISO standard.

7positive insert.

Screw-on type.

l/d is 3 to 5 times the diameter

(Carbide shank is 7 times the diameter).

The minimum cutting diameter is from &20.

Suitable for non-ferrous metal.

20positive insert.

Screw-on type.

l/d is 6 times the diameter.

Excellent vibration resistance.

DDUN

^ E025

SSKC

PSKN

STFC

^ E028

PTFN

^ E035

DPTF

^ E039

AL Type Boring Bars

KAPR

FSTUP

The minimum cutting diameter is

from &5.8.

11positive insert.

Screw-on type and Clamp-on type.

l/d is 3 to 5 times the diameter.

FSWL type is 7positive insert.

The minimum cutting diameter is

from &40.

Economical negative insert.

Lever lock type.

Exchangeable head type.

KAPR=93

SDUC

^ E029

FSDUC

^ E008

DVUN

^ E015

FCTU

^ E026

SVUC

^ E033

PDUN

^ E036

DPDU

^ E039

STFE

^ E042

SWUB

^ E016

STUC

^ E017

The minimum cutting diameter is

from &2.2.

Solid carbide type with two cutting

edges.

Continuous cutting from boring to facing.

With or without a chip breaker.

The minimum cutting diameter is

from &3.2.

Solid carbide type (Single cutting edges).

l/d is 5 times the diameter.

Cutting edge can be shaped

according to the application. Thus,

it covers a wide cutting range

(threading,grooving,copying, etc.).

CooFR-BLS

^ E022

(Note 1) Holders with blue colour symbol have an anti-vibration carbide shank. (For Micro-dex boring bars, carbide shank only.)

E002

FSVUB/C

^ E011

^ E010

FSCLC/P

FSDQC

^ E006

DCLN

^ E013

^ E009

FSVPB/C

^ E011

Small Diameter

Cutting

Specialized

Coolant Hole

Vibration

Resisiance

Operation

Efficiency

KAPR

Selection Standard

Clamp Rigidity

KAPR

KAPR

KAPR

KAPR

e e e

FSVJB/C

^ E012

BORING

FSWUB/P

KAPR=10730 11730 KAPR=142 KAPR=3,5

Low Cutting Resistance (Sharpness)

KAPR

KAPR=95

Economical

KAPR=93

DWLN

^ E015

FSWL

^ E027

SCLC

SDQC

^ E030

PCLN

^ E036

DPCL

^ E040

^ E031

PWLN

^ E037

SVQC

SCZC

^ E032

^ E034

PDQN

DPDH

e e

PDZN

^ E037

^ E040

^ E038

DPVP

^ E041

SCLC

^ E016

e

CBooRS(-B)

^ E019

CR

^ E020

(Note 2) e : 1st recommendation. u: 2nd recommendation.

(Note 3) Indicates that the shank material is carbide.

E003

BORING BARS

IDENTIFICATION

y DIMPLE BAR

nMin.Cutting Diameter

cInsert Shape

zFunction

BORING

Screw-on

vCutting Angle

Right Hand

Left Hand

16

16 16

34 34

20

20

18 18

40 40

25

25

11

20 20

32

32

10730

RHOMBIC 35

11730

TRIGON

142

bInsert Clearance

10

08

RHOMBIC 55

10

12

TRIANGULAR 60

10

16

RHOMBIC 80

25 25

12

95

6.35

12 12

30 30

93

.Cutting Edge Length (mm)

08

32 32

RHOMBIC 55

Inscribed circle 4.76 5.56

of insert

22 22

13 13

RHOMBIC 80

,Hand of Tool

R - 06

11

u

E - 2/3

11 Tool Length (Carbide shank only) (mm)

u

/Shank Material

7.94 9.525

Carbide Shank

Shank Dia.

10

12

16

20

Steel Shank

No symbol 140 160

180

220

250

120

145

165

90

110

125

06

0.8

09

07

11

2/3

90 105

TRIANGULAR 60 08

09

11

16

1/2

70

RHOMBIC 35 08

11

16

L3

04

06

TRIGON

(mm)

10 10

14 14

xClamp Structure

F Fixed type

mShank Diameter

(mm)

80

y ISO TYPE Boring tools

[For Aluminium Alloy, P-type and S-type]

16

L

n

C

m

09

cTool Length

zShank Material

Steel Shank

A with Coolant Hole

vClamp Structure

bInsert Shape

,Hand of Tool

Lever Lock

RHOMBIC 80

7Positive

Right Hand

100

Screw-on

RHOMBIC 55

20Positive

Left Hand

125

SQUARE 90

11Positive

Carbide Shank

Carbide Shank

with Coolant Hole

150

TRIANGULAR 60

Steel Shank

180

RHOMBIC 35

200

TRIGON

250

(mm)

mInsert Clearance

80

xShank Diameter

E004

(mm)

300

350

400

nCutting Angle

.Cutting Edge Length (mm)

08

91

Inscribed circle

of insert

10

10

75

RHOMBIC 80 06

08

09

12

12

12

95

RHOMBIC 55 07

11

15

16

16

09

12

19

20

20

TRIANGULAR 60 11

16

22

25

25

RHOMBIC 35 11

16

32

32

40

40

10730

93

SQUARE 90

6.35 7.94 9.525 12.70 19.05

19

FEATURES OF DIMPLE BAR

Highly rigid steel shank and a lightweight head configuration

designed by computer simulation analysis reduces chatter

and improves the vibration damping properties.

Chip disposal is improved by having

two channels for chip evacuation.

The lightweight head with its large

dimple reduces chatter.

The boring bar has a laser printed

scale on the shank to facilitate easy

installation.

"F and FS" breakers improves the quality

of the surface finish, "MV" breaker offers

excellent chip disposal. High wear

resistant CBN inserts are also available

for the machining of hardened materials.

y DEFLECTION RESISTANCE

BORING

Available in sizes smaller than the ISO

standard. Therefore the boring of

small diameter holes is possible.

y VIBRATION RESISTANCE

a DIMPLE BAR

Weight of the

Head

49.7g

Damping Time

15.8ms

Cutting Force

(Principal Force)

Cutting Force

(Back Force)

By reducing the weight of the head, the damping

properties are increased.

a Conventional Product

The unique cross sectional

shape engineered into the

dimple effectively balances

the cutting forces (principal

and back force), and reduces

deflection by up to 17 %.

Boring Bar

DIMPLE BAR

Conventional Bar

Weight of the

Head

70.1g

Damping Time

20ms

Deflection

28.3!m

34!m

simulation data stated above was conducted with a FSCLP1816R-09S holder, under the following conditions;

* The

l/d=5, depth of cut=0.5mm, and feed=0.05mm/rev.

y Direction for the use of CCG/MT CPG/MT CPMX TPG/MX type inserts

By changing the clamp screw, it is possible to use the inserts listed in the table below.

Holder : FSCLC/P FSCLC/P...E

Insert Number

Clamp Screw

Holder : FSTUP FSTUP...E

Insert Number

Clamp Screw

CCG/MT0602oo (& 6.35)

Can be used as it is.

TPG/MX0802oo (& 4.76)

Change to CS200T

CPG/MT0802oo (& 7.94)

Change to TS3

TPG/MX0902oo (& 5.56)

Change to CS250T

CPG/MT0903oo (& 9.525)

Change to TS4

TPG/MX1103oo (& 9.525)

Change to CS300890T

CPMX0802oo (& 7.94)

Can be used as it is.

