Académique Documents

Professionnel Documents

Culture Documents

UWP 25418 001 Elevated Water Tank 5000L CR02

Transféré par

rendaninDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

UWP 25418 001 Elevated Water Tank 5000L CR02

Transféré par

rendaninDroits d'auteur :

Formats disponibles

SCHEDULE OF FITTINGS

2200

800

REF ND

TANK FIXING LUG, ex.:

50 F 5 x 100 LONG

WITH 1-20dia HOLE

WELDED TO 'c' (6x)

AFTER ASSEMBLY OF FRAMEWORK

NUTS AND BOLTS TO BE WELDED

TOGHETER WITH 2mm FILLET WELD

200

U

62,5

75

TANK FIXING LUG, ex.:

50 F 5 x 100 LONG

WITH 1-20dia HOLE

WELDED TO 'c' (6x)

1300

OVERFLOW PIPE TO DISCHARGE

ACCORDING TO ENGINEERS

SITE INSTRUCTION

PIPE CLAMP SEE DETAIL

1300

62,5

1500

BOLT DETAIL

OUTLET

1:5

1350

SECTION H-H

LEGEND:

1:5

ELEVATION

TYPICAL LUG DETAIL (6x)

1:5

1:5

4500

1500

HRA = HOT ROLLED ANGLE

F = FLAT BAR

CRLC = COLD ROLLED LIPPED CHANNEL

B/B = BACK TO BACK ( 6 ) 100-500

B/M = BACKMARK

$ = UNLESS OTHERWISE SHOWN

QUANTITIES FOR SINGLE TANK STAND

ITEM

BASE PLATE

80 x 80 x 6 HRA

COLUMN

80 x 80 x 6 HRA

STRUT

40 x 40 x 6 HRA

FLOOR BEAM

125 x 75 x 10 HRA

PLANK

125 x 50 x 2 CRLC

VERT.BRACING

30 x 6 F

VERT.BRACING

30 x 6 F

HORI.BRACING

40 x 40 x 3 HRA

PIPE CLAMP

80 x 80 x 6 HRA

M10 U-SHAPED BOLT

WOOD BLOCK

FIXING PLATE

75 PL 6 75 LONG

BOLTS

M10 ST/STL

K

H

1500

PIPE CLAMP

DESCRIPTION

LENGTH

No.OFF

300mm

4000mm

1580mm

2200mm

2700mm

2180mm

2150mm

2200mm

100mm

125mm

140mm

75mm

55mm

4

4

10

2

11

12

4

4

6

6

6

8

64

D

PIPE CLAMP SEE DETAIL

300

1600

590

75

SUPERIMPOSED POSITION

OF FLOOR AREA

CONCRETE THRUST

BLOCK

OUTLET

TB

V = 0,1 cu m

TANK FIXING LUG

SEE DETAIL

2no

65

GALVANISED STEEL SCREW-ON FLANGE

SABS 11

2no

65

90 DEGREE MGI MALE/FEMALE BEND

2no

65

475mm LONG MGI PIPE PIECE THREADED BOTH ENDS

2no

65

90 DEGREE MGI FEMALE BEND

4no

65

330mm LONG MGI PIPE PIECE THREADED BOTH ENDS

2no

65

1020mm LONG MGI PIPE PIECE THREADED BOTH ENDS

1no

65

MGI CONICAL SEAT UNION

1no

65

MGI BARREL NIPPLE

1no

65

BRASS FEMALE THREADED FULLWAY GATE VALVE

1no

65

2000mm LONG MGI PIPE PIECE THREADED BOTH ENDS

1no

65

65x65x65ND MGI FEMALE EQUAL TEE

2no

65x50 65x50ND MGI REDUCING BUSH

2no

50

MGI BARREL NIPPLE

1no

50

BRASS FEMALE THREADED FULLWAY GATE VALVE

1no

50

50NDx50BSP MALE ADAPTOR COMPRESSION FITTING

2no

50

600mm LONG HIGH DENSITY POLYETHYLENE TYPE IV CLASS 6 PIPE

(TO SABS 533)

2no

2no

1no

50x40 50NDx40BSP MALE ELBOW COMPRESSION FITTING

50

1714mm LONG HIGH DENSITY POLYETHYLENE TYPE IV CLASS 6 PIPE

(TO SABS 533)

50

90 DEGREE ELBOW COMPRESSION FITTING

2no

65

3150mm LONG MGI PIPE PIECE THREADED BOTH ENDS

1no

5 000 LITRE POLYETHYLENE WATER TANK (2040mm HIGH x 1800mm

DIAMETER), COMPLETE WITH 50x40 NOM.DIA NYLON REDUCING

BUSHES, SEALED INTO ALL INLETS AND OUTLETS, INCLUDING

A 40 NOM.DIA GALV'D PLUG FITTED TO OPENING ABOVE INLET.

