Académique Documents

Professionnel Documents

Culture Documents

Investment Casting

Transféré par

Aravind PhoenixCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Investment Casting

Transféré par

Aravind PhoenixDroits d'auteur :

Formats disponibles

Investment casting produces very high surface quality and dimensional accuracy.

Investment casting is commonly used for precision equipment such as surgical equ

ipment,

for complex geometries and for precious metals.

This process is commonly used by artisans to produce highly detailed artwork.

The first step is to produce a pattern or replica of the finished mould. Wax is

most

commonly used to form the pattern, although plastic is also used.

Patterns are typically mass-produced by injecting liquid or semi-liquid wax into

a

permanent die.

Prototypes, small production runs and specialty projects can also be undertaken

by carving

wax models.

Cores are typically unnecessary but can be used for complex internal structures.

Rapid

prototyping techniques have been developed to produce expendable patterns.

Several replicas are often attached to a gating system constructed of the same m

aterial to

form a tree assembly. In this way multiple castings can be produced in a single

pouring.

Advantages

Parts of great complexity and intricacy can be cast

Close dimensional control and good surface finish

Wax can usually be recovered for reuse

Additional machining is not normally required - this is a net shape process

Disadvantages

Many processing steps are required

Relatively expensive process

Vous aimerez peut-être aussi

- Ce 2 Marks UpdatedDocument10 pagesCe 2 Marks UpdatedAravind PhoenixPas encore d'évaluation

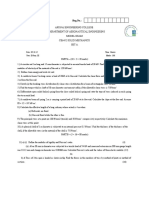

- Answer ALL Questions PART A - (10 X 2 10 Marks)Document1 pageAnswer ALL Questions PART A - (10 X 2 10 Marks)Aravind PhoenixPas encore d'évaluation

- Career Air Force-India (Candidate Section)Document1 pageCareer Air Force-India (Candidate Section)Aravind PhoenixPas encore d'évaluation

- AE6505 CE Nov Dec 2016 IMP QuestionDocument2 pagesAE6505 CE Nov Dec 2016 IMP QuestionAravind PhoenixPas encore d'évaluation

- Mon Slow Learners TTDocument2 pagesMon Slow Learners TTAravind PhoenixPas encore d'évaluation

- What Is The Load Factor? Explain The V-N Diagram in Detail With Neat Sketch. ADocument2 pagesWhat Is The Load Factor? Explain The V-N Diagram in Detail With Neat Sketch. AAravind PhoenixPas encore d'évaluation

- Tracking TipsDocument8 pagesTracking TipsAravind PhoenixPas encore d'évaluation

- SM Model Exam QuestionDocument5 pagesSM Model Exam QuestionAravind PhoenixPas encore d'évaluation

- Experimental Stress Analysis - AN 010 702Document2 pagesExperimental Stress Analysis - AN 010 702Aravind PhoenixPas encore d'évaluation

- GE2022 2 Marks PDFDocument23 pagesGE2022 2 Marks PDFsudharsonkumarPas encore d'évaluation

- Answer TQMDocument18 pagesAnswer TQMAravind PhoenixPas encore d'évaluation

- 16 MarksDocument3 pages16 MarksAravind PhoenixPas encore d'évaluation

- Oct Nov Dec 16 and Jan 17 NotificationDocument1 pageOct Nov Dec 16 and Jan 17 NotificationAravind PhoenixPas encore d'évaluation

- Quantitative AptitudeDocument2 pagesQuantitative AptitudeSivakumar MPas encore d'évaluation

- Had May2016Document3 pagesHad May2016Aravind PhoenixPas encore d'évaluation

- Review of Aircraft Design Project-1: Ex No: 1 DateDocument2 pagesReview of Aircraft Design Project-1: Ex No: 1 DateAravind PhoenixPas encore d'évaluation

- Forward Flight PerformanceDocument3 pagesForward Flight PerformanceAravind PhoenixPas encore d'évaluation

- Aircraft Structures I Nov 2015Document4 pagesAircraft Structures I Nov 2015Aravind PhoenixPas encore d'évaluation

- AD 2 Nov 2015Document3 pagesAD 2 Nov 2015Aravind PhoenixPas encore d'évaluation

- Assignment 1Document1 pageAssignment 1Aravind PhoenixPas encore d'évaluation

- BondedDocument1 pageBondedAravind PhoenixPas encore d'évaluation

- Testing Week 2 - August 2016Document4 pagesTesting Week 2 - August 2016Aravind PhoenixPas encore d'évaluation

- Docslide - Us - Direct Voice InputDocument29 pagesDocslide - Us - Direct Voice InputAravind PhoenixPas encore d'évaluation

- Title of The Project: Guide and Student DetailsDocument13 pagesTitle of The Project: Guide and Student DetailsAravind PhoenixPas encore d'évaluation

- Retest Time Table For Unit Test-IDocument4 pagesRetest Time Table For Unit Test-IAravind PhoenixPas encore d'évaluation

- INSTRUCCIONES V7.3 2017s English SpanishDocument15 pagesINSTRUCCIONES V7.3 2017s English Spanishjfernand81Pas encore d'évaluation

- Rajalakshmi Institutions - Eligible Database For Vulcan Tech - 2017 BatchDocument8 pagesRajalakshmi Institutions - Eligible Database For Vulcan Tech - 2017 BatchAravind PhoenixPas encore d'évaluation

- REC - TCS Technical Training - Aero, Auto, Civil, Mech, BME, BT & PG - 2017 Batch As On 9.8.2016Document36 pagesREC - TCS Technical Training - Aero, Auto, Civil, Mech, BME, BT & PG - 2017 Batch As On 9.8.2016Aravind PhoenixPas encore d'évaluation

- Zoho - Second Round PDFDocument28 pagesZoho - Second Round PDFAravind PhoenixPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)