CPMX0903oo (& 9.525)

Can be used as it is.

If the screw is too long the please shorten as necessary.

*(Note

) TPMT/W09, W11 types cannot be used due to a different clamp screw size.

E005

BORING BARS

DIMPLE BAR

FSCLC/P

a Excellent vibration resistance due to light dimple head.

a Chip disposal is improved by having two channels for chip evacuation.

a A laser printed scale on the side for easy installation (Steel shank).

a l/d is 3 to 5 times the diameter (Carbide shank is 7 to 8 times the diameter).

CCooinserts, CPooinserts

Finish

FP

Finish

FM

Light

LP

Light

LM

WF

95

95

GAMF RE LDRED

DMIN 5

H

DCON

LF

(06,09)

(06,09)

(06,09)

Medium

Medium

PCD/CBN

MP

(06,09)

MM

FSCLC1008R/L-06S=1

Right hand tool holder shown.

Order Number

Stock

Insert Number

R L

BORING

(06,09)

(06,09)

DCON

LF

LDRED WF

(06,08,09)

Dimensions(mm)

GAMF DMIN

RE

Maximum

recommendation

l/d

ratio Clamp

Wrench

Screw

CCG/MH

NP-CCGT

NP-CCGW

FSCLC1008R/L-06S

a a

0602pp

FSCLP1210R/L-08S

a a

0802pp

FSCLP1412R/L-08S

a a

0802pp

FSCLP1612R/L-09S

a a

FSCLP1816R/L-09S

a a

FSCLP2220R/L-09S

FSCLP3025R/L-09S

125 18

7.2 12

10

0.4

TS253 TKY08F

10

150 22.5

12

0.4

3.5

TS3D

TKY10F

12

150 27

11

14

0.4

TS3D

TKY10F

0903pp

12

150 30

11

16

0.4

TS4D

TKY15F

0903pp

16

180 36

15

3.5

18

0.4

TS4D

TKY15F

a a

0903pp

20

220 45

11

19

22

0.4

TS4D

TKY15F

a a

0903pp

25

250 56.3

15

23.4

30

0.4

TS4D

TKY15F

CPMH

NP-CPGB

NP-CPMB

NP-CPMH

* Clamp Torque (N m) : TS253=1.0, TS3D=2.5, TS4D=3.5

FSCLC/P-E

Carbide shank

with coolant hole

CCooinserts, CPooinserts

Finish

FP

Finish

FM

Light

LP

Light

LM

WF

95

95

GAMF RE LDRED

DMIN 5

H

DCON

LF

(06,09)

(06,09)

(06,09)

Medium

Medium

PCD/CBN

MP

(06,09)

MM

FSCLC1008R/L-06E (-2/3, -1/2)=1

Right hand tool holder shown.

Order Number

Stock

Insert Number

R L

E006

FSCLC1008R/L-06E

a a

FSCLC1008R-06E-2/3

FSCLC1008R-06E-1/2

FSCLP1210R/L-08E

(06,09)

(06,09)

DCON

LF

LDRED WF

(06,08,09)

Dimensions(mm)

GAMF DMIN

RE

Maximum

recommendation

l/d

ratio Clamp

Screw

0602pp

Wrench

CCGH

CCMH

0602pp

NP-CCGT

NP-CCGW 0602pp

140

13.8

7.2 12

10

0.4

TS253 TKY08F

90

13.8

7.2 12

10

0.4

TS253 TKY08F

70

13.8

7.2 12

10

0.4

TS253 TKY08F

a a

0802pp

10

160

16.0

12

0.4

7.5

TS3D

TKY10F

FSCLP1210R-08E-2/3

0802pp

10

105

16.0

12

0.4

7.5

TS3D

TKY10F

FSCLP1210R-08E-1/2

0802pp

10

80

16.0

12

0.4

7.5

TS3D

TKY10F

FSCLP1412R/L-08E

a a

0802pp

12

180

17.8

11

14

0.4

TS3D

TKY10F

FSCLP1412R-08E-2/3

0802pp

12

120

17.8

11

14

0.4

TS3D

TKY10F

FSCLP1412R-08E-1/2

0802pp

12

90

17.8

11

14

0.4

TS3D

TKY10F

FSCLP1816R/L-09E

a a

0903pp

16

220

21.8

15

3.5

18

0.4

TS4D

TKY15F

FSCLP1816R-09E-2/3

0903pp

16

145

21.8

15

3.5

18

0.4

TS4D

TKY15F

FSCLP1816R-09E-1/2

0903pp

16

110

21.8

15

3.5

18

0.4

TS4D

TKY15F

FSCLP2220R/L-09E

a a

0903pp

20

250

24.0

11

19

22

0.4

TS4D

TKY15F

FSCLP2220R-09E-2/3

0903pp

20

165

24.0

11

19

22

0.4

TS4D

TKY15F

FSCLP2220R-09E-1/2

0903pp

20

125

24.0

11

19

22

0.4

TS4D

TKY15F

CPMH

NP-CPGB

NP-CPMB

NP-CPMH

Clamp Torque (N m) : TS253=1.0, TS3D=2.5, TS4D=3.5

(Note 1) The insert photos are only examples. The letters refer to the chip breaker and the dimension refers to the inscribed circle.

(Note 2) When using insert with right and left hand chip breaker, please use left hand

insert for right hand holder and right hand insert for left hand holder.

CCpp type inserts

A126 A130

a : Inventory maintained in Japan.

CPpp type inserts

A131

CBN & PCD inserts

B039 B042, B059

FSTUP

TPooinserts

Finish

93

LDRED

H

LF

DCON

Insert Number

DCON

R L

(08,09,11)

LF

LDRED WF

FSTUP1008R/L-08S

a a

0802pp

125

18

7.2

FSTUP1210R/L-09S

a a

0902pp

10

150

22.5

FSTUP1412R/L-09S

a a

0902pp

12

150

27

FSTUP1210R/L-11S

a a

1103pp

10

150

FSTUP1412R/L-11S

a a

1103pp

12

FSTUP1816R/L-11S

a a

1103pp

FSTUP2220R/L-11S

a a

FSTUP3225R/L-16S

a a

TPGH

TPMH

NP-TPGB

NP-TPMB

NP-TPMH

(08,09,11,16)

Dimensions(mm)

Stock

CBN

R/L-F

Right hand tool holder shown.

Order Number

(08,09,11,16) (08,09,11,16)

PCD

RE

Medium

MV

GAMF DMIN

RE

Maximum

recommendation

l/d

ratio Clamp

Screw

Wrench

TKY06F

10

10

0.4

TS2D

12

0.4

3.5

TS25D TKY08F

11

14

0.4

TS25D TKY08F

22.5

12

0.4

3.5

TS31D TKY10F

150

27

11

14

0.4

TS31D TKY10F

16

180

36

15

18

0.4

TS31D TKY10F

1103pp

20

220

45

11

19

22

0.4

TS31D TKY10F

1603pp

25

270

56.3

16

23.4

32

0.8

TS4D

BORING

GAMF

DMIN

SV

(08,09)

WF

93

Light

FV

TKY15F

Clamp Torque (N m) : TS2D=0.6, TS25D=1.0, TS31D=2.5, TS4D=3.5

FSTUP-E

Carbide shank

with coolant hole

TPooinserts

Finish

Light

FV

SV

Medium

MV

WF

93

93

GAMF

DMIN

RE

LDRED

Stock

(08,09,11)

Insert Number

DCON

LF

(08,09,11)

LDRED WF

(08,09,11)

Dimensions(mm)

R L

CBN

DCON

Right hand tool holder shown.

