Académique Documents

Professionnel Documents

Culture Documents

The Fundamentals of Photovoltaic Systems

Transféré par

rajuanthatiDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

The Fundamentals of Photovoltaic Systems

Transféré par

rajuanthatiDroits d'auteur :

Formats disponibles

The Fundamentals of Photovoltaic Systems

1 of 5

http://ecmweb.com/print/contractor/fundamentals-photovoltaic-systems

print | close

Electrical Construction and Maintenance

Ryan Mayfield, Renewable Energy Associates

Sun, 2012-01-01 09:00

Over the past several years, the solar photovoltaic (PV) industry has enjoyed substantial growth. According to

the Solar Energy Industries Association (SEIA) and GTM Research, cumulative grid-connected PV in the United

States has now reached 3.1 GW 10 times the size of the countrys solar capacity in 2005. While some

projections call for this segment to hit a speed bump this year considering the uncertain effects of the U.S.

Treasury 1603 tax grant program possibly expiring at the end of the year (unless Congress extends it) coupled

with the U.S. governments reaction to a call for import duties on Chinese-manufactured PV cells and modules

most analysts anticipate the solar industry will continue on its expansion path. Thats good news for electrical

contractors.

A typical PV array mounted on a residential roof.

Individual modules are attached to a racking system

and wired together to form an array.

Thanks to popular demand, these systems are no longer installed exclusively by specialty solar contractors a

situation that opens up ongoing revenue streams for electrical contractors, who are being asked to broaden their

scope of work and provide PV installation services. This article will introduce you to the major system types and

most commonly used components within various types of PV systems. Armed with this fundamental

information, you should come away with a basic understanding of how these different systems operate and how

the associated components are involved in their design. In future articles, well focus on the exact design and

installation parameters for PV systems as a whole.

System Configurations

The first important point to establish is the difference between the most common types of PV systems. There are

applications for PV systems all the way from small electronics to solar attic fans to electric utility power plants.

However, the majority of installations most contractors come across involve residential and commercial

applications.

07-03-15 5:39 PM

The Fundamentals of Photovoltaic Systems

2 of 5

http://ecmweb.com/print/contractor/fundamentals-photovoltaic-systems

When it comes to residential projects, PV systems can be broadly categorized by the presence, or lack thereof, of

the electric utility grid. These systems are classified as either stand-alone or utility-interactive.

Stand-alone systems are those that do not have access to the electric utility grid, often referred to as off-grid

systems. Typically found in remote locations, they generally use batteries to store energy produced by the PV

array. Stand-alone systems normally use a traditional generator to charge batteries during times of the year

when solar resources are minimal or when the array is unable to keep up with energy demands of the household.

Generally more complex, these systems require more design and installation time than grid-direct systems.

Utility-interactive systems are those that do exactly that: interact with the electric utility power system. The

power electronics used in these systems, namely the inverters, monitor the grid and react automatically to the

conditions the grid presents. Utility-interactive systems can be broken down into two subcategories grid-direct

or backup systems. In commercial PV applications, the systems are nearly universally utility-interactive,

grid-direct systems.

Tax incentives and electric utility rebate programs have made utility-interactive systems the largest market for

PV to date. These systems are able to interconnect with and work in parallel with the electric utility grid. In a

situation where the PV array is producing more power than what is being consumed on site, the inverter is able

to push that power back onto the electric utility line, essentially running the customers meter backward and

allowing the customer to sell energy to the electric utility. Then, as the sun goes down and more loads are turned

on, the meter begins to run forward again, causing the customer to buy back energy from the electric utility.

When the sun is up but the loads within the building are consuming more than the solar system is producing, the

electric utility makes up the difference but the meter is moving slower than it would if the PV array wasnt

present.

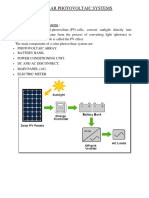

In utility-interactive, grid-direct systems, as shown in Fig. 1 (click here to see Fig. 1), there is no energy storage,

and the PV modules are connected to an inverter, which inverts the DC power produced by the PV modules into

AC power that matches the grid power. These systems have the advantage of higher efficiencies and are more

simplistic in their design/installation compared to their backup counterparts. Because the grid-direct systems

do not employ a method of storing energy, when the electric utility grid fails, they automatically shut down until

the grid is back up. On the other hand, utility-interactive, backup systems, as shown in Fig. 2 (click here to see

Fig. 2), do employ energy storage, typically in the form of a battery bank. These systems can operate specific

loads that have been isolated from the main distribution panel and are connected to a backup load center. It is

common for these systems to only run a few loads off the backup system, not the whole house. If a whole house

backup is required, doing so with a battery bank and inverter system can be difficult.

