Académique Documents

Professionnel Documents

Culture Documents

Spontaneous Glass Breakage

Transféré par

y2kareinCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Spontaneous Glass Breakage

Transféré par

y2kareinDroits d'auteur :

Formats disponibles

Spontaneous Glass Breakage: Why it happens and what to do about it | Construction S...

Page 1 of 4

About Us

Media Planner

Subscribe

Click here to read the latest issue of The Construction Specifier

Spontaneous Glass Breakage: Why it happens and what to do about it

Photo Wes Thompson. Photo courtesy PPG

by Michael L. Rupert

The past few years have seen several highly publicized incidents involving window and balcony glass breaking spontaneously and falling from high-rise

buildings in Toronto, Chicago, Las Vegas, and Austin, Texas. While such episodes are rare, the danger they pose has forced building code writers,

architects, government officials, and related industry professionals to reconsider which types of glass should be specified for glass applications where

strength and protection of passers-by are paramount.

For architects and specifiers, it is important to have an overview on the potential causes of spontaneous glass breakage, including some common

misconceptions about its actual spontaneity. The term safety glazing generally refers to any type of glass engineered to reduce the potential for serious

injury when it comes into human contact. In addition to balcony glass, safety glazings are commonly required for:

With an increase in spontaneous

glass breakage incidents, the glazi

industry is looking at new ways to

make assemblies safer. Images courte

PPG Industries

sliding glass doors;

shower doors;

patio furniture;

http://www.constructionspecifier.com/spontaneous-glass-breakage-why-it-happens-and-... 12-Jul-15

Spontaneous Glass Breakage: Why it happens and what to do about it | Construction S... Page 2 of 4

Tempered, laminated, and heat-strengthened glass

The most common type of safety glass is tempered glass, which is made by heating pre-cut panels of glass to about 650 C (1200 F), then cooling them

rapidly through a process called quenching. By cooling the outer surfaces of the panel more quickly than the center, quenching puts the surfaces and

edges of the glass in compression and the center of the glass in tension.

In addition to making tempered glass four to five times stronger than conventional annealed glass, re-heating and rapid quenching dramatically changes

the break characteristics of the glass. Consequently, when tempered glass is broken, it shatters into thousands of tiny pebblesthis practically eliminat

the danger of human injury caused by sharp edges and flying shards.

Another type of safety glazing, laminated glass, is made by sandwiching an interlayer of vinyl (typically polyvinyl butyral [PVB]) between two layers of gl

to hold the panel together if it is broken. Although laminated glass is most commonly associated with windshield glass for automobiles, it is increasingly

being specified for storefronts, curtain walls, and windows to meet codes for hurricane-resistant glass.

A third option, heat-strengthened glass, is not technically a safety glazing. This is because when it breaks, it may form larger sharp shards that can caus

serious injury. However, heat-strengthened glass still meets Consumer Product Safety Commission (CPSC) 16 Code of Federal Regulations (CFR) Par

1201 and Class A of American National Standards Institute (ANSI) Z97.1, Safety Glazing Materials Used in Buildings?Safety Performance Specification

and Methods of Test, for many safety glass applications when it is combined with a laminated interlayer that holds the glass together if it breaks.

As with tempering, heat-strengthening involves exposing pre-cut glass panels to temperatures of up to 650 C, but with a slower cooling process. Heatstrengthened glass is not as strong as tempered glass because the compression strength is lowerabout 24,130 to 51,710 kPa (3500 to 7500 psi)

compared to 68,950 kPa (10,000 psi) or greater. However, it is about twice as strong as annealed glass. For this reason, heat-strengthened glass is ofte

specified for applications demanding resistance to thermal stress and snow- and wind-loads.

