Académique Documents

Professionnel Documents

Culture Documents

MQ 04-42-00 00 Aerospace Welding

Transféré par

AlfredAriefMaulanaMuijsCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

MQ 04-42-00 00 Aerospace Welding

Transféré par

AlfredAriefMaulanaMuijsDroits d'auteur :

Formats disponibles

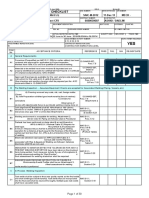

AEROSPACE WELDING

1 PURPOSE & APPLICATION

1.1 This procedure defines the process for performing Aerospace

Welding.

1.2 This procedure applies to all employees involved in Aerospace

Welding.

1.3 This procedure meets at a minimum AWS D17:2001 Specification

for Fusion Welding for Aerospace Structures.

2 RESPONSIBILITIES

2.1

The Quality Director

2.1.1 Oversees personnel certification and audits the process.

2.2 The Production Manager

2.2.1 Coordinates employee training and certification.

2.3 The Welder

2.3.1 Completes the certification process in the time frame

established by the Production Manager.

2.3.2 Keeps the work area clean and free from objects that are

detrimental to the process.

3 PROCEDURE

3.1

Weld Classifications

3.1.1 Classifications will be Class A, Class B, or Class C.

3.1.2 Classifications refer to the level of inspection required and to

the acceptance criteria in MQ-04-42-02-00.

3.2 Welding Consumables

3.2.1 Consumables used in welding (bare welding wire and welding

rods, electrodes, inserts and fluxes) will be identified with at least the

material, specification procured, and size.

3.2.2 If the identification marking is destroyed or missing, the

consumable will be disposed in accordance with Nonconforming

Material Control MQ-05-05-00-00.

3.2.3 When required traceability of the consumables must be

maintained throughout the welding process.

3.2.4 Welding filler materials shall be stored in a clean and dry

environment, such that each material are segregated by size and

material to prevent contamination of materials.

Aerospace Welding

MQ-04-42-00-00 rev 01

3.2.5 Heating may be employed as necessary to prevent moisture

accumulation.

3.2.6 Low Hydrogen SMAW and FCAW electrodes will be handled

and stored in accordance with the manufacturers recommendations.

3.2.7 Fluxes shall be labeled and segregated by type and /or by

their particular application.

3.2.8 Fluxes will be stored in sealed containers to prevent moisture

pickup.

3.3 Welding Gases

3.3.1 The shielding gases shall be procured to the following

requirements unless otherwise required by the customer.

Gas Requirements

Gas

Specification

Argon

Helium

Oxygen

Nitrogen

Hydrogen

Acetylene

Carbon Dioxide

MIL-A-18455

BB-H-1168

B-O-925, Type I or II

A-A-59503, Type I or II, Class I, Grade B

BB-H-886, Type I or II

BB-A-106, Grade B

BB-C-101, Grade B

3.3.2

Alternate

Specification

CGA G-11.1

CGA G-9.1

CGA G-4.3

CGA G-10.1

CGA G-5.3

CGA G-1.1

CGA G-6.2

Recommended Shielding Gases

Recommended Shielding Gases for Welding

Gas

Material

Ar He Ar-He Ar-O(1) Ar-H N CO2

Aluminum

X

X

X

Cobalt

X

X

X

X

Copper

X

X

X

Magnesium

X

X

X

Nickel

X

X

X

(3)

CRES(2)

X

X

X

X

(4)

Plain Carbon Steel X

X

X

X

Low Alloy Steel

X

X

X

X

|1|

Expires 1 day after printing

Ar-CO2

(4)

(4)

Date Printed

Oct 25, 2010

Titanium

3.6

Note: (1) 8% Oxygen Maximum (2) CRES=Corrosion resisting steel (3) Allowed for backing only

(4) Only recommended on plain carbons steels or low alloy steels with a max .25% nominal C

3.4

Welding Equipment

3.4.1 Equipment (welding machines, welding torches, regulators,

filler material feeders, etc) shall be capable of producing welds that

meet the acceptance criteria of MQ-04-42-02-00.

