Académique Documents

Professionnel Documents

Culture Documents

Slab Design Report

Transféré par

dulanbackup1Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Slab Design Report

Transféré par

dulanbackup1Droits d'auteur :

Formats disponibles

Reference

Description

Out put

1 DECK SLAB DESIGN

1.1 Deck data

Width of road

5m

BS 5400-2

No of notional lanes

1978

Width of a notional lane

2.5 m

3.2.9.3.1

Span of slab

3.5 + 0.5

4m

Thickness of slab

350 mm

Asphalt thickness

50 mm

new deck

new deck

0.5

existing deck

3.5

0.5

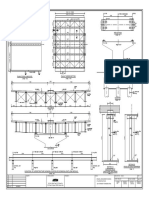

Figure 1.1 . Bridge deck arrangement

1.2 External Load and Internal Forces Calculation

BS 5400-2

Ha udl

1978

Cl 6.2

Ha kel

30 kN/m lane

12 kN/m2

120 kN/ lane

48 kN/m

Reference

Description

Out put

Density of concrete

24 kN/m3

Density of Asphalt

22 kN/m3

Load due to slab

8.4 kN/m2

Load due to asphalt

1.1 kN/m2

Load factors

Load

ULS

SLS

Concrete

1.15

1.00

Asphalt

1.75

1.20

Ha

1.50

1.20

Considering 1m stript

ULS BM (kNm/m)

Nominal

ULS

SLS

Concrete

16.8

19.3

16.8

Asphalt

2.2

3.9

2.6

Ha udl

24.0

36.0

28.8

Ha kel

48.0

72.0

57.6

Total Moment

91.0

131.2

105.8

ULS Design Moment

1.1 x Total moment

1.1 x

131.2

144.3

kNm/m

Reference

Description

Out put

SLS Moment

105.8

kNm/m

Mg

19.4

kNm/m

Mq

86.4

kNm/m

Mq/Mg

4.4

ULS SF due to

Concrete

19.3

Asphalt

3.9

Ha udl

36.0

Ha kel

72.0

Total Shear force

131.2

Design SF

1.1 x Total SF

1.1 x

131.2

144.3 kN

Reference

Description

Out put

1.3 Design for bending(ULS)

BS 5400

Part 4: 1990

Design BM

144.3

kNm/m

Thickness of the Abutment

350

mm

cover

50

mm

Diametre of main(vertical) R/F

16

mm

Characteristic strength of concrete, fcu

30

N/mm2

Effective depth, d

292

mm

cl.5.4.2

BS 5400

Part 4: 1990

M = (0.87fy)Asz

equation 1

cl.5.3.2.3

Z= (1 - 1.1fyAs/ fcubd) d

equation 5

From these two equations

Z= 0.5d [1+ (1-5M/fcubd2)1/2 ]

0.92

269

mm

Main reinforcement

As = M / 0.87fyz

As req =

As req =

use

16 @

0.46

1338

provide

mm2

T16-100 for

100

bottom main

As pro =

2011

mm2

direction

Reference

Description

Out put

1.4 Design for Shear ULS

BS 5400

Design Shear force at the face

144.3

kN/m

Effective depth, d

292

mm

Design shear stress, v

V / bd

144.287*1000/(1000*292)

0.75X(fcu)1/2

or

4.75 (minimum)

v

Part 4: 1990

5.3.3.1

0.49

N/mm2

4.11

N/mm

<

4.11

Hence O.K

equation 8

BS 5400

Part 4: 1990

Allow. shear resistance

(0.27/gm)(100As/bwd)

xs

(500/d)1/4

Where, depth ratio,

5.3.3.2

xsvc =

=

1/3

(fcu)

1/3

xs

0.7 (max)

or

1.14

(0.27/1.25)(100*2011/1000*292)^(1/3)*(30)^(1/3)*1.14

2

0.68 N/mm

v

Hence O.K

<

0.68

Reference

Description

Out put

1.5 Design for crack width and check stress at SLS

Design crack width

5.8.8.2

As Provided

2011

mm /m

eq : 24

1000

mm

292

mm

0.007

Es

200

kN/mm2

Ec

14

kN/mm2

BS 5400

3acrm

1+2(acr-cnom)/(h-dc)

