Académique Documents

Professionnel Documents

Culture Documents

United States: (12) Patent Application Publication (10) Pub. No.: US 2013/0301320 A1

Transféré par

jarmeeDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

United States: (12) Patent Application Publication (10) Pub. No.: US 2013/0301320 A1

Transféré par

jarmeeDroits d'auteur :

Formats disponibles

US 20130301320Al

(19) United States

(12) Patent Application Publication (10) Pub. No.: US 2013/0301320 A1

(43) Pub. Date:

Mariadassou et al.

(54)

COMPACT HIGH-POWER

DIODE/THYRISTOR RECTIFIER

ARCHITECTURE

Publication Classi?cation

(51)

(75) Inventors: Prithu Mariadassou, Paris (FR); Joel

Int. Cl.

H02M 7/08

(52) US. Cl.

USPC

(73) Assignee: Alstom Technology Ltd., Baden (CH)

PCT Filed:

Nov. 7, 2011

(86)

PCT No.:

PCT/EP2011/069557

371 (0X1)

(2), (4) Date:

Jul. 22, 2013

(30)

(FR) ..................................... ..

(57)

363/70

ABSTRACT

DC terminal includes multiple unidirectional electronic com

ponents connected in parallel and connected on one side to the

DC terminal by means of a conductive component set and on

the other side to the AC terminal. The invention is character

iZed in that the component set for at least one recti?er arm

includes a plurality of separate component busbars each hav

ing at least one end connected to the DC terminal, the unidi

rectional components being divided between the component

Foreign Application Priority Data

Nov. 10, 2010

.......................................................... ..

A GratZ-bridge converter-recti?er in Which at least one rec

ti?er arm situated between a single AC terminal and a single

13/884,545

(22)

(2006.01)

CPC ..................................... .. H02M 7/08 (2013.01)

Devautour, Le Pecq (FR)

(21) Appl. No.:

NOV. 14, 2013

1059313

busbars into as many component sets connected in parallel as

there are component busbars.

'|

AC

7

10

Patent Application Publication

Nov. 14, 2013 Sheet 1 0f 6

US 2013/0301320 A1

cg

Q

i

gzg

DC+

FIG. 1

U2+

U2

Patent Application Publication

Nov. 14, 2013 Sheet 2 0f 6

US 2013/0301320 A1

ImaxI

Imoy'

Imin I

V

(1%

60,0.

50,0.

40,0.

30,0.

20,0.

10,0.

0,0

1'2 I 3 I 4 I 5 I 6 I 7 I 8 I 9 '10'11'12'13'14'15'16'17'18'19'20' >0

FIG. 4

Patent Application Publication

Nov. 14, 2013 Sheet 3 0f 6

U2

V2+ V2 V2 W2

US 2013/0301320 A1

FIG.5

Patent Application Publication

P . //

Nov. 14, 2013 Sheet 4 0f 6

#gjAc

E

7

S

\9 9

rv5

10

US 2013/0301320 A1

Patent Application Publication

Nov. 14, 2013 Sheet 5 0f 6

US 2013/0301320 A1

AC

FIG. 98

3 I F|G.1OA

_

11B

Patent Application Publication

Nov. 14, 2013 Sheet 6 0f 6

US 2013/0301320 A1

1,

DC

5

7/\

11A\

TDC

Q

9A-KH:| ma

Q

lAC

[9 ? ?

115

m cu

m EH>|

m 42%

FIG. 11

Nov. 14, 2013

US 2013/0301320 A1

[0001]

COMPACT HIGH-POWER

DIODE/THYRISTOR RECTIFIER

ARCHITECTURE

[0012] The tWo three-phase GraeZ bridges are connected at

tWo common DC terminals, namely a positive DC terminal

DC+ and a negative DC terminal DC. These DC terminals

make it possible to deliver a DC current and voltage to the

TECHNICAL FIELD

plant to be supplied With poWer.

[0013] Each GraeZ bridge (R1, R2) includes six arms called

recti?er arms U1+, U1, V1+, V1, W1+, W1, U2+, U2,

V2+, V2, W2+, W2 arranged to connect each phase U1,

The present invention relates to the ?eld of high

current and/ or high- or medium-voltage power recti?ers.

[0002] This ?eld covers recti?ers able to deliver direct cur

rents up to 110 kiloamps (kA) and direct current (DC) volt

ages that may exceed 2200 volts (V).

[0003] The invention relates to the architecture of high

poWer (100 megavoltamp (MVA)) recti?ers used for feeding

V1, W1 and U2, V2, W2 to each of the tWo DC terminals

(DC+, DC). Accordingly, each recti?er arm of a GraeZ

bridge is connected betWeen an AC terminal and a DC termi

nal.

[0014] Eachrecti?erarmU1+, U1,V1+,V1, W1+, W1,

direct current to electro-intensive processes requiring high

poWer DC poWer supplies. Thus the invention may be used to

supply poWer to aluminum or non-ferrous metal (copper,

U2+, U2, V2+, V2, W2+, W2 is itselfformed by connect

ing in parallel n unidirectional electronic components 5, for

Zinc, chlorine) electrolysis plants. The invention may also be

components are so called because they alloW current to pass

used to supply poWer to other electro-intensive processes

requiring high-poWer DC poWer supplies such as direct cur

in only one direction and block current in the opposite direc

tion. BeloW the expression unidirectional component 5

rent arc fumaces.

refers interchangeably to a diode, a thyristor or some other

[0004] In the description beloW the use of such recti?ers for

supplying poWer to an electrolysis plant is used as one par

unidirectional electronic component.

[0015] The aim of this parallel connection of components is

ticular example.

example diodes or thyristors. The unidirectional electronic

to obtain an element functioning as a diode Whilst having a

suf?ciently high rating to rectify the poWer passing through

DESCRIPTION OF THE PRIOR ART

[0005] An electrical poWer supply for an electrolysis plant

consists of a plurality of poWer supply sources, usually called

groups, connected in parallel. FIG. 1 shoWs the theory of

operation of a poWer supply group. This poWer supply group

consists primarily of:

[0006]

a regulating transformer 1 for adjusting a grid volt

age to an intermediate voltage;

[0007] a transformer called a recti?er transformer 2 for

adjusting the intermediate voltage to an appropriate off-load

voltage depending on the value of the load voltage induced by

the plant to be supplied With poWer and for delivering the high

currents necessary for the electrolysis process;

[0008]

a recti?er 3 using semiconductor components (di

odes or thyristors) for delivering a recti?ed DC current and

voltage to the load; and

[0009]

a set of poWer busbars 4 for connecting the poWer

supply groups in parallel.

[0010] FIG. 2 shoWs one example of a tWelve-phase double

GratZ-bridge diode recti?er 3. This recti?er converter com

bines tWo GratZ-bridge structures R1 and R2, each con

nected to a transformer among a ?rst three-phase transformer

T1 and a second three-phase transformer T2. Each three

the recti?er 3. The n unidirectional components 5 are conven

tionally electrically connected on one side to the same con

ductive structure, called a component busbar 6, Which makes

it possible to transmit current betWeen the unidirectional

components 5 and the DC terminal.

[0016] Each unidirectional component 5 is preferably con

nected on the other side in series With a fuse resistor, called a

fuse 7. The fuses are used to break a fault current ?oWing in a

faulty unidirectional component 5, thereby protecting the

recti?er arm. Such a faulty unidirectional component passes

current in the opposite direction to that normally alloWed by

the unidirectional component 5. This Would limit the bene?t

of the recti?er arm. If only one unidirectional component is

faulty a current ?oWs in the opposite direction in said faulty

unidirectional component and in the fuse adjoining it at a

poWer corresponding to the full poWer of the transformer.