All utility-interactive systems use a safety feature known as anti-islanding to prevent the solar array from

remaining connected to the electric utility when the grid is down. The inverters used in utility interactive systems

are required by UL1741 listing to disconnect themselves from the grid when the voltage or frequency of the

electric utility falls out of a specific range. The inverters will automatically reconnect to the electric utility system

only after the voltage and frequency values are within the acceptable range for five continuous minutes. This is a

safety feature to protect electric utility line workers from being injured by PV systems that are pushing power

back on to otherwise de-energized power lines.

System Components

Now that you have a better feel for the major types of systems being designed and installed today, lets go over

the major system components used in these systems. This list will not be all inclusive, but rather a good primer

on the major components and the roles they play in the entire system.

Modules The heart of the PV system is the module, an individual unit that contains a number of PV cells,

07-03-15 5:39 PM

The Fundamentals of Photovoltaic Systems

3 of 5

http://ecmweb.com/print/contractor/fundamentals-photovoltaic-systems

typically encapsulated behind a sheet of glass with an aluminum frame protecting the edges. A number of PV

modules are wired together to produce a desired amount of voltage and current that matches the requirements

of the power electronics connected on the other end of the PV array. In grid-direct PV systems, a number of

modules are typically connected in series to create a string of modules that can operate at elevated voltages (i.e.,

up to 600VDC in some situations). Battery-based systems, either stand-alone or utility-interactive, will generally

operate at lower voltage levels but can still exceed 150VDC within the string. These PV strings are then

connected in parallel to create the PV array.

PV modules are offered in a variety of technologies; however, crystalline silicone modules are the most

commonly used. Thin film modules, such as amorphous crystalline or cadmium telluride, are another category

of PV modules you may come across.

Racking Traditional PV modules require a support structure to hold the array in place. There are modules

known as building integrated photovoltaics (BIPV) that actually replace the outer shell of a building, but these

systems are not as common as PV modules mounted to the exterior of a building or ones mounted at ground

level. PV modules can be installed in a variety of locations, and there are racking systems for every conceivable

location. The racking systems generally fall into one of three categories: roof mount, ground mount, or

top-of-pole mount. Within each of these general classifications, there are multiple subcategories.

Regardless of the mounting classification, racking systems are commonly made of extruded aluminum rails that

support the PV modules at four points along the modules aluminum frame. The exact form the racks extrusion

takes on is a function of the racking manufacturers engineering and final location of the array. Common

applications include flush-to-roof racking systems that hold the array parallel to and in close proximity (i.e.,

within 6 inches) to the roof surface, as shown in the Photo. Another racking type is a ballasted rack, which does

not penetrate the roof membrane or ground, and uses weights, such as concrete ballast blocks, to hold the array

in place. PV arrays can also be mounted close to the ground on piers that support the racking system, which

directly support the modules.

Combiner and junction boxes Today, PV modules are nearly universally manufactured with conductors

pre-installed on the back of the unit with quick-connect plugs on the end. These plugs allow the PV installer to

quickly make the series connections without additional tools. This wiring method is allowed per the NEC (Sec.

690.31). Once the conductors leave the vicinity of the array, either through a building, along the exterior of the

building, or through a trench in ground-mounted arrays, these source circuit conductors are most often

transitioned into a different wire type, such as THWN-2. This transition happens in either a PV combiner box or

a junction box. In a combiner, the source circuits are placed in parallel and very often include overcurrent

protection. A junction box is used solely as a location to make the transition from the outdoor-rated conductors

to the THWN-2 conductors.

The use of a combiner or junction box is a design decision that is made based on the specifics of the PV array

location, proximity to the power electronics, and the preferences of the designer and installer. The NEC has

requirements for placing disconnecting means in proximity to fused combiner boxes, so this can affect the

combiner versus junction box design decision.

For smaller residential installations, there may only be one or two PV source circuits to deal with, and the box

chosen is selected for its ability to transition into a raceway and route the conductors down off the roof through

the interior of the building. In large commercial applications, there can be hundreds of circuits located within

the array that require dozens of boxes to be strategically located and specified to minimize conductor size and

overall length.

