Académique Documents

Professionnel Documents

Culture Documents

Speed Control of PMBLDC Motor Using Fuzzy Logic Controller With Sensorless Technique

Transféré par

ijaertTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Speed Control of PMBLDC Motor Using Fuzzy Logic Controller With Sensorless Technique

Transféré par

ijaertDroits d'auteur :

Formats disponibles

International Journal of Advanced Engineering Research and Technology (IJAERT) 4

Volume 4 Issue 1, January 2016, ISSN No.: 2348 8190

Speed Control of PMBLDC motor using Fuzzy Logic Controller with

Sensorless Technique

1,2

Mohammad Zaid1, Mohammad Ayyub2

Department of Electrical Engineering, Zakir Hussain College of Engineering & Technology, Aligarh Muslim

University Uttar Pradesh, India

Abstract

Recent advances in the field of power electronics have

made PMBLDC motors very popular. They are being

used in host of applications because they posses

certain desirable features as compared to brushed DC

motor and servo motors. This paper presents speed

control of PMBLDC motor using Fuzzy logic

controller with sensorless operation of motor. The

simulation is carried out in MATLAB/SIMULINK

platform. The simulation result compares the

performance of Fuzzy Logic Controller with PI

controller.

Keywords: Fuzzy logic controller, PMBLDC motor, PI

controller, DC motor.

I.

INTRODUCTION

The first electronically commutated brushless DC

motor was developed with the help of Hall elements

in1962 [11], since then tremendous development has

been made in the field of power electronics and

permanent magnet materials. Today PMBLDC motor

is used in many applications from aerospace,

automobile industry to household appliances. The

PMBLDC motor posses certain desirable features such

as high efficiency, high power factor, lower

maintenance, precise and accurate control and high

power density. The PMBLDC motor generally has a

trapezoidal back emf which is different as compared

with PMSM which has a sinusoidal back EMF. The

PMBLDC motor is developed on the basis of brushed

DC motors, but unlike brushed DC motors the

commutation is electronically controlled and Hall

sensors are used for sensing the rotor position. The

output of Hall sensors are used for generation of

switching signals for the inverter. Hall sensors are

costly and less reliable especially in space application.

Due to these reasons various sensorless techniques

have been developed. Each of the sensorless

techniques employed have their own advantages and

disadvantages. These sensorless techniques are used to

detect the rotor position of the motor indirectly. Most

popular and widely used technique is back emf

detection using line voltage difference method.

Actually in any sensorless scheme we need to identify

exact commutation instants for the generation of

virtual Hall signals, in the scheme using difference of

line voltage the difference of two line voltages gives

the back emf of any one phase. The zero crossing

instants of that phase emf waveform gives the

approximate commutation instants of the current of

that phase. The zero crossing instants need to be phase

shifted to get the exact commutation point. A low pass

filter generally introduces the delay required for the

operation. Most of the back emf detection techniques

suffer from serious drawback that at low speeds it is

difficult to detect the back emf, hence some starting

methods needs to be employed before motor

accelerates to minimum threshold speed. Another

improved method for detection of rotor position is the

utilization of third harmonic component in the EMF

waveform of the motor. The voltage between the

artificial neutral and motor neutral gives the third

harmonic voltage component which contains the

information about the zero crossing instants of back

EMFs of the three phases. It can be shown that [9] this

voltage between the two neutrals is numerically equal

to mean of three EMFs. Zero crossings of third

harmonic voltage when properly processed

corresponds to exact commutation instants which is

needed for proper switching of inverter. In most of the

cases motor neutral is not accessible hence midpoint of

DC link can also be used for generation of third

harmonic voltage [9], but this signal is more noisy as

compared to the previous signal obtained between the

two neutrals.

In this paper we have employed sensorless technique

based on the line voltage difference method. We have

also used Fuzzy logic based controller for speed

control of motor. For comparison we have used a PI

controller and then fuzzy logic based controller. The

problem with conventional controllers comes when

either plant structure is unknown or if known is so

complex that design of controller by classical approach

would be impractical and cumbersome. The other

problem comes when model of a system is highly non

linear or rate of parameter change of plant is extremely

high. Fuzzy controllers perform very well in the

situations described above because by using FLC we

need not to know the plant structure and also by time

needed for design of controller may be significantly

shortened. However performance improvement using

FLC will depend on tuning and choosing a appropriate

rule base for FLC.

www.ijaert.org

International Journal of Advanced Engineering Research and Technology (IJAERT) 5

Volume 4 Issue 1, January 2016, ISSN No.: 2348 8190

II.

