Académique Documents

Professionnel Documents

Culture Documents

1

Transféré par

jsmnjasminesCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

1

Transféré par

jsmnjasminesDroits d'auteur :

Formats disponibles

HANG CHEONG

Project:

MACHINERY ENGINEERING (HK) CO., LTD

Subject:

Design Calculatin for Hoisting Lifting Frame

Date:

D & C of

Revision:

Re-provisioning of WSD

Utilities and Infrastructure

No. of Page:

for Centennial Campus, HKUPrepared by:

HANG CHEONG

MACHINERY ENGINEERING (HK) CO. LTD.

()

PROJECT

Re-provisioning of WSD Utilities and Infrastructure

Utilities and Infrastructure

for Centennial Campus, HKU

SUBJECT

Design Calculatin for Hoisting Lifting Frame

19-Oct-09

0

1

13

HANG CHEONG

Project:

MACHINERY ENGINEERING (HK) CO., LTD

D & C of

Re-provisioning of WSD

Subject: Design Calculatin for Hoisting Lifting Frame

Utilities and Infrastructure

Date:

Revision:

Sheet:

19-Oct-09

0

1 of 13

for Centennial Campus, HKU Prepared by:

1.0

Introduction

This design calculation is to check the stability of the temporary lifting platform.

The adopted mjaximum weight of loads to be lifted is 500kg with 25% excess load

when testing.

2.0

Design Standards & References

- Hong Kong Building (Construction) Regulations (1990)

- Structural use of steelwork in Building: BS5950 Part 1

- Guide to BS5950: Section Properties and Member Capacity

- Code of Practice on Wind Effects, HK 2004

HANG CHEONG

Project:

MACHINERY ENGINEERING (HK) CO., LTD

Subject: Design Calculatin for Hoisting Lifting Frame

D & C of

Re-provisioning of WSD

Utilities and Infrastructure

Date:

19-Oct-09

Revision:

Sheet:

0

2 of 13

for Centennial Campus, HKU Prepared by:

3.0

Design Notes and Data

- All structural steelworks shall be designed and constructed in accordance with

BS5950: Part 1 : 1990, Structural Use of Steelwork in Building and Hong Kong

Building (Construction) Regulations 1990.

- All stainless steelworks shall be Grade 316 complying with BS970: Part 1: 1990 an

BS1449: Part 2: 1983. Steel sections to be compiled with BS4: Part 1.

- Welding of stainless steel shall be in accordance with BS EN 1011: Part 3: 2000.

- Unless otherwise specified, all weldings to be 6mm continuous fillet welds.

- Material prpperties:

Stainless Steel

All structural stainless steel to be Grade 316 in accordance with BS970: Part 1: 1

and BS 1449: Part 2

Density

8000

kg/m3

0.2% proof stress

Y0.2

205

N/mm2

Ultimate tensile strength

Us

510

N/mm2

Densign strength

Py

205

N/mm2

Shear strength

Pv

123

N/mm2 (0.6Py)

200000

Modulus of elasticity

N/mm2

Welds

For stainless steel electrode to BS EN 1600: 1997

Design strength of weld

Pw

210

N/mm2

Bolts and Nuts

Design strength of structural steel bolts and nuts of Grade 8.8 to BS 4190 in

conformance to BS5950 area as follows:

Shear strength

Bearing strength

Tensile strength

Ps

375

N/mm2

Pbb =

1035

N/mm2

450

N/mm2

Pt

HANG CHEONG

Project:

MACHINERY ENGINEERING (HK) CO., LTD

D & C of

Re-provisioning of WSD

Subject: Design Calculatin for Hoisting Lifting Frame

Utilities and Infrastructure

19-Oct-09

Date:

Revision:

3 of 13

Sheet:

for Centennial Campus, HKU Prepared by:

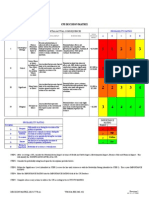

Design for lifting post and beam

Height of post =

2000

mm

Max. eccentricity of loading

e

1630.2

1630.2

mm

2000

4.0

Design Loads

1. Dead Loads

Weight of the post

=

16.8

0.165

x 9.81 x

10

-3

kN/m

2. Live Loads

Weight of Lifting Loading (W) (with 25% exceess working load)

=

500

kg

g

6.13

kN

1.25

So, factored design dead load=

0.165

1.4 =

0.231

kN/m

factored design live load =

6.131

1.6 =

9.810

kN

HANG CHEONG

Project:

MACHINERY ENGINEERING (HK) CO., LTD

D & C of

Re-provisioning of WSD

Subject: Design Calculatin for Hoisting Lifting Frame

19-Oct-09

Date:

Revision:

Utilities and Infrastructure

4 of 13

Sheet:

for Centennial Campus, HKU Prepared by:

5.0

Check

Post

D139.7x6.3 CHS

For

Grade 316 S.S.