Order Number

(08,09,11)

PCD

R/L-F

LF

(08,09)

GAMF DMIN

RE

Maximum

recommendation

l/d

ratio Clamp

Screw

Wrench

FSTUP1008R/L-08E

a a

0802pp

140

13.8

7.2

10

10

0.4

TS2D

TKY06F

FSTUP1008R-08E-2/3

0802pp

90

13.8

7.2

10

10

0.4

TS2D

TKY06F

FSTUP1008R-08E-1/2

0802pp

70

13.8

7.2

10

10

0.4

TS2D

TKY06F

FSTUP1210R/L-09E

a a

0902pp

10

160

16.0

12

0.4

7.5

TS25D TKY08F

FSTUP1210R-09E-2/3

0902pp

10

105

16.0

12

0.4

7.5

TS25D TKY08F

FSTUP1210R-09E-1/2

0902pp

10

80

16.0

12

0.4

7.5

TS25D TKY08F

0902pp

12

180

17.8

11

14

0.4

TS25D TKY08F

0902pp

12

120

17.8

11

14

0.4

TS25D TKY08F

0902pp

12

90

17.8

11

14

0.4

TS25D TKY08F

TPGH

TPMH

NP-TPGB

NP-TPMB

NP-TPMH

FSTUP1412R/L-09E

a a

FSTUP1412R-09E-2/3

FSTUP1412R-09E-1/2

FSTUP1816R/L-11E

a a

1103pp

16

220

21.8

15

18

0.4

TS31D TKY10F

FSTUP1816R-11E-2/3

1103pp

16

145

21.8

15

18

0.4

TS31D TKY10F

FSTUP1816R-11E-1/2

1103pp

16

110

21.8

15

18

0.4

TS31D TKY10F

FSTUP2220R/L-11E

a a

1103pp

20

250

24.0

11

19

22

0.4

TS31D TKY10F

FSTUP2220R-11E-2/3

1103pp

20

165

24.0

11

19

22

0.4

TS31D TKY10F

FSTUP2220R-11E-1/2

1103pp

20

125

24.0

11

19

22

0.4

TS31D TKY10F

Clamp Torque (N m) : TS2D=0.6, TS25D=1.0, TS31D=2.5

CUTTING CONDITIONS

TPpp type inserts

CBN & PCD inserts

A145 A147

B046, B062

SPARE PARTS

TECHNICAL DATA

E012

P001

Q001

E007

BORING BARS

DIMPLE BAR

a Excellent vibration resistance due to light dimple head.

a Chip disposal is improved by having two channels for chip evacuation.

a A laser printed scale on the side for easy installation (Steel shank).

a l/d is 3 to 5 times the diameter (Carbide shank is 7 to 8 times the diameter).

FSDUC

DCooinserts

Finish

FP

WF

93

GAMF

DMIN

RE

H

DCON

F2

93

LDRED

LF

Stock

BORING

R L

FSDUC1410R/L-07S

a a

FSDUC1612R/L-07S

a a

FSDUC2016R/L-07S

a a

FSDUC3220R/L-11S

a a

DCMT

DCET

DCGT

NP-DCMT

NP-DCMW

DCON LF LDRED WF

F2

Light

LM

(07,11)

(07,11)

(07,11)

(07,11)

Medium

PCD

CBN

MP

MM

(07,11)

R/L-F

(07,11)

(07,11)

(07,11)

Dimensions(mm)

Insert Number

Light

LP

Medium

Right hand tool holder shown.

Order Number

Finish

FM

Maximum

recommendation

l/d

GAMF DMIN RE ratio

Clamp

Screw

Wrench

7.5

14

0.4

3.5

TS25

TKY08F

0702pp

10

150 18

8.3 3.3

0702pp

12

150 20

9.3 3.3

11

16

0.4

TS25

TKY08F

0702pp

16

180 20

11.3 3.3

15

20

0.4

TS25

TKY08F

11T3pp

20

180 22.5 16.1 6.1

19

32

0.8

TS43

TKY15F

* Clamp Torque (N m) : TS25=1.0, TS43=3.5

FSDUC-E

Carbide shank

with coolant hole

DCooinserts

Finish

FP

Finish

FM

Light

LP

Light

LM

WF

93

GAMF

DMIN

RE

H

DCON

F2

93

LDRED

LF

(07,11)

(07,11)

(07,11)

(07,11)

Medium

Medium

PCD

CBN

MP

Right hand tool holder shown.

Order Number

Stock

R L

FSDUC1410R/L-07E

a a

FSDUC1612R/L-07E

a a

FSDUC2016R/L-07E

a a

FSDUC3220R/L-11E

a a

(07,11)

Dimensions(mm)

Insert Number

DCMT

DCET

DCGT

NP-DCMT

NP-DCMW

DCON LF LDRED WF

F2

MM

R/L-F

(07,11)

(07,11)

(07,11)

Maximum

recommendation

l/d

GAMF DMIN RE ratio

Clamp

Screw

Wrench

0702pp

10

160 16.0

8.3

3.3

7.5

14

0.4

7.5

TS25

TKY08F

0702pp

12

180 17.8

9.3

3.3

11

6.0

16

0.4

TS25

TKY08F

0702pp

16

220 21.8 11.3

3.3

15

5.0

20

0.4

TS25

TKY08F

11T3pp

20

250 24.0 16.1

6.1

19

5.0

32

0.8

TS43

TKY15F

Clamp Torque (N m) : TS25=1.0, TS43=3.5

(Note 1) The insert photos are only examples. The letters refer to the chip breaker and the dimension refers to the inscribed circle.

(Note 2) When using insert with right and left hand chip breaker, please use left hand

insert for right hand holder and right hand insert for left hand holder.

a

E008

: Inventory maintained in Japan.

DCpp type inserts

CBN & PCD inserts

A132 A135

B043, B044, B060

FSDQC

Finish

DCooinserts

FP

Finish

FM

Light

LP

Light

LM

RE

DMIN

LDRED

(07,11)

(07,11)

(07,11)

Medium

PCD

CBN

MP

H

DCON

LF

(07,11)

Medium

Right hand tool holder shown.

Order Number

Stock

R L

FSDQC1310R/L-07S

a a

FSDQC1612R/L-07S

a a

FSDQC2016R/L-07S

a a

FSDQC2520R/L-11S

a a

(07,11)

DCMT

DCET

DCGT

NP-DCMT

NP-DCMW

DCON LF LDRED WF

F2

R/L-F

(07,11)

(07,11)

(07,11)

Dimensions(mm)

Insert Number

MM

Maximum

recommendation

l/d

GAMF DMIN RE ratio

Clamp

Screw

Wrench

0702pp

10

150 20.5

7.6

2.6

13

0.4

3.5

TS25

TKY08F

0702pp

12

150 22.5

8.6

2.6

11

16

0.4

TS25

TKY08F

0702pp

16

180 22.5 10.6

2.6

15

20

0.4

TS25

TKY08F

11T3pp

20

180 26

3.7

19

25

0.8

TS43

TKY15F

13.7

BORING

GAMF

F2

107

30

WF

10730

* Clamp Torque (N m) : TS25=1.0, TS43=3.5

FSDQC-E

Carbide shank

with coolant hole

Finish

DCooinserts

FP

Finish

FM

Light

LP

Light

LM

GAMF

DMIN

RE

LDRED

LF

(07,11)

(07,11)

(07,11)

(07,11)

Medium

Medium

PCD

CBN

H

MP

DCON

F2

107

30

WF

10730

Right hand tool holder shown.