Causes of glass breakage

The incidents of spontaneous glass breakage in Chicago, Las Vegas, Austin, Texas, and Toronto occurred exclusively with tempered glass. Despite tha

materials high levels of strength and capacity to meet safety glazing requirements, it is uniquely vulnerable to these types of failures. Ironically, the cen

tension zone engineered into tempered glass through the quenching process is also what makes it so vulnerable to catastrophic breakage.

Poor edge quality

There are many potential causes for spontaneous breakage of tempered glass. The most

common is damage to the edges of glass as it is being pre-cut into panels, or nicks or chips to the

edges that occur when the glass is being packaged, shipped, or installed onsite.

While such damage may not be readily apparent, stress concentrations around these

imperfections can occur as the glass expands and contracts in response to in-service temperature

changes, wind load, building movement, and other environmental factors. Ultimately, when those

stresses cause the glass to break, the action may appear to have been spontaneous when, in

fact, the circumstances for failure had been put in place months or even years earlier.

Frame-related breakage

Expansion and contraction of glass framing members may also lead to frame-related

breakageanother common form of seemingly spontaneous failure. Such incidents occur when

the gaskets, setting blocks, or edge blocks in a metal window or curtain wall frame are missing or

do not sufficiently cushion the glass against glass-to-metal contact caused by temperature or

wind-related movement. This can cause edge and surface damage to the glass as it comes in

contact with the metal frames perimeter, producing stresses that eventually lead it to fail for no

apparent reason.

Safety glazings are commonly required for sliding

glass doors, shower doors, and patio furniture.

Safety glazing generally refers to any type of glass

that is engineered to reduce the potential for seriou

injury.

Thermal stress

Another potential cause of spontaneous glass breakage is thermal stress. Thermally induced stresses in glass are caused by a positive temperature

difference between the center and edge of the glass lite, meaning the former is hotter than the latter. The expansion of the heated glass center results in

tensile stress at the edge of the glass. If the thermally induced stress exceeds the edge strength of the glass, breakage occurs.

Accounting for thermal stress is especially critical today, as current design trends and the desire for daylighting are driving the industry toward the

specification of larger insulating glass units (IGUs) with high-performance solar control coatings. Large IGUs have inherently greater glass surface and

edge areas. When they are combined with coatings designed to manage the suns energy, more rigorous thermal stress analyses are required.

Nickel-sulfide inclusions

A far less commonbut often citedcause of spontaneous glass breakage is nickel-sulfide (NiS) inclusions in tempered glass. Small nickel-sulfide ston

can form randomly in the production of float glass. They are typically benign, even when occurring in tempered glass.

North American glass manufacturers do not use nickel in batch formulations for primary glass and go to great lengths to avoid nickel-bearing componen

in their glass-melting processes. Despite rigorous quality controls and procedures aimed at reducing the likelihood of nickel-sulfide stones, there is no

technology to completely eliminate their formation in todays float glass.

Nickel-sulfide stones are quite small and their

occurrence in the final glass product is covered

under ASTM C1036, Standard Specification for F

Glass, which permits blemishes (including nickelsulfide particles) of between 0.5 and 2.5 mm (1/50

1/10 in.) in float glass, depending on glass size an

quality.

Nickel-sulfide particles are tiny, extremely rare, and

only found randomly in float glass. This combination

makes visual inspection for such inclusions highly

impracticalif not outright impossible.

There is no known technology that completely

eliminates the possible formation of nickel

sulfide stones in float glass. Further, because

nickel sulfide stones are so small, there is no

practical way to inspect their presence in float

glass.