This poWer destroys the fuse 7, Which breaks the electrical

connection via the faulty unidirectional component 5. This

breaks the current ?oWing in the opposite direction. The

faulty unidirectional component 5 is taken out of circuit and,

even though a fault has occurred, a functional recti?er arm is

obtained having one feWer unidirectional component 5.

[0017] To increase the poWer circulating in the recti?er 3 it

is necessary to increase the voltage or the current.

phase transformer T1, T2 has three phases, namely phases

[0018]

U1, V1, W1 for the ?rst three-phase transformer T1 and U2,

V2, W2 for the second three-phase transformer T2. Each

three-phase transformer feeds a three-phase GraeZ bridge.

Each three-phase GraeZ bridge functions as a single-phase

GraeZ bridge having three terminals fed With alternating cur

cally to 2200 volts DC (Vdc) it is necessary to use diodes or

thyristors 5 able to Withstand a high reverse voltage. HoW

ever, current electronic component technology does not make

rent, called AC terminals, and tWo terminals delivering a

direct current. A three-phase GraeZ bridge makes it possible

to produce a current having a period of one-sixth of an initial

period of the three-phase transformer. Each phase U1, V1,

W1 and U2, V2, W2 is connected to the GraeZ bridge by one

of the above-mentioned AC terminals. For simplicity the AC

terminals and the phases have the same references.

[0011] In FIG. 1, to simplify the diagram, the tWo AC

If the value of the recti?ed voltage is increased (typi

it possible to produce high-current diodes or thyristors 5. As

described above, it is necessary to use multiple unidirectional

components 5 connected in parallel. To increase the recti?ed

current, it is also necessary to increase the number of unidi

rectional components 5 connected in parallel. Thus for a 100

kA 2200 Vdc recti?er it is necessary to connect between 18

and 20 diodes or thyristors in parallel in each recti?er arm,

depending on the type of electronic component used and the

operating conditions.

[0019]

Moreover, it is very dif?cult to obtain fuses 7 With a

terminals of the same phase are represented as connected

very high current rating if the recti?ed voltage is increased.

together.

This limits the current that may How in each fuse 7. It is then

Nov. 14, 2013

US 2013/0301320 A1

necessary to limit the current in each unidirectional compo

nent 5 and this leads to an increase in the number of [compo

nent +fuse] functional groups connected in parallel.

[0020]

Such parallel connection of the components gives

rise to problems of balancing the current betWeen the unidi

rectional components 5 of the same recti?er arm. FIG. 3 gives

an example of the current distribution for a typical recti?er

arm including n diodes.

[0021]

An order number assigned to each of the diodes in a

In the current state of the art there are various Ways to produce

this frame 8, the objective being to balance the distribution of

impedances betWeen the unidirectional components 5 and the

DC terminal. FIG. 5 shoWs the structure of a double GraeZ

bridge in Which each GraZ bridge recti?es three phases U1,

V1, W1 and U2, V2, W2 supplied With alternating current.

The double GraeZ bridge delivers a direct current at its output,

via tWo DC terminals DC+ and DC.

[0033] The unidirectional components 5 of a recti?er arm

recti?er arm starting from one end of a component busbar is

are connected on one side to a Water-cooled aluminum or

plotted on the abscissa axis. The current I carried by each

diode is plotted on the ordinate axis.

[0022] It is seen that one of the diodes is less loaded than the

copper conductive busbar 9 usually called a component bus

bar. The current I ?oWing in the recti?er arms is collected by

others and carries a current lmin and that at least one other

diode is more loaded than the others and carries a current

forming part of the above-mentioned frame 8 and perpendicu

one or more conductive busbars 10 called collector busbars

lmax. An average current lmoy is given by the total current in

lar to the component busbars 9. Each end of a component

busbar 9 is connected to a collector busbar 10. The collector

the recti?er arm divided by the number n of unidirectional

busbars 10 then form tWo opposite sides of the frame 8 and

components 5 in parallel.

connect the component busbars 9 to a DC terminal (DC+ or

[0023] It can be seen that the end diodes, located at the ends

of the component busbars, are the most current loaded. It can

DC) of the recti?er.

be explained by the geometry of the circuit but also by the

distribution of the magnetic ?eld, as explained beloW in ref

unidirectional component 5, the unidirectional component 5

being in series betWeen the fuse resistor 7 and the collector

erence to FIG. 7.

busbar 10. The fuse resistors 7 are carried by a conductive

busbar, called a fuse busbar 11, in copper or aluminum, Water

cooled. There is one fuse busbar 11 for each recti?er arm. The

fuse busbar 11 connects the unidirectional components 5 via

the fuse resistors 7 to a corresponding AC terminal of the

recti?er. A unidirectional component 5 and the associated

fuse resistor 7 form a functional group.

[0024] An imbalance (disequilibrium) percentage d % is

de?ned by the folloWing formula:

d %:Max (Imax/Imoy-l l lImin/Imoy-l l).

[0025]

Because of this imbalance betWeen the least loaded

and most loaded diodes of the recti?er arm, it is necessary to

[0034]

A fuse resistor 7 is connected to one side of each

rate all the components of a recti?er arm to Withstand a

[0035]

current lmax even though feW components really need to

W1, U2, V2, W2, a current passing through a recti?er arm G

carry such currents.

therefore passes through:

[0026]

[0036]

[0037]

FIG. 4 gives a feW typical values of imbalance d %

obtained in existing structures as a function of the number n of

diodes present on the component busbar of the recti?er arm.

The value of d % depends primarily on the mechanical struc

ture of the recti?er.

[0027] It is seen that the value of imbalance d % increases

very rapidly With the number n of components in parallel.

This induces very high variations of current from one diode to

another.

[0028] To rectify a high poWer, it is necessary to add uni

directional components 5 in parallel. This increases the

imbalance. Consequently, the average current lmoy passing

through the unidirectional component 5 decreases. It

becomes necessary to add further unidirectional components

5 in parallel in order to compensate the reduced value of lmoy,

Which further accentuates the imbalance.

[0029]

Finally, beyond a certain current value, existing rec

Accordingly, starting from an AC terminal U1, V1,

a conductive cable 12;

a fuse busbar 11 (the current in Which is divided

betWeen the functional groups);

[0038] a fuse 7;

[0039] a unidirectional component (diode or thyristor) 5 in

series With the fuse 7;

[0040] a component busbar 9 (in Which the currents from

the different functional groups are combined).

[0041] The current then leaves the recti?er arm and reaches

the collector busbars 10 of the frame 8 and is combined With

current from the other phases (U1, V1, W1, U2, V2, W2)

before joining a DC terminal to Which the frame 8 is con

nected.

[0042] The component busbars 9 and the fuse busbars 11

have a plurality of faces. The unidirectional components 5

and the fuses 7 are generally connected to tWo opposite faces

of the component busbars 9 and the fuse busbars 11 (see FIG.

ti?er structures have a number n of unidirectional compo

6). FIG. 6 is a perspective diagram illustrating this principle.

nents 5 to be connected in parallel that leads to a prohibitive

imbalance.

There are seen therein a fuse busbar 11 connected by one end

[0030]

Users of this type of recti?er 3 frequently impose a

maximum value of imbalance d % that is not to be exceeded

in the recti?ers. This imbalance criterion is an equipment

acceptance criterion.