Power electronics The output of the PV array will be connected to some form of power electronics. In systems

07-03-15 5:39 PM

The Fundamentals of Photovoltaic Systems

4 of 5

http://ecmweb.com/print/contractor/fundamentals-photovoltaic-systems

that employ battery backup, both utility-interactive and stand-alone, the array will connect to a charge

controller before going into the batteries. These battery-based systems will also use one or more inverters to then

invert the energy stored in the batteries to AC for use by the loads. For grid-direct PV systems, the array will go

directly into an inverter that will invert the DC energy from the array into AC for interconnection with the electric

utility. An example wiring diagram for grid-direct systems is shown in Fig. 3 (click here to see Fig. 3).

Charge controllers Charge controllers are only necessary for systems that use batteries. The primary purpose

of a charge controller is to keep the battery bank from becoming overcharged, which could damage the

batteries. Todays charge controllers also have multiple auxiliary features that can be used to do things like

engage relays and power up loads when the battery bank reaches meets certain conditions. One of the most

common applications is a relay that sends power to a vent fan when the batteries are charging so the buildup of

hydrogen gas does not occur.

In stand-alone systems, when the battery bank has been fully recharged, it is the charge controllers job to isolate

the PV array from the battery bank by opening the circuit and stopping all current flow from the PV array. For

PV systems that use battery storage as a form of backup to the electric utility, the charge controllers are now

manufactured with the ability to talk to the inverters connected to the other side of the battery bank and make

sure the PV array is able to send as much energy back into the electric utility when possible.

Inverters The inverters used in PV systems primarily are used to invert DC energy into AC that can be used

within the building to run loads or be pushed back onto the grid. The inverters used in stand-alone and utilityinteractive battery backup applications are very similar in their appearance and function, whereas the inverters

used in grid-direct systems are very different from the battery-based units.

Battery-based inverters are modular units, meaning multiple small units can be connected together to create a

single large power source. The most commonly used battery-based inverters are actually inverter/chargers,

meaning they have the ability to take the energy from the battery bank to run loads as well as connect to an AC

source and recharge the batteries as necessary. A stand-alone inverter will commonly have a traditional

generator connected to it to provide battery charging as needed. The generator is not a requirement in these

systems, but it gives users greater flexibility in their use of energy.

A utility-interactive, battery-based inverter will connect to the electric utility instead of a generator for its AC

source of power, allowing the user to send energy back to the grid and receive credits for that energy when the

PV array is able to produce more energy than is being consumed. The major difference between a stand-alone

inverter and a battery-based backup inverter is the ability to push current back toward the AC source. In

stand-alone systems, pushing current back into the generator can quickly damage the generator and serves no

good purpose. In utility interactive systems, pushing current toward the grid is a desirable situation and results

in a financial benefit to the system owner.

Grid-direct inverters come in a wide variety of power output sizes from hundreds of watts (micro-inverters) to

kilowatts (string-inverters) to thousands of kilowatts (central inverters). These inverters are simply a way to

invert the DC energy produced by the PV array and connect it directly to the utility grid. Multiple grid-direct

inverters can be combined to increase the overall power output as required. It is important to remember that

these systems offer no form of energy backup, so when the electric utility goes down, the inverter will shut down

and not come back online until the grid is back up.

The individual components listed here should give you a good idea of the major components used with most PV

systems. Additional components required for a complete installation will be covered in future articles.

Mayfield is a principal with Renewable Energy Associates, Corvallis, Ore. He can be reached at:

ryan@renewableassociates.com.

07-03-15 5:39 PM

The Fundamentals of Photovoltaic Systems

5 of 5

http://ecmweb.com/print/contractor/fundamentals-photovoltaic-systems

Source URL: http://ecmweb.com/contractor/fundamentals-photovoltaic-systems

07-03-15 5:39 PM

Vous aimerez peut-être aussi

- Anupam Vinay Surin 12PS05F P & Es, NitkDocument20 pagesAnupam Vinay Surin 12PS05F P & Es, NitkchethanPas encore d'évaluation

- Photovoltaics | 101: The hands-on beginner's guide for designing an on-grid or off-grid PV systemD'EverandPhotovoltaics | 101: The hands-on beginner's guide for designing an on-grid or off-grid PV systemPas encore d'évaluation

- SCL SolarGuideDocument20 pagesSCL SolarGuideEric OukoPas encore d'évaluation

- Solar Electricity Generation System with a DIY Sun-Tracking PropositionD'EverandSolar Electricity Generation System with a DIY Sun-Tracking PropositionPas encore d'évaluation

- Inspeccion Sistema SolarDocument8 pagesInspeccion Sistema SolarManuel TorijaPas encore d'évaluation

- Solar Electricity Basics: Solar Electric System ComponentsDocument12 pagesSolar Electricity Basics: Solar Electric System ComponentssebascianPas encore d'évaluation