Order Number

Stock

R L

FSDQC1310R/L-07E

a a

FSDQC1612R/L-07E

a a

FSDQC2016R/L-07E

a a

FSDQC2520R/L-11E

a a

(07,11)

Dimensions(mm)

Insert Number

DCMT

DCET

DCGT

NP-DCMT

NP-DCMW

DCON LF LDRED WF

F2

MM

R/L-F

(07,11)

(07,11)

(07,11)

Maximum

recommendation

l/d

GAMF DMIN RE ratio

Clamp

Screw

Wrench

0702pp

10

162 18.4

7.6

2.6

13

0.4

7.5

TS25

TKY08F

0702pp

12

182 20.2

8.6

2.6

11

16

0.4

TS25

TKY08F

0702pp

16

222 24.2 10.6

2.6

15

20

0.4

TS25

TKY08F

11T3pp

20

254 28.0 13.7

3.7

19

25

0.8

TS43

TKY15F

Clamp Torque (N m) : TS25=1.0, TS43=3.5

CUTTING CONDITIONS

DCpp type inserts

CBN & PCD inserts

A132 A135

B043, B044, B060

SPARE PARTS

TECHNICAL DATA

E012

P001

Q001

E009

BORING BARS

DIMPLE BAR

a Excellent vibration resistance due to light dimple head.

a Chip disposal is improved by having two channels for chip evacuation.

a A laser printed scale on the side for easy installation (Steel shank).

a l/d is 3 to 5 times the diameter (Carbide shank is 7 to 8 times the diameter).

FSWUB/P

WBooinserts, WPooinserts

Finish

R/L-FFS

93

(L3,04,06)

Medium

WF

93

GAMF

LDRED

RE

H

DCON

LF

DMIN

The &8 and & 10 shanks are 0

Order Number

Insert Number

DCON

BORING

R L

FSWUB1008R/L-L3S

a a

FSWUB1210R/L-L3S

a a

Right hand tool holder shown.

LF

LDRED WF

(L3,04,06)

Dimensions(mm)

Stock

MV

GAMF DMIN

RE

Maximum

recommendation

l/d

ratio Clamp

Screw

Wrench

L302pp

125

18

7.2

14

10

0.2

TS2

TKY06F

L302pp

10

150

22.5

11

12

0.2

3.5

TS2

TKY06F

FSWUP1412R/L-04S

a a

0402pp

12

150

27

11

14

0.4

TS253 TKY08F

FSWUP1816R/L-04S

a a

0402pp

16

180

36

15

18

0.4

TS253 TKY08F

FSWUP2220R/L-06S

a a

0603pp

20

220

45

11

19

22

0.8

TS4

TKY15F

FSWUP3025R/L-06S

a a

0603pp

25

250

56.3

15

23.4

30

0.8

TS4

TKY15F

WBMT

WBGT

WPMT

WPGT

* Clamp Torque (N m) : TS2=0.6, TS253=1.0, TS4=3.5

FSWUB/P-E

Carbide shank

with coolant hole

WBooinserts, WPooinserts

Finish

R/L-FFS

93

WF

(L3,04,06)

93

GAMF

DMIN

RE

Medium

H

LDRED

LF

MV

DCON

The & 8 and & 10 shanks are 0

Order Number

Right hand tool holder shown.

Stock

Insert Number

R L

DCON

LF

LDRED WF

(L3,04,06)

Dimensions(mm)

GAMF DMIN

RE

Maximum

recommendation

l/d

ratio Clamp

Screw

Wrench

FSWUB1008R/L-L3E

a a

L302pp

140

13.8

7.2

14

10

0.2

TS2

TKY06F

FSWUB1008R-L3E-2/3

L302pp

90

13.8

7.2

14

10

0.2

TS2

TKY06F

FSWUB1008R-L3E-1/2

L302pp

70

13.8

7.2

14

10

0.2

TS2

TKY06F

FSWUB1210R/L-L3E

a a

L302pp

10

160

16.0

11

12

0.2

7.5

TS2

TKY06F

FSWUB1210R-L3E-2/3

L302pp

10

105

16.0

11

12

0.2

7.5

TS2

TKY06F

FSWUB1210R-L3E-1/2

L302pp

10

80

16.0

11

12

0.2

7.5

TS2

TKY06F

FSWUP 1412R/L-04E

a a

0402pp

12

180

17.8

11

14

0.4

TS253 TKY08F

FSWUP 1412R-04E-2/3

0402pp

12

120

17.8

11

14

0.4

TS253 TKY08F

FSWUP 1412R-04E-1/2

0402pp

12

90

17.8

11

14

0.4

TS253 TKY08F

FSWUP 1816R/L-04E

a a

0402pp

16

220

21.8

15

18

0.4

TS253 TKY08F

FSWUP 1816R-04E-2/3

0402pp

16

145

21.8

15

18

0.4

TS253 TKY08F

FSWUP 1816R-04E-1/2

0402pp

16

110

21.8

15

18

0.4

TS253 TKY08F

FSWUP 2220R/L-06E

a a

0603pp

20

250

24.0

11

19

22

0.8

TS4

TKY15F

FSWUP 2220R-06E-2/3

0603pp

20

165

24.0

11

19

22

0.8

TS4

TKY15F

FSWUP 2220R-06E-1/2

0603pp

20

125

24.0

11

19

22

0.8

TS4

TKY15F

WBMT

WBGT

WPMT

WPGT

* Clamp Torque (N m) : TS2=0.6, TS253=1.0, TS4=3.5

(Note 1) The insert photos are only examples. The letters refer to the chip breaker and the dimension refers to the inscribed circle.

(Note 2) When using insert with right and left hand chip breaker, please use left hand

insert for right hand holder and right hand insert for left hand holder.

WBpp type inserts

a

E010

: Inventory maintained in Japan.

WPpp type inserts

PCD inserts

A155

A157

B065

FSVUB/C

VCooinserts, VBooinserts

Finish

FP

Finish

Light

FM

LP

Light

LM

93

RE

DMIN

LDRED

(11,16)

(11,16)

(11,16)

Medium

Medium

CBN

H

MP

DCON

LF

(11,16)

Medium

Right hand tool holder shown.