While nickel-sulfide inclusions may be present in

annealed or heat-strengthened glass, the problem

they cause are specific to tempered glass becaus

of the tempering process. Breakage is due to a

volumetric growth in the size of the stone. As

detailed earlier, during the annealing and heatstrengthening processes, glass is cooled at slowe

controlled temperatures that enable nickel-sulfide

particles that are present to complete a phase

transformation (known as the ? to ? phase change

during which they fully expand to their final size and remain stable thereafter.

http://www.constructionspecifier.com/spontaneous-glass-breakage-why-it-happens-and-... 12-Jul-15

Spontaneous Glass Breakage: Why it happens and what to do about it | Construction S... Page 3 of 4

In the tempering process, this phase transformation is arrested during rapid quenching, which causes any nickel-sulfide particles present to remain

confined to their shrunken, pre-transformation states. Then, when the tempered glass is exposed to higher in-service temperatures caused by solar hea

gain or other high-temperature influences, nickel-sulfide particles have the potential to resume their volumetric growth. If the expansion is large

enoughand the particle is located in the center tension zone of the tempered glass panelthe resulting stress may be enough to shatter the glass.

Is heat-soaking a solution?

As indicated, nickel-sulfide particles are tiny, extremely rare, and only found randomly in float glass. This combination makes visual inspection for such

inclusions highly impractical, if not impossible. For that reason, some glass fabricators and glazing contractors offer heat-soaking of tempered glass as

potential solution for minimizing the risk of spontaneous glass breakage.

In this procedure, the glass supplier exposes a

entire lot or statistical sampling of tempered gla

panels to temperatures of 288 to 316 C (550 to

600 F) for two to four hours. The goal is to initia

or accelerate the phase change of any nickelsulfide inclusions that may be present and to

cause the glass to break before it is shipped to

end customer.

When tempered glass is broken (as shown

above), it shatters into thousands of tiny pebbles,

practically eliminating the danger of human injury

caused by sharp edges and flying shards of glass.

The surface compression of heat-strengthened

glass makes it approximately twice as strong as

annealed glass. Heat-strengthened glass is

typically used when glass is required to meet

thermal or mechanical loads caused by heat, wind,

or snow.

While this break-now-instead-of-later procedu

may eliminate defective tempered glass panels

destroying them before they are shipped, it can

provide a 100 percent guarantee against

spontaneous breakage. Even advocates of hea

soaking are careful to state the procedure can

reduce or minimize the risk for spontaneous

breakage of tempered glass. They will not use

words such as prevent or guarantee.

Risks of heat-soaking

There are risks associated with the heat-soak procedure that may outweigh any perceived benefits. For instance, small, stable inclusions could undergo

the beginning of a phase change during the heat-soak. While the phase change may not be sufficient to cause breakage during the procedure, the

transformation could potentially continue after the glass is installed, causing it to break in-service.

Re-exposing tempered glass to the increased temperatures of heat-soaking also has the potential to reduce its surface compression, which is the sourc

its strength. Ultimately, this may undermine the glasss ability to fulfill the safety or strength requirements for which it was intended.

Further, heat-soaking adds another layer of handling to the manufacturing process, which creates more opportunities for edge damage, scratches or co

changes to the low-e coating, and other imperfections that could have an impact on the tempered glass units long-term durability and performance.

Solutions for safety

In recent months, two organizations made ma

announcements prompted largely in response

the incidents of falling glass in Toronto, Chica

Las Vegas, and elsewhere. Both shared a

common assessmentnamely, that using

laminated tempered glass or heat-strengthene

glass is the most viable solution to making

balcony and other types of overhead glass sa

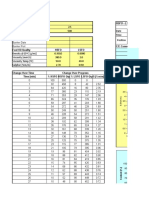

As these illustrations demonstrate, the heat-strengthened glass and tempered glass have distinctive

breakage patterns.

In Canada, an Expert Panel on Glass Panels

Balcony Guards established by the Ontario

Ministry of Municipal Affairs and Housing (MA

recommended local building codes be amend

to mandate the use of heat-strengthened

laminated glass for any outboard guard or

glazing located beyond the edge of a floor, or

within 50 mm (2 in.) of the edge of a floor. For

outboard glazings located more than 50 mm

inward from the edge, the panel recommende

heat-soaked tempered glass or heatstrengthened laminated glass.