3.4.2 Gas flow meters and pressure gages are for reference only.

They do not require calibration.

3.4.3 Austenitic stainless steel wire brushes or carbon steel wire

brushes may be used on carbon or low alloy steels.

3.4.4 Only austenitic stainless steel wire brushes may be used on

all other materials.

3.4.5 All wire brushes, once used, will be permanently marked a

minimum of all the way around the bottom of the handle in the

following colors for each material.

Wire brush marking colors

Material

Aluminum and its Alloys

Cobalt and its Alloys

Copper and its Alloys

Magnesium and its Alloys

Nickel and its Alloys

CRES Alloys(1)

Carbon and low Alloy Steels

Titanium and its Alloys

Color

Green

Orange

Blue

Purple

Yellow

Red

Black

White

Note: (1) CRES = Corrosion resisting steel

3.5

Preweld cleaning and other preparation

3.5.1 All surfaces to be welded and surfaces that may affect quality

of the resulting weld (ex. Welding filler materials and fixtures) shall

be free from slag, surface oxides, scale, protective finishes, oils,

grease, dirt, or other contaminants.

3.5.2 Chemical methods (ex. Alkaline cleaning, solvent wipe, or

etching) or Mechanical methods (ex. Wire brushing, scraping,

abrasive blasting, or machining) shall be used before welding, as

needed.

3.5.3 Previously cleaned surfaces shall be protected from

contamination. If contamination is suspected, the surface shall be

cleaned again per Paragraph 3.5.2.

Aerospace Welding

MQ-04-42-00-00 rev 01

Preweld joint preparation and fit-up

3.6.1 The edge of each joint member shall be prepared as

specified on the Engineering drawing.

3.6.2 The gap between joint members being welded and between

backing strips (when used) and joint members being welded shall be

in accordance with the Engineering drawing.

3.6.3 Flange joint fit-up shall be in accordance with the Engineering

drawing.

3.7 Preheating and Interpass temperature shall be established for

materials susceptible to cracking during or after welding and be included

in the Production router.

3.8 Filler material for tack welds shall be the same as that used for

subsequent welding unless otherwise specified on the engineering

drawing.

3.8.1 Tack welds shall be consumed during subsequent welding

unless removed in other processing.

3.8.2 The requirements of section 3.6 and 3.7 should be

considered during tack welding operations.

3.9 Weld start and run-off tabs, when used, shall be composed of the

same alloy as the joint members. They shall be welded with the same

filler materials as specified on the Engineering drawing.

3.10 The weld and the heat-affected zones (incl deposited weld metal

behind the weld pool in reactive materials, such as titanium) shall be

protected from oxidation during welding. The shielding method and the

shielding gas shall be included in the Production router.

3.11 Tungsten electrodes, when required shall be in accordance with

AWS A5.12.

3.12 Filler materials used shall be the ones specified on the Engineering

drawing and listed on the Production router.

3.13 Interpass cleaning shall be performed in accordance with

paragraph 3.5.

3.13.1 Interpass cleaning of titanium or titanium alloy parts shall only

be performed following a visual inspection and acceptance of the

surface discoloration requirements of AWS D17 Section 6.

3.14 Welding

3.14.1 The welding arc shall not be struck on any portion of the base

metal away from the surfaces to be joined. When indication of an

arc strike or an arc burn is present in an area other than the

deposited weld metal, the weldment shall be rejected as required in

AWS D17 Section 6.

3.14.2 In process correction

|2|

Expires 1 day after printing

Date Printed

Oct 25, 2010

3.14.2.1 Any correction made by the welder before submitting

the weld for acceptance inspection is and in-process correction.

3.14.2.2 The correction shall not change the metallurgical or

physical condition of the base metal.

