Académique Documents

Professionnel Documents

Culture Documents

BNZ Materials Castable Data Sheet

Transféré par

Leo CrisuCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

BNZ Materials Castable Data Sheet

Transféré par

Leo CrisuDroits d'auteur :

Formats disponibles

Refractory products

Hydraulic-Setting

Monolithic Refractories

BNZ

manufactures a variety

of insulating and dense

castable refractories to meet the

exacting needs of the high

temperature processing industries.

These hydraulic setting products are

suitable for installation by various

methods including gunning, casting or

slap-troweling. Each product is

specifically formulated to economically

obtain the desired properties for the

application and service

temperature for which

it is intended.

F I E D

E R T

BNZ Materials, Inc.

Insulating and Dense

Castables

and Gunning Mixes

QUALITY SYSTEM

Insulating Castables and Gunning Mixes

Refractory products

Hydraulic-Setting Monolithic Refractories

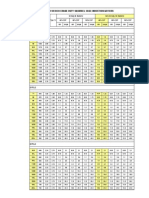

Physical Properties

Blazelite

2000 G

Blazelite

2100

Blazelite

2300

Blazelite

2300 LI

Blazelite

2300 VLI

Blazelite

2500

Blazelite

2600 LI

Maximum Service Temperature, F (C)

2100 (1149)

2100 (1149)

2300 (1260)

2300 (1260)

2300 (1260)

2500 (1371)

2600 (1427)

Yield, lbs dry mix required per cu. ft.

of construction without rebound (kg/m3)

62 (993)

60 (961)

64 (1025)

54 (865)

59 (945)

79 (1265)

74 (1185)

Density, lb/ft (kg/m )

Fired 5 hrs. at 1500F (816C)

64 (1025)

65 (1041)

70 (1121)

61 (977)

66 (1057)

78 (1249)

72 (1150)

Mixing Water Required, (Approx)

U.S. qt/100 lb dry material

(Liter/100 kg dry material)

26

54

25

52

30

63

32

67

31

65

20

41

24

49

Modulus of Rupture, psi (kg/cm2)

(MPa) ASTM C 258

Dried at

220F (104C)

Fired at

1000F (540C)

1500F (815C)

2000F (1095C)

2300F (1260C)

2500F (1371C)

Cold Crushing Strength, psi (kg/cm2)

Dried at

220F (104C)

Fired at

1000F (540C)

1500F (815C)

2000F (1095C)

2300F (1260C)

2500F (1371C)

Permanent Linear Change, %

ASTM C 269

Fired at

1000F (540C)

1500F (815C)

2000F (1095C)

2300F (1260C)

2500F (1371C)

Chemical Analysis, %

fired basis per ASTM C 573

Alumina Al2O3

Silica SiO2

Ferric Oxide Fe2O3

Titania TiO2

Calcium Oxide CaO

Magnesia MgO

Alkalies as Na2O + K2O

Others

ASTM Class C 64 & C 401

150

70

90

90

(1.03)

(0.46)

(0.62)

(0.62)

160

120

150

130

(1.10)

(0.83)

(1.03)

(0.90)

130

70

80

90

200

(0.90)

(0.48)

(0.55)

(0.62)

(1.38)

130

150

60

50

90

(0.90)

(1.03)

(0.40)

(0.34)

(0.62)

140

80

90

90

140

(0.97)

(0.55)

(0.62)

(0.62)

(0.97)

330

160

140

120

200

290

(2.78)

(1.10)

(0.93)

(0.83)

(1.38)

(2.00)

240

160

110

120

100

300

600

430

420

340

(4.13)

(2.96)

(2.90)

(2.34)

400

390

570

420

(2.75)

(2.69)

(3.93)

(2.84)

400

320

500

270

550

(2.75)

(2.21)

(3.45)

(1.86)

(3.79)

700

410

410

320

430

(4.82)

(2.82)

(2.82)

(2.20)

(2.96)

600

310

370

310

550

(4.13)

(2.14)

(2.55)

(2.19)

(3.86)

1500 (10.33)

1200 (8.27)

1200 (8.27)

800 (5.51)

1100 (7.58)

1400 (9.65)