Stock

Insert Number

R L

FSVUC1612R/L-08S

a a

FSVUB2016R/L-11S

a a

FSVUB2520R/L-11S

a a

FSVUB3425R/L-16S

a a

FSVUB4032R/L-16S

a a

(16)

Dimensions(mm)

DCON LF LDRED WF F2

VCGT

pp 12 150 25

VCMT 0802

1103pp

VBET

VBGT 1103pp

VBMT 1604pp

NP-VBGW

1604pp

11

(16)

(16)

(16)

*

Shim

8 16 0.4

TS202 TKY06F

H GAMF DMIN RE

5.5 11

Standard

Maximum recommendation

l/d ratio

Order Number

MM

Shim Pin Clamp

Screw Wrench

16 180 32.5 15.5 8

15

8 20 0.4

TS255 TKY08F

20 200 40.5 17.5 8

19

7 25 0.4

TS255 TKY08F

20.5 8.5 23.4 13 34 0.8

SPSVN32 BCP141 TS35D TKY15F

SPSVN32 BCP141 TS35D TKY15F

25 220 50

32 250 84.0 27.5 12

30.4

9 40 0.8

BORING

GAMF

F2

WF

93

* Clamp Torque (N m) : TS202=0.6, TS255=1.0, TS35D=3.5

FSVPB/C

VCooinserts, VBooinserts

Finish

FP

Finish

Light

FM

LP

Light

LM

GAMF

DMIN

RE

F2

117

30

WF

11730

LDRED

H

DCON

LF

(11,16)

(11,16)

(11,16)

(11,16)

Medium

Medium

Medium

CBN

MP

MM

Standard

Order Number

Stock

Dimensions(mm)

Insert Number

R L

DCON LF LDRED WF F2

VCGT

VCMT 0802pp 10 150 25

FSVPC1610R/L-08S

a a

FSVPB2012R/L-11S

a a

1103pp 12 150 28 10

FSVPB2516R/L-11S

a a

1103pp

FSVPB3020R/L-11S

a a

FSVPB3425R/L-16S

a a

FSVPB4032R/L-16S

a a

(16)

(16)

(16)

*

Shim

Shim Pin Clamp

Screw Wrench

8 16 0.4 3.5

TS202 TKY06F

8 20 0.4 4

TS255 TKY08F

15

5 25 0.4 5

TS255 TKY08F

19

5 30 0.4 5

TS255 TKY08F

4.5 11

16 180 35 12.5 5

VBET

VBGT

1103pp 20 200 40 15 5

VBMT

NP-VBGW 1604pp 25 220 50 17 5

1604pp 32 250 55 22

H GAMF DMIN RE

(16)

Maximum recommendation

l/d ratio

Right hand tool holder shown.

23.4 13 34 0.8 5

6.5 30.4

9 40 0.8 5

SPSVN32 BCP141 TS35D TKY15F

SPSVN32 BCP141 TS35D TKY15F

* Clamp Torque (N m) : TS202=0.6, TS255=1.0, TS35D=3.5

VBpp type inserts

VCpp type inserts

CBN & PCD inserts

A148 A150

A151, A152

B048, B064

CUTTING CONDITIONS

SPARE PARTS

TECHNICAL DATA

E012

P001

Q001

E011

BORING BARS

DIMPLE BAR

FSVJB/C

142

a Excellent vibration resistance due to light dimple head.

a Chip disposal is improved by having two channels for chip evacuation.

a A laser printed scale on the side for easy installation (Steel shank).

a l/d is 3 to 5 times the diameter.

VCooinserts, VBooinserts

Finish

Light

FM

LP

Light

LM

WF

142

GAMF RE

DMIN

5

LDRED

H

DCON

LF

(11)

Medium

Insert Number

R L

DCON

LF

LDRED WF

(11)

(11)

MV

(08,11)

(08,11)

Dimensions(mm)

Stock

Order Number

(11)

Finish

FV

Right hand tool holder shown.

BORING

Finish

FP

GAMF DMIN

RE

Maximum

recommendation

l/d

ratio Clamp

Screw

FSVJC1612R/L-08S

a a

FSVJC2016R/L-08S

a a

FSVJB2520R/L-11S

a a

FSVJB3025R/L-11S

a a

Wrench

VCGT

VCMT

0802pp

12

150

26

11

16

0.4

TS202 TKY06F

0802pp

16

180

36

15

20

0.4

TS202 TKY06F

VBET

VBGT

VBMT

1103pp

20

200

37.5

19

25

0.4

TS255 TKY08F

1103pp

25

250

45

3.5

23.4

30

0.4

TS255 TKY08F

* Clamp Torque (N m) : TS202=0.6, TS255=1.0

RECOMMENDED CUTTING CONDITIONS

Work Material

P

Mild Steel

Cutting

Mode

RecomBreaker

mendation

Finish

FV

Light

SV

< 180HB

Medium

Finish

Carbon Steel

Alloy Steel

MV

FV

Light

SV

Medium

MV

Finish

FV

180350HB

M

Stainless Steel

Light

SV

< 200HB

Gray Cast Iron

Tensile Strength

< 350MPa

Aluminium Alloy

H Heat Treated Steel 3565HRC

Grade

Cutting Speed

(m/min)

NX2525

l/d

l/d

<

<

3 (Steel shank)

6 (Carbide shank)

l/d = 4 5 (Steel shank)

l/d = 7 8 (Carbide shank)

Feed

(mm/rev)

Depth of Cut

(mm)

Feed

(mm/rev)

Depth of Cut

(mm)

170 (120 220)

0.10 (0.05 0.15)

0.5

0.10 (0.05 0.15)

0.5

1.0

NX3035

150 (100 200)

0.20 (0.10 0.25)

1.0

0.15 (0.05 0.20)

NX2525

160 (110 210)

0.20 (0.10 0.25)

1.0

0.15 (0.05 0.20)

1.0

NX3035

140 (90 190)

0.25 (0.15 0.35)

2.0

0.20 (0.15 0.25)

1.5

NX2525

150 (100 200)

0.25 (0.15 0.35)

2.0

0.20 (0.15 0.25)

1.5

VP15TF

140 (90 190)

0.10 (0.05 0.15)

0.5

0.10 (0.05 0.15)

0.5

NX2525

130 (80 180)

0.10 (0.05 0.15)

0.5

0.10 (0.05 0.15)

0.5

UE6020

140 (90 190)

0.20 (0.10 0.25)

1.0

0.15 (0.05 0.20)

1.0

NX3035

110 (60 160)

0.20 (0.10 0.25)

1.0

0.15 (0.05 0.20)

1.0

UE6020

130 (80 180)

0.25 (0.15 0.35)

2.0

0.20 (0.15 0.25)

1.5

NX3035

100 (60 150)

0.25 (0.15 0.35)

2.0

0.20 (0.15 0.25)

1.5

VP15TF

150 (110 190)

0.10 (0.05 0.15)

0.5

0.10 (0.05 0.15)

0.5

US735

125 (85 165)

0.20 (0.10 0.25)

1.0

0.15 (0.05 0.20)

1.0

VP15TF

130 (90 170)

0.20 (0.10 0.25)

1.0

0.15 (0.05 0.20)

1.0

US735

105 (70 135)

0.20 (0.15 0.25)

2.0

0.20 (0.15 0.25)

1.0

VP15TF

120 (80 160)

0.20 (0.15 0.25)

2.0

0.20 (0.15 0.25)

1.0

0.5

Medium

MV

Finish

F, FS

HTi10

130 (90 160)

0.15 (0.10 0.20)

0.5

0.15 (0.10 0.20)

Medium

MV

VP15TF

90 (60 120)

0.20 (0.15 0.25)

2.0

0.20 (0.15 0.25)

1.5

F, FS

HTi10

300 (200 400)

0.10 (0.05 0.15)

0.5

0.10 (0.05 0.15)

0.5

Flat Top

MD220

200 (150 250)

0.10 (0.05 0.15)

2.0

0.10 (0.05 0.15)

1.0

Flat Top

MB825

100 (80 200)

0.10 (0.05 0.15)

0.15

0.10 (0.05 0.15)

0.1

Finish

Finish

(Note 1) When vibrations occur, reduce cutting speed by 30%.

(Note 2) The depth of cut needs to be less than the corner diameter when using the FSVJ type.

(Note 1) The insert photos are only examples. The letters refer to the chip breaker and the dimension refers to the inscribed circle.