D139.7x6.3 CHS

Maximum bending moment

Maximum shear force

M =

9.81

15.99

kNm

Fv =

0.00

kN

Maximum axial compression loadN

For

9.810

10.27

kN

kNm

MT =

Maximum torsional moment

1.63

0.231

D139.7x6.3 CHS

Ix =

261

Iy =

rx =

3.32

cm

ry =

3.32

cm

A =

23.74

cm

cm

261

cm

Zx =

84.3

cm

Sx =

112.0

cm

Zy =

84.3

cm

Sy =

112.0

cm3

3

3

5.1 Check section of

D139.7x6.3 CHS

Post

Check bending moment and co-existent shear force

Shear capacity of section, Pv is given by:

Pv = 0.6PyAv

=

0.6

175.2

Av =

205

0.6

x A =

14.24

cm

-1

10

14.24

kN

Maximum design shear force

0.0

Fv =

kN

< Pv =

175.2

kN

OK!!

(Moment Capacity with low shear load)

Moment capacity of the section

Mcx = PySx

but

PySx =

205

23.0

kNm

1.2PyZx =

=

Mcx =

Mcx 1.2PyZx

20.7

1.2

20.7

kNm

112.00

205

kNm

10

84.30

x

10

10

3

-6

10

-6

HANG CHEONG

Project:

MACHINERY ENGINEERING (HK) CO., LTD

D & C of

Date:

Re-provisioning of WSD

Subject: Design Calculatin for Hoisting Lifting Frame

19-Oct-09

Revision:

Utilities and Infrastructure

Sheet:

0

5 of 13

for Centennial Campus, HKU Prepared by:

Maximum design bending moment

Mx

15.99

20.7

kNm < Mcx =

kNm

OK!!

Check compression force

LE

2000

LE/ry =

60.3

Effective length

Slenderness ratio

mm

Refer to table 27(a), BS5950, Part 1

60.3

For =

Pc

pc

223.6

N/mm2

= Agpc

=

23.7

530.7

223.55

10

-1

kN

10.27

> N =

kN

OK!!

Check overall buckling

g

N

Agpc

Mx

Mb

N =

10.27

Mb

= Mcx

=

N

Agpc

Mb

PyZy

kN

20.7

Mx

My

Mx

15.99

kNm

10.27

10

237.4

223.6

0.96

<

1.0

My

0.00

kNm

My

PyZy

=

=

15.99

20.74

OK!!

kNm

HANG CHEONG

Project:

MACHINERY ENGINEERING (HK) CO., LTD

D & C of

Date:

Re-provisioning of WSD

Subject: Design Calculatin for Hoisting Lifting Frame

19-Oct-09

0

Revision:

Utilities and Infrastructure

Sheet:

6 of 13

for Centennial Campus, HKU Prepared by:

6.0

Check

For

D1139.7x6.3 CHS

Beam

Grade 316 S.S.

D1139.7x6.3 CHS

Maximum bending moment

Maximum shear force

Mx =

9.81

15.99

kNm

Fv =

9.810

kN

0.00

kN

kNm

Maximum axial compression loadN

MT =

Maximum torsional moment

For

x 1.6302

D1139.7x6.3 CHS

Ix =

261

Iy =

rx =

3.32

cm

ry =

3.32

cm

A =

23.74

cm

cm

261

cm

Zx =

84.3

cm

Sx =

112.0

cm

Zy =

84.3

cm

Sy =

112.0

cm

3

3

3

6.1 Check section of

D1139.7x6.3 CHS

Beam

Check bending moment and co-existent shear force

Shear capacity of section, Pv is given by:

Pv = 0.6PyAv

=

0.6

175.2

Av =

205

0.6

x A =

14.24

cm

-1

10

14.24

kN

Maximum design shear force

9.8

Fv =

kN

< Pv =

175.2

kN

OK!!