700

1000

700

700

700

700

- 0.1

- 0.2

- 0.3

- 0.2

- 0.2

- 0.2

- 0.2

- 0.1

- 0.2

- 0.9

- 0.1

- 0.2

- 0.4

- 1.0

- 0.1

- 0.2

- 0.2

- 0.7

- 0.2

- 0.2

- 0.2

- 0.5

- 0.7

- 0.2

- 0.2

- 0.2

- 0.5

- 2.1

34.0

40.1

6.5

1.9

15.8

0.3

0.8

35.3

40.5

4.0

1.7

16.9

0.5

1.1

43.9

43.8

3.2

1.8

6.7

0.2

0.9

41.3

41.0

0.9

1.6

14.1

0.2

1.2

47.8

35.0

0.5

1.0

15.1

0.9

43.6

38.2

2.7

1.0

13.6

0.4

0.5

51.0

40.1

0.8

1.2

4.7

0.1

0.1

2.0

P&Q

O, P & Q

P&Q

(1.65)

(1.10)

(0.76)

(0.83)

(0.69)

(2.07)

(4.82)

(6.89)

(4.82)

(4.82)

(4.82)

(4.82)

3.8

3.8

3.4

3.4

3.0

2.6

Blazelite 2300

2.2

Blazelite 2300 LI

Blazelite 2100

1.8

1.4

Blazelite 2500

3.0

Blazelite 2600 LI

2.6

2.2

Blazelite 2300 VLI

Blazelite 2000 G

1.8

1.4

200

(93)

600

(316)

1000

(538)

1400

(760)

Mean Temperature, F (C)

BTU-in/ft2 , hr, F

BTU-in/ft2 , hr, F

Thermal Conductivity

1800

(982)

200

(93)

600

(316)

1000

(538)

1400

(760)

Mean Temperature, F (C)

1800

(982)

Dense Castables and Gunning Mixes

Refractory products

Hydraulic-Setting Monolithic Refractories

Physical Properties

Blazecrete

2300 ARG

Blazecrete

3000 G

Blazecrete

2500 HS

Blazecrete

2600

Blazecrete

2800

Blazecrete

3000

Blazecrete

3200

Maximum Service Temperature, F (C)

2300 (1260)

3000 (1649)

2500 (1371)

2600 (1427)

2800 (1537)

3000 (1649)

3200 (1760)

Density, lb/ft (kg/m )

Fired 5 hrs. at 1750F (955C)*

120 (1922)

130 (2082)

124 (1986)

130 (2082)

128 (2050)

135 (2162)

149 (2387)

Mixing Water Required, (Approx)

U.S. qt/100 lb dry material

(Liter/100 kg dry material)

7

(15)

7

(15)

6

(12)

7

(15)

6

(12)

5

(10)

Modulus of Rupture, psi (MPa)

ASTM C 268

Dried at

220F (104C)

Fired at

1000F (540C)

1500F (815C)

2000F (1095C)

2300F (1260C)

2500F (1371C)

At use limit

1100

300

300

200

300

Cold Crushing Strength, psi (MPa))

Dried at

220F (104C)

Fired at

1000F (540C)

1500F (815C)

2000F (1095C)

2300F (1260C)

2500F (1371C)

At use limit

Permanent Linear Change, %

ASTM C 269

Dried at

200F (104C)

Fired at

1000F (540C)

1500F (815C)

2000F (1095C)

2300F (1260C)

2500F (1371C)

At use limit

Chemical Analysis, %

fired basis per ASTM C 573

Alumina Al2O3

Silica SiO2

Ferric Oxide Fe2O3

Calcium Oxide CaO

Magnesia MgO

Alkalies as Na2O + K2O

Others, TiO2, etc.

(7.6)

(2.1)

(2.1)

(1.4)

(2.1)

200

100

100

130

200

250

1000

(1.4)

(0.7)

(0.7)

(0.9)

(1.4)

(1.7)

(6.9)

BTU-in/ft2 , hr, F

6.0

Blazecrete

2600

4.0

400

130

100

100

200

600

700

(2.8)

(0.9)

(0.7)

(0.7)

(1.4)

(4.1)

(4.8)

500

200

150

200

300

500

900

(3.4)

(1.4)

(1.0)

(1.4)

(2.1)

(3.4)

(6.2)

700

400

300

300

500

800

1000

(4.8)

(2.8)

(2.1)

(2.1)

(3.4)

(5.5)

(6.9)

1000

700

700

700

1200

1400

1200

(6.9)

(4.8)

(4.8)

(4.8)

(8.3)

(9.6)

(8.3)

1200 (8.3)