3.14.2.3 The correction shall occur before any heat treating

operations. (Note: for the purpose of this requirement a thermal

stress relief operation is not considered to be a heat treat

operation.)

3.14.2.4 Before initiating an in-process correction the surfaces

to be welded shall be cleaned in accordance with paragraph 3.5.

3.14.2.5 One in-process correction attempt is allowed in each

individual flaw location. When the in-process correction requires

more than one attempt at the same flaw location the Production

router must me changed to accommodate and document this

correction.

3.14.3 Weld reinforcement removal shall be accomplished using

methods that do not reduce the thickness of the base metal and

may only be removed for one or more of the following reasons.

3.14.3.1 When specified on the Engineering drawing.

3.14.3.2 When necessary to aid in the interpretation of nondestructive inspection indications. Remaining reinforcement

must be visually evident above the surface plane of the adjacent

joint member and extend throughout the weld bead width. The

weld toe area shall comply with the requirements of MQ-04-4202-00. When fit or function of the final assembly dictate material

removal. Remaining reinforcement must be visually evident

above the surface plane of the adjacent joint member and extend

throughout the weld bead width. The weld toe area shall comply

with the requirements of MQ-04-42-02-00.

3.15 The completed weldment shall be free of spatter, flux, scale, slag,

or other foreign material. Removal of such material shall not reduce the

weld bead size or base metal thickness below the Engineering drawing

requirements.

3.15.1 Postweld cleaning of welded titanium parts shall only be

performed after completion of a visual inspection and acceptance of

the surface discoloration in accordance with MQ-04-42-02-00.

3.16 Welder certification will be in accordance with MQ-04-42-01-00.

Aerospace Welding

MQ-04-42-00-00 rev 01

4 REVISION HISTORY Authored by Travis Mcilnay, approved 4

December 2006.

4.1 Added reference to Inspection Instruction MQ-04-42-02-00.

Authored by Travis Mcilnay, approved 9 December 2006.

Approvals

Document Custodian

9 Dec 2006

Date

Quality Director

9 Dec 2006

Date

President or Vice President

9-Dec 2006

Date

|3|

Expires 1 day after printing

Date Printed

Oct 25, 2010

Vous aimerez peut-être aussi

- Welding DiscontinuitiesDocument6 pagesWelding DiscontinuitiesKanth MekalaPas encore d'évaluation

- SAIC M 2012 (Structural Welding)Document30 pagesSAIC M 2012 (Structural Welding)rubda11100% (1)

- 02-02 - Paint and Protective CoatingsDocument43 pages02-02 - Paint and Protective CoatingsFolayemiPas encore d'évaluation

- Liquid Penetrant TestingDocument13 pagesLiquid Penetrant Testingishfaqurrehmanpk100% (2)

- 4.fabrication Procedure - Rev 2Document13 pages4.fabrication Procedure - Rev 2Nguyen Anh Tuan100% (1)

- Mil-A-8625F Anodizinig Coat For AluminumDocument25 pagesMil-A-8625F Anodizinig Coat For AluminumsrahhalPas encore d'évaluation

- GMW 3044-0405Document5 pagesGMW 3044-0405GilmarasanPas encore d'évaluation

- TSCDocument17 pagesTSCmailbkraoPas encore d'évaluation

- Guidelines for Quality Assurance Plan (QAP) for welding activitiesDocument39 pagesGuidelines for Quality Assurance Plan (QAP) for welding activitiesAchuthan KannankuttyPas encore d'évaluation

- 3PS Gaw 005 - 06Document46 pages3PS Gaw 005 - 06Viveck VivekPas encore d'évaluation

- Painting and Coating Specification GuideDocument21 pagesPainting and Coating Specification GuidealkhiatPas encore d'évaluation

- 02 Samss 012Document9 pages02 Samss 012slan79bisPas encore d'évaluation

- Method Statement For Structural Fabrication & ErectionDocument11 pagesMethod Statement For Structural Fabrication & ErectionBinay94% (16)