Similarly, in December 2012, the International Code Council (ICC) passed a code change proposed by the Glazing Industry Code Committee (GICC),

mandating use of laminated glass in handrail assemblies, guardrails, or guard sections. The newly approved code states laminated glass must be

constructed of either single fully tempered glass, laminated fully tempered glass, or laminated heat-strengthened glass, and comply with CPSC 16 CFR

Part 1201 or Class A of ANSI Z97.1.

Conclusion

Given the developments and recommendations

outlined in this article, it is clear a laminated glass

interlayer in combination with tempered or heatstrengthened glass may offer the optimal blend of

characteristics for applications where the risk of inj

from glass fallout is a primary concern. For non-saf

glass applications, where strength and resistance t

spontaneous breakage is desired, non-laminated

heat-strengthened glass should be considered due

its lower costs.

Fully tempered glass and heat-strengthened glass are made

using the same basic heating and quenching process.

Michael L. Rupert is PPG Industries director of

technical services and product development for flat

glass. A 39-year company veteran, he is a board

member for the Glass Association of North America

(GANA) and chairs the Flat Glass Manufacturing

Division. Rupert holds a bachelors degree in civil

engineering and an MBA from the University of

Pittsburgh. He can be reached at mrupert@ppg.c

http://www.constructionspecifier.com/spontaneous-glass-breakage-why-it-happens-and-... 12-Jul-15

Spontaneous Glass Breakage: Why it happens and what to do about it | Construction S... Page 4 of 4

San Franciscos Intercontinental

Hotel showcases the design trends

and desire for daylighting, which

are driving the industry toward

specification of larger insulating

glass units (IGUs) with highperformance solar control

coatings. The architect of record is

Hornberger + Worstell; the design

architect is Patri Merker Architects.

Photo Tom Kessler. Photo courtesy PPG

Industries

This entry was posted in 08 00 00 Openings, 08 80 00 Glazing, B20Exterior Vertical Enclosures, B2020Exterior Windows, B2080Exterior Wall

Appurtenances, Features, MasterFormat, UniFormat and tagged 08 81 00?Glass Glazing, B2080.50?Exterior Balcony Walls and Railings, Balconies,

Breakage, Heat-soaking, Security glass, Tempered on December 17, 2013 [http://www.constructionspecifier.com/spontaneous-glass-breakage-why-i

happens-and-what-to-do-about-it/] .

Leave a reply

Copyright 2015 Kenilworth Media Inc. All rights reserved.

Home | Media Planner | Privacy Policy | Contact

Advertisement

http://www.constructionspecifier.com/spontaneous-glass-breakage-why-it-happens-and-... 12-Jul-15

Vous aimerez peut-être aussi

- MULTIVER-Spontaneous Glass Breakage-Causes Solution enDocument7 pagesMULTIVER-Spontaneous Glass Breakage-Causes Solution enBoby PrimatamaPas encore d'évaluation

- Viracon Architectural Glass: Tech TalkDocument4 pagesViracon Architectural Glass: Tech TalkJohn LeungPas encore d'évaluation

- NiS HistoryDocument13 pagesNiS HistoryNor Hasni TaibPas encore d'évaluation

- Spontanous Breakage - Nis PDFDocument22 pagesSpontanous Breakage - Nis PDFNaveen KarkiPas encore d'évaluation

- 66spontaneous BreakagesDocument4 pages66spontaneous Breakageschuanhan_tanPas encore d'évaluation

- Silicone Spandrel Glass CoatingsDocument10 pagesSilicone Spandrel Glass CoatingsGino TironiPas encore d'évaluation

- Spontaneous Glass BreakageDocument6 pagesSpontaneous Glass BreakagefahadneoPas encore d'évaluation

- All About GlassDocument58 pagesAll About Glassdwivedi.p.kPas encore d'évaluation

- Delamination of GlassDocument5 pagesDelamination of Glassmercab15Pas encore d'évaluation