1100 (7.6)

900 (6.2)

900 (6.2)

1200 (8.3)

1500 (10.3)

5000 (34.5)

8000 (55.2)

6400 (44.1)

5600 (38.6)

2700 (18.6)

3400 (23.4)

5200 (35.8)

2600 (17.9)

2100 (14.5)

1800 (12.4)

1000 (6.9)

2100 (14.5)

4000 (27.6)

3000 (20.7)

2200 (15.2)

2500 (17.2)

1300 (9.0)

2200 (15.2)

5100 (35.1)

7000 (48.8)

4200 (28.9)

4300 (29.6)

3700 (25.5)

2700 (18.6)

3100 (21.4)

7100 (49.0)

9200 (63.4)

8400 (57.9)

5300 (36.5)

6100 (42.0)

4300 (29.6)

3900 (26.9)

5500 (37.9)

7800 (53.8)

- 0.1

- 0.2

- 0.3

- 0.3

- 1.1

- 0.1

- 0.1

- 0.1

- 0.3

- 0.5

- 0.9

+1.0

0.0

- 0.1

- 0.1

- 0.2

- 0.8

+ 0.2

0.0

0.0

0.0

- 0.2

- 0.2

+ 1.8

0.0

- 0.1

- 0.1

- 0.2

0.0

+ 1.0

+ 2.9

0.0

- 0.1

- 0.1

- 0.1

- 0.4

- 0.7

+ 0.1

0.0

- 0.1

- 0.1

- 0.1

- 0.4

- 0.4

+ 0.9

33.4

40.2

7.9

13.6

53.9

38.0

1.7

2.0

2.6

45.5

43.1

3.4

5.6

0.1

0.3

1.9

47.6

44.0

1.8

4.8

0.2

0.4

1.3

53.0

39.9

0.6

2.7

0.1

0.2

1.0

42.9

41.0

5.5

8.4

0.2

0.3

1.7

65.3

27.4

1.1

3.4

0.1

0.1

2.3

1.5

* Use this density for yield; approximate lbs/cu ft

of dry material required for construction.

10.0

8.0

(7.6)

(2.1)

(2.1)

(1.4)

(2.1)

(4.8)

7100 (48.9)

3200 (22.4)

3500 (24.1)

2400 (16.5)

2600 (17.9)

Thermal Conductivity

Blazecrete

3000

1100

300

300

200

300

700

4

(8)

te 2500

Blazecre

HS

Blazecrete

Blazecrete

2800

Blazecrete 3000 G

2300 ARG

The physical and chemical properties of BNZ's Insulating and Dense Castables and Gunning Mixes represent

values obtained in accordance with accepted test methods and are subject to normal manufacturing variations.

They are supplied as a technical service and are subject to

change without notice. Results should not be used for

specification purposes.

2.0

500

1000

1500

2000

Mean Temperature, F

Insulating and Dense Castables and Gunning Mixes

BNZ Materials, Inc.

Refractory products

Corporate Headquarters

Hydraulic-Setting Monolithic Refractories

Denver

6901 South Pierce Street

Suite 260

Littleton, CO 80128

Phone: (303) 978-1199

(800) 999-0890

FAX: (303) 978-0308

www.bnzmaterials.com

Blazelite Insulating Castables

Blazecrete 2300 ARG

The unique aggregate used in BNZ Insulating

Castables allows for the formulation of especially

low density, thermally efficient products unsurpassed by other products.

An alumina-silica castable with high strength

and abrasion resistance. For service to 2300F

(1260C). May be gunned or slap-troweled over

Blazelite 2000G to obtain a high strength hot

face with a good insulating back-up. Suitable for

ash pits, dust collector flues and other areas

where abrasive or erosive conditions exist.

Blazelite 2100

A general purpose lightweight castable for use

as an exposed hot face refractory or as a very

thermally efficient back-up to a dense refractory

lining. Can be installed by casting, gunning or

slap-troweling.

Blazelite 2300

A lightweight, general purpose insulating

castable. Can be used for back-up or exposed to

furnace conditions. Used for one-shot linings,

petrochemical heaters, combustion chambers

and furnace doors and covers. Frequently used

in those areas that would require a 2300F

(1260C) Insulating Fire Brick.

Blazelite 2300 LI and Blazelite 2300 VLI

Similar to Blazelite 2300 but suitable for those

applications where reducing conditions might be

encountered. These high purity, low iron products are specifically designed for both back-up

and exposed to furnace combustion conditions.