- Joint RES and Distribution Network Expansion Planning Under a Demand Response FrameworkD'EverandJoint RES and Distribution Network Expansion Planning Under a Demand Response FrameworkPas encore d'évaluation

- ChaptersDocument47 pagesChaptersAitha DeepakPas encore d'évaluation

- Design and Sizing of Solar Photovoltaic Systems R2Document125 pagesDesign and Sizing of Solar Photovoltaic Systems R2Andrei TaranuPas encore d'évaluation

- Off Grid Solar Power: The Ultimate Step by Step Guide to Install Solar Energy Systems. Cut Down on Expensive Bills and Make Your House Completely Self-SustainableD'EverandOff Grid Solar Power: The Ultimate Step by Step Guide to Install Solar Energy Systems. Cut Down on Expensive Bills and Make Your House Completely Self-SustainablePas encore d'évaluation

- Types of Solar Electric System With Its Various ComponentsDocument7 pagesTypes of Solar Electric System With Its Various ComponentsNgoc Thach PhamPas encore d'évaluation

- Solar Cell System Design-2Document12 pagesSolar Cell System Design-2spotifyladderPas encore d'évaluation

- Guide To Installing A Solar Electric System: Sclenergyadvisor@Seattle - GovDocument20 pagesGuide To Installing A Solar Electric System: Sclenergyadvisor@Seattle - GovmasakpPas encore d'évaluation

- Photovoltaic System ConfigurationsDocument4 pagesPhotovoltaic System Configurationsstuff93Pas encore d'évaluation

- TH - EnglishDocument87 pagesTH - EnglishBacamartePas encore d'évaluation

- Grid Connected PV System: More InfoDocument11 pagesGrid Connected PV System: More Infosai karthikPas encore d'évaluation

- Projectreport REDocument15 pagesProjectreport REUnzillahPas encore d'évaluation

- How A PV System Works - pdf-20200211100803465Document9 pagesHow A PV System Works - pdf-20200211100803465ahmed abusnoubarPas encore d'évaluation

- CH 5 PDFDocument24 pagesCH 5 PDFМихаил МироновPas encore d'évaluation

- CH 5Document24 pagesCH 5Михаил МироновPas encore d'évaluation

- Final Thesis Chap 2. Edited VersionDocument16 pagesFinal Thesis Chap 2. Edited VersionUmer Bin ZubairPas encore d'évaluation

- CH 5 PDFDocument24 pagesCH 5 PDFAhmed MohamedPas encore d'évaluation

- Solar Technical Lessons: Fight AcademyDocument81 pagesSolar Technical Lessons: Fight Academysharrath mPas encore d'évaluation

- Rooftop Solar Power PlantDocument13 pagesRooftop Solar Power PlantashishPas encore d'évaluation

- Lecture 3 Types of PV Systems.Document30 pagesLecture 3 Types of PV Systems.as2899142Pas encore d'évaluation

- UntitledDocument11 pagesUntitledmuhamad nadrPas encore d'évaluation

- Prospect of Rooftop Solar SystemDocument6 pagesProspect of Rooftop Solar Systemalok rajPas encore d'évaluation

- Tese Grid Connected PV 2001Document124 pagesTese Grid Connected PV 2001chauhan303Pas encore d'évaluation

- Solar Inverter - Wikipedia, The Free EncyclopediaDocument6 pagesSolar Inverter - Wikipedia, The Free EncyclopediaronniedakingpouPas encore d'évaluation

- Module 2Document33 pagesModule 2Vibin NivasPas encore d'évaluation

- 22661-RET Notes-UNIT 02Document25 pages22661-RET Notes-UNIT 02jayeshdeore398Pas encore d'évaluation

- Photovoltaic System TypesDocument3 pagesPhotovoltaic System Typesanmn123Pas encore d'évaluation

- Solar Technology: Seminar ContentsDocument19 pagesSolar Technology: Seminar ContentsObichere OnyekachiPas encore d'évaluation

- Solar Energy Compnents BriefDocument10 pagesSolar Energy Compnents Briefindrajeet KhumanPas encore d'évaluation

- Peres Unit 3Document86 pagesPeres Unit 3ulaganathanPas encore d'évaluation

- Solar Electric BasicsDocument9 pagesSolar Electric BasicspigrodraftsPas encore d'évaluation

- What Is A Solar Power Plant? How Does It Work?Document2 pagesWhat Is A Solar Power Plant? How Does It Work?Sumon ShariarPas encore d'évaluation