TANK TO BE SUPPLIED COMPLETE WITH SUFFICIENT

4mm DIA GALVANISED STEEL WIRE FOR ANCHORING

TO THE TANKSTAND PLATFORM AS DETAILED ON

PLAN NO. 125 826/97ME

1set

63

PVC CLASS 6 PIPING

12m

65

MGI HOLLOW PLUG

MISCELLANEOUS FITTINGS

1) PIPE CLAMPS AS DETAILED ON PLAN No. 125 825/97ME

2no

6no

2 CONCRETE:

2.1 PRESCRIBED MIX 10/19 IN BLINDING LAYERS.

2.2 PRESCRIBED MIX 20/19 IN COLUMN BASES.

3 STRUCTURAL STEELWORK:

3.1 ALL STRUCTURAL STEELWORK GRADE 300W

ACCORDING TO SABS 1431.

3.2 STEELWORK GENERALLY OF WELDED CONSTRUCTION

WITH SITE CONNECTIONS BOLTED.

UNLESS OTHERWISE SHOWN ARE :

ALL HOLES 12 DIA. FOR M10 BOLTS

ALL BOLTS GRADE 4.8

ALL GUSSETS 6mm PLATES

ALL WELDS 6mm FILLET

3.3 ALL STEELWORK SHALL BE SUPPLIED, FABRICATED

DELIVERED AND ERECTED IN ACCORDANCE WITH

SABS-1200H AND SABS-0164 1984.

3.4 SITE WELDING OF STEELWORK SHALL NOT BE

PERMITTED WITHOUT THE ENGINEERS APPROVAL.

3.5 CORROSION PROTECTION:

3.5 .1 PAINTWORK IN WORKSHOP:

EPOXY COATING SHALL BE AN APPROVED

TWO COMPONENT, POLYAMIDE CURED PIPE

COATING. IT SHALL BE APPLIED IN THE

WORKSHOP BY SPRAYING TO A FINAL

THICKNESS OF NOT LESS THAN 300 MICRON.

3.5 .2 PAINTWORK AFTER ERECTION:

a) AFTER INSTALLATION ANY CHIPS OR

SCRATCH MARKS SHALL BE MADE GOOD

ON SITE WITH BRUSH APPLIED EPOXY

PAINT.

b) AN INTERIM LAYER ACCORDING TO

SABS 681 TYPE I SHALL BE APPLIED

TO A FINAL THICKNESS OF 25 MICRON.

3.5 .3 FINAL FINISHING LAYER:

A FINAL ENAMEL LAYER ACCORDING TO SABS

630 GRADE 1 SHALL BE APPLIED WITHIN

24 HOURS AFTER THE INTERIM LAYER HAS

BEEN APPLIED, TO A FINAL THICKNESS OF

25 MICRON (COLOUR AS INSTRUCTED).

4 GENERAL:

4.1 READ THIS PLAN IN CONJUNCTION WITH ALL

THE RELEVANT DRAWINGS.

4.2 ALL DIMENSIONS IN MILLIMETERS.

ELEVATED

TANK

ELEVATED TANK

TANK FIXING LUG

SEE DETAIL

590

1032

90

TO RETICULATION

AND AS INSTRUCTED

BY ENGINEER

LAYOUT PLAN E-E

FENCE

2065

1032

500mm x 600mm

LOCKABLE CAST

IRON COVER OVER

FRAME.

13 / FLOOR MEMBERS ex.:

125 x 75 x 20 x 2 CRLC

(10 x 2 700 long +

1 x 1 650 long SINGLE TANK)

(13 x 2 700 long

REST OF MULTIPLE TANKS)

U

POSITION OF 5 000 LITRE

POLYETHYLENE WATER TANK

(FITTING `W')

CR02

1520

C

f

SABS 11

TWL

C

2700

1520

1600

SCALE:1:25

1 FOUNDATIONS:

1.1 DEPTHS OF ALL BASES SHALL BE DETERMINED AND

APPROVED ON SITE BY THE ENGINEER PRIOR TO

CONCRETING.

1.2 SAFE BEARING CAPACITY OF GROUND 200 kPa.

15000

OUTLET

SECTION A-A

TANK FIXING LUG

SEE DETAIL

TANK FIXING LUG

SEE DETAIL

PVC FLANGE ADAPTOR (CAST IRON)

NOTE:

N.T.S.

