Académique Documents

Professionnel Documents

Culture Documents

Leak Test

Transféré par

Christian D. OrbeDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Leak Test

Transféré par

Christian D. OrbeDroits d'auteur :

Formats disponibles

jqeng (Structural)

(OP)

4 Apr 11 09:58

I have a concrete tank that needs a leak test done. The leak test will be done after its

already been backfilled and the tank is 21m by 21m and holds about 3000m3 of water.

Wall thickness ranges from 600mm at the bottom to 450mm at the top (7.1m tall). My

question is once the tank is filled up, the concrete will absorb some of the water. How

long should I wait before I start my actual measurement of change in water height. How

long should I give the concrete to absorb the bulk of what it will absorb?

bimr (Civil/Environmental)4 Apr 11 10:34

Here is a specification for the test:

A. Upon completion, the tank shall be tested to determine watertightness. The tank shall

be filled with potable water to the maximum level.

The test shall consist of measuring the liquid level over the next 24 hours to determine if

any change has occurred. If a change is observed and exceeds the maximum allowance,

the test shall be extended to a total of five days. If at the end of five days the average

daily change has not exceeded the maximum allowance, the test shall be considered

satisfactory.

B. The liquid volume loss for a period of 24 hours shall not exceed one-twentieth of one

percent of the tank capacity, 0.0005 x tank volume. If the liquid volume loss exceeds this

amount, it shall be considered excessive, and the tank shall be repaired and retested.

C. Damp spots will not be permitted at any location on the tank wall. Damp spots are

defined as spots where moisture can be picked up on a dry hand. All such areas shall be

repaired as necessary.

D. Damp spots or standing water on the footing may occur upon tank filling and are

permissible within the allowable volume loss. Measurable flow in this area is not

permissible and must be corrected.

Per AWWA, the allowable leakage rate is 0.1 percent of the water volume in 24 hour.

You can always specify higher requirements than the minimum standards.

This issue was previously discussed:

http://www.eng-tips.com/viewthread.cfm?qid=222702&page=15

jqeng (Structural)

(OP)

4 Apr 11 10:57

Thanks bimr,

Would you be able to provide me a link to this specification and also does the AWWA

allowable leaked rate of 0.1 include concrete absorption? Shouldn't concrete absorption

vary for different concrete mixes and other factors?

MiketheEngineer (Structural)4 Apr 11 13:23

What about evaporation??

bimr (Civil/Environmental)4 Apr 11 16:16

You will need to allow the tank to stabilize for three (3) days while the water is absorbed

into the concrete.

http://www.mwua.org/Presentations/MalenfantAPR07.pdf

You also have to allow for evaporation and rain.

http://www.cement.org/bookstore/profile.asp?itemid=LT186

waterpipe (Mechanical)6 Apr 11 05:40

@bimr: I am not sure if AWWA provides a standard or a guideline for concrete water tanks.

Would you please provide the standard number for the allowable leakage rate is 0.1

percent of the water volume in 24 hour?

@jqeng: Please note that there is maximum rate of a filling for a water tank that is being

filled for the first time. I have the uniform rate of not greater than 2 m in 24 h in back of

my head.

Getting to your questions, the stabilizing period depends on the maximum design crack

width and the time needed for the healing. I remember it was 7 days for a crack width of

0.1 mm according to BS. there is also a limit for the maximum drop in level during this 7day test based on the full tank depth. I suggest to take a look to the latest BS standard.

BTW, there is also a separate test for the roof.

jqeng (Structural)

(OP)

6 Apr 11 11:35

@bimr: The link you gave quoted the ACI 350.01-01 Clause 2.3.5. I have the ACI 350.1-06

and could not find the wording from this clause anywhere do you know what the new

clause in the 06 version is?