Blazelite 2500

An extremely strong insulating castable designed

for general purpose use in those areas that require this combination of light weight and high

strength, such as forge furnace doors and roofs,

reheat furnace sub-hearths, petrochemical stills

and heater linings, metal heating furnace

hearths, cat-cracking units, reactor vessels, flue

and duct linings and kiln car tops.

Blazelite 2600 LI

A low iron, high purity castable for service to

2600F (1427C) in controlled atmosphere applications. Recommended for casting monolithic

shapes and furnace linings.

Blazelite 2000 G

Widely used for stack linings, heaters and vessels

where a gunning mix with low rebound loss is

required.

Blazecrete Gunning Mixes

Blazecrete 3000 G

Blazecrete Castables

Blazecrete 3200

A high alumina castable for service to 3200F

(1778C). It has good volume stability, extremely

high modulus of rupture and crushing strength,

and is of high purity for special furnace atmospheres. Designed for use in casting burner

blocks, roof centers in electric arc furnaces, continuous casting tundish covers, incinerators, and

other areas where these extremely high temperatures are encountered.

Blazecrete 3000

A high alumina, high strength, general purpose

castable for service to 3000F (1667C). Used for

casting burner blocks, door linings, car tops,

crucible furnace linings and special shapes. High

purity for special furnace atmospheres.

Blazecrete 2800

An economical, high alumina refractory for service to 2800F (1556C). Suitable for door linings, curbs and covers, pre-cast shapes, grey iron

ladles, aluminum reverberatory furnace upper

side walls and roofs.

Blazecrete 2600

A general purpose castable for service to 2600F

(1427C). It is especially effective in casting door

linings, boiler walls, monolithic car tops, hearths,

fire boxes, as well as safety linings in continuous

casting tundishes.

Blazecrete 2500 HS

A high-duty castable designed to withstand

loads and resist normal abrasion and erosion at

moderate temperatures to 2500F (1371C). Use

with Blazelite 2100 for a dual component lining

for combined high strength and insulation. Used

for ash hoppers, incinerator floors, dust collector

linings, cupola charging zones and fireplace

sidewalls and hearths.

High alumina castable for service to 3000F

(1667C). Used in building new and repairing

old refractory linings, for gunning applications

and heavy patching by slap-troweling.

Castables & Gunning Mixes

Plant Location

Zelienople

191 Front Street

Zelienople, PA 16063

Phone: (412) 452-8650

(800) 955-8650

FAX: (412) 452-1346

CS85, Marinite & Transite

Plant Location

Billerica

400 Iron Horse Park

North Billerica, MA 01862

Phone: (978) 663-3401

(800) 888-0061

FAX: (978) 663-2735

BNZ Materials manufactures, and is a

worldwide supplier of a range of specialty industrial insulations. BNZ Insulating Fire Brick has been manufactured

continuously at Zelienople, Pennsylvania

for over 50 years. Prior product identification was under the Johns-Manville JM

trademark.

In addition to the Insulating Fire Brick

product line, BNZ also manufactures

many grades of Structural Insulations

under the tradenames Marinite, Transite

and CS 85. These products are designed

for use from ambient temperatures to

1800F, in densities from 36 to 100 pcf,

and will meet the demanding requirements of a variety of

industries and their

specific needs.

Contact BNZ for

more information on these

products and

their applications.

Warranty

Limitation of Liability

BNZ Materials warrants that its products are manufactured in accordance

with its applicable material specifications and are free from defects in

workmanship and materials using BNZ's specifications as a standard. Every

claim under this warranty shall be deemed waived unless in writing and

received by BNZ within thirty (30) days of the date the defect was discovered

and within one (1) year of the date of the shipment of the product.

It is expressly understood and agreed that the limit of BNZ's liability shall be

the resupply of a like quantity of non-defective product and that BNZ shall

have no such liability except where the damage or claim results solely from

breach of BNZ's warranty.

BNZ MAKES NO OTHER REPRESENTATION OR WARRANTY OF ANY KIND,

EXPRESS OR IMPLIED, IN FACT OR IN LAW, INCLUDING WITHOUT

LIMITATION, THE WARRANTY OF MERCHANTABILITY OR THE WARRANTY

OF FITNESS FOR A PARTICULAR PURPOSE, OTHER THAN THE LIMITED

WARRANTY SET FORTH ABOVE.