SYSTEM CONFIGURATION

Van= Ria + (L-M) ia +Ea

Consider a star connected PMBLDC motor whose

stator is star connected. The motor stator is fed by a

three phase inverter which is operated in 1200 mode.

Only two phase conduct at a time and third phase is

floating. The switches are triggered utilizing the exact

rotor position of the motor .Figure 1 shows the overall

system configuration of the drive system. The speed

controller used can be a PI controller or a Fuzzy logic

controller. The control loop has outer speed controller

and inner current controller. Table 1 gives details of

PMBLDC motor specifications.

(1)

Similar equations can be written for phase b and c .

Vbn= Rib + (L-M) ib +Eb

(2)

Vcn= Ric + (L-M) ic +Ec

(3)

From these equations line to line voltages can be found

Vab = R(ia-ib) + L (ia-ib) +ean-ebn

(4)

Vbc= R(ib-ic) + L (ib-ic) +ebn-ecn

(5)

Vca=R(ic-ia) +L (ic-ia) +ecn-ean

(6)

Now to find the difference in line voltage subtract

equation five from four. No neutral point is required

for estimation of line voltages.

Vabbc= R(ia-2ib +ic) + L (ia-2ib+ic) + ean -2ebn+ecn (7)

Fig.1 Overall PMBLDC motor drive

Table 1 The PMBLDC motor specifications

Parameters Symbol

Value

Units

Resistance

R

2.875

Ohms

Inductance

L

2.7

mH

Back-emfke

0.42

V/rad/s

constant

Torque

kt

0.042

N-m/A

constant

Viscous

B

0.000089

NDamping

m/(rad/s)

Rotor

J

0.0005

Kg-m2

Inertia

Number of

P

4

Poles

III.

BACK EMF ZERO CROSSING

ESTIMATION

In this method the zero crossing point of back emf is

estimated using the difference in line voltage.Zero

crossing points will give us the virtual hall signals

needed for the proper switching of the inverter

switches. Consider the voltage of phase a of the motor

with respect to neutral point as

Now consider a situation in which phase a and phase c

is conducting and phase b is open. In this situation ean

= -ecn. Therefore, in that interval (7) may be simplified

as

Vabbc= ean-2ebn+ecn = -2ebn

(8)

The above result shows that the difference in line

voltage Vabbc gives the inverted and magnified

waveform of back emf of phase b. Similarly Vbcca and

Vcaab gives the inverted and magnified back emf wave

forms of phase c and a. The above derivation shows

that zero crossing of back emf can be estimated

indirectly by proper processing of three stator voltages.

A low pass filter is generally used for removing the

high frequency components present in the derived back

emf waveform. The other advantage we get by using

low pass filter is that sufficient amount of delay is

produced which gives exact commutation instants for

the generation of virtual hall signal.

IV.

IMPLEMENTATION OF FUZZY

LOGIC BASED SPEED CONTROLLER

The FLC scheme observes the pattern of the speed

loop error and correspondingly updates the output of

the controller to match the actual speed with the

reference speed. The triangular membership function

with 5 linguistic variables and 25 rules are used in the

FLC design. We have chosen a linear rule base which

is widely accepted with triangular membership

functions. All membership functions (MFs) for

controller inputs, i.e., error (e) and change of error

(e) incremental change in controller output u for PItype FLC are defined on common interval [-1,1]. Each

of the rules of FLC is characterized with an IF part

called antecedent and then part called consequent. We

have taken three scaling factors namely Ke, Kce and

Kdu. These scaling factors are very important for

tuning of FLC because once membership functions

along with rule base are defined they cannot be

changed every time. Hence to get the optimal response

we have to tune these scaling factors until we get the

www.ijaert.org

International Journal of Advanced Engineering Research and Technology (IJAERT) 6

Volume 4 Issue 1, January 2016, ISSN No.: 2348 8190

desired response. However every Fuzzy controller

design should tend to solve a control problem with a

minimal number of Fuzzy sets. If by succeeding to

solve a problem with a 5*5 Fuzzy rule base rather than

a 7*7 Fuzzy rule base, the processing of 25 instead of

49 rules will save a lot of computing time.