[0031] To be able to propose equipment capable of deliv

ering high poWers, it becomes necessary to create recti?er

to anAC terminal and a component busbar 9 connected by one

end to a collector busbar 10. Finally there are represented

multiple functional groups 60 each including a fuse 7 in series

With a unidirectional component 5. The functional groups 60

are not positioned directly betWeen the fuse busbar 1 1 and the

component busbar 9. Such a position Would clutter the space

betWeen the tWo busbars 9, 11.

architectures alloWing in each recti?er arm the parallel con

[0043]

nection of a large number n of diodes or thyristors at the same

are separated into tWo sets connected to the tWo busbars 9, 10

on the tWo sides of a plane P passing through the tWo busbars.

time as there being a limited imbalance, typically 30%.

[0032]

In prior art parallel connections the unidirectional

To declutter the structure, the functional groups 60

components 5 of a recti?er arm are generally connected to the

[0044] At present there are commercially available recti?

ers including up to 14 diodes or thyristors in parallel in each

DC terminal via an aluminum or copper frame 8 (see FIG. 5).

recti?er arm.

Nov. 14, 2013

US 2013/0301320 A1

It is also known from the prior art to provide at least

imbalance associated With n unidirectional components.

one intermediate busbar 13 known as the commutation busbar

[0045]

Each component set may thus be balanced independently of

the advantages of Which are described as allowing better

equilibrium in the ABB document 100 kA conversion units

the other component sets. It is then necessary to obtain an

overall balance betWeen the tWo sets of components.

for highly ef?cient aluminum smelters, reprint from Alumi

[0055]

num 2004/3, p 4. The intermediate busbar 13 is positioned at

the level of the frame 8 connected to the DC terminal. It

the recti?er arm With tWo component busbars compared to a

connects tWo collector busbars each situated at one end of a

component busbar. The intermediate busbar is situated

betWeen tWo component busbars and thus added to conduc

tive busbars that are situated at the ends of the collector

busbars.

[0046] The author of the above document indicates a value

of imbalance d % greater than 22% for a number n of diodes

or thyristors equal to 14.

[0047] The above prior art structures are unsatisfactory

because it is hardly possible to go beyond 16 or 18 compo

nents in parallel Without the imbalance becoming prohibitive.

[0048] It is therefore clear that, to enable conversion of

currents or voltages at high poWers, it is important to be able

to increase the number of functional groups in parallel. HoW

ever, by the same token, it is important to limit the magnitude

of the imbalance.

SUMMARY OF THE INVENTION

[0049]

Here the invention relates mainly to the architecture

Such an arrangement reduces the total imbalance of

prior art recti?er arm having 2n unidirectional components.

According to the invention, each component busbar includes

only n unidirectional components. The imbalance to be cor

rected for each component busbar is then of the order of the

imbalance associated With n unidirectional components

instead of the imbalance associated With 2n unidirectional

components. It is clear that if there are more than tWo com

ponent busbars the imbalance in each component busbar is

reduced commensurately compared to a prior art construc

tion.

[0056] In the situation of the parallel connection of a larger

number of components, for example 20 components, to tWo

component busbars, the invention makes it possible to reduce

the imbalance by a factor close to 2.

[0057]

Simulations that have been carried out yielded the

folloWing results:

[0058]

[0059]

[0060]

prior art With n:20: 50% imbalance;

invention With n:20: 20 to 25% imbalance.

A converter-recti?er of the invention performs bet

ter than a prior art converter-recti?er because replacing a

of the recti?er and aims to make it possible to connect a large

single component busbar by a plurality of component busbars

number of components in parallel Without exceeding the

maximum imbalance value imposed by users. The invention

introduces an additional degree of maneuver for balancing.

typically aims to connect in parallel 20, 24 or more compo

nents With a maximum imbalance betWeen 20% and 30%.

[0050] The invention proposes to create for each phase at

least tWo sets of functional groups in parallel. From a

By creating for each phase of the recti?er transformer a num

ber k of sets of n/k unidirectional components in parallel, With

k at least equal to 2, the balancing problem is reduced from

balancing the n components of each phase With one another,

to balancing ?rstly each of the k sets of n/k components

mechanical point of vieW, this consists in duplicating each

independently of the others, and to balancing secondly the k

component busbar and each fuse busbar so that there are at

least tWo component busbars and tWo fuse busbars connected

sets With one other.

in parallel.

[0051] The objective of the proposed neW architecture is to

address the problem of increasing the poWer to be delivered

by the recti?er.

[0052] Thus the invention provides a GraZ-bridge con

verter-recti?er including terminals fed With alternating cur

rent, called AC terminals, and tWo terminals adapted to feed

an exterior circuit With direct current, called DC terminals,

and recti?er arms connecting each AC terminal to each DC

terminal. Each recti?er arm is situated betWeen a single AC

terminal and a single DC terminal and includes multiple

unidirectional electronic components, called unidirectional

components, connected in parallel. The unidirectional com

ponents are connected on one side to the DC terminal by

means of a conductive set, called a conductive set, and on the

other side to the AC terminal.

[0053]

The invention is characterized in that the component

set for at least one recti?er arm includes a plurality of con

ductive busbars, called component busbars, each having at

least one end connected to the DC terminal. The unidirec

tional components are connected to the component busbars

and divided betWeen them into as many component sets con

nected in parallel as there are component busbars. It is there

fore clear that there are at least tWo component busbars for

each recti?er arm.

[0054] Thus according to the invention the imbalance is

con?ned to each component group.A recti?er of the invention

thus includes at least tWo sets of components each having an

[0061] A converter-recti?er of the invention is moreover

much more compact in terms of volume than current prior art

solutions and this is because the component busbar and the

fuse busbar have a length divided by 2, 3 or 4 or more com

pared to the prior art.

[0062] Thus the invention makes it possible to rectify

greater poWers than in the prior art Without thereby introduc

ing too much imbalance.

[0063]

The invention also relates to a recti?er arm Wherein

the connection betWeen the unidirectional components and

the AC terminal is effected by a fuse set. The fuse set includes

a fuse resistor, called a fuse, for each unidirectional compo

nent connected on one side in series With said unidirectional

component and on the other side to at least one fuse busbar

connected to the AC terminal. In other Words, the fuse set

includes at least one fuse busbar and fuse resistors adapted to

behave as fuses. The fuses are connected in parallel With each

other so that each unidirectional component is in series With

a fuse speci?c to it, forming a functional group. The func

tional groups are in parallel With each other in the same Way

that the unidirectional components are in parallel With each

other.

[0064] According to the invention, the recti?er arm

includes a plurality of separate component busbars. There

may be tWo, three, four or more component busbars, for

example, and the more separate component busbars there are,

the greater the number of unidirectional components that may

be grouped in parallel Whilst retaining a loW imbalance for

each component busbar. The additional dif?culty of having to

Nov. 14, 2013

US 2013/0301320 A1

BRIEF DESCRIPTION OF THE DRAWINGS

balance the component busbars With each other must never

theless be taken into account. The components assigned to the

same component busbar are preferably connected to the same

fuse busbar.

[0065] A recti?er arm of the invention may be such that the

fuse set includes at least one fuse busbar for each component

busbar. Each fuse busbar is electrically connected to the com

ponents assigned to a single component busbar. The fuse

busbars are connected together by a conductive busbar called

a distribution busbar. This makes it possible to have a better

resistance distribution betWeen the functional groups of a

recti?er arm.