Part 4

Depth of

concrete in

compression

dc/d

dc

Es/Ec

14.29

er [(1+2/aer)1/2-1]

103.9

mm

d-dc/3

257

105.84

mm

Check for stress levels

BS 5400

Bending moment at

Part 4

serviceability limit state

(Ms)

kNm/m

Table 2

sc

sca

sc

2Ms/bzdc

7.91

0.5 * Fcu

15

<

Hence ok

sca

N/mm2

N/mm2

Reference

Description

sse

Ms/zAs

2

205 N/mm

=

ssa

0.75 * fy

2

345 N/mm

=

sse

Out put

ssa

<

Hence ok

em

e1-e

{(3.8).bt.h.(a'-dc)/(es.As.(h-dc)}.{(1-Mq/Mg).10-9}

e1

sse

Es

(depth-dc)

(d-dc)

(Mg) =

19.4

kNm/m

(Mq) =

86.4

kNm/m

e1

0.00134

-0.00223

em

e1

acr

=

=

BS 5400

Design crack width

0.00134

[(50+16/2)^2 + (100/2)^2]^0.5 -16/2

69

mm

3acrm

1+2(acr-cnom)/(h-dc)

Part 4

eq : 24

BS 5400

Allowable crack width=

mm

0.25

mm

crack width

Part 4

Table 2

0.239

Hence OK

0.239 mm

Reference

Description

Out put

1.6 Design of main direction top bars

since slab is simply supported hogging moment is zero

but provde minimum reinforcement for top net main direction

assume 12 mm bars for top net main direction

d

100 x As/( b x d )

As

350-50-12/2

provide

294

T12-200 for

0.15

top main

=

=

0.15 x 1000 x 294 / 100

direction

441 mm2

provide 12 mm bars with 200 spacing

As provided

=

=

(1000/200) x x 6 x 6

565 mm2

1.7 Design of distribution bars

for bottom distribution bars use 12 mm @200mm

for top distribution bars use 12 mm @ 200mm

100 x As/( b x d )

As

350-50-16-6

278

provide

0.12

T12-200 for

=

=

top net As provided

0.12x 1000 x 278/ 100

334

top distribution

bars

=

=

(1000/200) x x 6 x 6

565 mm2

provide

T12-200 for

bottom

bottom net As provided

=

=

(1000/200) x x 8x8

1005 mm2

distribution

bars

Reference

Description

Out put

1.8 Check for punching shear for wheel load

shear capacity in lateral direction

Characteristic strength of concrete, fcu

30

N/mm2

Effective depth, d

278

mm

As pro =

565

mm2

BS 5400

Part 4: 1990

12 @

200

Allow. shear resistance

(0.27/gm)(100As/bwd)

xs

(500/d)

1.16

Where, depth ratio,

5.3.3.2

xsvc =

1/4

1/3

or

(fcu)

1/3

xs

0.7 (max)

(0.27/1.15)(100*565/1000*278)^(1/3)*(30)^(1/3)*1.16

2

0.46 N/mm

shear capacity in main direction

from 2.6

xsvc =

2

0.68 N/mm

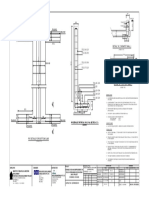

check for punching shere 1.5 d away from wheel load

perimeter

1.5 d =

417 mm

1134 mm

300 mm

417 mm

1134 mm

300 mm

Figure 2.5 Punching shere peremeter

Reference

Description

Out put

punching shear capacity

=

=

2 x (1134 x 292 x 0.68 + 1116 x 278 x 0.46) / 1000

736 kN

punching shear force (wheel load)

=

=

1.65 x 100

165 kN

<

736 kN

slab is safe

hence ok

for punching

shear

Vous aimerez peut-être aussi

- Pier Cap Plan: Project:-Client: - ConsultantsDocument1 pagePier Cap Plan: Project:-Client: - ConsultantsShaileshRastogiPas encore d'évaluation

- 2 Grillage Analysis of Bridge DecksDocument11 pages2 Grillage Analysis of Bridge Decksahmad fakhruddinPas encore d'évaluation