@waterpipe: thanks for your response, as a note Im new and I didnt think that my first

post worked so I reposted when I found this thread! Turns out they both worked.

bimr (Civil/Environmental)6 Apr 11 13:34

The ANSI/AWWA D110-04 (Wire- and Strand-Wound, Circular, Prestressed Concrete Water

Tanks) and the ANSI/AWWA D115-95 (CIRCULAR PRESTRESSED CONCRETE WATER

TANKS)have leakage rates specified. The net liquid loss for a period of 24 hr shall not

exceed 0.05 of 1 percent of the tank capacity.

http://files.engineering.com/getfile.aspx?folder=c99713d8-e983-49dd-b8ed-2e

nackra (Civil/Environmental)6 Apr 11 19:48

Is the purpose of the tank for potable water storage?

I worked on a project where inadequate concrete consolidation resulted in significant

segregration (you could see through the walls after the forms were removed. The

contractor used epoxy grout repairs and tried testing with this method to check repairs.

Wave action was an issue to record surface level changes. We tried a stilling well but still

could not get a "steady" level.

We excavated a few areas and found leaks where water squirted out of pinhole leaks.

Additional repairs were required.

Depending on the purpose of the tank and future maintenance costs - you might consider

coating the tank.

waterpipe (Mechanical)8 Apr 11 10:25

Thank you bimr.

I was thinking of ordinary reinforced concrete water tanks (normally rectangular), which is

not by AWWA. But I see no reason to apply the acceptance of the leakage for a

prestressed concrete water tanks to the ordinary one.

bimr (Civil/Environmental)8 Apr 11 11:10

waterpipe; Consider that the prestressed tank walls are typically thinner than standard

cast-in-place concrete, that quality concrete construction should be impermeable, that

wall segments for the ANSI/AWWA D115-95 standard are also cast-in-place concrete, and

that the application is also for storing water. Yhere should be no reason not to use the

same AWWA leakage rate.

http://www.durastortank.com/tabid/1583/Default.aspx

waterpipe (Mechanical)8 Apr 11 11:31

Thanks bimr.

Sorry but I meant:

" I see no reason NOT to apply the acceptance of the leakage for a prestressed concrete

water tanks to the ordinary one."

but I've missed the NOT, for the same reason I've missed "covered" before "by AWWA" in

my respond! So I fully agree with you on applicability of the leakage rate.

Well, this could be the Friday afternoon "allergy", which means I have to leave the office

for a happy hour! I do it in 10 minutes.

Have a nice weekend.

Will007 (Civil/Environmental)

(OP)

29 Jul 08 11:14

Hi,

Does anyone know what the allowable leakage is for a concrete tank. Some say its

0.5%. Is this correct?

We just put a 150k gallon up and is ready for commision, but we need to verify that the

leak test passed.

Please advise.

Thanks

Ussuri (Civil/Environmental)29 Jul 08 11:28

The text below is copied from the British Standard for water retaining tanks. Probably not

applicable for you but might give you some idea.

Quote (BS 8007 clause 9.2):

When first filled, the liquid level should be maintained by the addition of further liquid for a

stabilizing period while absorption and autogenous healing take place. The stabilizing period may be

7 days for a maximum design crack width of 0.1 mm or 21 days for 0.2 mm or greater. After the

stabilizing period the level of the liquid surface should be recorded at 24 h intervals for a test period

of 7 days. During this 7-day test period the total permissible drop in level, after allowing for

evaporation and rainfall, should not exceed 1/500th of the average water depth of the full tank, 10

mm or another specified amount.

JedClampett (Structural)29 Jul 08 13:20

We use .1% per day.

bimr (Civil/Environmental)29 Jul 08 16:54

A. Upon completion, the tank shall be tested to determine watertightness. The tank shall

be filled with potable water to the maximum level.

The test shall consist of measuring the liquid level over the next 24 hours to determine if

any change has occurred. If a change is observed and exceeds the maximum allowance,

the test shall be extended to a total of five days. If at the end of five days the average

daily change has not exceeded the maximum allowance, the test shall be considered

satisfactory.

B. The liquid volume loss for a period of 24 hours shall not exceed one-twentieth of one

percent of the tank capacity, 0.0005 x tank volume. If the liquid volume

loss exceeds this amount, it shall be considered excessive, and the tank shall be repaired

and retested.

