Académique Documents

Professionnel Documents

Culture Documents

Section 3: Specification Classification Product Description

Transféré par

Rudi SyamTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Section 3: Specification Classification Product Description

Transféré par

Rudi SyamDroits d'auteur :

Formats disponibles

SECTION

MANUFACTURERS OF A DIVERSE RANGE OF

ADVANCED WELDING CONSUMABLES

WI-0304 DS1 C-10, Rev. 0, Date 01.09.2008

C-10

DATA SHEET

NO.

CELLULOSE COATED ELECTRODE FOR

VERTICAL DOWN WELDS IN LARGE DIAMETER

CROSS-COUNTRY PIPELINES

SPECIFICATION

AWS A5.1

BS EN ISO 2560-B

CLASSIFICATION

E6010

E4310

PRODUCT

DESCRIPTION

The electrode contains some 35% of organic materials which in the arc transform

into a shielding gas and contributes to a concentrated deep penetrating arc with a

fast-freezing slag. The flux is extruded onto a mild steel core wire using only

sodium silicates which ensures coating strength.

WELDING

FEATURES

OF THE

ELECTRODE

The electrode is suited for use on DC+ only and is ideal for full penetration root

runs using a controlled root gap and root face and a stringer bead technique.

Slight grinding of the stringer bead with wire brushes prevents lateral inclusions

followed by a hot pass that particularly on high stressed and or high carbon steels

promotes hydrogen diffusion and thus reduces the probability of hydrogen

cracking.

Cross country pipelines - on site storage tanks in following materials - mainly root

pass:

APPLICATIONS

AND

MATERIALS

TO BE WELDED

Mild Steels: St 360, C-St 510 C, St 34.2, St 37.2, St 46.2, St 37.3, St 46.3, St 52.3.

Pressure vessel steels: H1, H11, St 35 KKW, St 41 KKW.

High strength steels: St52, St35.4, St45.4, St 52.4, StE210.7-StE415.7,

StE290.7, TM-StE415.7TM, St35.8, St45.8.

API 5LX: X42, X46, X52, X56, X60.

May also be used in root runs for higher tensile steels.

WELD METAL

ANALYSIS

COMPOSITION

% BY Wt.

Mn

Si

Cr

Ni

Mo

MIN

MAX

0.2

1.2

1.0

0.2

0.3

0.3

0.08

TYPICAL

0.1

0.6

0.2

0.03

0.02

0.04

0.05

0.02

0.01

PROPERTY

WELD METAL

PROPERTIES

(ALL WELD METAL)

WELDING

AMPERAGE

DC+ ONLY

OTHER DATA

APPROVED BY

UNITS

MINIMUM

TYPICAL

Tensile strength

N/mm

430

580

0.2% Proof stress

N/mm

330

450

Elongation on 4d

22

30

Reduction of Area (RA)

70

Impact energy -30 oC

27

50

(mm)

2.6

3.2

4.0

MIN

70

80

120

MAX

90

120

150

OTHERS

Electrodes that have become damp should be re-dried at 60oC for 30 mins.

LR - Grade 1

Fe

Bal.

Vous aimerez peut-être aussi

- Cathelco Evac ICPP ManualDocument85 pagesCathelco Evac ICPP ManualВладимир ПетрукPas encore d'évaluation

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsD'Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsÉvaluation : 4 sur 5 étoiles4/5 (1)

- Ti SPC Ohe Inscom 1070Document23 pagesTi SPC Ohe Inscom 1070hardeepsingh_08Pas encore d'évaluation

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationRudi SyamPas encore d'évaluation

- 6010Document1 page6010Starla HillPas encore d'évaluation

- Arc Brazing of Stainless Steel To Stainless Steel and Galvanised Mild SteelDocument3 pagesArc Brazing of Stainless Steel To Stainless Steel and Galvanised Mild Steelsujit kcPas encore d'évaluation

- Avesta 2205 AC DCDocument1 pageAvesta 2205 AC DCpipedown456Pas encore d'évaluation

- Nikko - Problem Steel E-309-16Document1 pageNikko - Problem Steel E-309-16TbayuPas encore d'évaluation

- Submerged Arc WeldingDocument21 pagesSubmerged Arc WeldingSACHIN A. MOREPas encore d'évaluation

- Metrode E2209 (B-60) ElectrodeDocument6 pagesMetrode E2209 (B-60) ElectrodeClaudia MmsPas encore d'évaluation