- Solar Energy Deployment in Off GridDocument3 pagesSolar Energy Deployment in Off Gridnelson fajardoPas encore d'évaluation

- Fiche 4 2 Solar Photovoltaic PDFDocument18 pagesFiche 4 2 Solar Photovoltaic PDFhitosnapPas encore d'évaluation

- Solar Cells & Their ApplicationDocument11 pagesSolar Cells & Their ApplicationpiyushPas encore d'évaluation

- Siemens Power Engineering Guide 7E 54Document1 pageSiemens Power Engineering Guide 7E 54mydearteacherPas encore d'évaluation

- Unit-3 SPTDocument6 pagesUnit-3 SPT222 PiyushPas encore d'évaluation

- SolarDocument57 pagesSolarRaghavendra Raghav100% (1)

- 120 Ds Standardcompliantcomponentsfrphotovoltaicapplications en 2945 201701171054541374Document24 pages120 Ds Standardcompliantcomponentsfrphotovoltaicapplications en 2945 201701171054541374cc_bauPas encore d'évaluation

- By Dale A Gulden, Solar Direct CEODocument22 pagesBy Dale A Gulden, Solar Direct CEOAbdulkhadir Suhair100% (1)

- R08-002 - Design and Sizing of Solar Photovoltaic - 240124 - 162025Document125 pagesR08-002 - Design and Sizing of Solar Photovoltaic - 240124 - 162025TECH CHO3013Pas encore d'évaluation

- Training Module Photovoltaic Project Analysis: Clean Energy Project Analysis Course Speaker'S NotesDocument14 pagesTraining Module Photovoltaic Project Analysis: Clean Energy Project Analysis Course Speaker'S NotespikermiPas encore d'évaluation

- CEA Concept PaperDocument6 pagesCEA Concept Paper123harsh123Pas encore d'évaluation

- Solar Photovoltaic Power For IndiaDocument74 pagesSolar Photovoltaic Power For IndiaH Janardan PrabhuPas encore d'évaluation

- Photovoltaic TechnologyDocument6 pagesPhotovoltaic TechnologyGharamPas encore d'évaluation

- 1111111111111111111111111111trainingggg Manual 18686Document16 pages1111111111111111111111111111trainingggg Manual 18686Sunil SinghPas encore d'évaluation

- Experiment No10BME6 - SolarDocument6 pagesExperiment No10BME6 - SolarSolo RapidPas encore d'évaluation

- 2 Types of PV SystemsDocument4 pages2 Types of PV SystemsIsabel GuevaraPas encore d'évaluation

- 24 31artical1123Document9 pages24 31artical1123Sersio BordiosPas encore d'évaluation

- Photovoltaics: Basic Design Principles and Components: Introduction To Photovoltaic (Solar Cell) SystemsDocument10 pagesPhotovoltaics: Basic Design Principles and Components: Introduction To Photovoltaic (Solar Cell) SystemsSingam Sridhar100% (1)

- Residential Photovoltaics: 1.0 System DescriptionDocument13 pagesResidential Photovoltaics: 1.0 System DescriptionAreovaldo Ferreira VieiraPas encore d'évaluation

- Role of Solar Farm in Power Factor Improvement of Grid Connected SystemsDocument20 pagesRole of Solar Farm in Power Factor Improvement of Grid Connected SystemsDevyansh GuptaPas encore d'évaluation

- Installation Testing Troubleshooting Starters Overload RelaysDocument2 pagesInstallation Testing Troubleshooting Starters Overload RelaysrajuanthatiPas encore d'évaluation

- Installation Testing Troubleshooting Starters Overload RelaysDocument34 pagesInstallation Testing Troubleshooting Starters Overload RelaysGogula Gunasekhar100% (1)

- 2012 Revisions To NFPA 70EDocument6 pages2012 Revisions To NFPA 70ErajuanthatiPas encore d'évaluation

- Specifying Adjustable Frequency Drives For Electromagnetic Compatibility in HVAC ApplicationsDocument4 pagesSpecifying Adjustable Frequency Drives For Electromagnetic Compatibility in HVAC ApplicationsrajuanthatiPas encore d'évaluation

- Iaei March 2003Document48 pagesIaei March 2003rajuanthatiPas encore d'évaluation

- Installation Testing Troubleshooting Starters Overload RelaysDocument2 pagesInstallation Testing Troubleshooting Starters Overload RelaysrajuanthatiPas encore d'évaluation

- Methods of Equipment Grounding, Part 2Document1 pageMethods of Equipment Grounding, Part 2rajuanthatiPas encore d'évaluation