C. Damp spots will not be permitted at any location on the tank wall. Damp spots are

defined as spots where moisture can be picked up on a dry hand. All such areas shall be

repaired as necessary.

D. Damp spots or standing water on the footing may occur upon tank filling and are

permissible within the allowable volume loss. Measurable flow in this area is not

permissible and must be corrected.

RWF7437 (Civil/Environmental)29 Jul 08 17:01

"10 mm or another specified amount."

Perfect !

Ussuri (Civil/Environmental)31 Jul 08 04:32

RWF7437, yeah, that is a good one. I believe the purpose of the statement is to allow you

to impose a more restrictive limit if you so desire.

JStephen (Mechanical)1 Aug 08 16:43

If it's built to an AWWA standard, that standard should specify allowable leakage.

cvg (Civil/Environmental)6 Aug 08 19:16

A properly constructed concrete tank should exhibit essentially no leakage. If any leaks

are observed on the structure or on the ground, they should be investigated and

repaired. Go with the smallest allowable amount you can measure. This will depend a bit

on the geometry of your tank and your measuring equipment. BIMR's spec is probably

about the smallest amount you can easily measure. However, now that the tank is

completely constructed is a bit late to tell the contractor what the allowable leakage will

be

Vous aimerez peut-être aussi

- QA/QC Plan Ensures Project ComplianceDocument18 pagesQA/QC Plan Ensures Project ComplianceSen IMO67% (3)

- rev01-METHOD STATEMENT FOR INSTALLATION OF LINER TANK FOUNDATIONDocument7 pagesrev01-METHOD STATEMENT FOR INSTALLATION OF LINER TANK FOUNDATIONMahaboob PashaPas encore d'évaluation

- GRP Installation GuideDocument13 pagesGRP Installation GuidepparreraPas encore d'évaluation

- Construction Method Statement For Under Ground Water TankDocument2 pagesConstruction Method Statement For Under Ground Water Tanksandycrackjack0% (1)

- P610 Beinn Eagagach Hydroelectric Scheme Construction MethodDocument14 pagesP610 Beinn Eagagach Hydroelectric Scheme Construction MethoddjgiumixPas encore d'évaluation

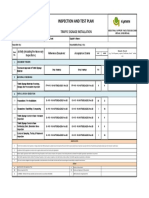

- Traffic Signage Installation ITPDocument1 pageTraffic Signage Installation ITPmoytabura96Pas encore d'évaluation

- Install Insulated CladdingDocument16 pagesInstall Insulated CladdingfabinPas encore d'évaluation

- Method Statement - Chemical CleaningDocument12 pagesMethod Statement - Chemical Cleaningdadz mingiPas encore d'évaluation

- 027 ITP For Pre Cast Concrete PDFDocument27 pages027 ITP For Pre Cast Concrete PDFlinga2014Pas encore d'évaluation

- Method of Statement For HDPE Pipe InstallationDocument2 pagesMethod of Statement For HDPE Pipe InstallationYe Yint100% (2)

- Epoxy Painting Method GuideDocument3 pagesEpoxy Painting Method GuideKaram MoatasemPas encore d'évaluation

- ITP C 005 (Structural Concrete)Document4 pagesITP C 005 (Structural Concrete)segun ajibolaPas encore d'évaluation

- Construction Method StatementDocument18 pagesConstruction Method StatementAziz RahmanPas encore d'évaluation

- De-Watering Method StatementDocument1 pageDe-Watering Method StatementSupun SandaruwanPas encore d'évaluation

- Surface GI Conduit Installation Method StatementDocument4 pagesSurface GI Conduit Installation Method StatementJanePas encore d'évaluation

- Screeding WorksDocument1 pageScreeding WorksCindy AmyzaPas encore d'évaluation

- Renovation Works at Al Forsan Sports ResortDocument7 pagesRenovation Works at Al Forsan Sports ResortAshimolowo BabatundePas encore d'évaluation

- Installation Of Ductile Iron Flange Type Joint MethodDocument10 pagesInstallation Of Ductile Iron Flange Type Joint MethodshahidPas encore d'évaluation