(Moment Capacity with low shear load)

Moment capacity of the section

Mcx = PySx

but

PySx =

205

23.0

kNm

1.2PyZx =

=

Mcx =

Mcx 1.2PyZx

20.7

> Mx =

1.2

20.7

112.00

205

10

84.30

x

10

10

3

-6

10

kNm

kNm

16 0

16.0

kNm

OK!!

-6

HANG CHEONG

Project:

MACHINERY ENGINEERING (HK) CO., LTD

D & C of

Date:

Re-provisioning of WSD

Subject: Design Calculatin for Hoisting Lifting Frame

19-Oct-09

0

Revision:

Utilities and Infrastructure

7 of 13

Sheet:

for Centennial Campus, HKU Prepared by:

7.0 Welding between member

D139.7x6.3 CHS

Post and steel base plate

Maximum bending moment at connectionM =

16.0

kNm

Maximum vertical load at connection

10.3

kN

Maximum shear force at connection

0.0

kN

Maximum torsional moment at connectionMT =

0.0

kNm

For

D139.7x6.3 CHS

Weld length

thickness of the membe t =

8.08

mm

L = D

Inertia of weld I

929.2

mm

1.931

10

mm

Load on weld due to shear

Fs =

0.0

929.2

0 00

0.00

N/mm

Load on weld due to moment & vertical load

FT =

=

=

M*y

Ix

15.99

N

L

x

10

1.931

431.7

x

10

50.80

6

10.3

0.929

N/mm

Resultant load on weld

FR =

431.7

Provide

N/mm

mm fillet weld, strength =

210

1171

> FR =

x 929.19

N/mm

431.7 N/mm

OK!!

HANG CHEONG

Project:

MACHINERY ENGINEERING (HK) CO., LTD

D & C of

Re-provisioning of WSD

Subject: Design Calculatin for Hoisting Lifting Frame

19-Oct-09

Date:

Revision:

Utilities and Infrastructure

8 of 13

Sheet:

for Centennial Campus, HKU Prepared by:

7.1

Column Base Design

For the moment about major axis,

eN =

Maximum member axial load (Compression) N =

10.27 kN

Maximum bending moment

M =

15.99 kNm

6.3

mm

Member size

520

Provide

6

139.7

Nos.

520

20

20

mm dia. Grade

mm

CHS

mm thick M.S. base plate and

8.8 steel bolts as holding

209

101.6

209

Assume that the maximum permissible

30

stresses occur simultaneously in the

concrete and steel.

M

eN

From the elastic theory of reinforced

concrete design,

g , the depth

p to the neutral

e

C

axis is given by

la

dn = (

mpc

d1

) d1

mpc + pst

m = modular ratio =

dn/3

520

15

pst = permissible stress in holding down bolt

150

N/mm

pc = permissible stress of concrete (Grade 30D/2=

7.5

N/mm

d1 =

490

So,

dn = (

mm

15

15

x

7.5

7.5

210.00

150

490

= 210.00 mm

The level arm

la = d1 - dn/3

=

490

= 420.00 mm

HANG CHEONG

Project:

MACHINERY ENGINEERING (HK) CO., LTD

D & C of

Re-provisioning of WSD

Subject: Design Calculatin for Hoisting Lifting Frame

Date:

Revision:

Utilities and Infrastructure

Sheet:

for Centennial Campus, HKU Prepared by:

Take moments about the centreline of bolts in tension:

Cla = M + Na

C =

=

15.9918 + 10.2715 x

0.230

0.420

43.70

Since

kN

C =

So

=

=

x dn x b x

2 x C

dn x b

43.70

2 x

210.00

N/mm2

0.80

520

< pc =

7.5

N/mm2

OK!!

The tensile force in holding down bolts is

T = C - N

=

43.70

33.43

kN

10.27

Tensile force per bolt =

33.43

16.71

/ 2

kN

The moment in the base slab due to compressive force

Consider a cantilever strip 1 x

209 mm

Base pressure at section xx

fcx = (

210.00

0.00

209.20

210.00

0.80

N/mm2

Mx = (

0.00

209.20

69.73

/ 2 +

0.80

209.20

139.47

/ 2

= 0.0117 kNm/mm

19-Oct-09

0

9 of 13

HANG CHEONG

Project:

MACHINERY ENGINEERING (HK) CO., LTD

D & C of

Re-provisioning of WSD

Subject: Design Calculatin for Hoisting Lifting Frame

19-Oct-09

Date:

Revision:

Utilities and Infrastructure

10 of 13

Sheet:

for Centennial Campus, HKU Prepared by:

Vx = (

x

0.80

0.00

209

1.0 mm thick

cantilever strip

= 0.0840 kN/mm

209

The moment in the base slab due to bolt

tension

Bolt Load

M =

33

16.71

33.43

kN

179

= 2

0.80 N/mm2

520

= 0.01152 kNm/mm

fcx = 0.00 N/mm2

V =

=

33

0.064

520

139

kNm/mm

/

Therefore,

Design bending moment on base plate

11.70

kNm/m

Design shear force on base plate

84.04

kN/m

69.7

HANG CHEONG

Project:

MACHINERY ENGINEERING (HK) CO., LTD

D & C of

Date:

Re-provisioning of WSD

Subject: Design Calculatin for Hoisting Lifting Frame

19-Oct-09

0

Revision:

Utilities and Infrastructure

Sheet:

11 of 13

for Centennial Campus, HKU Prepared by:

7.2

Checking of Base Plate

Maximum tensile force

T =

33.43

10

kN

Check the plate thickness by BS5950

Assume the thickness of the plate

t = [

2.5w

pyp

where

t = [

t =

Provide

2.5

2

2

a - 0.3b

w =

33.43

a =

209.2

mm

x

205

6.8

20

0.12

209

<

520

b =

2

mm

) = 0.12 N/mm2

520

209.2 mm

0.3

209.2

mm

mm thick base plate

OK!!

0.5

HANG CHEONG

Project:

MACHINERY ENGINEERING (HK) CO., LTD

D & C of

Date:

Re-provisioning of WSD

Subject: Design Calculatin for Hoisting Lifting Frame

19-Oct-09

0

Revision:

Utilities and Infrastructure

Sheet:

12 of 13

for Centennial Campus, HKU Prepared by:

7.3

Anchor Bolt Design

Maximum Tensile Load per bo =

16.71

kN

Maximum Shear Load per bolt =

0.00

kN

Provide

Nos.

20

mm dia. Grade

8.8 steel bolts as holding

down bolts for fixing the base plate

Ps

Shear strength

Bearing strength

375

N/mm2

Pbb =

1035

N/mm2

450

N/mm2

Pt

Tensile strength

ft = Ft / At

Design tensile stress

on bolt:

68.22

N/mm2

<

450

N/mm2

fs = Fs / As

Design shear stress

on bolt:

where

where

0.00

N/mm2

<

375

N/mm2

At =

245

mm2

At =

314

mm2

Combined tensile and shear

fs

Ps

ft

Pt

0.152

<

1.4

OK!!

HANG CHEONG

Project:

MACHINERY ENGINEERING (HK) CO., LTD

D & C of

Date:

Re-provisioning of WSD

Subject: Design Calculatin for Hoisting Lifting Frame

Revision:

Utilities and Infrastructure

Sheet:

19-Oct-09

0

13 of 13

for Centennial Campus, HKU Prepared by:

8.0

Check Bearing Capacity of Lifting Eye

Pbs

dtpbs

60

330.0

10

550

10

10

550

-3

kN

AND

Pbs

0.5etpbs

0.5

Take

8.1

20

55

kN

Pbs

55.0

10

-3

(Governing)

9.8

kN >

kN

(the max. resultant force) OK!

Check shear capacity of lifting eye

p

Pv = Avpv

=

0.9

py

where Av = 0.9tD,, p

pv = 0.6py

x

10

35

0.6

340

64.3

kN

>

9.8

kN (the max. resultant force)

OK!

Vous aimerez peut-être aussi

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Safe Scaffolding CodeDocument56 pagesSafe Scaffolding Codejsmnjasmines100% (1)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Decision MatrixDocument12 pagesDecision Matrixrdos14Pas encore d'évaluation

- McKinsey & Co - Nonprofit Board Self-Assessment Tool Short FormDocument6 pagesMcKinsey & Co - Nonprofit Board Self-Assessment Tool Short Formmoctapka088100% (1)

- Boston Qualitative Scoring System for Rey-Osterrieth Complex Figure Effective for Detecting Cognitive Impairment in Parkinson's DiseaseDocument9 pagesBoston Qualitative Scoring System for Rey-Osterrieth Complex Figure Effective for Detecting Cognitive Impairment in Parkinson's DiseaseJuanPas encore d'évaluation

- Health and Safety Manual SampleDocument20 pagesHealth and Safety Manual Samplefaluda1973Pas encore d'évaluation

- Pengenalan Icd-10 Struktur & IsiDocument16 pagesPengenalan Icd-10 Struktur & IsirsudpwslampungPas encore d'évaluation