[0066]

The unidirectional components of each component

busbar are advantageously divided into tWo groups each posi

tioned on an opposite side of the component busbar. As in the

[0074]

The invention can be more clearly understood and

other details, advantages and features of the invention

become apparent on reading the folloWing description given

by Way of non-limiting example and With reference to the

appended draWings, in Which:

[0075] FIG. 1 (prior art) is a simpli?ed electrical circuit

diagram of a plant DC poWer supply architecture;

[0076]

FIG. 2 (prior art) is an electrical circuit diagram of a

GraZ-bridge recti?er including at the input three phases fed

With alternating current;

[0077] FIG. 3 (prior art) is a graph representing the current

passing through a component as a function of its position on

a component busbar;

[0078]

FIG. 4 (prior art) is a graph illustrating the evolution

prior art, this arrangement makes it possible to reduce the

structural differences betWeen the unidirectional components

of the imbalance betWeen the components as a function of the

number of components present on the same component bus

and to reduce the imbalance.

bar;

[0067] A GraZ-bridge converter-recti?er that includes a

collector busbar preferably connects the DC terminal to sepa

rate component busbars connected to a plurality of AC termi

nals. In other Words, the collector busbar of a DC terminal

[0079] FIG. 5 (prior art) shoWs a GraeZ-bridge recti?er

representing in simpli?ed form the structure of the recti?er

connects the DC terminal to the recti?er arms coming from

arms at the level of the component busbars and the fuse

busbars;

the various AC terminals. The collector busbar is preferably

[0080] FIG. 6 is a perspective vieW of an arrangement of

functional groups relative to a component busbar, a fuse bus

?xed to one end of the component busbars.

bar, and a collector busbar;

[0068]

[0081] FIG. 7 shoWs in a simpli?ed manner the structure of

the recti?er arms at the level of the component busbars and the

There may be a plurality of collector busbars each

connected to one end of at least one component busbar and

assembled together to form a frame connected to the DC

terminal. This makes it possible to transport the current

betWeen the unidirectional components and the DC terminal

fuse busbars and the arrangement of the component busbars

relative to the collector busbars in a ?rst embodiment of the

invention;

more e?iciently. There are more conduction paths betWeen

[0082]

the DC terminal and each unidirectional component.

[0069] In one embodiment of the invention, the separate

busbar;

component busbars are situated on the same side of the col

ture of the recti?er arms at the level of the component busbars

lector busbar.

[0070] Conversely, the component busbars are situated on

and the fuse busbars according to another embodiment of the

[0083]

FIG. 8 is a variant of FIG. 7 With only one collector

FIGS. 9A and 9B shoW in simpli?ed form, the struc

invention;

either side of a collector busbar called a central collector

[0084]

busbar, they are connected by one end to said collector bus

structure of the recti?er arms at the level of the component

bar. In this case, tWo component busbars are shifted With

respect to one another at their binding to the collector busbar.

[0071] Advantageously, the component busbars are electri

cally connected With each other, by one end, to the same

FIGS. 10A and 10B shoW in a simpli?ed form, the

busbars and the fuse busbars, according to the invention,

Wherein the component busbars are connected With each

other, via a connecting busbar ?xed to a collector busbar, the

collector busbar being spaced from the connecting busbar;

connecting busbar, said connecting busbar being connected to

[0085]

a collector busbar via a conductor. The conductor spaces the

in Which there are as many fuse busbars 11A, 11B as compo

collector busbar from the connecting busbar. To improve the

imbalance of the components, it is preferable that the conduc

tor is connected, substantially, in the middle of the connecting

busbar.

[0072] To improve the compactness of the converter-recti

?er, it is preferable that the component busbars are located

substantially in the same plane and that the conductor and the

nent busbars; and

[0086] FIG. 12 shoWs an embodiment of the invention

including more than tWo component busbars.

[0087] Identical, similar or equivalent parts of the various

?gures carry the same reference numbers to facilitate moving

collector busbar to Which it is connected are disposed sub

stantially in the same other plane, the tWo planes being sub

stantially perpendicular.

[0073]

When the invention relates to a multi-phase GraeZ

bridge converter-recti?er, each transformer is connected by

AC terminals to a GraeZ bridge speci?c to it. Moreover, the

GraeZ bridges of the various transformers each have a positive

DC terminal and a negative DC terminal connected to a circuit

to be fed With direct current, the GraeZ bridges have their

positive DC terminals commoned and their negative DC ter

minals commoned. If the transformers are three-phase trans

formers the GraeZ bridges are three-phase GraeZ bridges.

FIG. 11 shoWs a third embodiment of the invention

from one ?gure to another.

[0088] To simplify the ?gures the various parts represented

in the ?gures are not necessarily represented to a uniform

scale.

[0089]

The ?gures shoWing various embodiments of the

device of the invention are provided by Way of example and

are not limiting on the invention.

DETAILED DESCRIPTION OF PARTICULAR

EMBODIMENTS

[0090]

The invention relates ?rstly to a three-phase GraZ

bridge recti?er arm designed to be included in a converter

recti?er. The recti?er arm is described beloW as such or as if

included in the converter-recti?er. Generally speaking, FIGS.

Nov. 14, 2013

US 2013/0301320 A1

7 to 12, illustrating the invention, are diagrams of a single

[0098]

recti?er arm of the invention and not of the converter-recti?er

connected to the unidirectional components 5. Although only

as a Whole.

the fuses 7 on the right-hand side of the ?gure are represented

[0091]

as connected to the fuse busbar 11, it is to be understood that

all the fuses 7 are connected to the fuse busbar 11, and that this

As shown in FIG. 2, a three-phase GraZ-bridge

recti?er R1, R2 is formed of six recti?er arms connecting

each of tWo AC terminals of each of the three phases U1, V1,

W1 or U2, V2, W2 fed With alternating current to tWo DC

FIG. 7 shoWs the fuse busbar 11 and the fuses 7

applies to all subsequent ?gures.

[0099]

From an electrical point of vieW, the unidirectional

The three-phase GraeZ bridge therefore has a positive DC

terminal DC+, seen With a positive polarity by the electrical

circuit, and a negative DC terminal DC, seen With a negative

components 5 are arranged in the same Way relative to each

other as in the prior art. HoWever, from a structural point of

vieW, the unidirectional components 5 are not attached to a

single component busbar connected to one or more collector

terminals of an electrical circuit to be fed With direct current.

polarity by the electrical circuit. Each phase U1, V1, W1, U2,

busbars 10, 100 at its ends, but to at least tWo independent

V2, W2 includes tWo recti?er arms U1+, U1, V1+, V1,

component busbars 9A, 9B electrically connected by at least

W1+, W1, U2+, U2, V2+, V2, W2+, W2, G2 connecting

one of their ends to one or more collector busbars 10, 100.

anAC terminal of one phase and one of the tWo DC terminals.

[0100] In one embodiment, as shoWn in FIG. 7, the collec

tor busbars 10, 100 may form a frame 8 around the component

busbars 9A, 9B. The frame may have only three sides as in

FIGS. 7, 10, 12 or four sides as in FIG. 9B. The collector

busbars 10, 100 are ?xed to the tWo ends of each of the

component busbars 9A, 9B and are connected to each other.

[0092] Each recti?er arm U1+, U1,V1+,V1, W1+, W1,

U2+, U2, V2+, V2, W2+, W2 includes a set of electronic

components that alloW current to pass in only one direction.

These components are referred to as unidirectional compo

nents. The recti?er arms U1+, U1, V1+, V1, W1+, W1,

U2+, U2, V2+, V2, W2+, W2 are arranged so that their

conjugation produces a direct current at the DC terminals

from an alternating current fed to the AC terminals.

[0093] The set of unidirectional electronic components of a

recti?er arm includes in particular a given number n of diodes

or thyristors connected in parallel. In the remainder of the

description, the expression unidirectional component 5

refers interchangeably to a diode, a thyristor or some other

unidirectional electronic component.