- Eva Film Inter Layer For Laminated GlassDocument7 pagesEva Film Inter Layer For Laminated GlassPeter LinPas encore d'évaluation

- Glass CorrosionDocument8 pagesGlass CorrosionCan Yigit DincPas encore d'évaluation

- WK4-Salhia Shading CoeffficientDocument17 pagesWK4-Salhia Shading CoeffficienttriplbingaziPas encore d'évaluation

- HTBS Brochure ENG NetDocument12 pagesHTBS Brochure ENG NetehincapiemPas encore d'évaluation

- GlassDocument221 pagesGlassManuel CassarPas encore d'évaluation

- 07 Jorma Vitkala GLASTONDocument43 pages07 Jorma Vitkala GLASTONTheAnh TranPas encore d'évaluation

- Condensation On GlassDocument3 pagesCondensation On GlassMancasi RazvanPas encore d'évaluation

- Bearing Stress GlassDocument4 pagesBearing Stress GlasslingchenhPas encore d'évaluation

- SSGPGDocument56 pagesSSGPGtroyel99Pas encore d'évaluation

- Heat Soak TestingDocument9 pagesHeat Soak Testinghisham1958Pas encore d'évaluation

- Heat and Toughened GlassDocument4 pagesHeat and Toughened GlassJohneal MatiasPas encore d'évaluation

- Silicone Structural Glazing Manual - Dow CorningDocument52 pagesSilicone Structural Glazing Manual - Dow Corningnithya174100% (2)

- Overall Aspects of Non-Traditional Glasses: Synthesis, Properties and ApplicationsD'EverandOverall Aspects of Non-Traditional Glasses: Synthesis, Properties and ApplicationsPas encore d'évaluation

- Splicing of Mullion at Curtain WallDocument14 pagesSplicing of Mullion at Curtain WallKIARA ARGELPas encore d'évaluation

- 8-High Performance WindowsDocument5 pages8-High Performance WindowsaomareltayebPas encore d'évaluation

- MEPLADocument4 pagesMEPLAinitbashPas encore d'évaluation

- Glass Industry Vocabulary - Learn What Glass Industry Terms Mean - Signa SystemDocument15 pagesGlass Industry Vocabulary - Learn What Glass Industry Terms Mean - Signa SystemkrajasrinivasPas encore d'évaluation

- Factors That Caused Glass Curtain Wall Visual DistortionDocument4 pagesFactors That Caused Glass Curtain Wall Visual DistortionHAN HAN100% (1)

- Design Components For Structural GlazingDocument8 pagesDesign Components For Structural GlazingnonspodPas encore d'évaluation

- Factors That Affect Tempered Glass FlatnessDocument3 pagesFactors That Affect Tempered Glass FlatnessHan JoePas encore d'évaluation

- PVB Laminated Glass Vs SGP Laminated GlassDocument3 pagesPVB Laminated Glass Vs SGP Laminated GlassHAN HANPas encore d'évaluation

- Delamination of Laminated GlassDocument4 pagesDelamination of Laminated Glassreagan_roy8177100% (1)

- Quality Control of Tempered Glass Panels With PhotoelasticityDocument8 pagesQuality Control of Tempered Glass Panels With PhotoelasticityMohamedPas encore d'évaluation

- Facade SelectionDocument34 pagesFacade SelectionSarvesh TalelePas encore d'évaluation

- Glass Processing Line ALLBESTDocument49 pagesGlass Processing Line ALLBESTShailendra KelaniPas encore d'évaluation

- SJ MEPLA Calculation Protocol:: Spacers in Insulating Glass UnitsDocument5 pagesSJ MEPLA Calculation Protocol:: Spacers in Insulating Glass UnitsSudhakar KrishnamurthyPas encore d'évaluation

- Structural Assessment of Mashrabiya PerfDocument9 pagesStructural Assessment of Mashrabiya PerfSrikanth BhaskaraPas encore d'évaluation