- 2011 NEC Requirements For Articles 514 Through 525Document4 pages2011 NEC Requirements For Articles 514 Through 525rajuanthatiPas encore d'évaluation

- Using AC Coils On DC PowerDocument3 pagesUsing AC Coils On DC PowerrajuanthatiPas encore d'évaluation

- Hint - Hammer TimeDocument2 pagesHint - Hammer TimerajuanthatiPas encore d'évaluation

- 2011 NEC Requirements For Articles 514 Through 525Document4 pages2011 NEC Requirements For Articles 514 Through 525rajuanthatiPas encore d'évaluation

- Illustrated Code Catastrophes - Sections 314.22, 314.29, 410.6, 410.56 (B), 410.42 and 410Document3 pagesIllustrated Code Catastrophes - Sections 314.22, 314.29, 410.6, 410.56 (B), 410.42 and 410rajuanthatiPas encore d'évaluation

- What Lamps Will Be Phased OutDocument6 pagesWhat Lamps Will Be Phased OutrajuanthatiPas encore d'évaluation

- Financing Trends in The Solar Sector PDFDocument7 pagesFinancing Trends in The Solar Sector PDFrajuanthatiPas encore d'évaluation

- Troubleshooting Small-Scale Photovoltaic (PV) SystemsDocument5 pagesTroubleshooting Small-Scale Photovoltaic (PV) SystemsrajuanthatiPas encore d'évaluation

- Troubleshooting Small-Scale Photovoltaic (PV) SystemsDocument5 pagesTroubleshooting Small-Scale Photovoltaic (PV) SystemsrajuanthatiPas encore d'évaluation

- Calculating Current Ratings of Photovoltaic Modules PDFDocument5 pagesCalculating Current Ratings of Photovoltaic Modules PDFrajuanthatiPas encore d'évaluation

- The Truth Behind Energy Project EconomicsDocument4 pagesThe Truth Behind Energy Project EconomicsrajuanthatiPas encore d'évaluation

- Solar Photovoltaic (PV) Product ShowcaseDocument12 pagesSolar Photovoltaic (PV) Product ShowcaserajuanthatiPas encore d'évaluation

- Construction and Demolition Recycling in The Electrical IndustryDocument6 pagesConstruction and Demolition Recycling in The Electrical IndustryrajuanthatiPas encore d'évaluation

- Special Occupancies and The NECDocument4 pagesSpecial Occupancies and The NECrajuanthatiPas encore d'évaluation

- The Truth Behind Energy Project EconomicsDocument4 pagesThe Truth Behind Energy Project EconomicsrajuanthatiPas encore d'évaluation

- Solar Photovoltaic (PV) Product ShowcaseDocument12 pagesSolar Photovoltaic (PV) Product ShowcaserajuanthatiPas encore d'évaluation

- Special Occupancies and The NECDocument4 pagesSpecial Occupancies and The NECrajuanthatiPas encore d'évaluation

- Grounding, Conduits, Overcurrent Protection & MoreDocument3 pagesGrounding, Conduits, Overcurrent Protection & MorerajuanthatiPas encore d'évaluation

- Equipment Temperature Terminal Rating For Sizing ConductorsDocument3 pagesEquipment Temperature Terminal Rating For Sizing ConductorsrajuanthatiPas encore d'évaluation

- Illustrated Code Catastrophes - Article 440, Sections 110.26 and 314Document2 pagesIllustrated Code Catastrophes - Article 440, Sections 110.26 and 314rajuanthatiPas encore d'évaluation

- Hint - Replacement PartsDocument2 pagesHint - Replacement PartsrajuanthatiPas encore d'évaluation

- Disconnect Requirements For Articles 422 Through 450Document4 pagesDisconnect Requirements For Articles 422 Through 450rajuanthatiPas encore d'évaluation

- Illustrated Code Catastrophes - Table 110.28 and Section 440Document2 pagesIllustrated Code Catastrophes - Table 110.28 and Section 440rajuanthatiPas encore d'évaluation

- SF6 Analyser 973 3-035-R GBDocument3 pagesSF6 Analyser 973 3-035-R GBSivakumar NatarajanPas encore d'évaluation

- Sot Sc70 OcapDocument63 pagesSot Sc70 OcapPBlurnz005100% (2)

- CODA - LINUS DSP & Amplification FINALDocument18 pagesCODA - LINUS DSP & Amplification FINALJaime Cataño GarciaPas encore d'évaluation