- Span 20 MDocument111 pagesSpan 20 MajayPas encore d'évaluation

- Design of Balanced Cantilever BridgeDocument37 pagesDesign of Balanced Cantilever BridgeArafat RahmanPas encore d'évaluation

- Hmmer Head Pier DesignDocument24 pagesHmmer Head Pier DesignabadittadessePas encore d'évaluation

- Bearing Design For ROB at Chainage 145+368 (47m CC of E.J.)Document11 pagesBearing Design For ROB at Chainage 145+368 (47m CC of E.J.)amitkuknaPas encore d'évaluation

- T. Viswanathan 3. Ultimate Limit State of Linear Elements (Modified 28-Jul)Document69 pagesT. Viswanathan 3. Ultimate Limit State of Linear Elements (Modified 28-Jul)Bridge DepartmentPas encore d'évaluation

- Neutral Axis of A Beam & Moment of Inertia IcgDocument8 pagesNeutral Axis of A Beam & Moment of Inertia Icgassaad006Pas encore d'évaluation

- Cross Section Dimension:: Deck Slab DetailsDocument1 pageCross Section Dimension:: Deck Slab DetailsSuman NakarmiPas encore d'évaluation

- Moving Load As Per IRCDocument23 pagesMoving Load As Per IRCSaurabh PandeyPas encore d'évaluation

- Box Culvert Section: 4 Input Data 4.1 Geometry of The SectionDocument7 pagesBox Culvert Section: 4 Input Data 4.1 Geometry of The SectionmidhunvarPas encore d'évaluation

- ACI 318M-11 RC Beam Ledge Design - v0.04 - 2020-07-23Document5 pagesACI 318M-11 RC Beam Ledge Design - v0.04 - 2020-07-23Vietanh PhungPas encore d'évaluation

- Name of The Work Nabard Construction FoDocument48 pagesName of The Work Nabard Construction FodiablopapanatasPas encore d'évaluation

- Elastomeric Bearings: 6 (1) Design Load On BearingsDocument8 pagesElastomeric Bearings: 6 (1) Design Load On BearingsCivil MexPas encore d'évaluation

- Pier Cap DesignDocument2 pagesPier Cap DesignAnand SoniPas encore d'évaluation

- Lea Associates South Asia Pvt. LTDDocument41 pagesLea Associates South Asia Pvt. LTDajayPas encore d'évaluation

- Grade of Concrete Permissible Stress in Compression Bending DirectDocument37 pagesGrade of Concrete Permissible Stress in Compression Bending DirectKasiPas encore d'évaluation

- Designed Date Details Checked Title DocnoDocument4 pagesDesigned Date Details Checked Title DocnovivekPas encore d'évaluation

- Abutment With 28 Tonne SBCDocument131 pagesAbutment With 28 Tonne SBCV P GUPTAPas encore d'évaluation

- Design File Type RUBDocument116 pagesDesign File Type RUBAbilaash VPas encore d'évaluation

- Cable Profile For Prestressing and Calculation of Eccentricities of Substiture CableDocument4 pagesCable Profile For Prestressing and Calculation of Eccentricities of Substiture Cablerabindra choudhary0% (1)

- Slab Culvert Irc 21 Irc 112Document5 pagesSlab Culvert Irc 21 Irc 112imamtaPas encore d'évaluation

- Alternative Forms of Two Lane T-Beam Bridge Superstructure - Study by Grillage AnalogyDocument9 pagesAlternative Forms of Two Lane T-Beam Bridge Superstructure - Study by Grillage AnalogyAnkur SrivastavaPas encore d'évaluation

- T Girder Bridge Deck Diaphragm-20 MDocument14 pagesT Girder Bridge Deck Diaphragm-20 MAmitabha DebPas encore d'évaluation

- Project: Date: Location: Designed By: Title: Checked By:: C C C R T C BDocument6 pagesProject: Date: Location: Designed By: Title: Checked By:: C C C R T C BDev LamichhanePas encore d'évaluation

- Detailed Design Calculations For 1 X 2.0M X 2.0M Size RCC Box CulvertDocument1 pageDetailed Design Calculations For 1 X 2.0M X 2.0M Size RCC Box Culvertnandu523Pas encore d'évaluation