- A List of Most Common Glass Types in The Flat Glass IndustryDocument11 pagesA List of Most Common Glass Types in The Flat Glass IndustryShikha Aggarwal100% (1)

- Hilti HIT HY70 For Structural Glass Brochure ASSET DOC LOC 2521814Document8 pagesHilti HIT HY70 For Structural Glass Brochure ASSET DOC LOC 2521814Efraim Fernandes FernandesPas encore d'évaluation

- Glass SpecificationDocument36 pagesGlass SpecificationSayed Abdul Hafiz100% (1)

- ACG Glass Installation - Setting Block, Edge CoverDocument29 pagesACG Glass Installation - Setting Block, Edge CoverDave LiPas encore d'évaluation

- Glass & FiberglassDocument6 pagesGlass & FiberglasstintinchanPas encore d'évaluation

- GGF Good Practice Guide Dec 13 PDFDocument89 pagesGGF Good Practice Guide Dec 13 PDFKhurshed Alam IndiaPas encore d'évaluation

- AGC - Interior Glass - Cleaning & Maintenance GuideDocument7 pagesAGC - Interior Glass - Cleaning & Maintenance GuideengkankwPas encore d'évaluation

- A1-10 Curtain WallsDocument58 pagesA1-10 Curtain WallsZYWPas encore d'évaluation

- Fire-Rated Glass Document38Document5 pagesFire-Rated Glass Document38jefftemple0% (1)

- Final BMC Glass FlooringDocument20 pagesFinal BMC Glass FlooringARAV PRAJAPATIPas encore d'évaluation

- Buckling Behavior of Split MullionDocument41 pagesBuckling Behavior of Split MullionNguyễn SơnPas encore d'évaluation

- Glass Handbook 2010 English For Eastern Europe PDFDocument300 pagesGlass Handbook 2010 English For Eastern Europe PDFJuan Pablo Tejada OntónPas encore d'évaluation

- Dow Corning Glazing MethodDocument32 pagesDow Corning Glazing Methody2kareinPas encore d'évaluation

- Silicone Structural Glazing ManualDocument52 pagesSilicone Structural Glazing ManualSean Couzyn100% (1)

- Structural Silicone Glazing Manual: Tremco Sealant SolutionsDocument0 pageStructural Silicone Glazing Manual: Tremco Sealant SolutionsPrantik Adhar SamantaPas encore d'évaluation

- Previews-ANSI Z97!1!2009 PreDocument12 pagesPreviews-ANSI Z97!1!2009 PreMetzy Nieto SanchezPas encore d'évaluation

- Structural Use of Adhesives in Glass SheetsDocument3 pagesStructural Use of Adhesives in Glass SheetsPaloma ValePas encore d'évaluation

- Aama 204-98Document7 pagesAama 204-98DavidPas encore d'évaluation

- SJ Mepla Version 40 f88f9Document4 pagesSJ Mepla Version 40 f88f9wal1547Pas encore d'évaluation

- X6Daf: Extruded Aluminum LouverDocument2 pagesX6Daf: Extruded Aluminum LouverAlaaBadwyPas encore d'évaluation

- European Building CodeDocument2 pagesEuropean Building CodeArdrick BoscoPas encore d'évaluation

- SJ MEPLA Calculation Protocol:: Basic Form: QuadrangleDocument5 pagesSJ MEPLA Calculation Protocol:: Basic Form: Quadranglewaweng22Pas encore d'évaluation

- Jotun India Private Limited Chennai Office Surat Office:: ND NDDocument4 pagesJotun India Private Limited Chennai Office Surat Office:: ND NDy2kareinPas encore d'évaluation

- Sustainable and High Performance FacadesDocument56 pagesSustainable and High Performance Facadesy2kareinPas encore d'évaluation

- Compression Seal TechnologyDocument75 pagesCompression Seal Technologyy2kareinPas encore d'évaluation