We have chosen 25 rule base system. Also it may seem

that a larger number of Fuzzy sets will result in a better

designed controller, practical experience has proven

that the number of Fuzzy sets involved is not so

important. The 25 rules along with their meaning used

in Table 2 gives Fuzzy inference system. Table 3 gives

meaning of linguistic variables of Fuzzy inference

system.

Table 2: Rule table for Fuzzy inference system

Table 3: Meaning of linguistic variables in Fuzzy

inference system

NVB

Negative very big

NB

Negative big

NM

Negative medium

NS

Negative small

Z

Zero

PS

Positive small

PM

Positive medium

PB

Positive big

PVB

Positive very big

e

Speed error

ce

Change in speed error

Fig.3 Membership function for input variable ce

Fig.4 Fuzzy Logic based speed controller

Figure 5 and 6 shows the membership function of

output variable and relationship between input and

output variables.

Above rule base in words can be defined as IF e is

NB and ce NB then u(output change) is NVB.

Figure 2 and 3 shows the membership functions of

error and change in error in speed. Figure 4 shows the

overall design of Fuzzy logic controller with scaling

factors.

Fig.2 Membership function for input variable e

Fig.5 Membership function for input variable e

Fig.6 Surface showing relationship between e, ce and

u based on rule base

www.ijaert.org

International Journal of Advanced Engineering Research and Technology (IJAERT) 7

Volume 4 Issue 1, January 2016, ISSN No.: 2348 8190

Figure 7 shows the modelling of back emf waveform

using look up tables.

Fig.7 Modelling of back emfs

V.

SIMULATION RESULTS AND

DISCUSSION

The performance of the developed PMBLDC motor is

simulated in Simulink. Simulation results of motor

speed, current and emf along with PWM signals are

obtained. Figure 8 shows Simulink based model of

PMBLDC motor drive system.

zero crossing because of the spikes present in the

voltage, hence an appropriate filter design is necessary.

The other problem is to determine the instant when the

control is shifted from sensor control to sensorless

control, practically this is done by first exciting two

phases out of three for a predetermined duration called

prepositioning time, which may be fixed on the inertia

of motor and its load capability. At the end of the

predetermined period motor have moved from an

unknown position to a predetermined position. Figure

9 shows the line voltage difference Vabbc which gives

zero crossing for back EMF of phase a. Figure 10

shows the zero crossing estimated by difference in line

voltage method. Filtering helps in acquiring accurate

commutation instants. Exact commutation instant will

be 30 degree phase shifted from zero crossing point

The exact commutation instants are being shown in

figure 11. A low pass second order filter with cut off

frequency of 24 Hertz is being used for filtering. From

the above figure it can concluded that zero crossing

estimated by difference of line voltage is the real

commutation instant which we require for generation

of virtual hall signal. Figure 12 and 13 gives

comparison between real hall signal originally

generated by sensors and virtual hall signals generated

by detecting exact commutation instants, both signals

should exactly match for satisfactory operation of

motor in sensorless control.

Fig.9 Line Voltage difference Vabbc

Fig. 8 PMBLDC motor model with PI and FLC based

speed controller

The motor is first started with sensors and is then

switched over to sensorless control at 200ms. The

main problem in this method is detecting the actual

Fig. 10 Estimation of ZCP of phase b from line voltage

difference Vabbc

www.ijaert.org

International Journal of Advanced Engineering Research and Technology (IJAERT) 8

Volume 4 Issue 1, January 2016, ISSN No.: 2348 8190

Fig. 15 Speed response with PI controller (Tl=1Nm)

Fig. 11 Estimation of ZCP of phase b from filtered line

voltage difference Vabbc

Fig. 16 Speed response with PI controller (Tl=1Nm)

Fig.12 Virtual hall signal b

Fig.13 Real hall signal b

Figure 14 shows the motor position in radians in

sensorless control.