BNZ R-614-W

11/97

IT IS ALSO AGREED THAT BNZ SHALL NOT BE LIABLE FOR ANY INCIDENTAL,

CONSEQUENTIAL, OR OTHER DAMAGES FOR ANY ALLEGED NEGLIGENCE,

BREACH OF WARRANTY, STRICT LIABILITY, OR ANY OTHER THEORY,

OTHER THAN THE LIMITED LIABILITY SET FORTH ABOVE.

Printed in USA

Vous aimerez peut-être aussi

- 210 SuperlonFR Insulation BrochureDocument8 pages210 SuperlonFR Insulation BrochurealexPas encore d'évaluation

- Needle MatDocument1 pageNeedle MatBruce FerreiraPas encore d'évaluation

- Material Inconel 600Document16 pagesMaterial Inconel 600arvindgupta_2005100% (1)

- Nu Tech Catalog 2019 For Website PDFDocument60 pagesNu Tech Catalog 2019 For Website PDFkaranPas encore d'évaluation

- Kaolite Insulating CastablesDocument2 pagesKaolite Insulating CastablesChan Keng ChunPas encore d'évaluation

- Nelson Heat Trace Self Regulating Heater Cables For Fire Sprinkler Systems en 1527968Document12 pagesNelson Heat Trace Self Regulating Heater Cables For Fire Sprinkler Systems en 1527968abdulafoajjawiPas encore d'évaluation

- 2.lighting Systems Training 2012Q2Document46 pages2.lighting Systems Training 2012Q2AyuWardanaPartIIPas encore d'évaluation

- VSP 70-03-06-00-Mo84Document2 pagesVSP 70-03-06-00-Mo84lgrypvPas encore d'évaluation

- Rockwool Rocktech WM en DsDocument4 pagesRockwool Rocktech WM en DsZain Al AbidinPas encore d'évaluation

- Hastaloy H230Document28 pagesHastaloy H230shahyarzPas encore d'évaluation

- Seismic Load Sprectrum - ProjectDocument13 pagesSeismic Load Sprectrum - ProjectRahulPas encore d'évaluation

- Plastik Szintillator EJ230Document1 pagePlastik Szintillator EJ230aloooooPas encore d'évaluation

- Furring Channels and Custom Top Hat Sections Technical Data Sheet UnlockedDocument2 pagesFurring Channels and Custom Top Hat Sections Technical Data Sheet UnlockedCONSULTANTS KELPas encore d'évaluation

- Texaco Meropa 320 Eng M0010Document2 pagesTexaco Meropa 320 Eng M0010Ady MihailaPas encore d'évaluation

- W22 Smoke Extraction: Motor For Smoke Exhaustion African MarketDocument60 pagesW22 Smoke Extraction: Motor For Smoke Exhaustion African MarketAgustynho MagimbaPas encore d'évaluation

- Technical Data Sheet R 600a Gas ServeiDocument2 pagesTechnical Data Sheet R 600a Gas Serveiskaw flatPas encore d'évaluation

- Actuadores Neumaticos TS - AdasDocument25 pagesActuadores Neumaticos TS - AdasDaniel SanPas encore d'évaluation

- Versatile Quartz AmberDocument6 pagesVersatile Quartz AmberSaqib JavedPas encore d'évaluation

- Rockwool SeriesDocument12 pagesRockwool SeriesUsamah AhmadPas encore d'évaluation

- FTJ Series Product Guide PDFDocument12 pagesFTJ Series Product Guide PDFJhon SendokPas encore d'évaluation

- Monel 400Document16 pagesMonel 400amr kouranyPas encore d'évaluation

- Three-Phase Tefc High Efficiency Motor: Eff1 / Ie2Document8 pagesThree-Phase Tefc High Efficiency Motor: Eff1 / Ie2Gea Mandiri ciptaPas encore d'évaluation

- Fluke 1650B Series: Multifunction Installation TestersDocument10 pagesFluke 1650B Series: Multifunction Installation TestersWasinchai KanjanapanPas encore d'évaluation

- Fichas TécnicasDocument22 pagesFichas TécnicasCarlos LopezPas encore d'évaluation

- Allrig Lifting ChainDocument14 pagesAllrig Lifting ChainAwanPas encore d'évaluation