- Field Welding ProceduresDocument102 pagesField Welding Procedureslaz_k100% (2)

- SSPC SP3Document2 pagesSSPC SP3hidromecanico78% (9)

- 41 18765 M SP 003 Surface Protection Rev ADocument16 pages41 18765 M SP 003 Surface Protection Rev ARemons PurbaPas encore d'évaluation

- Fab & Erection Pro 20000klR1Document17 pagesFab & Erection Pro 20000klR1Gandhi OnoPas encore d'évaluation

- 0170 g11Document19 pages0170 g11Lokesh NarasimhaiahPas encore d'évaluation

- 3PS Gaw 002Document6 pages3PS Gaw 002ravi00098Pas encore d'évaluation

- Fabrication Inspection ProcedureDocument11 pagesFabrication Inspection Procedurewill_herry100% (6)

- GMW - 4707-2002 Corrosion Protective Coating Zinc Plating OrganicDocument3 pagesGMW - 4707-2002 Corrosion Protective Coating Zinc Plating Organichorse888Pas encore d'évaluation

- CNH Spec MAT2010 - Casting Soundness & Surface QualityDocument14 pagesCNH Spec MAT2010 - Casting Soundness & Surface QualityJoe Scopelite100% (2)

- Reinforced Concrete StandardsDocument13 pagesReinforced Concrete StandardsdophongxdPas encore d'évaluation

- Def Stan 03-32 Part 3 Paint-Systems For Aluminium ArmourDocument10 pagesDef Stan 03-32 Part 3 Paint-Systems For Aluminium ArmourDeepto BanerjeePas encore d'évaluation

- B2020-TDC-VF-009 Vessel Fabrication R0Document5 pagesB2020-TDC-VF-009 Vessel Fabrication R0Ramalingam PrabhakaranPas encore d'évaluation

- TCVN 6008 - 1995: Vietnam StandardDocument11 pagesTCVN 6008 - 1995: Vietnam StandardNguyễn Minh TânPas encore d'évaluation

- Mil DTL 13924Document11 pagesMil DTL 13924Bryan MartinezPas encore d'évaluation

- 1-0september 1993Document20 pages1-0september 1993Bryan MartinezPas encore d'évaluation

- SAIC-M-2012 Rev 7supportsDocument33 pagesSAIC-M-2012 Rev 7supportsvijayachiduPas encore d'évaluation

- Pipeline welding specificationsDocument5 pagesPipeline welding specificationsntrkulja@hotmail.comPas encore d'évaluation

- Checklist for Chapter VIII of ASME B31.3 for Category M PipingDocument5 pagesChecklist for Chapter VIII of ASME B31.3 for Category M PipingiaftPas encore d'évaluation

- 9g V 09 PaintingDocument15 pages9g V 09 Paintingdiuska13100% (1)

- Saj Iacs VSM FertigungsstandardsDocument45 pagesSaj Iacs VSM FertigungsstandardsMajdi JerbiPas encore d'évaluation

- Surface Preparation Specification No. 15: SSPC: The Society For Protective CoatingsDocument6 pagesSurface Preparation Specification No. 15: SSPC: The Society For Protective CoatingsManolo CastilloPas encore d'évaluation

- Ams 2412 KDocument8 pagesAms 2412 KThaís FalcãoPas encore d'évaluation

- Section 16-Part 10-Protective TreatmentDocument3 pagesSection 16-Part 10-Protective TreatmentAdamPas encore d'évaluation

- Piping Welding General Specification Consortium) Rev-3Document48 pagesPiping Welding General Specification Consortium) Rev-3rvsreddy1972Pas encore d'évaluation

- Castings NDE Guide PDFDocument24 pagesCastings NDE Guide PDFAdityaJainPas encore d'évaluation

- A-320 - Fire Proofing of Steel StructureDocument11 pagesA-320 - Fire Proofing of Steel StructurePoorvi Bhave75% (4)