Fuzzy Logic controller with sensorless control is

employed here. The load torque of 1Nm is applied at

t=0.2 second, similar to what we have done with PI

controller .The speed response in figure 17 shows that

there is almost no reduction in speed of the motor

when load torque is applied at t=0.2 second which

shows the superiority of fuzzy logic controller if

properly tuned over PI controller. It can be seen from

figure 18 that the reduction in speed after application

of load torque is less than 1 rad/s, and motor gets back

to set point speed almost instantaneously. This is great

improvement over PI controller which takes almost 0.3

seconds to get back at same speed reference for same

amount of load torque applied. Figure 19 shows the

speed response of motor using fuzzy logic controller

when step change in reference speed is made .

Fig.14 Rotor position in radians

The performance of PI controller with sensorless

control is evaluated in this section. Load torque is

applied at 0.2 seconds. From figure 15 and 16 it can be

seen that there is a significant reduction in set point

speed with application of load torque. Speed is reduced

to 194 rad/s from set point speed of 200 rad/s. Motor

speed again reaches set point speed after significant

delay of 0.3 seconds.

www.ijaert.org

Fig. 17 Speed response with FLC (Tl=1Nm)

International Journal of Advanced Engineering Research and Technology (IJAERT) 9

Volume 4 Issue 1, January 2016, ISSN No.: 2348 8190

The use of Fuzzy controller has generally reduced the

rise time and settling time of the speed response of the

motor. Hence a tuned Fuzzy controller has

outperformed conventional PI controller. However the

main advantage of using Hall sensors is that motor

design remains simple, and no extra circuitry is

needed.

Fig. 18 Speed response with PI controller (Tl=1Nm)

Fig.19 Set point speed increased from 200 rad/s to 300

rad/s with FLC.

The trapezoidal waveform of back emf of phase a and

current of phase a is shown in figure 20 and 21.

Fig.20 Back emf phase a

Fig.21 current phase a

VI.

CONCLUSION

A detailed Simulink model of PMBLDC motor with

and without Hall sensors has been developed and its

speed is controlled by using both Fuzzy logic and PI

controller Motor is found to be running smoothly in

sensorless operation and all the waveforms i.e. motor

phase currents, back Emf, rotor position has been

obtained from Simulink model. Speed control using

both Fuzzy controller and PI controller has been done.

REFERENCES

[1] George K. I. Mann, Bao-Gang Hu and G. Gosine

Analysis of Direct Action Fuzzy PID Controller

Structures, IEEE TRANSACTIONS ON SYSTEMS, MAN,

AND CYBERNETICSPART B: CYBERNETICS, VOL. 29,

NO. 3, JUNE 1999.

[2] Rajani K. Mudi and Nikhil R. Pal, A Robust SelfTuning Scheme for PI- and PD-Type Fuzzy Controllers,

IEEE TRANSACTIONS ON FUZZY SYSTEMS, VOL. 7, NO.

1, FEBRUARY 1999.

[3] Ming-Fa Tsai, Tran Phu Quy, Bo-Feng Wu, and ChungShi Tseng , Model Construction and Verification of a

BLDC Motor Using MATLAB/SIMULINK and FPGA

Control,IEEE Conference Publications Singapore,2011.

[4] E.Kaliappan, C.Chellamuthu, Modeling, simulation and

experimental analysis of permanent magnet brushless DC

motors for sensorless operation Archives of Electrical

Engg.Vol.61,2012

[5]. Paul P. Acarnley and John F. Watson, Review of

Position sensorless operation of Brushless Permanent

Magnet machines, IEEE Transactions on Industrial

Electronics, VOL. 53, NO. 2, APRIL 2006.

[6]. Kim D.K., Lee K.W., Kwon B.I., Commutation torque

ripple reduction in a position sensorless brushless DC motor

drive. IEEE Trans. Power Electron. 21(6): 1762 1768

(2006).

[7] Aakanksha Girolkar and G. Bhuvaneswari, Control of

PMBLDC Motor Using Third harmonic back emf sensing

with zigzag transformer, IEEE Conference Publications

,2013.