- Application ProcedureDocument18 pagesApplication ProcedureTeguh SilaPas encore d'évaluation

- Hume Pipe Method StatementDocument2 pagesHume Pipe Method StatementDurgawati Mishra67% (3)

- Testing and inspection of pipelines and structuresDocument6 pagesTesting and inspection of pipelines and structureskarri1963100% (1)

- Earthwork Excavation-Method StatementDocument4 pagesEarthwork Excavation-Method StatementKhaled AbdelbakiPas encore d'évaluation

- Method Statements of Surface Treatment and Painting For Valves Nh3 ProjectDocument5 pagesMethod Statements of Surface Treatment and Painting For Valves Nh3 ProjectDuongthithuydung0% (1)

- Epoxy Method 2Document11 pagesEpoxy Method 2Mohamed BadrPas encore d'évaluation

- Method Statement For GRP Pipe InstallationDocument8 pagesMethod Statement For GRP Pipe Installationdj_holo100% (1)

- Inspection & Test Plan: Stone Works As Shown in The DrawingsDocument2 pagesInspection & Test Plan: Stone Works As Shown in The DrawingsharikrishnaPas encore d'évaluation

- Sewerage and WWTP measures in the city of Korca“ project testing proceduresDocument9 pagesSewerage and WWTP measures in the city of Korca“ project testing proceduresJohnny RamboPas encore d'évaluation

- SITE-SPECIFIC QC PLANDocument3 pagesSITE-SPECIFIC QC PLANloveanbu24100% (1)

- MS For Leak Testing of TanksDocument5 pagesMS For Leak Testing of TanksOmar Tocmo100% (1)

- METHOD OF BLINDING CONCRETE WORKSDocument6 pagesMETHOD OF BLINDING CONCRETE WORKSMohd Muksin100% (1)

- Method Statement For Fire TankDocument2 pagesMethod Statement For Fire TankJoyanta DebPas encore d'évaluation

- UPVC High Pressure Water Supply Piping System Installation ProcedureDocument3 pagesUPVC High Pressure Water Supply Piping System Installation ProcedureAl Mumeen Construction ServicesPas encore d'évaluation

- Method Statement For Wall Panels InstallationDocument11 pagesMethod Statement For Wall Panels InstallationChristos LoutrakisPas encore d'évaluation

- Method Statement For ScaffoldingDocument3 pagesMethod Statement For ScaffoldingDouglas JambaPas encore d'évaluation

- Water RecDocument9 pagesWater RecToyEn MEgatPas encore d'évaluation

- Method StatementDocument4 pagesMethod StatementSagar ParabPas encore d'évaluation

- Method Statement For Painting of ValvesDocument4 pagesMethod Statement For Painting of ValvesRashid Kayum100% (1)

- Method Statement For Claustra Block Works.Document12 pagesMethod Statement For Claustra Block Works.sathiyaprasath80% (5)

- MOS For Water Supply Pipe InstallationDocument3 pagesMOS For Water Supply Pipe InstallationDon Roseller Dumaya100% (1)

- Method Statement FOR Embedded Conduits, Boxes and Fittings InstallationDocument6 pagesMethod Statement FOR Embedded Conduits, Boxes and Fittings InstallationWalidPas encore d'évaluation

- Cem Tec White PuDocument2 pagesCem Tec White Pupravi3434Pas encore d'évaluation

- ITP For Concrete Paving WorkDocument15 pagesITP For Concrete Paving WorkShewale PravinPas encore d'évaluation

- CV-0013-005 - Method Statement For Concrete Work (Revised)Document13 pagesCV-0013-005 - Method Statement For Concrete Work (Revised)한상호Pas encore d'évaluation

- Method Statement: Water Leakage Detection SurveyDocument16 pagesMethod Statement: Water Leakage Detection SurveyPhara LuckyPas encore d'évaluation

- MGB-MS-003-ST-003 Formwork InstallationDocument8 pagesMGB-MS-003-ST-003 Formwork InstallationImho Tep100% (1)

- Concreting MethodologyDocument2 pagesConcreting Methodologyervnglen08Pas encore d'évaluation