(Note 2) When using insert with right and left hand chip breaker, please use left hand

insert for right hand holder and right hand insert for left hand holder.

VBpp type inserts

a

E012

: Inventory maintained in Japan.

VCpp type inserts

CBN & PCD inserts

A148 A150

A151, A152

B048, B064

DIMPLE BAR

DCLN

a Economical negative insert.

a Single action type.

a Excellent vibration resistance due to a light dimple head. (With coolant hole.)

a l/d is 3 to 4 times the diameter.

CNooinserts

With coolant hole

Finish

FH

GAMF

WF

IN

DM

95

95

RE LDRED

(12)

(12)

(12)

(12)

Medium

Stainless

CBN

Right hand tool holder shown.

Order Number

Insert Number

DCON LF LDRED WF

R L

A25R-DCLNR/L12

a a

A32S-DCLNR/L12

a a

A40T-DCLNR/L12

a a

Standard

MM

(12)

(12)

(12)

CNMA 1204pp 25 200 40

CNMG

1204pp 32 250 50

CNMM

CNGG 1204pp 40 300 63

(12)

Dimensions(mm)

Stock

Medium

MP

DCON

LF

Light

LP

Medium

MH

Light

SA

H GAMF DMIN RE

Shim

Shim Pin

Clamp

Bridge

Clamp

Screw

Spring

Wrench

17

23 11 32 0.8 LLSCP42 LLP14 DCK2613 DCS1 DC0621T TKY20F

22

30 13 40 0.8 LLSCN42 LLP14 DCK2613 DCS1 DC0621T TKY20F

27

37 10 50 0.8 LLSCN42 LLP14 DCK2613 DCS1 DC0621T TKY20F

BORING

DOUBLE

CLAMP

* Clamp Torque (N m) : DC0621T=5.0

DDUN

DNooinserts

With coolant hole

Finish

FH

93

GAMF

WF

IN

DM

93

RE LDRED

Right hand tool holder shown.

Order Number

Stock

R L

A25R-DDUNR/L15

a a

A32S-DDUNR/L15

a a

A40T-DDUNR/L15

a a

(15)

(15)

(15)

(15)

Stainless

G class

CBN

MM

R/L

(15)

(15)

(15)

DCON LF LDRED WF

DNMA 1504pp 25 200 40

DNMG

DNMX 1504pp 32 250 50

DNGA

DNGG 1504pp 40 300 63

(15)

Dimensions(mm)

Insert Number

Medium

MH

DCON

LF

Medium

MP

Medium

Standard

Light

LP

H GAMF DMIN RE

Shim

Shim Pin

Clamp

Bridge

Spring

Clamp

Screw

Wrench

17

23 13 35 0.8 LLSDP42 LLP14 DCK2613 DCS1 DC0621T TKY20F

22

30 13 40 0.8 LLSDN42 LLP14 DCK2613 DCS1 DC0621T TKY20F

27

37 10 50 0.8 LLSDN42 LLP14 DCK2613 DCS1 DC0621T TKY20F

Clamp Torque (N m) : DC0621T=5.0

RECOMMENDED CUTTING CONDITIONS

Work Material

Carbon Steel

Alloy Steel

Stainless Steel

Gray Cast Iron

Hardness

Cutting

Mode

180350HB

< 200HB

Tensile Strength

< 350MPa

l/d < 3

l/d=34

Cutting Speed

(m/min)

Feed

(mm/rev)

Depth of Cut

(mm)

Cutting Speed

(m/min)

Feed

(mm/rev)

Depth of Cut

(mm)

Medium

110 (80 140)

0.25 (0.1 0.4)

5.0

110 (80 140)

0.2 (0.1 0.3)

4.0

Medium

80 (60 100)

0.2 (0.1 0.3)

4.0

70 (50 100)

0.15 (0.1 0.25)

3.0

Medium

80 (60 100)

0.25 (0.1 0.4)

5.0

80 (60 100)

0.2 (0.1 0.3)

4.0

CNpp type inserts

DNpp type inserts

CBN & PCD inserts

A092 A097

A098 A103

B022 B027, B055

SPARE PARTS

TECHNICAL DATA

P001

Q001

E013

BORING BARS

DOUBLE

CLAMP

DIMPLE BAR

DSKN

a Economical negative insert.

a Single action type.

a Excellent vibration resistance due to a light dimple head. (With coolant hole.)

a l/d is 3 to 4 times the diameter.

SNooinserts

With coolant hole

Finish

FH

WF

IN

DM

75

75

GAMF

RE LDRED

Stock

(12)

(12)

(12)

Stainless

G class

CBN

BORING

R L

A25R-DSKNR/L12

A32S-DSKNR/L12

SNMA

a a SNMG

SNMM

a a SNGA

SNGG

DCON LF LDRED WF

(12)

R/L

(12)

(12)

(12)

H GAMF DMIN RE

Shim

Shim Pin

Clamp

Bridge

Spring

Clamp

Screw

Wrench

1204pp 25 200 40

17

23 13 32 0.8 LLSSP42 LLP14 DCK2613 DCS1 DC0621T TKY20F

1204pp

22

30 13 40 0.8 LLSSN42 LLP14 DCK2613 DCS1 DC0621T TKY20F

32 250 50

Clamp Torque (N m) : DC0621T=5.0

DTFN

TNooinserts

With coolant hole

Finish

FH

WF

IN

DM 91

91

GAMF

RE LDRED

Stock

Insert Number

LF

A32S-DTFNR/L16

TNMA

a a TNMG

TNMM

a a TNGA

TNGG

DCON LF LDRED WF

Medium

MH

(16)

(16)

(16)

(16)

Medium

Stainless

G class

CBN

MM

R/L

(16)

(16)

(16)

H GAMF DMIN RE

(16)

Dimensions(mm)

R L

A25R-DTFNR/L16

Medium

MP

DCON

Right hand tool holder shown.

Order Number

Light

LP

Standard

MM

Dimensions(mm)

Insert Number

Medium

MH

(12)

Right hand tool holder shown.

Order Number

Medium

MP

Medium

Standard

H

DCON

LF

Light

LP

Shim

Shim Pin

Clamp

Bridge

Spring

Clamp

Screw

Wrench

1604pp 25 200 40

17

23 13 32 0.8 LLSTP32 LLP23 DCK2211 DCS2 DC0520T TKY15F

1604pp 32 250 50

22

30 13 40 0.8 LLSTN32 LLP23 DCK2211 DCS2 DC0520T TKY15F

Clamp Torque (N m) : DC0520T=3.5

(Note 1) The insert photos are only examples. The letters refer to the chip breaker and the dimension refers to the inscribed circle.

(Note 2) When using insert with right and left hand chip breaker, please use left hand

insert for right hand holder and right hand insert for left hand holder.

SNpp type inserts

a

E014

: Inventory maintained in Japan.

TNpp type inserts

CBN & PCD inserts

A105 A109

A110 A115

B028 B031, B056

IN

93

GAMF

RE LDRED

(16)

(16)

(16)

(16)

Stainless

G class

CBN

Standard

DCON LF LDRED WF

R L

A40T-DVUNR/L16

MM

R/L

(16)

(16)

(16)

a a VNMA 1604pp 40 300 63

VNGA

H GAMF DMIN RE

27

37

(16)

Dimensions(mm)

Insert Number

Medium

MH

Medium

Right hand tool holder shown.