- Bridge Design (Shear Force and Bending Moment Calculation) : Irc Class Aa Tracked VehicleDocument20 pagesBridge Design (Shear Force and Bending Moment Calculation) : Irc Class Aa Tracked VehicleBhavsar NilayPas encore d'évaluation

- Appendix 5 RC Pier DesignDocument11 pagesAppendix 5 RC Pier DesignebsiPas encore d'évaluation

- Corbel RainaDocument13 pagesCorbel RainaMadhurimaMitra100% (1)

- Sarda Rikhe Pier Found FinalDocument9 pagesSarda Rikhe Pier Found FinalHimal KaflePas encore d'évaluation

- Bridge Design HardikDocument9 pagesBridge Design HardikmahakPas encore d'évaluation

- PSCG 20m 35SK R0Document149 pagesPSCG 20m 35SK R0Ankush SharmaPas encore d'évaluation

- 70R Loading, Live LoadDocument12 pages70R Loading, Live LoadTashi TamangPas encore d'évaluation

- Design-Psc T GirderDocument143 pagesDesign-Psc T GirderAtanu AdhiakryPas encore d'évaluation

- Cross Section Properties (All Dimensions Are in CMS)Document2 pagesCross Section Properties (All Dimensions Are in CMS)Hanamantrao KhasnisPas encore d'évaluation

- Counterfort Retaining WallDocument16 pagesCounterfort Retaining Wallvidhiyadav1021Pas encore d'évaluation

- Technical Proposal For Retrofitting of Cast in Situ Girder, Jalda Bridge 18.02.2020Document108 pagesTechnical Proposal For Retrofitting of Cast in Situ Girder, Jalda Bridge 18.02.2020Partha GangopadhyayPas encore d'évaluation

- 1.design ConditionDocument22 pages1.design Conditionakshay magarPas encore d'évaluation

- Combined Footing 33Document4 pagesCombined Footing 33Narayan WPas encore d'évaluation

- 41-Pile FoundationDocument56 pages41-Pile Foundationsharif uddinPas encore d'évaluation

- Example of Box Girder Bridge CalculationDocument79 pagesExample of Box Girder Bridge CalculationStructural SpreadsheetsPas encore d'évaluation

- Implication of IRC 112 - 2011 On RCC Bridge DesignDocument8 pagesImplication of IRC 112 - 2011 On RCC Bridge DesignkrunalPas encore d'évaluation

- 1 - Slab Bridge Final April23 - 2014Document11 pages1 - Slab Bridge Final April23 - 2014teweldePas encore d'évaluation

- New PSC I GirderDocument64 pagesNew PSC I Girderrahul sumanPas encore d'évaluation

- For Review and Approval: SECTION-1-1Document1 pageFor Review and Approval: SECTION-1-1Mandar GPas encore d'évaluation

- Pier Cap P7Document49 pagesPier Cap P7Anonymous vg8JEo0100% (1)

- RCC Detail Design of Abutment and PierDocument20 pagesRCC Detail Design of Abutment and Piershashibhushan singh100% (1)

- Design of Bridge 01Document40 pagesDesign of Bridge 01dikunPas encore d'évaluation

- LRFD Pre-Stressed Beam Example With MATHCADDocument71 pagesLRFD Pre-Stressed Beam Example With MATHCADistructePas encore d'évaluation

- Design of Superstructure - 25mDocument243 pagesDesign of Superstructure - 25mmrinal kayal0% (1)

- Confinement DesignDocument405 pagesConfinement DesignJAcc COncepcionPas encore d'évaluation

- Part 3 Abut - Well Foundation DesignDocument46 pagesPart 3 Abut - Well Foundation Designshashi rajhansPas encore d'évaluation

- Transverse-Design771 TriDocument17 pagesTransverse-Design771 TriBasava SowmyaPas encore d'évaluation

- Circular Pier With Circular FootingDocument25 pagesCircular Pier With Circular FootinglibraryaslamPas encore d'évaluation

- Design of RCC Solid Slab - 2.0m-12.00Document27 pagesDesign of RCC Solid Slab - 2.0m-12.00Chandra Prakash Jyoti0% (1)