[8] J.C Moriera, Indirect Sensing of rotor flux position of

permanent magnet AC motor operation over a wide speed

range; IEEE Trans. Ind. Appl., vol. 32,no.6,pp 13941401,Nov/Dec 1996.

[9] J.P.Johnson, M.Ehsani and Yilcan Guzelgunler, Review

of Sensorless Methods For Brushless DC, IA Conference,

1999. Thirty Fourth IAS Annual Meeting Conference

Record of the 1999 IEEE, Vol.1, October 1999, pp. 143150.

[10] N. Matsui, Sensorless permanent magnet brushless DC

and synchronous drives, in Proc. Electro motion 3,1996,

pp. 172-180.

[11] Chang Liang Xia, Permanent Magnet Brushless DC

Motor Drives and Controls, Wiley Press, Beijing, 2012.

[12] Chetan K. Lad, R. Chudamani, Sensorless Brushless

DC Motor Drive based on Commutation instants derived

from the Line Voltages and Line Voltage Differences, 2013

Annual IEEE India Conference (INDICON)

[14] J. X. Shen, Member, Z. Q. Zhu, Sensorless FluxWeakening Control of Permanent-Magnet Brushless

Machines Using Third Harmonic Back EMF, IEEE

TRANSACTIONS ON INDUSTRY APPLICATIONS, VOL.

38, NO. 4, NOVEMBER/DECEMBER 2004.

www.ijaert.org

Vous aimerez peut-être aussi

- Numerical-Based Analysis For Cost-Effectiveness Verification of Long-Reach Optical Access NetworksDocument7 pagesNumerical-Based Analysis For Cost-Effectiveness Verification of Long-Reach Optical Access NetworksijaertPas encore d'évaluation

- Appraisal of Optimal Production Quantity in Small and Medium Scale IndustryDocument9 pagesAppraisal of Optimal Production Quantity in Small and Medium Scale IndustryijaertPas encore d'évaluation

- Simulation and Analysis of LLC Resonant Converter Using Closed Loop PI ControllerDocument3 pagesSimulation and Analysis of LLC Resonant Converter Using Closed Loop PI ControllerijaertPas encore d'évaluation

- Changes in The Physical State of Ceramics Materials Brought About by The Removal of Free WaterDocument5 pagesChanges in The Physical State of Ceramics Materials Brought About by The Removal of Free WaterijaertPas encore d'évaluation

- Effect of Cassava Peel On The Insulating Properties of Ogugu Clay DepositDocument8 pagesEffect of Cassava Peel On The Insulating Properties of Ogugu Clay DepositijaertPas encore d'évaluation

- Self-Medical Analysis Using Internet-Based Computing Upon Big DataDocument6 pagesSelf-Medical Analysis Using Internet-Based Computing Upon Big DataijaertPas encore d'évaluation

- Detection of Melanoma Using Asymmetric FeaturesDocument7 pagesDetection of Melanoma Using Asymmetric FeaturesijaertPas encore d'évaluation

- Geological/survey of Clay MaterialDocument9 pagesGeological/survey of Clay MaterialijaertPas encore d'évaluation

- A Review On Ceramics and Its Economic EmpowermentDocument4 pagesA Review On Ceramics and Its Economic EmpowermentijaertPas encore d'évaluation

- Log Based Web Pages Recommendation Using User ClusteringDocument6 pagesLog Based Web Pages Recommendation Using User ClusteringijaertPas encore d'évaluation

- A Review: Technology and ProductionDocument5 pagesA Review: Technology and ProductionijaertPas encore d'évaluation

- Advancement in Knitted Structure For Industrial Applications - A ReviewDocument8 pagesAdvancement in Knitted Structure For Industrial Applications - A ReviewijaertPas encore d'évaluation

- Online Educational Collaborative Platform: Design, Development and ImplementationDocument9 pagesOnline Educational Collaborative Platform: Design, Development and ImplementationijaertPas encore d'évaluation

- Fuzzy Logic Based Maximum Power Point Tracker For Photo Voltaic SystemDocument6 pagesFuzzy Logic Based Maximum Power Point Tracker For Photo Voltaic SystemijaertPas encore d'évaluation