- LEvitonDocument2 pagesLEvitonAndres Barbosa LargoPas encore d'évaluation

- MATLAB and Simulink Modelling of A Full State Observer Controller of Armature Controlled and Field Controlled DC Motor Using State Space ApproachDocument8 pagesMATLAB and Simulink Modelling of A Full State Observer Controller of Armature Controlled and Field Controlled DC Motor Using State Space ApproachNitsuga PomeloréPas encore d'évaluation

- LNCTGroup Data Login IDs - For DisplayDocument18 pagesLNCTGroup Data Login IDs - For DisplaySiddharth NagayachPas encore d'évaluation

- 1 - PKAC Q MS 027 Method Statement Control Measurement REV 01Document19 pages1 - PKAC Q MS 027 Method Statement Control Measurement REV 01shahidPas encore d'évaluation

- 3631 Op ManualDocument23 pages3631 Op ManualVuong PhanPas encore d'évaluation

- Data Sheet Led 5mm RGBDocument3 pagesData Sheet Led 5mm RGBMuhammad Nuzul Nur مسلمPas encore d'évaluation

- HBM P3 Top ClassDocument10 pagesHBM P3 Top ClasslgustavolucaPas encore d'évaluation

- SRN/ SEN15/ SEN25: General Electric HornsDocument2 pagesSRN/ SEN15/ SEN25: General Electric HornsRigoberto GomezPas encore d'évaluation

- TASKalfa 1800 1801 2200 2201 PL UK - Rev2 PDFDocument49 pagesTASKalfa 1800 1801 2200 2201 PL UK - Rev2 PDFMarch Dominick CatoPas encore d'évaluation

- Calibration Check List For Fresenius Medical CareDocument3 pagesCalibration Check List For Fresenius Medical CareAntra NovalPas encore d'évaluation

- Mhor04 R8042KDocument32 pagesMhor04 R8042KaleksandrPas encore d'évaluation

- Weapons and Gear For Fallout 3 Using Basic Role PlayingDocument535 pagesWeapons and Gear For Fallout 3 Using Basic Role PlayingJohn MillerPas encore d'évaluation

- ARFCN GSM SpecsDocument7 pagesARFCN GSM SpecsEyotrePas encore d'évaluation

- Understanding The New IEEE 1584-2018 Guide For Performing Arc-Flash Hazard Calculations and The 2017 NEC Arc Energy Reduction ArticlesDocument42 pagesUnderstanding The New IEEE 1584-2018 Guide For Performing Arc-Flash Hazard Calculations and The 2017 NEC Arc Energy Reduction ArticlesEdison EstrellaPas encore d'évaluation

- A Review On Surface Treatment For Concrete - Part 2 - Performance OkeDocument11 pagesA Review On Surface Treatment For Concrete - Part 2 - Performance Okealdi sophianPas encore d'évaluation

- E8500 Manual PDFDocument45 pagesE8500 Manual PDFAnggaraPerbawaPutraPas encore d'évaluation

- Stock Statement AUG-18.Document38 pagesStock Statement AUG-18.Atul TiwariPas encore d'évaluation

- Growatt SPA1000-3000TL BL DatasheetDocument2 pagesGrowatt SPA1000-3000TL BL DatasheetElias RizkPas encore d'évaluation

- User Manual Flash Machine T1511M enDocument18 pagesUser Manual Flash Machine T1511M enMarius StefanPas encore d'évaluation

- EMV Multi Cable Transit Modular System (EMC-System) : PDFDocument7 pagesEMV Multi Cable Transit Modular System (EMC-System) : PDFbakien-canPas encore d'évaluation

- Howland Current SourceDocument9 pagesHowland Current SourceanugrasPas encore d'évaluation

- Cat Eeg9100Document8 pagesCat Eeg9100Juan Carlos Barrios Granados0% (1)

- BZX55CV24Document4 pagesBZX55CV24kcraussPas encore d'évaluation

- Cmos Check Sum ErrorDocument3 pagesCmos Check Sum Erroryogeshdhuri22Pas encore d'évaluation

- Exploracion Geofisica PDFDocument188 pagesExploracion Geofisica PDFJose Joaquin Alvarez EncisoPas encore d'évaluation

- (TUTORIAL) Unlock Sim Network On Samsung Galaxy Mini S5570, Ace S5830, Gio S5660, Pop I559, Fit S5670Document30 pages(TUTORIAL) Unlock Sim Network On Samsung Galaxy Mini S5570, Ace S5830, Gio S5660, Pop I559, Fit S5670edwartcano50% (2)