- Pier Sheet Hollow r0Document1 pagePier Sheet Hollow r0Varun VermaPas encore d'évaluation

- Box Design 6x6Document79 pagesBox Design 6x6SM ConsultantsPas encore d'évaluation

- Isolated Sloped Footing SpreadsheetDocument283 pagesIsolated Sloped Footing Spreadsheetarif_rubin100% (3)

- Structural Report On 400 KLD STPDocument16 pagesStructural Report On 400 KLD STPVipin SinghalPas encore d'évaluation

- Jutpani SS20Document23 pagesJutpani SS20Suman NakarmiPas encore d'évaluation

- RBP-P2-1551 Submission DWG 20160926Document12 pagesRBP-P2-1551 Submission DWG 20160926dulanbackup1100% (1)

- Chapter 5 - Bridge No: JB 2275Document7 pagesChapter 5 - Bridge No: JB 2275dulanbackup1Pas encore d'évaluation

- Beam Slab ArrangementDocument1 pageBeam Slab Arrangementdulanbackup1Pas encore d'évaluation

- Beam Slab Arrangement PDFDocument1 pageBeam Slab Arrangement PDFdulanbackup1Pas encore d'évaluation

- Bridge 1551 BoQ Submission 20160926Document5 pagesBridge 1551 BoQ Submission 20160926dulanbackup1Pas encore d'évaluation

- BH 1529Document7 pagesBH 1529dulanbackup1Pas encore d'évaluation

- Pile Rectification Report 11Document4 pagesPile Rectification Report 11dulanbackup1Pas encore d'évaluation

- Bridge Cbuk 1693Document13 pagesBridge Cbuk 1693dulanbackup1Pas encore d'évaluation

- Proposed CostDocument1 pageProposed Costdulanbackup1Pas encore d'évaluation

- Proposed CostDocument1 pageProposed Costdulanbackup1Pas encore d'évaluation

- Gampaha District: LI Ii UilaDocument7 pagesGampaha District: LI Ii Uiladulanbackup1Pas encore d'évaluation

- Study On Structural Design of Highway Box Structures: Supervised by DR - BaskaranDocument32 pagesStudy On Structural Design of Highway Box Structures: Supervised by DR - Baskarandulanbackup1Pas encore d'évaluation

- For HB LANE4 Defined (2 Notional Lane Wide Lane)Document4 pagesFor HB LANE4 Defined (2 Notional Lane Wide Lane)dulanbackup1Pas encore d'évaluation

- Nural NetworkDocument12 pagesNural Networkdulanbackup1Pas encore d'évaluation

- Prestress Continuous Box Girder DesignDocument26 pagesPrestress Continuous Box Girder Designdulanbackup1Pas encore d'évaluation

- Dynamic AnalysisDocument17 pagesDynamic Analysisdulanbackup1Pas encore d'évaluation

- Student DirectoryDocument16 pagesStudent Directorydulanbackup1Pas encore d'évaluation

- Assignment 1.1Document9 pagesAssignment 1.1dulanbackup1Pas encore d'évaluation

- Analysis of Skew Bridge With Varying Skew AnglesDocument5 pagesAnalysis of Skew Bridge With Varying Skew AnglesFaheemPas encore d'évaluation

- 2010 Masterformat Sample JobCost Codes + NotesDocument11 pages2010 Masterformat Sample JobCost Codes + NotesYay B. GicoPas encore d'évaluation

- Rainas Municipality Office of The Municipal Executive AOC: Tinpiple, Lamjung, Gandaki Province, NepalDocument10 pagesRainas Municipality Office of The Municipal Executive AOC: Tinpiple, Lamjung, Gandaki Province, NepalLaxu KhanalPas encore d'évaluation

- Ub356 Bolted SpliceDocument4 pagesUb356 Bolted SpliceihpeterPas encore d'évaluation

- Component Catalog Tree ViewDocument5 pagesComponent Catalog Tree ViewRandistya FahmyPas encore d'évaluation

- Design of Two Way SlabDocument64 pagesDesign of Two Way SlabVINOTHINI100% (1)

- 12 Construction Details (High Rise)Document24 pages12 Construction Details (High Rise)faezah adnan100% (20)