[0094] To limit the imbalance that occurs When many uni

directional components 5 are connected in parallel to the

same component busbar 9, the invention proposes to use for

each recti?er arm U1+, U1, V1+, V1, W1+, W1, U2+,

U2, V2+, V2, W2+, W2 at least tWo component busbars

9A, 9B instead of only one (see FIG. 7). Distributing the

unidirectional components 5 betWeen tWo component bus

bars 9A, 9B instead of one, halves the number of unidirec

tional components 5 to be balanced for each component bus

bar 9A, 9B. It is then easy to balance the component busbars

9A, 9B With each other.

[0095] Each component busbar 9A, 9B may have one end

connected to a collector busbar 10 and the other end con

nected to another collector busbar 100, the tWo collector

busbars 10, 100 being connected to each other and to the same

DC terminal.

[0096]

According to the invention, each collector busbar

In a variant (FIG. 8), the component busbars 9A, 9B may be

positioned on the same side of a single collector busbar 10.

One end of each component busbar 9A, 9B is connected to a

collector busbar 10 and its other end may be free or connected

to a second collector busbar 100.

[0101] In the con?guration of FIG. 7, the current ?oWing

through the collector busbars 10, 100 have the same polarity,

thus the magnetic ?eld in the vicinity of the unidirectional

components 5 located at the ends of the component busbars

9A, 9B is more intense than the magnetic ?eld at the level of

the median unidirectional components 5. The extreme unidi

rectional components 5 are more current loaded than the

median unidirectional components 5.

[0102]

In another embodiment, the component busbars 9A,

9B may be situated on either side of a central collector busbar

101 (FIG. 9A). The tWo component busbars 9A, 9B are sepa

rate and offset relative to each other at their connection to the

central collector busbar. In some circumstances (FIG. 9B),

tWo component busbars 9A, 9B may be assembled With a

central collector busbar 101. The tWo component busbars 9A,

9B are thus in line With each other. Furthermore, additional

collector busbars 102, 103 are provided at the other extremi

ties of component busbars 9A, 9B, not ?xed at the central

collector busbar 101. Said additional collector busbars 102,

103 are then connected to the central collector busbar 101 so

as to form a frame 8 around the component busbars 9A, 9B.

ing at least tWo sets of components 71, 72. The tWo compo

This enables the component busbars 9A, 9B to evacuate all

the current transmitted from the unidirectional components

(diodes or thyristors) 5 via tWo ends instead of only one end,

the tWo ends of the component busbars 9A, 9B being con

nected to a collector busbar 101, 102, 103.

[0103] In a further embodiment, shoWn in FIGS. 10A and

10B, the component busbars 9A, 9B of the same recti?er arm

nent busbars 9A, 9B are themselves connected to one or more

may be connected together at one or both ends by a conduc

collector busbars 10, 100 so that the sets of components 71, 72

are connected in parallel With each other.

[0097] The collector busbars 10, 100 are generally common

tive busbar 80, 800 called a connecting busbar. The connect

ing busbars 80, 800 differ from the collector busbars in that

they are speci?c to only one recti?er arm. Moreover, they do

to the three recti?er arms of the same three-phase GraeZ

not pass a current from another phase or passing via an AC

terminal other than that to Which the recti?er arm is con

10, 100 is then connected to at least tWo component busbars

9A, 9B of said recti?er arm. In other Words, of the unidirec

tional components 5 connected in parallel in the same recti?er

arm some are connected to a given component busbar 9A and

others to another, separate component busbar 9B, thus form

bridge connecting the AC terminals of the same transformer

to the same DC terminal. They are also generally common to

the recti?er arms of various transformers, in the case of a

multitransforrner converter-recti?er, for example as shoWn in

FIG. 5 Which represents a tWelve-phase converter With tWo

three-phase GraeZ bridges connected in parallel.

nected, unlike the collector busbars 10, 100. The component

busbars 9A, 9B are separate.

[0104] The connecting busbars 80, 800 are each connected

by a single conductor 81, 82 to a single collector busbar 10,

100. If there are tWo connecting busbars 80, 800, they are

Nov. 14, 2013

US 2013/0301320 A1

connected to tWo different collector busbars 10, 100 that are

themselves connected to each other and to the DC terminal. In

unidirectional component, and said unidirectional compo

nent to the component busbar. This electrical connection

both cases, each collector busbar 10, 100 is spaced from the

connecting busbar 80, 800 to Which it is connected. This

space is due to the presence of the conductor 81, 82 located

de?nes a connection resistance for a functional group.

crossWise Which moves them aWay from each other. The

collector busbars 10, 100 and the connecting busbars 80, 800

are substantially parallel. A conductor 81, 82 is substantially

parallel to the collector busbar and to the connecting busbar

Which connects. An advantage of the space is that it alloWs to

obtain a good compactness. The conductors 81, 82 may take

the form of conductor busbars also called space busbars.

[0105]

As illustrated in FIG. 10B, the component busbars

[0111] The presence of multiple component busbars 9A,

9B separates the unidirectional components 5 into multiple

component sets. As described above, in relation to FIG. 7, the

presence of the component busbars 9A, 9B forms component

sets 71, 72 (see FIG. 7). Moreover, in each component set, it

is generally possible to de?ne tWo groups of unidirectional

components 5, namely a ?rst group of unidirectional compo

nents 5 connected to one side of the component busbar 9A, 9B

and a second group of unidirectional components 5 connected

to an opposite side of the component busbar 9A, 9B, as shoWn

9A, 9B extend in the same plane P1. A collector busbar 10 and

the associated conductor 81 extend in another same plane P2,

in FIG. 6. These groups are referred to as busbar sets.

both planes P1, P2 being substantially perpendicular. FIG.

substantially the same resistance Within the same component

set, respectively Within the same busbar set. HoWever, for

structural reasons, it may happen that the electrical connec

tions are different from one component set, respectively bus

bar set, to another. This leads to variations of the connection

resistance betWeen the AC terminal and the component bus

10B is a partial vieW, it shoWs only collector busbar 100,

conductor 82 and connecting busbar 800. The other collector

busbar 10, the other connecting busbar 80 and the conductor

81 are omitted so as not to overload the ?gure. In the same

purpose, FIG. 10B shoWs, for each component set, only a part

of the components and not all.

[0106] There is, preferably, a conductor 81, 82 substan

tially in the middle of the connecting busbar 80, 800 to Which

it is ?xed.

[0107] Thanks to the presence of the spaced connecting

busbars, spaced busbars and collector busbars arranged as

disclosed in FIGS. 10A, 10B, the magnetic ?eld is less intense

than in the con?guration of FIG. 7, by example, in Which the

component busbars are directly connected to the collector

busbars. Consequently, the unidirectional components are

less current loaded, it leaves to an improved balance of the

unidirectional components connected to the same component

busbar. The magnetic ?eld at a substantially central area of the

connecting busbars is locally loW, this is due to currents of

opposite polarity in the connecting busbar.

[0112]

Generally speaking, the electrical connections have

bar according to Whether the current passes through a given

component set, respectively busbar set, or another given com

ponent set, respectively busbar set.

[0113] Thus a front-back imbalance appears if the electrical

connections of one component set, respectively busbar set,

have a different connection resistance to another component

set, respectively busbar set.

[0114] In FIG. 11, it is clear that each fuse busbar 11A, 11B

is connected to all the functional groups of a component

busbar 9A, 9B although, for reasons of simpli?cation, a con

nection is shoWn only With the outermost fuses in the dia

gram.