- SECTION 700 (Pipe Drains, Pipe Culvert, Concrete Channels)Document9 pagesSECTION 700 (Pipe Drains, Pipe Culvert, Concrete Channels)akvosmPas encore d'évaluation

- Method Statement for New Petrol Filling Station DemolitionDocument15 pagesMethod Statement for New Petrol Filling Station DemolitionmuthunayakePas encore d'évaluation

- Method of Statement For Surface Preparation & PaintingDocument27 pagesMethod of Statement For Surface Preparation & PaintingABAID ULLAH100% (1)

- Method Statement For Installation Anchor BoltsDocument7 pagesMethod Statement For Installation Anchor BoltsSyed AtherPas encore d'évaluation

- Hose Testing Doors WindowsDocument6 pagesHose Testing Doors WindowsRavi ValiyaPas encore d'évaluation

- KAPSARC-MRK-Concrete Repair work-METHOD STATEMENTDocument4 pagesKAPSARC-MRK-Concrete Repair work-METHOD STATEMENTsherwin suarezPas encore d'évaluation

- Material Receiving ProcedureDocument10 pagesMaterial Receiving ProcedureRaziKhanPas encore d'évaluation

- Method Statement For Stone WorksDocument10 pagesMethod Statement For Stone WorksvisanuPas encore d'évaluation

- 03 Strength Assessment of Recycled Aggregate Concrete by Ultrasonic Pulse Velocity Test PDFDocument5 pages03 Strength Assessment of Recycled Aggregate Concrete by Ultrasonic Pulse Velocity Test PDFYati R. TankPas encore d'évaluation

- MOS of BackfillingDocument2 pagesMOS of BackfillingPoru ManPas encore d'évaluation

- General Civil Work Method Statement For RoadsDocument3 pagesGeneral Civil Work Method Statement For RoadsKaram MoatasemPas encore d'évaluation

- Part I - 12 Material HandlingDocument7 pagesPart I - 12 Material Handlingsalah abddayemPas encore d'évaluation

- Spe 147765 Advanced Chemical Water-Shutoff Treatments in Multilayer Gas Reservoirs: A Case Study Frompeciko Field, East Kalimantan, IndonesiaDocument12 pagesSpe 147765 Advanced Chemical Water-Shutoff Treatments in Multilayer Gas Reservoirs: A Case Study Frompeciko Field, East Kalimantan, Indonesiahade wantoPas encore d'évaluation

- Disposal Water WellsDocument4 pagesDisposal Water WellsRichi SBPas encore d'évaluation

- Al Dhow Passport Request FormDocument1 pageAl Dhow Passport Request FormChristian D. OrbePas encore d'évaluation

- How To Pay Your Kaiser Premiums or Mutual Fund Investments Rev1Document4 pagesHow To Pay Your Kaiser Premiums or Mutual Fund Investments Rev1Christian D. OrbePas encore d'évaluation

- Christian Excuse LettersDocument3 pagesChristian Excuse LettersChristian D. OrbePas encore d'évaluation

- Doosan Heavy Industries Approves Fosroc's Supercast SW30 WaterstopDocument1 pageDoosan Heavy Industries Approves Fosroc's Supercast SW30 WaterstopChristian D. OrbePas encore d'évaluation

- Loading Analysis of Existing PipelinesDocument13 pagesLoading Analysis of Existing PipelinesRahmat RiskiPas encore d'évaluation

- 10 - Vol3 - 1939 Seismic Forces in Underground StructuresDocument6 pages10 - Vol3 - 1939 Seismic Forces in Underground StructuresChristian D. OrbePas encore d'évaluation

- Audit Procedures - ACCA Qualification - Students - ACCA GlobalDocument4 pagesAudit Procedures - ACCA Qualification - Students - ACCA GlobalChristian D. OrbePas encore d'évaluation

- Room For Rent For Pilipino Only: Original Room or Partition Room at Block 10, Fahaheel Back of Police Steak Available NowDocument1 pageRoom For Rent For Pilipino Only: Original Room or Partition Room at Block 10, Fahaheel Back of Police Steak Available NowChristian D. OrbePas encore d'évaluation