Stock

Medium

MP

DCON

LF

Order Number

Light

LP

93

WF

DM

Finish

FH

Shim

Shim Pin

Clamp

Bridge

Spring

Clamp

Screw

Wrench

50 0.8 DCSVN32 LLP13 DCK3113 DCS2 DC0520T TKY15F

Clamp Torque (N m) : DC0520T=3.5

DWLN

WNooinserts

With coolant hole

Finish

FH

WF

IN

DM 95

95

GAMF

RE LDRED

(08)

(08)

(06,08)

Medium

Rough

Stainless

Right hand tool holder shown.

Order Number

Stock

RP

R L

DCON LF LDRED WF

(08)

MM

(08)

(08)

(06,08)

Dimensions(mm)

Insert Number

Medium

MH

DCON

LF

Medium

MP

Medium

Standard

Light

LP

H GAMF DMIN RE

Shim

Shim Pin

Clamp

Bridge

Spring

Clamp

Screw

Wrench

A25R-DWLNR/L06

a a

WNMG 0604pp 25 200 40

17

23 13 35 0.8 LLSWP32 LLP23 DCK2211 DCS2 DC0520T TKY15F

A25R-DWLNR/L08

a a

17

23 13 35 0.8 LLSWP42 LLP14 DCK2613 DCS1 DC0621T TKY20F

A32S-DWLNR/L08

a a

22

30 13 40 0.8 LLSWN42 LLP14 DCK2613 DCS1 DC0621T TKY20F

A40T-DWLNR/L08

a a

0804pp 25 200 40

WNMA

0804pp 32 250 50

WNMG

0804pp 40 300 63

27

37 10 50 0.8 LLSWN42 LLP14 DCK2613 DCS1 DC0621T TKY20F

BORING

DVUN

VNooinserts

With coolant hole

Clamp Torque (N m) : DC0520T=3.5, DC0621T=5.0

RECOMMENDED CUTTING CONDITIONS

Work Material

Carbon Steel

Alloy Steel

Stainless Steel

Gray Cast Iron

Hardness

Cutting

Mode

180350HB

< 200HB

Tensile Strength

< 350MPa

l/d < 3

l/d=34

Cutting Speed

(m/min)

Feed

(mm/rev)

Depth of Cut

(mm)

Cutting Speed

(m/min)

Feed

(mm/rev)

Depth of Cut

(mm)

Medium

110 (80 140)

0.25 (0.1 0.4)

5.0

110 (80 140)

0.2 (0.1 0.3)

4.0

Medium

80 (60 100)

0.2 (0.1 0.3)

4.0

70 (50 100)

0.15 (0.1 0.25)

3.0

Medium

80 (60 100)

0.25 (0.1 0.4)

5.0

80 (60 100)

0.2 (0.1 0.3)

4.0

VNpp type inserts

WNpp type inserts

CBN & PCD inserts

A116 A118

A119 A123

B032 B034, B057

SPARE PARTS

TECHNICAL DATA

P001

Q001

E015

BORING BARS

MICRO-DEX

BORING BARS

SCLC

a The minimum cutting diameter is from

a 7 positive insert, carbide shank type.

a Easy-to-use tool geometries.

a Suitable for small workpieces.

& 5.

a l/d

is 5 times the diameter.

WF

GAMF

DMIN

L-F

(03,04)

DCON

95

95

Finish

CCooinserts

Carbide shank

RE

PCD/CBN

H

LF

Order Number

Stock

Right hand tool holder only.

Insert Number

DCON

LF

WF

03S1pp

90

2.5

3.7

15

03S1pp

100

3.0

4.7

13

R

BORING

Dimensions(mm)

GAMF DMIN

RE

(03,04)

2

Clamp

Screw

Wrench

0.2

TS16

TKY06F

0.2

TS16

TKY06F

C04GSCLCR03

C05HSCLCR03

C06JSCLCR04

NP-CCMW 04T0pp

110

3.5

5.7

13

0.2

TS21

TKY06F

C07KSCLCR04

04T0pp

125

4.0

6.7

11

0.2

TS21

TKY06F

1

*CCGT

of inscribed circle is special. (For SCLC type)

*12 Diameter

Clamp Torque (N m) : TS16=0.6, TS21=0.6

*

SWUB

WF

GAMF

DMIN

L-F

(02,L3)

DCON

93

93

Finish

WBGT inserts

Carbide shank

RE

LF

Order Number

Stock

Right hand tool holder only.

Insert Number

C06JSWUBR02

C07KSWUBRL3

WBGT

GAMF DMIN

DCON

LF

WF

0201ppL-F

100

3.0

4.7

15

0201ppL-F

110

3.5

5.7

13

L302ppL-F

125

4.0

6.7

15

C05HSWUBR02

Dimensions(mm)

RE

Clamp

Screw

Wrench

0.2

TS21

TKY06F

0.2

TS2C

TKY06F

0.2

TS2

TKY06F

Clamp Torque (N m) : TS21=0.6, TS2C=0.6, TS2=0.6

(Note) The insert photos are only examples. The letters refer to the chip breaker and the dimension refers to the inscribed circle.

CCGT type inserts

a

E016

: Inventory maintained in Japan.

WBGT type inserts

CBN inserts

A127

A155

B040, B041, B059

STUC

RE

0.35

WF

GAMF 27

DMIN

LF

Right hand tool holder only.

Stock

Insert Number

TCGT

0601pp

DCON

LF

WF

GAMF

DMIN

RE

125

4.0

6.7

12

0.2

Clamp

Screw

Wrench

TS2C

TKY06F

Clamp Torque (N m) : TS2C=0.6

BORING

Dimensions(mm)

C07KSTUCR06

(06)

Depth of cut is limited

when cutting backwards.

Order Number

L-F

DCON

93

93

Finish

TCGT inserts

Carbide shank

RECOMMENDED CUTTING CONDITIONS

Work Material

Grade

Cutting Speed

(m/min)

Feed

(mm/rev)

Depth of Cut

(mm)

l/d

Carbon Steel, Alloy Steel

NX2525

80 (40120)

0.03 (0.010.05)

0.2 (0.10.3)

35

Stainless Steel

VP15TF

80 (40120)

0.03 (0.010.05)

0.2 (0.10.3)

35

Gray Cast Iron

VP15TF

80 (40120)

0.03 (0.010.05)

0.2 (0.10.3)

35

VP15TF

120 (80160)

0.05 (0.010.08)

0.4 (0.10.6)

35

MD220

120 (80160)

0.05 (0.010.08)

0.4 (0.10.6)

35

MB810

80 (40120)

0.03 (0.010.05)

0.1 (0.030.2)

35

180350HB

< 200HB

< 350MPa

N

Non-Ferrous Meterial

Heat Treated Steel

3565HRC

TCGT type inserts

SPARE PARTS

TECHNICAL DATA

A141

P001

Q001

E017

BORING BARS

MICRO-DEX

BORING BARS

STANDARD HOLDER

5

3-M4 x 0.7

S2

D5

S1

S2

3-M4 x 0.7

D5

S1

DCON

DCB

10

z

S3

20

10

c

LF

Stock

BORING

*22

*2

*2

*

RBH 15840N

RBH 15850N

RBH 15860N

RBH 15870N

RBH 1640N

RBH 1650N

RBH 1660N

RBH 1670N

RBH19040N

RBH19050N

RBH19060N

RBH19070N

RBH 2040N

RBH 2050N

RBH 2060N

RBH 2070N

RBH 2240N

RBH 2250N

RBH 2260N

RBH 2270N

RBH 2540N

RBH 2550N

RBH 2560N

RBH 2570N

RBH 25440N

RBH 25450N

RBH 25460N

RBH 25470N

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

a

Dimensions(mm)