- Erecting Altering Dismantling Scaffolding Prefabricated Steel Modular Scaffolding Industry Safety Standard 2373Document32 pagesErecting Altering Dismantling Scaffolding Prefabricated Steel Modular Scaffolding Industry Safety Standard 2373madhav0303Pas encore d'évaluation

- Fea 7 Fem ConceptsDocument104 pagesFea 7 Fem Conceptsjsmnjasmines100% (1)

- Roman Questions II PDFDocument738 pagesRoman Questions II PDFjlinderski100% (3)

- Appointment Letter JobDocument30 pagesAppointment Letter JobsalmanPas encore d'évaluation

- Automation With APDLDocument40 pagesAutomation With APDLjsmnjasminesPas encore d'évaluation

- Finger Relaxation Technique Reduces Post-Appendectomy PainDocument13 pagesFinger Relaxation Technique Reduces Post-Appendectomy PainIan ClaxPas encore d'évaluation

- 10 Quadratic Equations-1Document8 pages10 Quadratic Equations-1Jonie Quintal MatienzoPas encore d'évaluation

- Company Policy TemplateDocument4 pagesCompany Policy TemplatejsmnjasminesPas encore d'évaluation

- Applications of Computational Fluid DynamicsDocument7 pagesApplications of Computational Fluid DynamicsjsmnjasminesPas encore d'évaluation

- Answers Key: SET 1: 1.B 2.B 3.B 4.A 5.BDocument2 pagesAnswers Key: SET 1: 1.B 2.B 3.B 4.A 5.BjsmnjasminesPas encore d'évaluation

- C 2 Tutorial BDocument4 pagesC 2 Tutorial BjsmnjasminesPas encore d'évaluation

- Reliance CaseDocument3 pagesReliance CaseAshok ChoudharyPas encore d'évaluation

- Case Study UberDocument2 pagesCase Study UberjsmnjasminesPas encore d'évaluation

- Metric1807 1808Document1 pageMetric1807 1808jsmnjasminesPas encore d'évaluation

- Technology Training & Research Centre Recruitment Drive Objective Questionnaire Set 1Document1 pageTechnology Training & Research Centre Recruitment Drive Objective Questionnaire Set 1jsmnjasminesPas encore d'évaluation

- Balykina GalinaDocument8 pagesBalykina GalinajsmnjasminesPas encore d'évaluation

- 100 Dia Pre ChecklistDocument2 pages100 Dia Pre ChecklistjsmnjasminesPas encore d'évaluation

- Assembly Mdli Modeling Elearning: Peter Barrett November 2012Document16 pagesAssembly Mdli Modeling Elearning: Peter Barrett November 2012jsmnjasminesPas encore d'évaluation

- CAEA v14 Update Part1 Struct Demos 0Document135 pagesCAEA v14 Update Part1 Struct Demos 0joejo_s_hotmailPas encore d'évaluation

- ANSYS LEFM Example Demonstrates Methods to Predict Crack BehaviorDocument13 pagesANSYS LEFM Example Demonstrates Methods to Predict Crack BehaviorjsmnjasminesPas encore d'évaluation

- CAEA v145 Update CFDDocument39 pagesCAEA v145 Update CFDAnonymous ETBwIduGiPas encore d'évaluation

- SL - No Type Course Title Description Duration Next Batch - Last Date FeesDocument1 pageSL - No Type Course Title Description Duration Next Batch - Last Date FeesjsmnjasminesPas encore d'évaluation

- Raci Matrix Template Aaplmajestic JV For TTRCDocument3 pagesRaci Matrix Template Aaplmajestic JV For TTRCjsmnjasminesPas encore d'évaluation

- AAPL Capability Statement - Engineering ServicesDocument41 pagesAAPL Capability Statement - Engineering ServicesjsmnjasminesPas encore d'évaluation

- Adventure Works Adventure Works: S B S ! S B S !Document1 pageAdventure Works Adventure Works: S B S ! S B S !jsmnjasminesPas encore d'évaluation

- Dr. I Ramesh Mithanthaya: 1. Prof. / Vice Principal / Dean (Academics) / Chief Project LeaderDocument7 pagesDr. I Ramesh Mithanthaya: 1. Prof. / Vice Principal / Dean (Academics) / Chief Project LeaderjsmnjasminesPas encore d'évaluation