- Mild Steel 490mpa High Tensile Strength SteelDocument38 pagesMild Steel 490mpa High Tensile Strength SteelCarlos PadillaPas encore d'évaluation

- Data Sheet: Crane 2StDocument1 pageData Sheet: Crane 2StPrajapati AtulkumarPas encore d'évaluation

- 11KV TRANSMISSION LINES SpecificationDocument16 pages11KV TRANSMISSION LINES SpecificationIwan Tristiawan0% (1)

- ConsumablesDocument28 pagesConsumablesadeoye_okunoyePas encore d'évaluation

- 6 Metal Arc Welding With Coated Electrodes: 6.1 Description of The MethodDocument5 pages6 Metal Arc Welding With Coated Electrodes: 6.1 Description of The MethodstiryakiiPas encore d'évaluation

- Fire Alarm SystemDocument10 pagesFire Alarm SystemchenPas encore d'évaluation

- Mild Steel Welding Electrodes: Salient FeaturesDocument16 pagesMild Steel Welding Electrodes: Salient FeaturesHandrea Hadi SaputraPas encore d'évaluation

- B-62 2507 Rev 06Document5 pagesB-62 2507 Rev 06Shaik ShahPas encore d'évaluation

- Oxide Scale Measurement Application SolutionDocument20 pagesOxide Scale Measurement Application Solutionนูโน่ โกเมซPas encore d'évaluation

- About Welding Process 49Document1 pageAbout Welding Process 49XerexPas encore d'évaluation

- 22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeDocument7 pages22%Cr Duplex Stainless Steels: Astm Bs en & Din BS UNS Proprietary Alloys IncludeNguyen Anh TuanPas encore d'évaluation

- Avesta 2205 VDX Ac DCDocument1 pageAvesta 2205 VDX Ac DCpipedown456Pas encore d'évaluation

- Supercore D 81Document1 pageSupercore D 81camelod555Pas encore d'évaluation

- 1.smaw All PDFDocument76 pages1.smaw All PDFkaviatchennaiPas encore d'évaluation

- Dual Shield 7000a1Document1 pageDual Shield 7000a1Gokul RajanPas encore d'évaluation

- Cathodic Protection of Steel in ConcreteDocument5 pagesCathodic Protection of Steel in ConcretegersomPas encore d'évaluation

- Duplex Stainless Steel WeldingDocument25 pagesDuplex Stainless Steel Weldingkdsenipah6667Pas encore d'évaluation

- Duplex Stainless Steel WeldingDocument25 pagesDuplex Stainless Steel WeldingcfcshakerPas encore d'évaluation

- Comparison of The Use of Rutile and Cellulosic Electrodes - Job Knowledge 142Document5 pagesComparison of The Use of Rutile and Cellulosic Electrodes - Job Knowledge 142tuanPas encore d'évaluation

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationTheo AnggaraPas encore d'évaluation

- E - Lead Sheath CableDocument34 pagesE - Lead Sheath CableNelson GarvizuPas encore d'évaluation

- Chapter 14 WeldingDocument22 pagesChapter 14 WeldingRiian ApriansyahPas encore d'évaluation

- Water Agencies' Standards Standard SpecificationsDocument9 pagesWater Agencies' Standards Standard SpecificationsAdelChPas encore d'évaluation

- A 4043 TdsDocument2 pagesA 4043 Tdssajeev27Pas encore d'évaluation

- UV 420 TTR C WeldDocument1 pageUV 420 TTR C WeldasadqhsePas encore d'évaluation

- FWDocument1 pageFWDeepak BhatiPas encore d'évaluation

- CW CAT TABEL25!08!09 BewerkversieDocument46 pagesCW CAT TABEL25!08!09 BewerkversieAdeKusumahPas encore d'évaluation

- Paper - 5QA 002 SA1Document12 pagesPaper - 5QA 002 SA1kreksomukti5508100% (1)

- Spec - Ohe - Cat (Cu MG) 0120 (11 - 12 PDFDocument21 pagesSpec - Ohe - Cat (Cu MG) 0120 (11 - 12 PDFanuj sharmaPas encore d'évaluation

- Eil Spec Bo16-000-80-44-Ol-S001 Rev ADocument2 pagesEil Spec Bo16-000-80-44-Ol-S001 Rev AjaganPas encore d'évaluation