- Crosby 2140 Shackle DatasheetDocument1 pageCrosby 2140 Shackle DatasheetKikitornado 22Pas encore d'évaluation

- ARLON Substrate - Important PDFDocument16 pagesARLON Substrate - Important PDFrahul05singhaPas encore d'évaluation

- Isover Cladding Roll 40 Product Datasheet April 2020Document2 pagesIsover Cladding Roll 40 Product Datasheet April 2020WyliePas encore d'évaluation

- Extreme Copper PCBsDocument12 pagesExtreme Copper PCBsskgPas encore d'évaluation

- Seismic Base Coe. NBC 105-2016Document11 pagesSeismic Base Coe. NBC 105-2016Aditya JoshiPas encore d'évaluation

- BCH Crane Duty Motors-Technical Data SheetDocument1 pageBCH Crane Duty Motors-Technical Data SheetNaveen GuptaPas encore d'évaluation

- Equipment in Bread MakingDocument4 pagesEquipment in Bread MakingIanBautistaPas encore d'évaluation

- BS 3059-1 PDFDocument9 pagesBS 3059-1 PDFabhiPas encore d'évaluation

- Thermal Ceramics - Dense Concretes FirecreteDocument2 pagesThermal Ceramics - Dense Concretes FirecretenmmartinsPas encore d'évaluation

- Eucaro Offshore CatalogDocument36 pagesEucaro Offshore CatalogSaulo Roseira100% (1)

- KMBD 240C-2700C - 1857-1 Instruction Manual Kinney Vacuum BoostersDocument34 pagesKMBD 240C-2700C - 1857-1 Instruction Manual Kinney Vacuum Boostersahmed100% (1)

- Spiral Wound Gasket BrochureDocument36 pagesSpiral Wound Gasket BrochureVlas BogdănPas encore d'évaluation

- RBX10L840 Arr22sDocument7 pagesRBX10L840 Arr22sflorencio vazquezPas encore d'évaluation

- Monel K500Document20 pagesMonel K500Ion PopescuPas encore d'évaluation

- Material SpecificationDocument50 pagesMaterial SpecificationSangyt Karna0% (2)

- Steel UserguideDocument50 pagesSteel UserguideBhanu Pratap ChoudhuryPas encore d'évaluation

- Is 228 (Part 1) : 1987 Methods For Chemical Analysis Of: (Reaffirmed 2008)Document5 pagesIs 228 (Part 1) : 1987 Methods For Chemical Analysis Of: (Reaffirmed 2008)Indira BanerjeePas encore d'évaluation

- Technische Beschreibung SanitaerDocument39 pagesTechnische Beschreibung SanitaerBegüm ÖzgünPas encore d'évaluation

- Seismic Load SprectrumDocument10 pagesSeismic Load Sprectrumvirat_davePas encore d'évaluation

- Inconel 690Document8 pagesInconel 690Ronak shahPas encore d'évaluation

- Short Circuit Current RatingsDocument1 pageShort Circuit Current Ratingsvanessa quispePas encore d'évaluation

- 4408 Fully Synthetic Heavy Duty Industrial Gear OilDocument3 pages4408 Fully Synthetic Heavy Duty Industrial Gear OilYoong TanPas encore d'évaluation

- Residential Multi Split DatabookDocument168 pagesResidential Multi Split DatabooksaruthanPas encore d'évaluation

- Katalog KumoloDocument13 pagesKatalog KumoloAdrianus Ivan SebastianPas encore d'évaluation

- Userguide For SSDocument26 pagesUserguide For SSehsan4uPas encore d'évaluation

- SF-600 TDS 2023Document1 pageSF-600 TDS 2023Rajneesh RallanPas encore d'évaluation

- OWS Booklet v27Document5 pagesOWS Booklet v27blay40251Pas encore d'évaluation

- DACE Labour Norms Equipment Installation V2Document22 pagesDACE Labour Norms Equipment Installation V2Amir AbazaPas encore d'évaluation

- Drilling Fluids Processing HandbookD'EverandDrilling Fluids Processing HandbookÉvaluation : 4.5 sur 5 étoiles4.5/5 (4)

- Modern Glass CharacterizationD'EverandModern Glass CharacterizationMario AffatigatoPas encore d'évaluation

- Working Guide to Drilling Equipment and OperationsD'EverandWorking Guide to Drilling Equipment and OperationsÉvaluation : 5 sur 5 étoiles5/5 (9)