NOTE

ALL FLANGES TO BE DRILLED ACCORDING TO SABS 1123-1977 TABLE 11

(STEEL SCREWED BOSS FLANGES - 1000/4) AND REFERED TO AS SABS

11 IN THE SCHEDULE OF FITTINGS

1520

PLAN

125

75

63ND PVC CLASS 6

PIPELINE FROM BOREHOLE

PUMP STATION

37.5

125

Y

E

F

E

63

2600

37.5

NGL

PLUGGED OUTLET FOR

FUTURE EXTENSION

WATER TANK TO BE SUITABLY

HELD IN POSITION ON PLATFORM

USING MIN. 2 x STRANDS 4,0mm

GALVANISED STEEL WIRE FIXED

TO TANK FIXING LUG AND

PLATFORM SUPPORT BEAMS

NM

O

P

15000

SUPERIMPOSED POSITION OF

TANKSTAND

1350

NOTE:

POSITION OF 5000 LITRE

POLYETHYLENE WATER TANK

(FITTING `W')

GATE POSITION

(MAY VARY)

PIPE CLAMP SEE DETAIL

a : 80 x 80 x 6 HRA (45B/M $)

b : 40 x 40 x 6 HRA (23B/M $)

c : 125 x 75 x 10 HRA (45B/M $)

d : 30 x 6 F (25B/M $)

e : 40 x 40 x 3 HRA (23B/M $)

f : 125 x 50 x 20 x 2,5 CRLC

2700

DESCRIPTION

2600

Min.25mm

POSITION OF 5 000 LITRE

POLYETHYLENE WATER TANK

(FITTING `W')

TREATMENT

WALL FLANGE GALVA- EPOXY QTY

't'

DRILLING NISED RESIN

mm

PAINT

800

1:25

FENCE

FLOOR LAYOUT

1:25

PLAN VIEW

CHLORINATOR

MANHOLE

30

40

65

1:5

35

38

27

65

45

86

17

100

10

35

200

200

200

50mm WIDE x 70mm HIGH x 140mm

LONG SHAPED HARD WOOD BLOCK

HAVING 2 x 12mm DIA. HOLES

DRILLED FOR ANCHOR BOLT

80 x 80 x 6 HRA 100mm LONG

FULLY WELDED TO 'a' WITH

1-12 DIA. HOLE FOR M10

U-BOLT (No. REQUIRED : 6x)

SEE SECTION B-B FOR

POSITIONS

40

25

b

b

d

6

35

39

75 PL 6 x 75 LONG

FULLY WELDED TO 'a'

WITH 1-12 DIA. HOLE

FOR 1-M10 BOLT

(No. REQUIRED : 8x)

SEE FLOOR LAYOUT FOR

POSITIONS

VIEW A

3

d

16 MAY 2014

VERIFIED

L.POOK

16 MAY 2014

AS SHOWN

STATUS LEGEND

I = INFORMATION

T = TENDER

C = CONSTRUCTION

AB = AS BUILT

CLIENT

5700

500

CR02

STORAGE SUMP AND IN-LINE CHLORINATOR DETAILS

1500

1210

375

250

375

1000 SQUARE

NON-RETURN VALVE

PROJECT

FOOTING DETAIL FOR

SANDY CONDITIONS

b

b

b

300

1:25

200

1000

500

200

200

1200 x 1200 x 100 20MPA

CONCRETE BASE

20mm OUTLET FROM CHLORINATOR TO

THE INLET PIPE THROUGH A 32mm SLEEVE

275

800

720

250

800

275

300

275

800

720

2320

TYPICAL SECTION THROUGH CHLORINATING UNIT

NTS

ACCELERATED SCHOOLS INFRASTRUCTURE

DELIVERY INITIATIVE (ASIDI)

CONSTRUCTION OF WATER AND SANITATION

INFRASTRUCTURE AT SCHOOLS IN THE

EASTERN CAPE PROVINCE.

DRAWING TITLE

200

700

DOUBLE DOORS WITH LOCK

PROTECTION

500

950

20mm HDPE

VALVE

250

3 x 20 L CONTAINERS FILLED

WITH CONCENTRATED ADDITIVE

300

RISING MAIN (PIPE DIA. VARIES)

20mm HDPE

D.DICKSON

VALIDATED

1:5

DOSATRON OR SIMILAR

APPROVED

DRAWN

1500

80

1:5

20mm OUTLET FROM INLET PIPE TO THE

CHLORINATOR THROUGH A 32mm SLEEVE

16 MAY 2014

S.RICHTER

1500

80

1:5

CABINET FASTENED TO GALVANISED METAL

FRAME AND FASTENED TO CONCRETE BASE

WITH FOUR STAINLESS STEEL BOLTS AND NUTS

DATE

SCALE

37

(6 OFF REQUIRED)

FULLWAY GATE VALVE (TO COMPLY WITH

SABS 776-1975 CLASS 8)

SIGNATURE

d

43

630

UWP CONSULTING (PTY)