- 12+internal Audit ProceduresDocument1 page12+internal Audit ProceduresChristian D. OrbePas encore d'évaluation

- DLSU Student Admission OfficeDocument3 pagesDLSU Student Admission OfficeChristian D. OrbePas encore d'évaluation

- 2016 SSS Guidebook FuneralDocument4 pages2016 SSS Guidebook FuneralKen LesterPas encore d'évaluation

- Design TruckLoads PDFDocument6 pagesDesign TruckLoads PDFChristian D. OrbePas encore d'évaluation

- Christmastide Ahmadi 2016 PDFDocument1 pageChristmastide Ahmadi 2016 PDFChristian D. OrbePas encore d'évaluation

- ASCE 07-2005 Live Loads PreviewDocument2 pagesASCE 07-2005 Live Loads PreviewChristian D. OrbePas encore d'évaluation

- A Practical Guide For Using Micro Station V8i SS2Document180 pagesA Practical Guide For Using Micro Station V8i SS2Leon TralyPas encore d'évaluation

- Sheet Pile Design HandbookDocument368 pagesSheet Pile Design HandbookLandon Mitchell92% (12)

- CapacityDocument1 pageCapacityChristian D. OrbePas encore d'évaluation

- Mechanics of Pile Cap and Pile GroupDocument69 pagesMechanics of Pile Cap and Pile Grouppk100% (1)

- SMC Financial Statements 2012Document104 pagesSMC Financial Statements 2012Christian D. OrbePas encore d'évaluation

- Getting Started PDFDocument261 pagesGetting Started PDFChristian D. OrbePas encore d'évaluation

- Special Power of AttorneyDocument1 pageSpecial Power of AttorneyNowhere Man92% (12)

- Ametank Model Example 2 API 650 Calculation Report PDFDocument54 pagesAmetank Model Example 2 API 650 Calculation Report PDFChristian D. Orbe100% (1)

- Deed of Donation FormsDocument5 pagesDeed of Donation FormsJecky Delos Reyes100% (1)

- Permission To Stay Outside Kuwait More Than 6 MonthsDocument1 pagePermission To Stay Outside Kuwait More Than 6 MonthsChristian D. Orbe100% (1)

- Deed of Sale Motorcycle FranchiseDocument1 pageDeed of Sale Motorcycle FranchiseChristian D. OrbePas encore d'évaluation

- KWT83617 EnglishDocument25 pagesKWT83617 EnglishAbdalla JamousPas encore d'évaluation

- Sik AP VilleDocument8 pagesSik AP VilleChristian D. OrbePas encore d'évaluation

- Mcleod Investigation 2013 PDFDocument203 pagesMcleod Investigation 2013 PDFChristian D. OrbePas encore d'évaluation

- Lessons in Water Treatment and DistributionDocument203 pagesLessons in Water Treatment and DistributionChristian D. OrbePas encore d'évaluation

- Christmastide Ahmadi 2016Document1 pageChristmastide Ahmadi 2016Christian D. OrbePas encore d'évaluation

- 127 Permenakertrans No. Per.15 Men Viii 2008 Tentang Pertolongan Pertama Pada Kecelakaan Di Tempat KerjaDocument6 pages127 Permenakertrans No. Per.15 Men Viii 2008 Tentang Pertolongan Pertama Pada Kecelakaan Di Tempat KerjaWAHYUDI SYAHPUTRA SKMPas encore d'évaluation

- Exhaust GasDocument6 pagesExhaust Gaschinnasamy76Pas encore d'évaluation

- 26369477.aus H Converting Units AusDocument28 pages26369477.aus H Converting Units AusShane RajapakshaPas encore d'évaluation

- Math 5 Q4 W4 Day 1 2Document23 pagesMath 5 Q4 W4 Day 1 2Maribel Felipe ValdezPas encore d'évaluation

- JZ 2019Document36 pagesJZ 2019msimic57Pas encore d'évaluation

- Superquadrics and Their Geometric PropertiesDocument27 pagesSuperquadrics and Their Geometric PropertiesBRANDON ALBERTO QUINTERO CIFUENTESPas encore d'évaluation