- Self Compacting Concrete Column (SCC) Mix Design and Flowability TestDocument3 pagesSelf Compacting Concrete Column (SCC) Mix Design and Flowability TestijaertPas encore d'évaluation

- A Review of IP Security For InternetworkingDocument5 pagesA Review of IP Security For InternetworkingijaertPas encore d'évaluation

- Study and Analysis Precoded Orthogonal Fdma Uplink SystemDocument4 pagesStudy and Analysis Precoded Orthogonal Fdma Uplink SystemijaertPas encore d'évaluation

- Design of Robust Type-2 Fuzzy Logic Power System Stabilizer Using Hopf BifurcationsDocument5 pagesDesign of Robust Type-2 Fuzzy Logic Power System Stabilizer Using Hopf BifurcationsijaertPas encore d'évaluation

- Characterization of Ezzodo Clay Deposit For Its Industrial PotentialsDocument8 pagesCharacterization of Ezzodo Clay Deposit For Its Industrial PotentialsijaertPas encore d'évaluation

- A Review On Synthesis, Characterization and Applications of Silica ParticlesDocument7 pagesA Review On Synthesis, Characterization and Applications of Silica ParticlesijaertPas encore d'évaluation

- Structural Optimisation in Building DesignDocument3 pagesStructural Optimisation in Building DesignijaertPas encore d'évaluation

- A New Stability Enhanced Power System Based On Adaptive Controller and Space Vector TechniqueDocument7 pagesA New Stability Enhanced Power System Based On Adaptive Controller and Space Vector TechniqueijaertPas encore d'évaluation

- Optimization of Gear To Improve Performance of GearboxDocument4 pagesOptimization of Gear To Improve Performance of Gearboxijaert100% (1)

- Clustering Approach: An Efficient Method To Prevent Black Hole Attack in Mobile Adhoc NetworksDocument4 pagesClustering Approach: An Efficient Method To Prevent Black Hole Attack in Mobile Adhoc NetworksijaertPas encore d'évaluation

- Image Denoising Via Self-Learning Based Image Decomposition Using DWTDocument7 pagesImage Denoising Via Self-Learning Based Image Decomposition Using DWTijaertPas encore d'évaluation

- Design of RC Beam With and Without Welded Mesh As Shear Reinforcement in Flexural and Shear BehaviourDocument4 pagesDesign of RC Beam With and Without Welded Mesh As Shear Reinforcement in Flexural and Shear Behaviourijaert100% (1)

- An Advanced MPC Based Grid Current Compensator For Grid-Connected Distributed GenerationDocument5 pagesAn Advanced MPC Based Grid Current Compensator For Grid-Connected Distributed GenerationijaertPas encore d'évaluation

- Feature Selection Approach For Intrusion Detection System Based On Pollination AlgorithmDocument5 pagesFeature Selection Approach For Intrusion Detection System Based On Pollination AlgorithmijaertPas encore d'évaluation

- Visual Tracking Using HOG and SVMDocument4 pagesVisual Tracking Using HOG and SVMijaertPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Balawala Pump House: Bisalpur Jaipur Water Supply Project Daily Report - Pumping OperationDocument21 pagesBalawala Pump House: Bisalpur Jaipur Water Supply Project Daily Report - Pumping Operationlibin88Pas encore d'évaluation

- Electrical Vendor ListDocument11 pagesElectrical Vendor Listshantanu11181Pas encore d'évaluation

- SVET Overview: Add To Quote RequestDocument3 pagesSVET Overview: Add To Quote RequestthuronPas encore d'évaluation

- Circuits 2 Lab Report No. 5Document4 pagesCircuits 2 Lab Report No. 5Carlo Caniedo80% (5)

- Quickcmc - Determine Zone Reach and Trip: Time of Zone 1 of A Distance RelayDocument12 pagesQuickcmc - Determine Zone Reach and Trip: Time of Zone 1 of A Distance RelayNga VũPas encore d'évaluation

- Ccs 646v e GV e DatasheetDocument2 pagesCcs 646v e GV e DatasheetLeonardPas encore d'évaluation

- Disclosure To Promote The Right To InformationDocument15 pagesDisclosure To Promote The Right To InformationduonzaPas encore d'évaluation