LTD

P.O. Box 19276

TECOMA

5214

Tel: (043) 721-0186

Fax: (043) 721-0288

A0

FILTER

1070

TECHNICAL SUPPORT

SHEET SIZE

TYPICAL ARRANGEMENT FOR INLINE CHLORINATOR

NTS

DESIGNED

(4 OFF REQUIRED)

1000 x 1000 x 100 CONCRETE

PLINTH FOR MOUNTING OF

CHLORINATOR

SIGN

NAME

8 BAR GLYCERINE PRESSURE GAUGE

POWDER COATED GALVANISED

METAL CABINET TO HOUSE

CHLORINATOR. DOORS - DOUBLE

WITH LOCK PROTECTION SIZE 1020(H) x 1000(WIDE) x 600(DEEP)

MATERIAL - 1.6mm THICK

GALVANISED MILD STEEL

DESCRIPTIONS

1500

PIPE CLAMP DETAIL

20mm OUTLET FROM INLET PIPE

TO THE CHLORINATOR THROUGH

A 32mm SLEEVE

REVISIONS

23

40

52

70

R=38

37

BASE PLATE DETAIL 1

220mm THICK BRICK MANHOLE (WITH

WEEPHOLES AT INVERT) (BRICKWORK TO BE

PLASTERED INTERNALLY AND EXTERNALLY)

DATE

MVULA TRUST

P.O. Box 8112

Nahoon

East London

5201

Tel: (043) 726-2255/6/7

Fax: (043) 726-2344

550

1:25

20mm OUTLET FROM THE

CHLORINATOR TO THE INLET

PIPE THROUGH A 32mm SLEEVE

1600

80

1650

S.G.R.

2700

100

INLET AND OVERFLOW

SECTION B-B

TOP SLAB: (FLOATED FINISH)

1650mm x 1070mm x 150mm WITH

600mm x 600mm LOCKABLE

MANHOLE COVER AND FRAME

200

CONCRETE

THRUST BLOCK

200

1000

A

TB

V = 0,1 cu m

200

27

200

550

B

C

200

63ND PVC CLASS 6

D

PIPELINE FROM BOREHOLE

B

PUMP STATION

200

250

NGL

200

OVERFLOW PIPE TO

DISCHARGE ACCORDING

TO ENGINEERS SITE

INSTRUCTION

ISSUED FOR CONSTRUCTION

IMPLEMENTING AGENT

500

200

5700

200

35

17

300

200

300

CR00

SCALE: N.T.S.

80

a

PIPE CLAMP SEE DETAIL

12-11-2013

ELEVATED WATER TANK SCHEMATIC

1:5

38

18

20

1200 MAX.

380

TOP FLANGE OF HRA TO HAVE

11-12dia HOLES, ENDS SPACED AS

DETAILED THE REST AT 200mm

CRS FOR 11- M10 BOLTS FOR

FIXING OF 125 x 50 x 20 x 2 CRLC

VIEW B

140

PIPE CLAMP

S.G.R.

80

R=38

125

CHLORINATOR ADDED TO DETAILS

2600

M10 U-SHAPED BOLT HAVING

125mm LONG LEGS OF WHICH THE

ENDS ARE THREADED FOR A A

DISTANCE OF 50mm, COMPLETE

WITH NUTS AND WASHERS

80 x 80 x 6 HRA BASEPLATE TO BE

WELDED TO THE COLUMN AND

CASTED INTO THE CONCRETE

FOOTING.

CR01

PLASSON SADDLES WITH

STAINLESS STEEL BOLTS

AND NUTS 20mm DIA HDPE

PIPES TO CHLORINATOR.

79

60

125

1:5

FULLWAY GATE VALVE

(TO COMPLY WITH SABS

776-1975 CLASS 8)

45

DETAIL 3

PIPE CLAMP

BASE SLAB: 1750mm x 1170mm

x 150mm 20MPa CONCRETE

WITH MESH REF 245

DETAIL 2

04-12-2013

REVISION TABLE

1500

1200

4500

80

75

80 x 80 x 6 HRA COLUMN

INLET

d

35

S.G.R.

INLET

1500

40

8 BAR GLYCERINE

PRESSURE GAUGE

CHLORINATOR REVISED TO NEW DESIGN

105

35

RISING MAIN

FROM BOREHOLE

40

PIPE CLAMP SEE DETAIL

TANKSTAND

1320

80

75 PL 6 x 75 LONG

FULLY WELDED TO 'a'