- Splash Zone Coating For Riser PipesDocument11 pagesSplash Zone Coating For Riser PipesĐiệnBiênNhâm100% (2)

- 3PS Gaw 003Document5 pages3PS Gaw 003ravi00098Pas encore d'évaluation

- Corus - A Corrosion Protection GuideDocument6 pagesCorus - A Corrosion Protection GuideBellana SirishPas encore d'évaluation

- MIL-DTL-13924D Black Oxide Coatings SpecificationDocument11 pagesMIL-DTL-13924D Black Oxide Coatings SpecificationltdemonPas encore d'évaluation

- Division 05 MetalsDocument88 pagesDivision 05 MetalsvtalexPas encore d'évaluation

- ITP Structural SteelDocument14 pagesITP Structural SteelNavneet SinghPas encore d'évaluation

- QCS 2010 Part 17.06 WorkmanshipDocument8 pagesQCS 2010 Part 17.06 WorkmanshipRotsapNayrbPas encore d'évaluation

- Api-582-2016-Welding-Guidelines-For-The-Chemical-Oil-And-Gas-Industries-Apiasme-Practice-Test Clause 11.3Document4 pagesApi-582-2016-Welding-Guidelines-For-The-Chemical-Oil-And-Gas-Industries-Apiasme-Practice-Test Clause 11.3Ahmed ElsharkawPas encore d'évaluation

- SECTION 03230 Post-Tensioned TendonsDocument11 pagesSECTION 03230 Post-Tensioned TendonsMohammed Misbahuddin AsifPas encore d'évaluation

- Welding Procedure SpecificationDocument5 pagesWelding Procedure SpecificationyazPas encore d'évaluation

- Offshore Mooring Chain Cables and AccessoriesDocument8 pagesOffshore Mooring Chain Cables and Accessoriesscofiel1Pas encore d'évaluation

- Design Guidelines for Surface Mount TechnologyD'EverandDesign Guidelines for Surface Mount TechnologyÉvaluation : 5 sur 5 étoiles5/5 (1)

- Steel Structures Design Based on Eurocode 3D'EverandSteel Structures Design Based on Eurocode 3Évaluation : 3 sur 5 étoiles3/5 (1)

- Civil Engineering Structures According to the Eurocodes: Inspection and MaintenanceD'EverandCivil Engineering Structures According to the Eurocodes: Inspection and MaintenancePas encore d'évaluation

- Working Guide to Drilling Equipment and OperationsD'EverandWorking Guide to Drilling Equipment and OperationsÉvaluation : 5 sur 5 étoiles5/5 (9)

- Weld Like a Pro: Beginning to Advanced TechniquesD'EverandWeld Like a Pro: Beginning to Advanced TechniquesÉvaluation : 4.5 sur 5 étoiles4.5/5 (6)

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeD'EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticePas encore d'évaluation

- Gasket Calculator 6.0: Quick TorqueDocument22 pagesGasket Calculator 6.0: Quick TorqueAsghat SuicnoPas encore d'évaluation

- Maulana Rosyid Hidayat: Curiculum Vitae 2022Document2 pagesMaulana Rosyid Hidayat: Curiculum Vitae 2022Ridho ImmahdiPas encore d'évaluation

- 2024 Aluminium SheetDocument1 page2024 Aluminium SheetGeorge ChachlakisPas encore d'évaluation

- KP 100Document1 pageKP 100Bhavik Dhami0% (3)

- Eliminating Post-Weld Heat Treatment in Repair Welding by Temper Bead TechniqueDocument9 pagesEliminating Post-Weld Heat Treatment in Repair Welding by Temper Bead TechniqueSyarief NahdiPas encore d'évaluation

- BEE Cement Plant Code FinalDocument4 pagesBEE Cement Plant Code FinalHazem DiabPas encore d'évaluation

- Foopak PE Board (SL) : Technical Data Sheet / Product SpecificationDocument1 pageFoopak PE Board (SL) : Technical Data Sheet / Product SpecificationJonny WijayaPas encore d'évaluation