- Review On PhotoconductivityDocument6 pagesReview On PhotoconductivitySumon DebnathPas encore d'évaluation

- MIL-HDBK-217F Reliability Prediction For Electronic EquipmentDocument205 pagesMIL-HDBK-217F Reliability Prediction For Electronic Equipmentgeoffxyz0Pas encore d'évaluation

- Chapt 1 Microwave Engineering and DevicesDocument3 pagesChapt 1 Microwave Engineering and DevicesBlessing TanakaPas encore d'évaluation

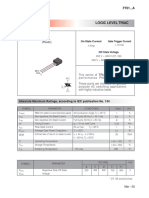

- LOGIC LEVEL TRIAC TECHNICAL SPECIFICATIONSDocument4 pagesLOGIC LEVEL TRIAC TECHNICAL SPECIFICATIONSAnatoly WolkoffPas encore d'évaluation

- Strong Fet Irfb7437Pbf: V 40V R Typ. 1.5Mω Max. 2.0M I 250Ac I 195ADocument10 pagesStrong Fet Irfb7437Pbf: V 40V R Typ. 1.5Mω Max. 2.0M I 250Ac I 195Arov1976Pas encore d'évaluation

- Loco Breaker Test SystemDocument11 pagesLoco Breaker Test SystemtvjithinPas encore d'évaluation

- 2090 CSWM1DF 14aa05 PDFDocument132 pages2090 CSWM1DF 14aa05 PDFsoayPas encore d'évaluation

- Dual Slope Integrating Type DVM EceDocument7 pagesDual Slope Integrating Type DVM Eceవంశీ క్రిష్ణPas encore d'évaluation

- Electrical Products Company ProfileDocument8 pagesElectrical Products Company ProfilevjrPas encore d'évaluation

- Cambridge International Examinations International General Certificate of Secondary EducationDocument8 pagesCambridge International Examinations International General Certificate of Secondary EducationChong Xue ErPas encore d'évaluation

- DPR - IPDS Jammu - 30.4.2015Document82 pagesDPR - IPDS Jammu - 30.4.2015Manoj ManhasPas encore d'évaluation

- Omron SensorDocument2 pagesOmron SensoryamelPas encore d'évaluation

- Error List For Mitsubishi HeavyDocument54 pagesError List For Mitsubishi HeavynovyPas encore d'évaluation

- Akash Singh's Document on Liquid LensesDocument27 pagesAkash Singh's Document on Liquid LensesAbhay SinghPas encore d'évaluation

- 13 Determination of Equivalent Circuit Parameters of A 1-Ph Induction Motor.Document3 pages13 Determination of Equivalent Circuit Parameters of A 1-Ph Induction Motor.Ashwani BhadaniPas encore d'évaluation

- DMB-01-C-M24: TIMER M/FUNCTION 24VDC/24-240VAC SUPPLY 1 C/O 0.1S-100H Catalogue NoDocument4 pagesDMB-01-C-M24: TIMER M/FUNCTION 24VDC/24-240VAC SUPPLY 1 C/O 0.1S-100H Catalogue Noyassine yassinePas encore d'évaluation

- J12-1000 A 07-3.1Document99 pagesJ12-1000 A 07-3.1SawonPas encore d'évaluation

- Final Earthing V3Document22 pagesFinal Earthing V3RewanEsamPas encore d'évaluation

- ZAB - UN1020 User Manual 3BHS335648 E82 PDFDocument195 pagesZAB - UN1020 User Manual 3BHS335648 E82 PDFdhinakaran100% (5)

- Columbs LawDocument6 pagesColumbs Lawasadaliawanatd1Pas encore d'évaluation

- Principles of Operation Principle of High-Frequency Oscillation Type Inductive Proximity SensorDocument9 pagesPrinciples of Operation Principle of High-Frequency Oscillation Type Inductive Proximity SensorRanaIfteePas encore d'évaluation

- Es340 132kv Open Terminal Circuit BreakersDocument35 pagesEs340 132kv Open Terminal Circuit BreakersXin LiPas encore d'évaluation

- Bipolar Junction Transistors (BJTS) 1Document19 pagesBipolar Junction Transistors (BJTS) 1ጁንታው ነኝPas encore d'évaluation