WITH 1-12 DIA. HOLE FOR

1-M10 BOLT

(No.REQUIRED : 8x) SEE

FLOOR LAYOUT FOR

POSITIONS

16

75

400

PIPE CLAMP

PIPE CLAMP

50 F 5 x 100 LONG

WITH 1-12dia HOLE

FOR 1-M10 BOLT

23

220mm THICK

BRICK MANHOLE

100

CR02

23

40

A

L

177

16-05-2014

175

223

50

45

45

10

30

45

1100

30

29

10

PIPE CLAMP

500

50 F 5 x 100 LONG

WITH 1-12dia HOLE

FOR 1-M10 BOLT

125

75

45

PIPE CLAMP

35

400

NTS

250

700

950

250

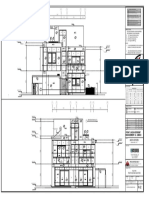

4.5m HIGH ELEVATED WATER TANK (5000 l)

DETAILS AND SECTIONS

275

800

2320

SECTION C-C

SECTION D-D

1:25

1:25

DBE DRAWING NUMBER

EMS NUMBER

DISCIPLANE

DRAWING NUMBER

UWP-25418-001

STATUS

REVISION

CR02

Vous aimerez peut-être aussi

- ANALYSIS AND DESIGN OF Sadddddddddddddd - v4 - 6-5-21Document43 pagesANALYSIS AND DESIGN OF Sadddddddddddddd - v4 - 6-5-21bok1221Pas encore d'évaluation

- Table of Estimation 2Document15 pagesTable of Estimation 2Mylene Robles GupitPas encore d'évaluation

- C-PURLINS 75MM X 50MM X 1.2 THK SPACED @ 600MMDocument1 pageC-PURLINS 75MM X 50MM X 1.2 THK SPACED @ 600MMalezandro del rossiPas encore d'évaluation

- Structural Design Criteria: Load Type Type of OccupancyDocument8 pagesStructural Design Criteria: Load Type Type of OccupancyJoseph TuzonPas encore d'évaluation

- Delta Electronics Chennai Tender Compound Wall PlanDocument1 pageDelta Electronics Chennai Tender Compound Wall Plandox4usePas encore d'évaluation

- Elevated Water TankDocument1 pageElevated Water Tankmr. onePas encore d'évaluation

- Prepared By:: Engr. Mark Roger R Huberit Ii Civil / Structural Engineer PRC NO. 072279Document9 pagesPrepared By:: Engr. Mark Roger R Huberit Ii Civil / Structural Engineer PRC NO. 072279Mark Roger Huberit IIPas encore d'évaluation

- Factory ShedDocument4 pagesFactory ShedKaustubh BharatanshPas encore d'évaluation

- Concrete Estimate by Jack FajardoDocument67 pagesConcrete Estimate by Jack FajardojAck oяensePas encore d'évaluation

- Bar Bending Schedule Slab ReinforcementDocument6 pagesBar Bending Schedule Slab Reinforcementvignesh kumarPas encore d'évaluation

- Proposed Two Storey Residence ReportDocument27 pagesProposed Two Storey Residence ReportchorgedPas encore d'évaluation

- 01 Guard House DetailDocument12 pages01 Guard House DetailAnonymous LuetrJWVpCPas encore d'évaluation

- Structural DrawingDocument8 pagesStructural DrawingS Raj100% (2)

- Bill of Materials Northgate TownhouseDocument4 pagesBill of Materials Northgate TownhouseJohnPas encore d'évaluation

- Rebar Take Off (Skyway)Document2 pagesRebar Take Off (Skyway)Allan SorianoPas encore d'évaluation

- Two Storey Structural DesignDocument9 pagesTwo Storey Structural Designking taugPas encore d'évaluation

- Protection WorkDocument1 pageProtection Workrajivkannan100% (1)

- Estimating - Quantity Take OffDocument11 pagesEstimating - Quantity Take OffpierorrosazzaPas encore d'évaluation

- Elevations R-02-Front and Rear ElevationDocument1 pageElevations R-02-Front and Rear Elevationshonan talpadePas encore d'évaluation

- Structural ReportDocument13 pagesStructural ReportDan SantosPas encore d'évaluation

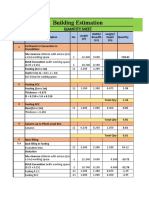

- Building EstimationDocument22 pagesBuilding EstimationMelkamu AmushePas encore d'évaluation

- ReinforcementDocument34 pagesReinforcementKristle Jane VidadPas encore d'évaluation

- Building Estimate DurganagarDocument8 pagesBuilding Estimate DurganagarMriganka GhoshPas encore d'évaluation

- Rusty EstimatesDocument27 pagesRusty EstimatesKim SapongPas encore d'évaluation

- Math1151 Matlab Lab Test PracticeDocument5 pagesMath1151 Matlab Lab Test PracticekelvinPas encore d'évaluation

- Foundation Plan and DetailsDocument1 pageFoundation Plan and DetailsbalramtcsPas encore d'évaluation

- Structural DesignDocument27 pagesStructural Designlandsurveynec100% (1)