- Jntuh SA II March-2021 PyqpDocument2 pagesJntuh SA II March-2021 PyqpPradeepkumarKatgiPas encore d'évaluation

- En 12699 2000Document70 pagesEn 12699 2000esplityPas encore d'évaluation

- Concrete Box Girder BrigdeDocument139 pagesConcrete Box Girder Brigdesujups100% (1)

- Shell StructuresDocument57 pagesShell StructuresSayed Jalilullah Ahmadi0% (1)

- Steel Fiber Reinforced ConcreteDocument6 pagesSteel Fiber Reinforced ConcretehfgfgPas encore d'évaluation

- Building StructuresDocument26 pagesBuilding StructuresYuan MingPas encore d'évaluation

- Estimation of GGBS and HVFA Strength Efficiencies in Concrete With AgeDocument6 pagesEstimation of GGBS and HVFA Strength Efficiencies in Concrete With AgeSOMPas encore d'évaluation

- Reinforced and Prestressed ConcreteDocument11 pagesReinforced and Prestressed ConcreteFiel Ericson SolaresPas encore d'évaluation

- Detail "A" (Parapet Wall) : R/F Details For Typical Wing Wall Section (C-C)Document1 pageDetail "A" (Parapet Wall) : R/F Details For Typical Wing Wall Section (C-C)sathiyanPas encore d'évaluation

- Jumbo Firewall 63/120: System: Brand: Thickness: Fire PropertiesDocument1 pageJumbo Firewall 63/120: System: Brand: Thickness: Fire PropertiesWaltonPas encore d'évaluation

- Unsymmetrical Bending and Shear CentreDocument11 pagesUnsymmetrical Bending and Shear CentreNaveen ParthasarathyPas encore d'évaluation

- COMPARATIVE STUDY OF RCC STEEL AND COMPOSITE STRUCTURES FOR INDUSTRIAL BUILDING Ijariie10646Document11 pagesCOMPARATIVE STUDY OF RCC STEEL AND COMPOSITE STRUCTURES FOR INDUSTRIAL BUILDING Ijariie10646NikhilARPas encore d'évaluation

- Daily Concrete Load Test Results Ph-cc-845 - Aug09Document2 pagesDaily Concrete Load Test Results Ph-cc-845 - Aug09Design Office njcPas encore d'évaluation

- Assignment 4 Model Answer PDFDocument8 pagesAssignment 4 Model Answer PDFRyan HuangPas encore d'évaluation

- Comparative Study On The Compressive Strength and Production Cost of Hollow Concrete Block (HCB) With and Without Red Ash in Tepi Town, EthiopiaDocument7 pagesComparative Study On The Compressive Strength and Production Cost of Hollow Concrete Block (HCB) With and Without Red Ash in Tepi Town, EthiopiaKaramara Training & ConsultancyPas encore d'évaluation

- U-Shape Drain (T-25) DU Series: FUJI Precast Concrete SolutionDocument4 pagesU-Shape Drain (T-25) DU Series: FUJI Precast Concrete SolutionshreyashPas encore d'évaluation

- Numerical Analaysis of Fire in A 24 Story StructureDocument43 pagesNumerical Analaysis of Fire in A 24 Story StructureAbrahim KazzazPas encore d'évaluation

- 21 PlasteringDocument21 pages21 Plasteringfaimy josephPas encore d'évaluation

- SECTION 400X400 - 3.5mDocument1 pageSECTION 400X400 - 3.5mloc khaPas encore d'évaluation

- Sheet Piles PT ANDALAN GLOBALINDODocument28 pagesSheet Piles PT ANDALAN GLOBALINDOqdod_waffi100% (1)

- Bpi Family Savings Bank Construction Checklist Form: Client InstructionsDocument2 pagesBpi Family Savings Bank Construction Checklist Form: Client InstructionsLouie EnriquezPas encore d'évaluation

- Bridge Technical Note 201400110 Mechanical AnchorsDocument2 pagesBridge Technical Note 201400110 Mechanical AnchorsTarek Abulail0% (1)

- Evolution of Highrise Buildings: Architectural Design - 7 SEMDocument41 pagesEvolution of Highrise Buildings: Architectural Design - 7 SEMVismithaPas encore d'évaluation