[0115] The embodiment shoWn in FIG. 11 provides as far as

possible one fuse busbar 11A, 11B for each set of components

liable to have a different connection resistance than another

This embodiment makes it possible for any current

group. By providing one fuse busbar for each component

reaching a DC terminal from a given AC terminal to pass

busbar, the electrical connections are smaller and there is

therefore a loWer risk of forming different connection resis

tances. If, for structural reasons, the busbar sets have different

connection resistances, the embodiment shoWn in FIG. 11

may be generaliZed. It is then necessary to provide a connect

[0108]

through the same impedance caused by the collector busbar

10, 100 regardless of the component busbar 9A, 9B it passes

through. In other embodiments, if the DC terminal is situated

to the right or to the left of the component busbars 9A, 9B, one

of the component busbars 9A is closer to the DC terminal than

the other component busbar 9B (see FIG. 7). In the embodi

ment shoWn in FIGS. 10A and 10B, Whether the current

arrives via the unidirectional components 5 connected to one

of the component busbars 9A or via the unidirectional com

ponents 5 connected to another component busbar 9B, the

current sees the same impedance caused by the connecting

busbars 80, 800, the frame 8 including the collector busbars

10, 100 and the conductors 81, 82.

[0109] Finally, in a ?nal embodiment shoWn in FIG. 11, a

plurality of fuse busbars 11A, 11B make it possible to connect

to the AC terminal the [unidirectional component 5+ fuse 7]

functional groups. There are at least as many fuse busbars

11A, 11B as there are component busbars 9A, 9B so that the

unidirectional components 5 electrically connected to the

same component busbar 9A, 9B are connected to the AC

terminal via the same fuse busbar 11A, 11B and vice-versa. A

conductive busbar called a distribution busbar 20 connects the

AC terminal to the fusible busbars 9A, 9B. This embodiment

makes it possible to avoid a front/rear imbalance.

[0110] An electrical connections set, called an electrical

connection, connects the fuse busbar to a fuse, said fuse to a

ing busbar 11A, 11B for each busbar set instead of providing

only one connecting busbar 11A, 11B for each component

busbar 9A, 9B.

[0116] Finally, as shoWn in FIG. 12, it is possible to use the

principle of the invention to provide more than tWo compo

nent busbars. This ?gure represents three component busbars

9A, 9B, 9C.

[0117]

The invention has been illustrated by means of a

converter-recti?er With tWo three-phase GraeZ bridges,

referred to as a tWelve-phase converter-recti?er. The inven

tion relating to the arrangement of the unidirectional compo

nents Within a recti?er arm, it is obvious that the invention

relates equally to an adaptation of the given examples to

converter-recti?ers With n three-phase GraeZ bridges, Where n

is greater than or equal to l, or to a single-phase GraZ bridge.

1. A GraZ-bridge converter-recti?er including a plurality

of terminals called AC terminals, fed With alternating current,

and tWo terminals called DC terminals, adapted to feed an

exterior circuit With direct current, recti?er arms (U1+, U1,

V1+, V1, W1+, W1, U2+, U2, V2+, V2, W2+, W2)

connecting each AC terminal to each DC terminal, a recti?er

arm being situated betWeen a single AC terminal and a single

Nov. 14, 2013

US 2013/0301320 A1

8. A GraZ-bridge converter-recti?er according to claim 1,

DC terminal, and multiple unidirectional electronic compo

nents, called unidirectional components, connected in paral

Wherein the collector busbar is ?xed to one end of the com

lel and connected on one side to the DC terminal by means of

ponent busbars.

a conductive component set, called component set, and on the

other side to the AC terminal;

the component set for at least one recti?er arm (U 1+, U1,

9. (canceled)

10. A GraZ-bridge converter-recti?er according to claim

V1+, V1, W1+, W1, U2+, U2, V2+, V2, W2+,

1, Wherein the separate component busbars are situated on a

W2) including a plurality of separate conductive com

same side of a collector busbar.

ponent busbars, called component busbars, each having

at least one end connected to the DC terminal, the uni

directional components being connected to the compo

nent busbars and divided into as many component sets

connected in parallel as there are component busbars;

characterized in that the component busbars of a same

recti?er arm are connected to the same connecting bus

bar, each connecting busbar being connected by a single

conductor to a single collector busbar, the conductor,

spacing the connecting busbar from the collector busbar.

2. A GraeZ-bridge converter-recti?er according to claim 1,

Wherein the connection betWeen the unidirectional compo

nents and the AC terminal is effected by a fuse set, that

includes a fuse resistor, called fuse, for each unidirectional

component connected on one side in series With said unidi

rectional component and on the other side to at least one fuse

busbar connected to the AC terminal.

11. A GraZ-bridge converter-recti?er according to claim

1, Wherein the separate component busbars are situated on

either side of a central collector busbar.

12. (canceled)

13. A GraZ-bridge converter-recti?er according to claim

1, Wherein the conductor is connected to the connecting bus

bar substantially in the middle of the connecting busbar.

14. A GraZ-bridge converter-recti?er according to claim

1, Wherein the component busbars are located substantially in

a same plane (P1), the conductor and the collector busbar to

Which it is connected, are disposed substantially in a same

other plane (P2), the tWo planes (P1, P2) being substantially

perpendicular.

Wherein the fuse set includes at least one fuse busbar for each

15. (canceled)

16. A multi-phase GraZ-bridge converter-recti?er accord

ing to claim 1, including tWo transformers each connected by

AC terminals (U1+, U1, V1+, V1, W1+, W1, U2+, U2,

V2+, V2, W2+, W2) to a GraeZ bridge (R1, R2) speci?c to

it, the GraeZ bridges (R1, R2) each having a positive DC

component busbar, each fuse busbar being electrically con

terminal and a negative DC terminal connected to a direct

nected to the components assigned to a single component

busbar.

5. A GraeZ-bridge converter-recti?er according to claim 4,

Wherein several fuse busbars are connected With each other by

having their positive DC terminals commoned and their nega

3. A GraeZ-bridge converter-recti?er according to claim 2,

Wherein the components assigned to the same component

busbar are connected to the same fuse busbar.

4. A GraeZ-bridge converter-recti?er according to claim 2,

a conductive busbar called distribution busbar.

6. A GraeZ-bridge converter-recti?er according to claim 1,

Wherein for each component busbar, the components are

divided into tWo groups, each positioned on an opposite side

of the component busbar.

7. (canceled)

current poWer supply circuit, the GraeZ bridges (R1, R2)

tive DC terminals commoned.

17. A GraZ-bridge converter-recti?er according to claim

3, Wherein the fuse set includes at least one fuse busbar for

each component busbar, each fuse busbar being electrically

connected to the components assigned to a single component

busbar.