- Useful Guidelines For Design of RCC Slab Basic Rules For Slab DesignDocument7 pagesUseful Guidelines For Design of RCC Slab Basic Rules For Slab DesignUsman Shahid100% (1)

- Door Panel & Wall Elevations for Commercial Sari-Sari StoreDocument1 pageDoor Panel & Wall Elevations for Commercial Sari-Sari StoreSharazil Mabanag100% (1)

- 5 Storey OfficeDocument1 page5 Storey Officemaryeonee12Pas encore d'évaluation

- Reinforcement in Column Below Plinth Level Is Less Than That Above. 6 Nos. It Needs To Be ConfirmedDocument3 pagesReinforcement in Column Below Plinth Level Is Less Than That Above. 6 Nos. It Needs To Be ConfirmedSaroj AcharyaPas encore d'évaluation

- One Storey Commercial Building W Mezzanine (Semi-Concrete) - 18-008B - PinagsamaDocument21 pagesOne Storey Commercial Building W Mezzanine (Semi-Concrete) - 18-008B - PinagsamaJohn Michael TalanPas encore d'évaluation

- UG TankDocument27 pagesUG TankJebin JacobPas encore d'évaluation

- Floor Plan SamplesDocument6 pagesFloor Plan SamplesAdewale RajiPas encore d'évaluation

- DPWH School Building Construction ProjectDocument7 pagesDPWH School Building Construction ProjectVernadethCahibaybayanPas encore d'évaluation

- Structural Plan CommentedDocument6 pagesStructural Plan CommentedmikollimPas encore d'évaluation

- Chapter 4.1.2018 - Pad FoundationDocument45 pagesChapter 4.1.2018 - Pad FoundationHawaiiChongPas encore d'évaluation

- DETAILED ESTIMATE FOR RESIDENTIAL BUILDINGDocument6 pagesDETAILED ESTIMATE FOR RESIDENTIAL BUILDINGßålå ĮíPas encore d'évaluation

- Garage Working DrawingDocument2 pagesGarage Working DrawingDante GerundioPas encore d'évaluation

- Project Two Storey Residence Subject Bil PDFDocument5 pagesProject Two Storey Residence Subject Bil PDFRox CardonaPas encore d'évaluation

- House Construction Cost CalculatorDocument2 pagesHouse Construction Cost CalculatorklevinPas encore d'évaluation

- Reference Calculations Output: Project N/A CalculationDocument2 pagesReference Calculations Output: Project N/A CalculationIndustry Standard Structural DesignPas encore d'évaluation

- Extrude Solutions Company Profile October 2009Document11 pagesExtrude Solutions Company Profile October 2009Ernest Christian NanolaPas encore d'évaluation

- Strip Footing Design For WallDocument15 pagesStrip Footing Design For WallAnonymous xIh8FuDtPas encore d'évaluation

- Lintel Beam and Chajja DetailsDocument1 pageLintel Beam and Chajja DetailsIrshad KhanPas encore d'évaluation

- Residential Flats Typical Floor Roof Beam Layout Key PlanDocument1 pageResidential Flats Typical Floor Roof Beam Layout Key Planvenkat rajuPas encore d'évaluation

- Bill of QuantitiesDocument4 pagesBill of QuantitiesMark SorianoPas encore d'évaluation

- Structure DrawingsDocument79 pagesStructure DrawingsxyzhynPas encore d'évaluation

- Sample EstimateDocument13 pagesSample Estimateart freakPas encore d'évaluation

- Proposed Isolation Facility Key MapsDocument13 pagesProposed Isolation Facility Key MapsJohn Alvin MoralesPas encore d'évaluation

- What Is The Size of The Column Reinforcement For A Two-Storey Building With A Span of 4.5 Meters - QuoraDocument3 pagesWhat Is The Size of The Column Reinforcement For A Two-Storey Building With A Span of 4.5 Meters - Quorajohn reyesPas encore d'évaluation

- Beam Design ThumbruleDocument5 pagesBeam Design ThumbrulehipreyashPas encore d'évaluation

- Estimate of SBTWDocument17 pagesEstimate of SBTWSaral MajumderPas encore d'évaluation

- Structural Design Criteria 1.0 Codes and StandardsDocument4 pagesStructural Design Criteria 1.0 Codes and StandardsChrispin BarnigoPas encore d'évaluation

- Steel Reinforcements: Applications, Uses, and SpecsDocument11 pagesSteel Reinforcements: Applications, Uses, and SpecsMa. Christina BangngayPas encore d'évaluation

- Warehouse Floor PlanDocument1 pageWarehouse Floor PlanMaffie Cruz100% (1)

- 4-Storey Steel Structure Residential Building: Toe Myint Naing Curtin Malaysia InternDocument26 pages4-Storey Steel Structure Residential Building: Toe Myint Naing Curtin Malaysia InternMg ToecherrymyayPas encore d'évaluation