- The SQUID Handbook: Fundamentals and Technology of SQUIDs and SQUID SystemsD'EverandThe SQUID Handbook: Fundamentals and Technology of SQUIDs and SQUID SystemsPas encore d'évaluation

- OC3 Commands PDFDocument11 pagesOC3 Commands PDFLeo CrisuPas encore d'évaluation

- BucatarieDocument3 pagesBucatarieLeo CrisuPas encore d'évaluation

- Product Instruction Bulletin Installation Tools PDFDocument10 pagesProduct Instruction Bulletin Installation Tools PDFLeo CrisuPas encore d'évaluation

- Install Notes (Please Read)Document1 pageInstall Notes (Please Read)Leo CrisuPas encore d'évaluation

- Product Instruction Bulletin Installation ToolsDocument10 pagesProduct Instruction Bulletin Installation ToolsLeo CrisuPas encore d'évaluation

- How To Register EUEEA CitizensDocument1 pageHow To Register EUEEA CitizensLeo CrisuPas encore d'évaluation

- Sorbead H BASF - Data Sheet PDFDocument2 pagesSorbead H BASF - Data Sheet PDFLeo Crisu100% (1)

- 35Document7 pages35Leo CrisuPas encore d'évaluation

- Industrial InsulationDocument9 pagesIndustrial Insulationahad_shiraziPas encore d'évaluation

- Sds Plicast LWI 20 Trowl MixDocument4 pagesSds Plicast LWI 20 Trowl MixLeo CrisuPas encore d'évaluation

- Insilation PipeDocument14 pagesInsilation Pipesbala_810Pas encore d'évaluation

- Aluminium Mold BasesDocument20 pagesAluminium Mold BasessferrandPas encore d'évaluation

- Models - Pipe.pipeline InsulationDocument16 pagesModels - Pipe.pipeline InsulationLeo CrisuPas encore d'évaluation

- Sds Plicast CG LWIDocument4 pagesSds Plicast CG LWILeo CrisuPas encore d'évaluation

- Kelvion Bro en Charge Air Cooler DIN A4!11!2015 LowResDocument13 pagesKelvion Bro en Charge Air Cooler DIN A4!11!2015 LowResHeryanto SyamPas encore d'évaluation

- Adham SamerDocument40 pagesAdham SamerLeo CrisuPas encore d'évaluation

- SG 557 Racorduri Ermeto PDFDocument27 pagesSG 557 Racorduri Ermeto PDFLeo CrisuPas encore d'évaluation

- Kelvion Factsheet CW Tube en 01-2016 LowResDocument2 pagesKelvion Factsheet CW Tube en 01-2016 LowResLeo CrisuPas encore d'évaluation

- Cutting Edge Vol 3Document20 pagesCutting Edge Vol 3Leo CrisuPas encore d'évaluation

- Chapter 78 - Oil and Natural GasDocument29 pagesChapter 78 - Oil and Natural GasLeo CrisuPas encore d'évaluation

- Flare TypeDocument44 pagesFlare TypeBre WirabumiPas encore d'évaluation

- Comes Sa: Leading Manufacturer of Equipment and Spare Parts For Chemical/petrochemical, Gas & Oil and Nuclear IndustriesDocument24 pagesComes Sa: Leading Manufacturer of Equipment and Spare Parts For Chemical/petrochemical, Gas & Oil and Nuclear IndustriesLeo CrisuPas encore d'évaluation

- Pachete Matrite Standard DMEDocument132 pagesPachete Matrite Standard DMELeo CrisuPas encore d'évaluation

- Allied Mineral Refractory Castable - Refractory Cement - Allied Mineral PDFDocument2 pagesAllied Mineral Refractory Castable - Refractory Cement - Allied Mineral PDFLeo CrisuPas encore d'évaluation

- Pid Legend PDFDocument1 pagePid Legend PDFSocMed Dtk UI0% (1)

- Pachete Standard EURODocument132 pagesPachete Standard EUROLeo CrisuPas encore d'évaluation

- 26Document44 pages26nirajmodi20985Pas encore d'évaluation

- Kelvion Air Preheater Air Dryer en 100616 1Document20 pagesKelvion Air Preheater Air Dryer en 100616 1Leo CrisuPas encore d'évaluation

- Sliding Core MoldsDocument72 pagesSliding Core Moldsprofesorul_emil15Pas encore d'évaluation