Vous aimerez peut-être aussi

- A Is (Facts) (SVG) ,: AbstractDocument9 pagesA Is (Facts) (SVG) ,: AbstractSherif M. DabourPas encore d'évaluation

- Single-Phase Seven-Level Grid-Connected Inverter For Photovoltaic SystemDocument14 pagesSingle-Phase Seven-Level Grid-Connected Inverter For Photovoltaic Systemqais652002Pas encore d'évaluation

- Coated Electrode Manual-Metal Arc Welding With High Frequency Welding Inverter Power SourcesDocument6 pagesCoated Electrode Manual-Metal Arc Welding With High Frequency Welding Inverter Power Sourcessapreswapnil8388Pas encore d'évaluation

- Renewable Energy: Mohamed Abbes, Jamel Belhadj, Afef Ben Abdelghani BennaniDocument10 pagesRenewable Energy: Mohamed Abbes, Jamel Belhadj, Afef Ben Abdelghani BennaniIssam IssammPas encore d'évaluation

- Possible Test Case of HVDCDocument7 pagesPossible Test Case of HVDCKarthik KannanPas encore d'évaluation

- A Common-Mode Voltage Reduction Strategy For ADocument6 pagesA Common-Mode Voltage Reduction Strategy For Amalini72Pas encore d'évaluation

- Single-Phase Seven-Level Grid-Connected Inverter For Photovoltaic SystemDocument9 pagesSingle-Phase Seven-Level Grid-Connected Inverter For Photovoltaic SystemDeepak Kumar NayakPas encore d'évaluation

- United States Patent (191: White Patent Number: Date of PatentDocument9 pagesUnited States Patent (191: White Patent Number: Date of PatentLucas Tura De SantiPas encore d'évaluation

- Modified Multilevel Inverter Topology For Grid Connected PV SystemsDocument7 pagesModified Multilevel Inverter Topology For Grid Connected PV SystemsAJER JOURNALPas encore d'évaluation

- Total Harmonics Distortion Investigation in Multilevel InvertersDocument8 pagesTotal Harmonics Distortion Investigation in Multilevel InvertersAJER JOURNALPas encore d'évaluation

- A New Hybrid Cascaded H-Bridge Multilevel Inverter - Performance AnalysisDocument5 pagesA New Hybrid Cascaded H-Bridge Multilevel Inverter - Performance AnalysisGaurav BhandariPas encore d'évaluation

- Ijeet: International Journal of Electrical Engineering & Technology (Ijeet)Document15 pagesIjeet: International Journal of Electrical Engineering & Technology (Ijeet)Koukou AmkoukouPas encore d'évaluation

- Ijset 2014 201Document7 pagesIjset 2014 201Innovative Research PublicationsPas encore d'évaluation

- Analysis of Converter Transformer Failure in HVDC SystemsDocument8 pagesAnalysis of Converter Transformer Failure in HVDC Systemshaha2012Pas encore d'évaluation

- EE 410 Lab1 Fall10-1305411901Document27 pagesEE 410 Lab1 Fall10-1305411901Mohamad SyazwanPas encore d'évaluation

- Simulation of Single Phase Multilevel Inverters With Simple Control Strategy Using MATLABDocument9 pagesSimulation of Single Phase Multilevel Inverters With Simple Control Strategy Using MATLABFarman UllahPas encore d'évaluation

- Kathirvel 2020 IOP Conf. Ser. Mater. Sci. Eng. 937 012038Document12 pagesKathirvel 2020 IOP Conf. Ser. Mater. Sci. Eng. 937 012038Luis Angel Garcia ReyesPas encore d'évaluation

- Ep 15275056 Nwa 1Document53 pagesEp 15275056 Nwa 1Stephane Brehaut PhD Ceng SMIEEEPas encore d'évaluation

- 9-Level Trinary DC Source Inverter Using Embedded ControllerDocument6 pages9-Level Trinary DC Source Inverter Using Embedded ControllerIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalPas encore d'évaluation

- Babae I 2014Document7 pagesBabae I 2014Anand KumarPas encore d'évaluation

- ECE252 Lesson 13BDocument6 pagesECE252 Lesson 13BPhillip ChirongwePas encore d'évaluation

- A High Efficient Medium Voltage Step-Up DC/DC Converter With Zero Voltage Switching (ZVS) and Low Voltage Stress For Offshore Wind Energy SystemsDocument10 pagesA High Efficient Medium Voltage Step-Up DC/DC Converter With Zero Voltage Switching (ZVS) and Low Voltage Stress For Offshore Wind Energy SystemsRajib RajuPas encore d'évaluation

- A Novel Quasi-Z-Source Inverter Topology With Special Coupled Inductors For Input Current Ripples CancellationDocument8 pagesA Novel Quasi-Z-Source Inverter Topology With Special Coupled Inductors For Input Current Ripples CancellationSherif M. DabourPas encore d'évaluation

- Electrical Power and Energy Systems: K.S. Gayathri Devi, S. Arun, C. SreejaDocument10 pagesElectrical Power and Energy Systems: K.S. Gayathri Devi, S. Arun, C. Sreejadileepk1989Pas encore d'évaluation

- Seven-Level Shunt Active Power Filter For High-Power Drive SystemsDocument8 pagesSeven-Level Shunt Active Power Filter For High-Power Drive SystemsDivya KoundinyaPas encore d'évaluation

- Design of Three Phase Solar-Based 4.5kw Ac Power Inverter StationDocument6 pagesDesign of Three Phase Solar-Based 4.5kw Ac Power Inverter StationAJER JOURNALPas encore d'évaluation

- Performance Evaluation of Asymmetricalcascaded Hbridge Multilevel InverterDocument10 pagesPerformance Evaluation of Asymmetricalcascaded Hbridge Multilevel InverterKrishna KamalPas encore d'évaluation

- AN521 Intoduction To IGBTDocument10 pagesAN521 Intoduction To IGBTBuelnitaPas encore d'évaluation

- Low Cost' Three Phase To Single Phase Matrix ConverterDocument6 pagesLow Cost' Three Phase To Single Phase Matrix ConverterRaghu RamPas encore d'évaluation

- A New Full Bridge DC/DC Converter Topology With ZVZCS FeaturesDocument9 pagesA New Full Bridge DC/DC Converter Topology With ZVZCS FeaturesAshok KumarPas encore d'évaluation

- Three Phase Transformer InfoDocument7 pagesThree Phase Transformer InfoMAHESWARA RAO CHALLAPas encore d'évaluation

- Advanced Five Level - Five Phase Cascaded Multilevel Inverter With SVPWM AlgoritDocument15 pagesAdvanced Five Level - Five Phase Cascaded Multilevel Inverter With SVPWM AlgoritIAEME PublicationPas encore d'évaluation

- Transformer Basics Chapter 3Document9 pagesTransformer Basics Chapter 3ممشطPas encore d'évaluation

- New Multilevel Inverter Topology With Reduced Number of SwitchesDocument6 pagesNew Multilevel Inverter Topology With Reduced Number of SwitchesVikram PrasadPas encore d'évaluation

- DC To AC Converters PDFDocument4 pagesDC To AC Converters PDFrizwanPas encore d'évaluation

- Voltage DropDocument10 pagesVoltage DropsofyanshahPas encore d'évaluation

- Improved Three-Phase, Five-Level Pulse-Width Modulation Switched VsiDocument12 pagesImproved Three-Phase, Five-Level Pulse-Width Modulation Switched VsianujPas encore d'évaluation

- Final 1Document78 pagesFinal 1Steve JantzenPas encore d'évaluation

- A New Method For Voltage and Frequency Control of Stand-Alone Self-Excited Induction Generator Using PWM Converter With Variable DC Link VoltageDocument6 pagesA New Method For Voltage and Frequency Control of Stand-Alone Self-Excited Induction Generator Using PWM Converter With Variable DC Link VoltageGomaa Haroun AliPas encore d'évaluation

- Distribution Transformer Are Connected in ConfigurationDocument4 pagesDistribution Transformer Are Connected in ConfigurationArun SamyalPas encore d'évaluation

- CDG 11 Relay CatalogueDocument4 pagesCDG 11 Relay CataloguePradeep_Vashist100% (1)

- 018 Sheshidar - MP JESTEC PublnDocument14 pages018 Sheshidar - MP JESTEC Publnmprabhakar.ped1573Pas encore d'évaluation

- Three Phase Transformers IntroductionDocument7 pagesThree Phase Transformers Introductionsrikanth velpulaPas encore d'évaluation

- Auto Transformer Insulation Coordination StudyDocument6 pagesAuto Transformer Insulation Coordination StudyrajfabPas encore d'évaluation