- BUDO Swimming Pool BOQs PDFDocument18 pagesBUDO Swimming Pool BOQs PDFMohamed Rushdy79% (14)

- Residential house plans and detailsDocument1 pageResidential house plans and detailsIga_DanPas encore d'évaluation

- Scientific American Supplement, No. 470, January 3, 1885D'EverandScientific American Supplement, No. 470, January 3, 1885Pas encore d'évaluation

- 218140-100 RS-02 First Floor Reinforcement LayoutDocument1 page218140-100 RS-02 First Floor Reinforcement LayoutrendaninPas encore d'évaluation

- 218140-100 RS-02 First Floor Reinforcement LayoutDocument1 page218140-100 RS-02 First Floor Reinforcement LayoutrendaninPas encore d'évaluation

- HCF PDFDocument68 pagesHCF PDFSushmit SharmaPas encore d'évaluation

- 2-25062015 Fly Ash Concrete Has Economical and Environmental Advantages Traa PDFDocument4 pages2-25062015 Fly Ash Concrete Has Economical and Environmental Advantages Traa PDFrendaninPas encore d'évaluation

- Groundwater Investigation - Karoo National Park Technical MeetingDocument3 pagesGroundwater Investigation - Karoo National Park Technical MeetingrendaninPas encore d'évaluation

- GLA-Class Speclist 26052016 ePDFDocument39 pagesGLA-Class Speclist 26052016 ePDFrendaninPas encore d'évaluation

- Irba Audit Compliance FaqDocument7 pagesIrba Audit Compliance FaqrendaninPas encore d'évaluation

- Project Tutorial FEN4702Document26 pagesProject Tutorial FEN4702rendaninPas encore d'évaluation

- 00 Basement Foundation LayoutDocument1 page00 Basement Foundation LayoutrendaninPas encore d'évaluation

- Ramela 1st Floor Slab LayoutDocument1 pageRamela 1st Floor Slab LayoutrendaninPas encore d'évaluation

- VoidCon Technical CatalogueDocument24 pagesVoidCon Technical Cataloguerendanin67% (3)

- 200-01 Basement Foundation ReinforcementDocument1 page200-01 Basement Foundation ReinforcementrendaninPas encore d'évaluation

- Rencrete Designs Offers Quotation for Office of the Premier AdvertisementsDocument1 pageRencrete Designs Offers Quotation for Office of the Premier AdvertisementsrendaninPas encore d'évaluation

- NCCI Design of Reinforced Concrete Filled Hot Finished PDFDocument101 pagesNCCI Design of Reinforced Concrete Filled Hot Finished PDFLau Kim HwaPas encore d'évaluation

- Reinforced Concrete Slab To Be Designed Expansion Joint To DetailDocument1 pageReinforced Concrete Slab To Be Designed Expansion Joint To DetailrendaninPas encore d'évaluation

- 219090-400-RS-01 RC Base BA ReinforcementDocument1 page219090-400-RS-01 RC Base BA ReinforcementrendaninPas encore d'évaluation

- NRS048 1Document14 pagesNRS048 1rendanin100% (1)

- Green Drop Report 2013: Status and Performance of South African Wastewater SystemsDocument7 pagesGreen Drop Report 2013: Status and Performance of South African Wastewater SystemsrendaninPas encore d'évaluation

- 219090-400-RS-01 RC Base BA ReinforcementDocument1 page219090-400-RS-01 RC Base BA ReinforcementrendaninPas encore d'évaluation

- 219090-400-RS-01 RC Base BA ReinforcementDocument1 page219090-400-RS-01 RC Base BA ReinforcementrendaninPas encore d'évaluation

- RUCC Ministries - Contract For StaircaseDocument36 pagesRUCC Ministries - Contract For StaircaserendaninPas encore d'évaluation

- 219090-400-RS-06 Rev 01 First Floor and Staircase Reinforcement DetailsDocument1 page219090-400-RS-06 Rev 01 First Floor and Staircase Reinforcement DetailsrendaninPas encore d'évaluation

- P218261-30 - 01 Gabions DetailsDocument1 pageP218261-30 - 01 Gabions DetailsrendaninPas encore d'évaluation

- 219090-400-RS-01 RC Base BA ReinforcementDocument1 page219090-400-RS-01 RC Base BA ReinforcementrendaninPas encore d'évaluation

- 219090-400-RS-05 Rev 01 Ground Beam ReinforcementDocument1 page219090-400-RS-05 Rev 01 Ground Beam ReinforcementrendaninPas encore d'évaluation

- Rationalized User Specification: Part 3: Procedures For Measurement and ReportingDocument25 pagesRationalized User Specification: Part 3: Procedures For Measurement and ReportingrendaninPas encore d'évaluation