- Slide 2 Photovoltaic System 4Document71 pagesSlide 2 Photovoltaic System 4Chea LichhingPas encore d'évaluation

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesD'EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesÉvaluation : 4.5 sur 5 étoiles4.5/5 (21)

- Introduction to Power System ProtectionD'EverandIntroduction to Power System ProtectionÉvaluation : 5 sur 5 étoiles5/5 (1)

- A Pathway to Decarbonise the Shipping Sector by 2050D'EverandA Pathway to Decarbonise the Shipping Sector by 2050Pas encore d'évaluation

- RV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!D'EverandRV Living Collection: RV living for beginners, RV travel for the whole family, RV repair and RV mobile solar power: Experience Freedom on the roads alone or with your family with this collection. Learn how to repair your motorhome while using renewable energy!Pas encore d'évaluation

- The Permaculture City: Regenerative Design for Urban, Suburban, and Town ResilienceD'EverandThe Permaculture City: Regenerative Design for Urban, Suburban, and Town ResiliencePas encore d'évaluation

- Fire on the Horizon: The Untold Story of the Gulf Oil DisasterD'EverandFire on the Horizon: The Untold Story of the Gulf Oil DisasterPas encore d'évaluation

- Shorting the Grid: The Hidden Fragility of Our Electric GridD'EverandShorting the Grid: The Hidden Fragility of Our Electric GridÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Nuclear Energy in the 21st Century: World Nuclear University PressD'EverandNuclear Energy in the 21st Century: World Nuclear University PressÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Heat Transfer Engineering: Fundamentals and TechniquesD'EverandHeat Transfer Engineering: Fundamentals and TechniquesÉvaluation : 4 sur 5 étoiles4/5 (1)

- Offshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsD'EverandOffshore Wind Energy Generation: Control, Protection, and Integration to Electrical SystemsPas encore d'évaluation

- Practical Power Distribution for IndustryD'EverandPractical Power Distribution for IndustryÉvaluation : 2.5 sur 5 étoiles2.5/5 (2)

- Renewable Energy: A Very Short IntroductionD'EverandRenewable Energy: A Very Short IntroductionÉvaluation : 4.5 sur 5 étoiles4.5/5 (12)

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsD'EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsPas encore d'évaluation

- Solar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsD'EverandSolar Power Demystified: The Beginners Guide To Solar Power, Energy Independence And Lower BillsÉvaluation : 4.5 sur 5 étoiles4.5/5 (2)

- Fundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsD'EverandFundamentals of Hydrogen Production and Utilization in Fuel Cell SystemsPas encore d'évaluation

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successD'EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Global Landscape of Renewable Energy FinanceD'EverandGlobal Landscape of Renewable Energy FinancePas encore d'évaluation

- Live Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerD'EverandLive Off Grid: Escape The City, Learn How To Travel Intelligently Using Solar PowerPas encore d'évaluation

- Electrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977D'EverandElectrical Load-Curve Coverage: Proceedings of the Symposium on Load-Curve Coverage in Future Electric Power Generating Systems, Organized by the Committee on Electric Power, United Nations Economic Commission for Europe, Rome, Italy, 24 – 28 October 1977Pas encore d'évaluation

- Idaho Falls: The Untold Story of America's First Nuclear AccidentD'EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentÉvaluation : 4.5 sur 5 étoiles4.5/5 (21)

- Practical Reservoir Engineering and CharacterizationD'EverandPractical Reservoir Engineering and CharacterizationÉvaluation : 4.5 sur 5 étoiles4.5/5 (3)

- Grid-Scale Energy Storage Systems and ApplicationsD'EverandGrid-Scale Energy Storage Systems and ApplicationsFu-Bao WuPas encore d'évaluation

- Industrial Waste Treatment HandbookD'EverandIndustrial Waste Treatment HandbookÉvaluation : 5 sur 5 étoiles5/5 (1)

- An Introduction to Renewable Energy Sources : Environment Books for Kids | Children's Environment BooksD'EverandAn Introduction to Renewable Energy Sources : Environment Books for Kids | Children's Environment BooksPas encore d'évaluation

- Renewable Energy Sources - Wind, Solar and Hydro Energy Revised Edition : Environment Books for Kids | Children's Environment BooksD'EverandRenewable Energy Sources - Wind, Solar and Hydro Energy Revised Edition : Environment Books for Kids | Children's Environment BooksPas encore d'évaluation

- Simulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetD'EverandSimulation of Some Power Electronics Case Studies in Matlab Simpowersystem BlocksetÉvaluation : 2 sur 5 étoiles2/5 (1)