*Clamp Screw

Wrench

Torque

(N m)

HKY20F

HKY20F

2.0

2.0

A

A

HKY20F

HKY20F

2.0

2.0

A

A

A

A

HKY20F

HKY20F

2.0

2.0

A

A

A

A

A

A

HKY20F

HKY20F

2.0

2.0

C04GSpppRpp

C05HSpppRpp

B

B

B

B

B

B

HKY20F

HKY20F

2.0

2.0

C06JSpppRpp

C07KSpppRpp

B

B

B

B

B

B

HKY20F

HKY20F

2.0

2.0

15

15

C04GSpppRpp

C05HSpppRpp

A

A

B

B

B

B

HKY20F

HKY20F

2.0

2.0

15

20

15

20

C06JSpppRpp

C07KSpppRpp

A

A

B

B

B

B

HKY20F

HKY20F

2.0

2.0

125

125

15

15

15

15

12.5 C04GSpppRpp

12.5 C05HSpppRpp

A

A

B

B

B

B

A

A

HKY20F

HKY20F

2.0

2.0

15

16

125

125

15

20

15

20

15

15

C06JSpppRpp

C07KSpppRpp

A

A

B

B

B

B

A

A

HKY20F

HKY20F

2.0

2.0

4

5

13

14

150

150

15

15

15

15

C04GSpppRpp

C05HSpppRpp

A

A

C

C

C

C

HKY20F

HKY20F

2.0

2.0

25

25

6

7

15

16

150

150

15

20

15

20

C06JSpppRpp

C07KSpppRpp

A

A

C

C

C

C

HKY20F

HKY20F

2.0

2.0

25.4

25.4

4

5

13

14

150

150

15

15

15

15

C04GSpppRpp

C05HSpppRpp

A

A

C

C

C

C

HKY20F

HKY20F

2.0

2.0

25.4

25.4

6

7

15

16

150

150

15

20

15

20

C06JSpppRpp

C07KSpppRpp

A

A

C

C

C

C

HKY20F

HKY20F

2.0

2.0

DCON DCB

D5

LF

S1

S2

S3

15.875

15.875

4

5

15

15

100

100

15

15

15

15

15.875

15.875

6

7

15

15

100

100

15

20

15

20

16

16

4

5

15

15

100

100

15

15

16

16

6

7

15

15

100

100

19.05

19.05

4

5

18

18

19.05

19.05

6

7

20

20

MICRO-DEX

C04GSpppRpp

C05HSpppRpp

A

A

A

A

A

A

C06JSpppRpp

C07KSpppRpp

A

A

A

A

15

15

C04GSpppRpp

C05HSpppRpp

A

A

15

20

15

20

C06JSpppRpp

C07KSpppRpp

125

125

15

15

15

15

18

18

125

125

15

20

15

20

4

5

13

14

125

125

15

15

20

20

6

7

15

16

125

125

22

22

4

5

13

14

22

22

6

7

25

25

number of clamp screw A=HSS04004, B=HSS04006, C=HSS04008

*12 Order

Revised order number.

*

Conventional Order

Number

Revised Order

Number

RBH1940N

RBH1950N

RBH1960N

RBH1970N

RBH19040N

RBH19050N

RBH19060N

RBH19070N

E018

RBH158ppN, RBH16ppN,

RBH190ppN

RBH22ppN has a temporary set screw for different machine specifications.

(Represented by number 4)

Order Number

x

LF

: Inventory maintained in Japan. (MICRO-MINI TWIN is available in 1 piece in one pack.)

MICRO-MINI TWIN

CB

For internal machining

DCON

LF

L19

Right hand tool only.

LDRED

Stock

Coated

TF15 VP15TF

Order Number

Micro

Grain

CB02RS

CB02RS-B

CB02RS-01

CB02RS-01B

CB02RS-02

CB02RS-02B

CB03RS

CB03RS-B

CB03RS-01

CB03RS-01B

CB03RS-02

CB03RS-02B

CB04RS

CB04RS-B

CB04RS-01

CB04RS-01B

CB04RS-02

CB04RS-02B

CB05RS

CB05RS-B

CB05RS-02

CB05RS-02B

CB06RS

CB06RS-B

CB06RS-02

CB06RS-02B

CB07RS

CB07RS-B

CB07RS-02

CB07RS-02B

CB08RS

CB08RS-B

CB08RS-02

CB08RS-02B

with

without

with

without

with

without

with

without

with

without

with

without

with

without

with

without

with

without

with

Breaker

without

with

without

with

without

with

without

with

without

with

without

with

without

with

without

Dimensions(mm)

DMIN 1

l/d < 3 l/d>3

2.2

3.6

2.2

3.9

2.2

3.6

2.2

4.2

2.2

3.6

2.2

4.9

3.2

4.2

3.2

4.4

3.2

4.2

3.2

4.5

3.2

4.2

3.2

4.8

4.2

5.1

4.2

5.2

4.2

5.1

4.2

5.3

4.2

5.1

4.2

5.5

5.2

6.0

5.2

6.1

5.2

6.0

5.2

6.4

6.2

7.2

6.2

7.3

6.2

7.2

6.2

7.8

7.2

8.6

7.2

8.8

7.2

8.6

7.2

9.2

8.2

9.5

8.2

9.6

8.2

9.5

8.2

9.8

RE

DCON

LF

L19

LDRED

WF

F2

0.05

0.05

0.1

0.1

0.2

0.2

0.05

0.05

0.1

0.1

0.2

0.2

0.05

0.05

0.1

0.1

0.2

0.2

0.05

0.05

0.2

0.2

0.05

0.05

0.2

0.2

0.05

0.05

0.2

0.2

0.05

0.05

0.2

0.2

2

2

2

2

2

2

3

3

3

3

3

3

4

4

4

4

4

4

5

5

5

5

6

6

6

6

7

7

7

7

8

8

8

8

50

50

50

50

50

50

50

50

50

50

50

50

60

60

60

60

60

60

70

70

70

70

75

75

75

75

85

85

85

85

95

95

95

95

5

5

5

5

5

5

7.5

7.5

7.5

7.5

7.5

7.5

10

10

10

10

10

10

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

12.5

15

15

15

15

6

6

6

6

6

6

9

9

9

9

9

9

12

12

12

12

12

12

15

15

15

15

18

18

18

18

21

21

21

21

24

24

24

24

1

1

1

1

1

1

1.5

1.5

1.5

1.5

1.5

1.5

2

2

2

2

2

2

2.5

2.5

2.5

2.5

3

3

3

3

3.5

3.5

3.5

3.5

4

4

4

4

0.25

0.25

0.25

0.25

0.25

0.25

0.35

0.35

0.35

0.35

0.35

0.35

0.45

0.45

0.45

0.45

0.45

0.45

0.55

0.55

0.55

0.55

0.65

0.65

0.65

0.65

0.75

0.75

0.75

0.75

0.85

0.85

0.85

0.85

1.8

1.8

1.8

1.8

1.8

1.8

2.7

2.7

2.7

2.7

2.7

2.7

3.6

3.6

3.6

3.6

3.6

3.6

4.5

4.5

4.5