- GPLDocument5 pagesGPLAjay DevPas encore d'évaluation

- Help with your trip ticketDocument1 pageHelp with your trip ticketranju93100% (1)

- (Business Name) : We Have Your Landscape Needs CoveredDocument1 page(Business Name) : We Have Your Landscape Needs CoveredjsmnjasminesPas encore d'évaluation

- Design of Compression MemberDocument29 pagesDesign of Compression MemberFerry Triyana AnirunPas encore d'évaluation

- What Is Architecture?Document17 pagesWhat Is Architecture?Asad Zafar HaiderPas encore d'évaluation

- Mitchell 1986Document34 pagesMitchell 1986Sara Veronica Florentin CuencaPas encore d'évaluation

- Grammar Booster: Lesson 1Document1 pageGrammar Booster: Lesson 1Diana Carolina Figueroa MendezPas encore d'évaluation

- The Stolen Bacillus - HG WellsDocument6 pagesThe Stolen Bacillus - HG Wells1mad.cheshire.cat1Pas encore d'évaluation

- Blank Character StatsDocument19 pagesBlank Character Stats0114paolPas encore d'évaluation

- IS BIOCLIMATIC ARCHITECTURE A NEW STYLE OF DESIGNDocument5 pagesIS BIOCLIMATIC ARCHITECTURE A NEW STYLE OF DESIGNJorge DávilaPas encore d'évaluation

- Lesson Rubric Team Group (Lesson Plan 1)Document2 pagesLesson Rubric Team Group (Lesson Plan 1)Yodalis VazquezPas encore d'évaluation

- Balkan TribesDocument3 pagesBalkan TribesCANELO_PIANOPas encore d'évaluation

- SMK ST GabrielDocument39 pagesSMK ST Gabrielzanariah1911Pas encore d'évaluation

- STAR Worksheet Interviewing SkillsDocument1 pageSTAR Worksheet Interviewing SkillsCharity WacekePas encore d'évaluation

- MC145031 Encoder Manchester PDFDocument10 pagesMC145031 Encoder Manchester PDFson_gotenPas encore d'évaluation

- Google Fusion Tables: A Case StudyDocument4 pagesGoogle Fusion Tables: A Case StudySeanPas encore d'évaluation

- Vocabulary Prefixes ExercisesDocument2 pagesVocabulary Prefixes ExercisesMarina García CarrascoPas encore d'évaluation

- Saline Water Intrusion in Coastal Aquifers: A Case Study From BangladeshDocument6 pagesSaline Water Intrusion in Coastal Aquifers: A Case Study From BangladeshIOSRJEN : hard copy, certificates, Call for Papers 2013, publishing of journalPas encore d'évaluation

- Malla Reddy Engineering College (Autonomous)Document17 pagesMalla Reddy Engineering College (Autonomous)Ranjith KumarPas encore d'évaluation

- HTTP - WWW - Aphref.aph - Gov.au - House - Committee - Pjcis - nsl2012 - Additional - Discussion Paper PDFDocument61 pagesHTTP - WWW - Aphref.aph - Gov.au - House - Committee - Pjcis - nsl2012 - Additional - Discussion Paper PDFZainul Fikri ZulfikarPas encore d'évaluation

- Fluorescent sensors for detection of heavy metalsDocument36 pagesFluorescent sensors for detection of heavy metalskawtherahmedPas encore d'évaluation

- Perceptron Example (Practice Que)Document26 pagesPerceptron Example (Practice Que)uijnPas encore d'évaluation

- GR 5 Unit Plan 18-19 Art Warli ArtDocument4 pagesGR 5 Unit Plan 18-19 Art Warli ArtSanjay RautPas encore d'évaluation

- Factors That Affect Information and Communication Technology Usage: A Case Study in Management EducationDocument20 pagesFactors That Affect Information and Communication Technology Usage: A Case Study in Management EducationTrần Huy Anh ĐứcPas encore d'évaluation

- Tiger Facts: Physical Characteristics of the Largest CatDocument14 pagesTiger Facts: Physical Characteristics of the Largest CatNagina ChawlaPas encore d'évaluation

- 【小马过河】35 TOEFL iBT Speaking Frequent WordsDocument10 pages【小马过河】35 TOEFL iBT Speaking Frequent WordskakiwnPas encore d'évaluation

- Tamil Literary Garden 2010 Lifetime Achievement Award CeremonyDocument20 pagesTamil Literary Garden 2010 Lifetime Achievement Award CeremonyAnthony VimalPas encore d'évaluation