- Astm C1376-2003Document3 pagesAstm C1376-2003y2kareinPas encore d'évaluation

- High-Performance Polycarbonate Security Solutions For FacadesDocument42 pagesHigh-Performance Polycarbonate Security Solutions For Facadesy2kareinPas encore d'évaluation

- Engineering Design Basis - CivilDocument10 pagesEngineering Design Basis - Civily2kareinPas encore d'évaluation

- Importance of Facade TestingDocument10 pagesImportance of Facade Testingy2kareinPas encore d'évaluation

- Air Water Structural Field TestingDocument2 pagesAir Water Structural Field Testingy2kareinPas encore d'évaluation

- Ecological PlanningDocument12 pagesEcological Planningy2kareinPas encore d'évaluation

- Code of Conduct For IGBC Third Party AssessorsDocument1 pageCode of Conduct For IGBC Third Party Assessorsy2kareinPas encore d'évaluation

- Boil Test 3 Ply GlassDocument6 pagesBoil Test 3 Ply Glassy2kareinPas encore d'évaluation

- Astm / Aama Water TestingDocument3 pagesAstm / Aama Water Testingy2kareinPas encore d'évaluation

- Aluminium Fire StructuresDocument38 pagesAluminium Fire Structuresy2kareinPas encore d'évaluation

- LexUriServ DoDocument79 pagesLexUriServ Doy2kareinPas encore d'évaluation

- Thermal Performance Impacts of Center-of-Glass Deflections in Installed Insulating Glazing UnitsDocument21 pagesThermal Performance Impacts of Center-of-Glass Deflections in Installed Insulating Glazing Unitsy2kareinPas encore d'évaluation

- High Pressure Laminate (HPL) Installation InstructionDocument17 pagesHigh Pressure Laminate (HPL) Installation Instructiony2karein100% (1)

- Building Construction: Report OnDocument15 pagesBuilding Construction: Report Ony2kareinPas encore d'évaluation

- Referral Letter - ObesityDocument6 pagesReferral Letter - Obesityy2karein67% (3)

- Cradle Restraint SystemsDocument1 pageCradle Restraint Systemsy2kareinPas encore d'évaluation

- Paint and Coating Testing Manual (MNL 17) (14th Ed. of The Gardner-Sward HBK.) - J. Koleske (ASTM, 1995) WWDocument920 pagesPaint and Coating Testing Manual (MNL 17) (14th Ed. of The Gardner-Sward HBK.) - J. Koleske (ASTM, 1995) WWkmoor90% (20)

- Techbro Wa LRDocument44 pagesTechbro Wa LRy2kareinPas encore d'évaluation

- Fall 2015Document44 pagesFall 2015y2kareinPas encore d'évaluation

- Convert PDFDocument4 pagesConvert PDFy2kareinPas encore d'évaluation

- (DBBV) Reference ListDocument13 pages(DBBV) Reference ListCassy AbulenciaPas encore d'évaluation

- Stegbar AluminiumDocument28 pagesStegbar Aluminiummike_ole02Pas encore d'évaluation

- (P&id1) PDFDocument1 page(P&id1) PDFHatem FaroukPas encore d'évaluation

- Oil & Gas Industry in Saudi ArabiaDocument19 pagesOil & Gas Industry in Saudi ArabiaSuleiman BaruniPas encore d'évaluation

- References BI - Storage Tanks and SpheresDocument1 pageReferences BI - Storage Tanks and SpheresAmine Ben salemPas encore d'évaluation

- BS 7159 (1989) Design and Construction of Glass Reinforced Plastics (GRP) Piping Systems For Individual Plants or SitesDocument90 pagesBS 7159 (1989) Design and Construction of Glass Reinforced Plastics (GRP) Piping Systems For Individual Plants or SitesGregory Simmon100% (13)