- DWA Annual Report 2017-18 - Final PDFDocument419 pagesDWA Annual Report 2017-18 - Final PDFrendaninPas encore d'évaluation

- Hardy Cross Solutions Rev 04Document2 pagesHardy Cross Solutions Rev 04rendaninPas encore d'évaluation

- Rationalized User Specification: Part 5: Instrumentation and Transducers For Voltage Quality Monitoring and RecordingDocument29 pagesRationalized User Specification: Part 5: Instrumentation and Transducers For Voltage Quality Monitoring and RecordingrendaninPas encore d'évaluation

- NRS048 2Document33 pagesNRS048 2rendanin100% (1)

- Critical Summary PDFDocument2 pagesCritical Summary PDFDillen NgoPas encore d'évaluation

- GO Elementary Problems Cho ChikunDocument115 pagesGO Elementary Problems Cho ChikunfarcasiunPas encore d'évaluation

- Urdu Adab Dehli Shamim Hanfi Number October 2017 Mar 2018Document270 pagesUrdu Adab Dehli Shamim Hanfi Number October 2017 Mar 2018Rashid Ashraf100% (1)

- TDS - Muki Z 2008 - English (Uk) - Issued.26.11.2010Document4 pagesTDS - Muki Z 2008 - English (Uk) - Issued.26.11.2010Keith ChooPas encore d'évaluation

- Top 10 Favorite Heroes in TamilDocument5 pagesTop 10 Favorite Heroes in Tamilfaimie_mohdPas encore d'évaluation

- Brazil Badlands Landscapes RevealedDocument42 pagesBrazil Badlands Landscapes RevealedIvamauro SilvaPas encore d'évaluation

- Web Designer and ERP Software Front End Designer ResumeDocument2 pagesWeb Designer and ERP Software Front End Designer ResumesriniPas encore d'évaluation

- Ofmiceandmen Finalreview 2Document9 pagesOfmiceandmen Finalreview 2api-236119989Pas encore d'évaluation

- Optical Microscope Basic Training PDFDocument96 pagesOptical Microscope Basic Training PDFAndrew HolmesPas encore d'évaluation

- Navigate Intermediate CBDocument215 pagesNavigate Intermediate CBAna MaríaPas encore d'évaluation

- Rizal's Life in Asian CountriesDocument3 pagesRizal's Life in Asian CountriesJenemar0% (1)

- S19 DAP CatalogueDocument109 pagesS19 DAP CataloguepescemagroPas encore d'évaluation

- Unit-4 Landscaping of Functional AreasDocument71 pagesUnit-4 Landscaping of Functional AreaschaplinPas encore d'évaluation

- High Score 1o ESO RevisionDocument5 pagesHigh Score 1o ESO RevisionDaniela osorioPas encore d'évaluation

- Fashion of Early 20th Century Part1Document38 pagesFashion of Early 20th Century Part1MaggieWoods100% (7)

- Chennai MTC Bus RoutesDocument14 pagesChennai MTC Bus RoutesanbugobiPas encore d'évaluation

- Kourtessi Philippakis PDFDocument2 pagesKourtessi Philippakis PDFcatalinPas encore d'évaluation

- Libertango ScoreDocument12 pagesLibertango Scoreapi-406109711100% (2)

- God in LiteratureDocument7 pagesGod in LiteratureJiya AshPas encore d'évaluation

- Apophthegmata Patrum ArticleDocument3 pagesApophthegmata Patrum ArticleGeorge FaragPas encore d'évaluation

- All Over The World - Literary AnalysisDocument2 pagesAll Over The World - Literary AnalysisAndrea Gail Sorrosa100% (1)

- Prem AdrDocument72 pagesPrem AdrHitesh KumarPas encore d'évaluation

- 2011.august NewsletterDocument4 pages2011.august NewsletterHoly Anargyroi Greek Orthodox ChurchPas encore d'évaluation

- Demiroren Mall Case StudyDocument4 pagesDemiroren Mall Case StudyangelmayalPas encore d'évaluation

- Oral Presentation RubricDocument2 pagesOral Presentation Rubricanaojer100% (2)

- Rock Guitar LicksDocument4 pagesRock Guitar LicksAlekanian AlainPas encore d'évaluation

- Paid Client Sample Data CRM HackerDocument12 pagesPaid Client Sample Data CRM HackerUpendraPas encore d'évaluation

- EF3e Preint Progresstest 1 6bDocument8 pagesEF3e Preint Progresstest 1 6bEva Barrales100% (1)

- Silver Danceleb ScriptDocument46 pagesSilver Danceleb ScriptGMGScriptwritingPas encore d'évaluation

- IB History BooksDocument1 pageIB History Booksgarimatiwari_choithramPas encore d'évaluation