- Dimensions of Physical Quantities DensityDocument100 pagesDimensions of Physical Quantities DensityGerman Rincon UrregoPas encore d'évaluation

- Volume of Rectangular PrismsDocument8 pagesVolume of Rectangular PrismsMary Rose Usi BalingitPas encore d'évaluation

- Cambridge IGCSE: MATHEMATICS 0580/43Document20 pagesCambridge IGCSE: MATHEMATICS 0580/43kdebipershadPas encore d'évaluation

- Principles of Gas-Solid Flows-Fan, Zhu PDFDocument575 pagesPrinciples of Gas-Solid Flows-Fan, Zhu PDFcankushbjk100% (1)

- Medical Gases: E-Tender Document For The Supply ofDocument31 pagesMedical Gases: E-Tender Document For The Supply ofFWEFWEFWPas encore d'évaluation

- Tappi 0502 17 Papermaker Formula PDFDocument19 pagesTappi 0502 17 Papermaker Formula PDFHgagselim SelimPas encore d'évaluation

- K/ We/Fltf: Ijht Dtl1Sa-Y S/'J) JfiDocument1 pageK/ We/Fltf: Ijht Dtl1Sa-Y S/'J) JfiLit Pao WongPas encore d'évaluation

- 10 Similar SolidsDocument4 pages10 Similar SolidsJeffrey Melon TinaganPas encore d'évaluation

- Chain Rule, Implicit Differentiation and Linear Approximation and DifferentialsDocument39 pagesChain Rule, Implicit Differentiation and Linear Approximation and Differentialsanon-923611100% (1)

- Expirement No.1 MEASUREMENTSDocument4 pagesExpirement No.1 MEASUREMENTSskt zedPas encore d'évaluation

- Viscosity and Density Measurements of LiquidsDocument11 pagesViscosity and Density Measurements of LiquidsJames Aaron SantiagoPas encore d'évaluation

- Aggregate Angularity NumberDocument5 pagesAggregate Angularity NumberAdnan AhmadPas encore d'évaluation

- QRT4 WEEK 4 TG Lesson 90Document5 pagesQRT4 WEEK 4 TG Lesson 90Madonna Arit MatulacPas encore d'évaluation

- JuiceboxweeblyDocument17 pagesJuiceboxweeblyapi-31341638050% (2)

- NITP 10.1 National Instrument Test Procedures For LPG DispensersDocument33 pagesNITP 10.1 National Instrument Test Procedures For LPG DispensersJorge Kovach AlvaradoPas encore d'évaluation

- Govt-Approved Calibration Experts Explain Tank Calibration MethodsDocument28 pagesGovt-Approved Calibration Experts Explain Tank Calibration MethodsParameshPas encore d'évaluation

- Student Exploration: Density Laboratory: Vocabulary: Buoyancy, Density, Graduated Cylinder, Mass, Matter, Scale, VolumeDocument5 pagesStudent Exploration: Density Laboratory: Vocabulary: Buoyancy, Density, Graduated Cylinder, Mass, Matter, Scale, VolumeYesenia Montanez100% (1)

- All You Wanted To Know About: Cargo CalculationsDocument35 pagesAll You Wanted To Know About: Cargo CalculationsGlen Mac100% (1)

- SAP IS-OIL Silos ManagementDocument14 pagesSAP IS-OIL Silos ManagementIsaac Andrade100% (2)

- Tank Volume CalculatorDocument1 pageTank Volume Calculatorpappu_bharat007Pas encore d'évaluation

- ElectrostaticsExercise 2Document3 pagesElectrostaticsExercise 2Rushwin VaishnavPas encore d'évaluation

- Mary L Boas Edisi 3 Bab5 Integral PermukaanDocument7 pagesMary L Boas Edisi 3 Bab5 Integral Permukaansel viaPas encore d'évaluation

- 1st Year Experiment 1 - 2022Document6 pages1st Year Experiment 1 - 2022gerald07bwalyaPas encore d'évaluation