- LSFO Calculator: 2.5 FO System Capacity (Liters) 500 Date Time Position FO Consumption (M /HR)Document8 pagesLSFO Calculator: 2.5 FO System Capacity (Liters) 500 Date Time Position FO Consumption (M /HR)dharmawanPas encore d'évaluation

- Pit Volume CalculatorDocument24 pagesPit Volume CalculatorHunterPas encore d'évaluation

- Lease Line Well AgreementsDocument3 pagesLease Line Well AgreementsAhmed Mohammed ShaabanPas encore d'évaluation

- Schedule of Doors and Windows: Engr. Joel Dalumpines Two-Storey Residential Building Jesus A. Calsado JRDocument1 pageSchedule of Doors and Windows: Engr. Joel Dalumpines Two-Storey Residential Building Jesus A. Calsado JRjoanPas encore d'évaluation

- Glassware: Dazzle Your Customers With IMAX's Rich Selection of Glassware Sure To Complement Any Product GroupingDocument24 pagesGlassware: Dazzle Your Customers With IMAX's Rich Selection of Glassware Sure To Complement Any Product GroupingnjlaportePas encore d'évaluation

- Paj-7e 201906Document2 pagesPaj-7e 201906Anum AkramPas encore d'évaluation

- EscravosDocument2 pagesEscravosJorge Rodriguez HerreraPas encore d'évaluation

- Malaysian Oil and Gas StatisticDocument1 pageMalaysian Oil and Gas StatisticAnonymous 6ZljVVvETPas encore d'évaluation

- CPCL Project ReportDocument15 pagesCPCL Project ReportSivathangavelu MuruganPas encore d'évaluation

- Simulation Diagram of Simple RefineryDocument1 pageSimulation Diagram of Simple RefineryTouhidBinAnwarPas encore d'évaluation

- Paraffin CairDocument1 pageParaffin CairInkPas encore d'évaluation

- GLASSDocument8 pagesGLASSNowella MendozaPas encore d'évaluation

- Economics CcacaatutorialDocument16 pagesEconomics CcacaatutorialMohd ZulhafiziPas encore d'évaluation

- Astm E1300 16Document14 pagesAstm E1300 16AmulyaRajbharPas encore d'évaluation

- The History of Oil and Gas in Malaysia Starts From The Beginning of 20th CenturyDocument2 pagesThe History of Oil and Gas in Malaysia Starts From The Beginning of 20th CenturyAnonymous fMCxYHuPK2Pas encore d'évaluation

- Subject: Petroleum Refining Technology Code: CHCE 3010 Faculty: Dr. Seim TimungDocument19 pagesSubject: Petroleum Refining Technology Code: CHCE 3010 Faculty: Dr. Seim Timungprathamesh singhPas encore d'évaluation

- Wip 17Document18 pagesWip 17Ankit BinjolaPas encore d'évaluation

- Petroleum Potential of Onshore Timor Leste (2016)Document9 pagesPetroleum Potential of Onshore Timor Leste (2016)Luiz EduardoPas encore d'évaluation

- Asia Offshore PlatformDocument1 pageAsia Offshore PlatformPand AemonaEon100% (3)

- Api RP 520 PT IDocument76 pagesApi RP 520 PT IĮňyįd KānPas encore d'évaluation

- 2023 Refining 101Document45 pages2023 Refining 101ebook ebookPas encore d'évaluation

- Benchmarking Study: Comparison of Performance in The E&P Upstream BusinessDocument17 pagesBenchmarking Study: Comparison of Performance in The E&P Upstream BusinessDeepesh PathakPas encore d'évaluation

- كنوز النفط والحدود السياسيةDocument73 pagesكنوز النفط والحدود السياسيةFadhlPas encore d'évaluation

- 2012 - Global - Data - Oil and Gas Exploration and Production (E&P) in ColombiaDocument64 pages2012 - Global - Data - Oil and Gas Exploration and Production (E&P) in Colombiamanueljaimes13Pas encore d'évaluation