- Flanges EN 1092Document7 pagesFlanges EN 1092GagrigorePas encore d'évaluation

- Application Guide Jotamastic 90: Areas For Immersed ExposureDocument1 pageApplication Guide Jotamastic 90: Areas For Immersed ExposureTamerTamerPas encore d'évaluation

- BMM3643 Manufacturing Process: 8.0 Materials Removal PROCESSES: MachiningDocument16 pagesBMM3643 Manufacturing Process: 8.0 Materials Removal PROCESSES: MachiningRima ChinnasamyPas encore d'évaluation

- A. Stucki Company: Retroxt LP Bolt On Side Bearing 07563Document1 pageA. Stucki Company: Retroxt LP Bolt On Side Bearing 07563oliveira1305Pas encore d'évaluation

- WWW Steelss Com Carbon Steel St37 3u HTMLDocument4 pagesWWW Steelss Com Carbon Steel St37 3u HTMLdjpinguimPas encore d'évaluation

- Woodworking 101 PDFDocument33 pagesWoodworking 101 PDFGhita HerdeanPas encore d'évaluation

- Qatar Building Engineering Company Site Work Procedure for Building PaintingDocument5 pagesQatar Building Engineering Company Site Work Procedure for Building PaintingTATATAHERPas encore d'évaluation

- Piping Fittings of Wrought Carbon Steel and Alloy Steel For Low-Temperature ServiceDocument6 pagesPiping Fittings of Wrought Carbon Steel and Alloy Steel For Low-Temperature ServicePaulo GalvãoPas encore d'évaluation

- Bangalore Aircraft FacilitiesDocument2 pagesBangalore Aircraft FacilitiesAmit YadavPas encore d'évaluation

- Amendment No. 1 Hot-Dip Zinc Coatings On Steel and Cast Iron ProductsDocument2 pagesAmendment No. 1 Hot-Dip Zinc Coatings On Steel and Cast Iron ProductsGMSPas encore d'évaluation

- Tritech Water Poramax Brochures 8 en SingleDocument5 pagesTritech Water Poramax Brochures 8 en SingleWendyPas encore d'évaluation

- Fully Enclosed: PP - PolypropyleneDocument2 pagesFully Enclosed: PP - PolypropyleneNataliaPas encore d'évaluation

- Top View Section View: CHB Perimeter Walls To Serve As A Catch BasinDocument1 pageTop View Section View: CHB Perimeter Walls To Serve As A Catch BasinJan GarciaPas encore d'évaluation

- Weber 2016Document6 pagesWeber 2016charon lastPas encore d'évaluation

- Click Bond CB309Document2 pagesClick Bond CB309echobravo1Pas encore d'évaluation

- Sopramastic: DescriptionDocument2 pagesSopramastic: DescriptionGabriel Salas OvallePas encore d'évaluation

- Lab ManuDocument12 pagesLab ManuMuhd Muzafar100% (1)

- TDS Nitoproof Damp Protect India2Document2 pagesTDS Nitoproof Damp Protect India2hitesh315Pas encore d'évaluation

- Hempafloor Self-Level 200Document2 pagesHempafloor Self-Level 200Fadi MagdyPas encore d'évaluation

- Reliable Sprinkler Product Services Bulletin 063Document6 pagesReliable Sprinkler Product Services Bulletin 063thebrightsPas encore d'évaluation

- TR7 CNC Machinist and Fitter Roles EmailDocument2 pagesTR7 CNC Machinist and Fitter Roles EmailJemimah BandaPas encore d'évaluation

- Standard Practice For Preparation of Copper and Copper-Base Alloys For Electroplating and Conversion CoatingsDocument4 pagesStandard Practice For Preparation of Copper and Copper-Base Alloys For Electroplating and Conversion CoatingsJulio EcheverryPas encore d'évaluation

- Permanent Mold CastingDocument9 pagesPermanent Mold CastingBrown MeshPas encore d'évaluation