- Pachete Matrite Standard DMEDocument132 pagesPachete Matrite Standard DMELeo CrisuPas encore d'évaluation

- Procedure of PVC, FRP Welding and Jointing ProcedureDocument5 pagesProcedure of PVC, FRP Welding and Jointing ProcedureHasan AhmedPas encore d'évaluation

- Hci It6200Document12 pagesHci It6200Maria Ana AmoloPas encore d'évaluation

- Regional Islamic ArchitectureDocument27 pagesRegional Islamic ArchitectureAnuj DagaPas encore d'évaluation

- 2015ebook Nuage PDFDocument90 pages2015ebook Nuage PDFalfagemeoPas encore d'évaluation

- Comparing Dell Compellent Network-Attached Storage To An Industry-Leading NAS SolutionDocument19 pagesComparing Dell Compellent Network-Attached Storage To An Industry-Leading NAS SolutionPrincipled TechnologiesPas encore d'évaluation

- Introduction To Site PlanningDocument14 pagesIntroduction To Site PlanningRan Ran Sora100% (1)

- Dudek I-Beams (Dib) Span Tables Floor AplicationsDocument4 pagesDudek I-Beams (Dib) Span Tables Floor AplicationsJoseph BookerPas encore d'évaluation

- MNFSTDocument11 pagesMNFSTVincentiuz RobertoPas encore d'évaluation

- Steel TipsDocument123 pagesSteel TipsEngr AxlePas encore d'évaluation

- Bluetooth Low EnergyDocument2 pagesBluetooth Low Energygvs_2000Pas encore d'évaluation

- TurriDocument3 pagesTurrihuyPas encore d'évaluation

- Postgres PTHDocument7 pagesPostgres PTHKarthik BsPas encore d'évaluation

- CharacterAss 3 Tall BuildingsDocument28 pagesCharacterAss 3 Tall BuildingsMadan MohanPas encore d'évaluation

- Catalogo TSMDocument41 pagesCatalogo TSMcivil_jonathanPas encore d'évaluation

- National Artists For ArchitectureDocument16 pagesNational Artists For ArchitecturebbalacyPas encore d'évaluation

- RTLS Installation Manual: Date Modified: June 4, 2014Document52 pagesRTLS Installation Manual: Date Modified: June 4, 2014Asif Belal100% (1)

- Building Drawing (CE3G) - IntroductionDocument36 pagesBuilding Drawing (CE3G) - Introductionsudhir shinde100% (2)

- Ibr FormsDocument117 pagesIbr FormsAkhilesh KumarPas encore d'évaluation

- MOJAVE Single 2016 - OptimizedDocument20 pagesMOJAVE Single 2016 - OptimizedDonnarose DiBenedettoPas encore d'évaluation

- Bridging The Dutch Landscape - Design Guide For BridgesDocument164 pagesBridging The Dutch Landscape - Design Guide For BridgesEdward AveryPas encore d'évaluation

- Answer:: ExplanationDocument5 pagesAnswer:: ExplanationUmaish NairPas encore d'évaluation

- NBC 2005 - HighlightsDocument9 pagesNBC 2005 - Highlightsbijnor officePas encore d'évaluation

- Components For Smoke and Heat Control Systems. Functional Recommendations and Calculation Methods For Smoke and Heat ExhaustDocument42 pagesComponents For Smoke and Heat Control Systems. Functional Recommendations and Calculation Methods For Smoke and Heat ExhaustBasil Oguaka100% (3)

- Test Architecture, Test RetrofitDocument22 pagesTest Architecture, Test RetrofitReza MobashsherniaPas encore d'évaluation

- Timber Framed BibliographyDocument8 pagesTimber Framed BibliographyDr Richard Haddlesey100% (2)

- Bel Air E BrochureDocument31 pagesBel Air E BrochureChandra MohanPas encore d'évaluation

- DALI Digital Lighting ControlDocument2 pagesDALI Digital Lighting Controlbusterwong9958Pas encore d'évaluation

- Vent Size & Max. Distance From Fixture PDFDocument1 pageVent Size & Max. Distance From Fixture PDFbilal almelegyPas encore d'évaluation

- Convert HEIC To PNGDocument3 pagesConvert HEIC To PNGEjaz AlamPas encore d'évaluation

- CCNA DiscussionsDocument53 pagesCCNA DiscussionsnetsharonPas encore d'évaluation