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationIam FroilanPas encore d'évaluation

- Offshore 6 10kv Power Cable Bs6883 Iec60092 3 Iec60332 UkooaDocument2 pagesOffshore 6 10kv Power Cable Bs6883 Iec60092 3 Iec60332 UkooaSudip ChakrabortyPas encore d'évaluation

- Job Knowledge 12Document3 pagesJob Knowledge 12Mehmet SoysalPas encore d'évaluation

- OK 48.20 ESAB 36 H (SPL) : A Basic Coated Low-Hydrogen Electrode For MMAW A Basic Coated Electrode For MMAWDocument1 pageOK 48.20 ESAB 36 H (SPL) : A Basic Coated Low-Hydrogen Electrode For MMAW A Basic Coated Electrode For MMAWGokul RajanPas encore d'évaluation

- NSB 316LR0 PDFDocument1 pageNSB 316LR0 PDFDika AnggaraPas encore d'évaluation

- Chapter - E12: Requirements of Auxiliary Items Aluminium Tubular ConductorDocument10 pagesChapter - E12: Requirements of Auxiliary Items Aluminium Tubular ConductorvenkateshbitraPas encore d'évaluation

- Lecture 7 & 8: Submerged Arc WeldingDocument4 pagesLecture 7 & 8: Submerged Arc Weldingরিপন মন্ডলPas encore d'évaluation

- API Self NotesDocument13 pagesAPI Self NotesOwais AlamPas encore d'évaluation

- Ministry of Railways Manak Nagar, Lucknow 226 011Document24 pagesMinistry of Railways Manak Nagar, Lucknow 226 011Sameer KattiPas encore d'évaluation

- Types of InductorsDocument14 pagesTypes of InductorsSan G. AbirinPas encore d'évaluation

- 1.4462 EN-material Duplex PDFDocument3 pages1.4462 EN-material Duplex PDFtien100% (1)

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationTheo AnggaraPas encore d'évaluation

- Welding of Copper and Its AlloysDocument30 pagesWelding of Copper and Its Alloysaj87_goswami100% (2)

- D&H Secheron in Cement ApplicationDocument1 pageD&H Secheron in Cement ApplicationGyanaranjan2011Pas encore d'évaluation

- Electro Slag Strip Cladding ProcessDocument5 pagesElectro Slag Strip Cladding ProcessIJMERPas encore d'évaluation

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesD'EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesPas encore d'évaluation

- Argonaut Bogie Spare Parts Listing PAGE 7Document1 pageArgonaut Bogie Spare Parts Listing PAGE 7Rudi SyamPas encore d'évaluation

- Dalle BesarDocument7 pagesDalle BesarRudi SyamPas encore d'évaluation

- Argonaut Bogie Spare Parts Listing Page 8Document1 pageArgonaut Bogie Spare Parts Listing Page 8Rudi SyamPas encore d'évaluation

- Vendor Registration FormDocument7 pagesVendor Registration FormRudi SyamPas encore d'évaluation

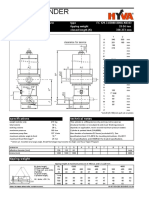

- HyvaDocument2 pagesHyvaRudi SyamPas encore d'évaluation

- Service Manual: TF SeriesDocument52 pagesService Manual: TF SeriesRudi SyamPas encore d'évaluation

- Accumulator PartsDocument98 pagesAccumulator PartsRudi Syam100% (1)

- Alfagoma 6j511Document1 pageAlfagoma 6j511Rudi SyamPas encore d'évaluation

- HPF Catalog OpenAndCloseDocument68 pagesHPF Catalog OpenAndCloseRudi SyamPas encore d'évaluation

- Aringo ComputerDocument1 pageAringo ComputerRudi SyamPas encore d'évaluation

- IrwinDocument8 pagesIrwinRudi SyamPas encore d'évaluation

- Raychem JBS100Document3 pagesRaychem JBS100Rudi SyamPas encore d'évaluation

- En RaychemE100LAendseal IM H59141 Tcm432 51607Document8 pagesEn RaychemE100LAendseal IM H59141 Tcm432 51607Rudi SyamPas encore d'évaluation

- Coverall NomexDocument60 pagesCoverall NomexRudi SyamPas encore d'évaluation

- Drawing3 ModelDocument1 pageDrawing3 ModelRudi SyamPas encore d'évaluation