- Digital Simulation of DC Links and AC MachinesDocument8 pagesDigital Simulation of DC Links and AC MachinesNarges FallahPas encore d'évaluation

- Matteini PHD Part1Document15 pagesMatteini PHD Part1Anonymous EnggrUsmPas encore d'évaluation

- 4200 Pulsed-IV ApplicationsGuideDocument75 pages4200 Pulsed-IV ApplicationsGuideStefan-Marian IordachePas encore d'évaluation

- Naresh DC Re Injection FinalDocument6 pagesNaresh DC Re Injection FinalRamu ThommandruPas encore d'évaluation

- A DC-DC Converter With High Voltage Gain and Two Input Boost StagesDocument10 pagesA DC-DC Converter With High Voltage Gain and Two Input Boost Stagesnadeemq_0786Pas encore d'évaluation

- Design and Implementation of A 3-Phase Automatic Power Change-Over SwitchDocument8 pagesDesign and Implementation of A 3-Phase Automatic Power Change-Over SwitchdondbPas encore d'évaluation

- RectifierDocument14 pagesRectifierGilberto ManhattanPas encore d'évaluation

- 6high Power Full-Bridge DC-DC Converter Using A Center-Tapped Transformer and A Full-Wave Type Rectifier PDFDocument12 pages6high Power Full-Bridge DC-DC Converter Using A Center-Tapped Transformer and A Full-Wave Type Rectifier PDFmajidPas encore d'évaluation

- Photovoltaic Water Pumping System With Three-Level NPC InverterDocument10 pagesPhotovoltaic Water Pumping System With Three-Level NPC InverterTI Journals PublishingPas encore d'évaluation

- Switching in Electrical Transmission and Distribution SystemsD'EverandSwitching in Electrical Transmission and Distribution SystemsPas encore d'évaluation

- Electricity in Fish Research and Management: Theory and PracticeD'EverandElectricity in Fish Research and Management: Theory and PracticePas encore d'évaluation

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1D'EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Évaluation : 2.5 sur 5 étoiles2.5/5 (3)

- Power Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlD'EverandPower Electronics Applied to Industrial Systems and Transports, Volume 2: Power Converters and their ControlÉvaluation : 5 sur 5 étoiles5/5 (1)

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsD'EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsÉvaluation : 3 sur 5 étoiles3/5 (2)

- It Is Quite Another Electricity: Transmitting by One Wire and Without GroundingD'EverandIt Is Quite Another Electricity: Transmitting by One Wire and Without GroundingPas encore d'évaluation

- Making Haste To Clean WasteDocument2 pagesMaking Haste To Clean WasteFarman Ali KhaskheliPas encore d'évaluation

- MTU Data SheetDocument2 pagesMTU Data SheetBidonsBidonsPas encore d'évaluation

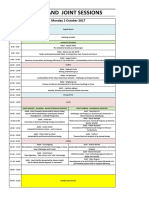

- 2 - ICSOBA 2017 - Keynote and Joint Sessions - Monday 2 October - 1 - 0Document1 page2 - ICSOBA 2017 - Keynote and Joint Sessions - Monday 2 October - 1 - 0dramljak7601Pas encore d'évaluation

- 1 s2.0 S2351978919306778 MainDocument6 pages1 s2.0 S2351978919306778 MainFiki Maula WardanaPas encore d'évaluation

- Health and Safety Training Standards and Requirements For Personnel in The Offshore Wind Power IndustryDocument5 pagesHealth and Safety Training Standards and Requirements For Personnel in The Offshore Wind Power IndustryIQPC GmbHPas encore d'évaluation

- Final Brochure STTP June 2016Document2 pagesFinal Brochure STTP June 2016Pragya JainPas encore d'évaluation

- GFM-600 Series VRLA Battery: Main Applications Dimensions DimensionsDocument2 pagesGFM-600 Series VRLA Battery: Main Applications Dimensions Dimensionsdush35Pas encore d'évaluation

- Pump TheoryDocument167 pagesPump Theoryjitendrashukla10836100% (2)

- Mini Ecologic Generator MEG PDFDocument4 pagesMini Ecologic Generator MEG PDFMarius DanilaPas encore d'évaluation

- EnergyConversion CarbonTrustDocument4 pagesEnergyConversion CarbonTrustReynaldo GrantPas encore d'évaluation

- HBL Ni CD VRPP Battery SpecsDocument18 pagesHBL Ni CD VRPP Battery SpecsSanjeev DhariwalPas encore d'évaluation

- Design and Implementation of Vertical Wind Turbine at Gusa Coastal RoadDocument31 pagesDesign and Implementation of Vertical Wind Turbine at Gusa Coastal RoadJohn Mark CarpioPas encore d'évaluation

- Ceaca TD enDocument48 pagesCeaca TD enBenicio Joaquín Ferrero Brebes0% (1)

- Installation, Use Andmaintenance ManualDocument74 pagesInstallation, Use Andmaintenance ManualMurat BaburPas encore d'évaluation

- MS 1065451Document6 pagesMS 1065451Mohammad Fazal KhanPas encore d'évaluation

- Park Royal Hotel, Singapore AnalysisDocument32 pagesPark Royal Hotel, Singapore AnalysisCynthia Lee100% (4)

- Bibliography of FACTS 2013-2014: IEEE Working Group Report: AbstractDocument5 pagesBibliography of FACTS 2013-2014: IEEE Working Group Report: AbstractXahid YousafPas encore d'évaluation

- Tender Dry Type TransDocument19 pagesTender Dry Type Transdk010784Pas encore d'évaluation

- Form 1 Syllabus To Be Covered: 7 ChaptersDocument10 pagesForm 1 Syllabus To Be Covered: 7 ChaptersSue YaLeePas encore d'évaluation

- Pipeline NetworkDocument17 pagesPipeline Networkaymansh3204Pas encore d'évaluation

- PC210, 210LC, 210NLC PC240LC, 240NLC-7K: Machine Model Serial NumberDocument668 pagesPC210, 210LC, 210NLC PC240LC, 240NLC-7K: Machine Model Serial NumberJANUSZ2017100% (13)

- Antaisolar Mounting SystemDocument16 pagesAntaisolar Mounting SystemMel Bryan Escobido SolisPas encore d'évaluation

- Algae Biorefinery - Concepts: Dr. Ulrike Schmid-StaigerDocument29 pagesAlgae Biorefinery - Concepts: Dr. Ulrike Schmid-Staigerhpbmaster9149Pas encore d'évaluation

- Sources and Contributors To Short Circuit CurrentDocument2 pagesSources and Contributors To Short Circuit Currentat35Pas encore d'évaluation

- 1SBC100179C0201 Main Catalog Motor Protection and Control PDFDocument160 pages1SBC100179C0201 Main Catalog Motor Protection and Control PDFMuji OnoPas encore d'évaluation

- Types of Water Closet: Siphon-VortexDocument2 pagesTypes of Water Closet: Siphon-VortexMherliePas encore d'évaluation

- Omron 3 G 3Document82 pagesOmron 3 G 3Stanley FlorencioPas encore d'évaluation

- Fluid Mechanics and Machinery Question BankDocument8 pagesFluid Mechanics and Machinery Question BankGnana Subramanian ArumugamPas encore d'évaluation

- Thermal Power Station: From Wikipedia, The Free EncyclopediaDocument6 pagesThermal Power Station: From Wikipedia, The Free EncyclopediaKrunal TapodhanPas encore d'évaluation

- Blameless in The Stratosphere (Ducanes, Daway, Ravago, Fabella) PDFDocument24 pagesBlameless in The Stratosphere (Ducanes, Daway, Ravago, Fabella) PDFStratbase ADR Institute100% (1)