Académique Documents

Professionnel Documents

Culture Documents

Drill Pipe Configuration: 95 % Inspection Class

Transféré par

Saurav SenguptaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Drill Pipe Configuration: 95 % Inspection Class

Transféré par

Saurav SenguptaDroits d'auteur :

Formats disponibles

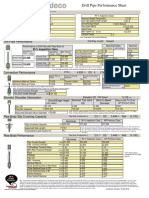

Drill Pipe Performance Sheet

www.NOV.com/GrantPrideco

Phone: +1 (281) 878-8000

Failure: Connection ID is too large. Note: Connection operational tension at Maximum MUT is less than 95% inspection class pipe body in tension, a lower MUT should be considered. Connection

torsional strength is less than 80% pipe body torsional strength.

Drill Pipe Configuration

Pipe Body OD

Pipe Body Wall Thickness

Pipe Body Grade

Drill Pipe Length

Connection

Tool Joint OD

Tool Joint ID

Pin Tong

Box Tong

(in)

(in)

(in)

(in)

(in)

(in)

95 % Inspection Class

Nominal Weight Designation

40.05

(ft) 31.9

Drill Pipe Approximate Length

(in) 3/32 Raised

SmoothEdge Height

(psi) 120,000

Tool Joint SMYS

Upset Type

IEU

(in) 6.906

Max Upset OD (DTE)

Friction Factor

1.0

6.625

0.625

S-135

Range2

GTM69

8.500

5.250

10

15

Note: Tong space may include hardfacing.

Drill-Pipe Length

Drill Pipe Performance

Best Estimates

Performance of Drill Pipe with Pipe Body at

(without Coating)

95 % Inspection Class

Applied Make-up

Torque

Max Tension

Operational

Torque (ft-lbs)

(lbs)

(ft-lbs)

Maximum MUT

59,200

Minimum MUT

49,300

Tension Only

Combined Loading

Tension Only

Combined Loading

0

59,200

1,478,000

1,434,400

0

49,300

1,503,000

1,455,800

Drill Pipe Adjusted Weight

Fluid Displacement

Fluid Displacement

Fluid Capacity

Fluid Capacity

Drift Size

47.98

0.73

(Bbls/ft) 0.0175

(gal/ft) 1.15

(Bbls/ft) 0.0273

(in) 5.125

GTM69

8.500

Applied Make-up

Tension at Shoulder

Torque

Separation

(ft-lbs)

59,200

49,300

(ft-lbs)

(lbs)

(lbs)

Tensile Limited

1,679,100

SmoothEdge Height

(in)

(lbs)

3/32 Raised

8.688

2,251,500

Assumed Elevator Bore Diameter

46.23

0.71

0.0168

1.17

0.0279

(lbs/ft)

1.14

0.0271

OD X

(in)

5.250

Tension at Connection

Yield

(lbs)

(in)

Pipe Body Slip Crushing Capacity

(psi)

Tool Joint Dimensions

Balanced OD

1,478,000

1,760,000

(in)

Minimum Tool Joint OD for API

(in)

Premium Class

Minimum Tool Joint OD for

Counterbore

(in)

8.389

Not Applicable

7.816

Worn to Min TJ OD for

API Premium Class

8.500

1,972,800

Not Applicable

0

8.250

1,610,700

Pipe Body Configuration

(lbs)

(in)

Pipe Body Performance

995,100

8.688

(in)

(ft-lbs)

(ft-lbs)

(psi)

(psi)

(in)

(in)

(in)

(in^2)

(in^2)

(in^2)

(in^3)

(in^3)

6.625 (in) OD

95 % Inspection Class

944,400

Pipe Body Configuration

(lbs)

0.625 (in) Wall

S-135 )

API Premium Class

792,700

Note: Slip Crushing: Slip crushing load is calculated with the Spiri-Reinhold equation from Why Does Drill Pipe

Fail in the Slip Area World Oil, 1959 for the slip length and transverse load factor shown and is for reference

only. Slip crushing is dependent on the slip design and condition, coefficient of friction, loading conditions, time in

slips, drill pipe OD and wall variation, and other factors. Consult with the slip manufacturer for additional

information.

16.5

4.2

Nominal

Pipe Tensile Strength

Pipe Torsional Strength

TJ/PipeBody Torsional Ratio

80% Pipe Torsional Strength

Burst

Collapse

Pipe OD

Wall Thickness

Nominal Pipe ID

Cross Sectional Area of Pipe Body

Cross Sectional Area of OD

Cross Sectional Area of ID

Section Modulus

Polar Section Modulus

120,000

Elevator OD 3/32 Raised

Nominal Tool Joint

Worn to Bevel

OD

Diameter

Nominal

Assumed Slip Length

Transverse Load Factor (K)

Note: Elevator capacity based on assumed Elevator Bore, no wear factor, and contact stress of 110,100psi.

Note: A raised elevator OD increases elevator capacity without affecting make-up torque.

7.031

Slip Crushing Capacity

ID

(in)

Internal Gas Pressure Rating (psi) = Envelope

External Gas Pressure Rating (psi) = Envelope

98,600

1,760,000

Elevator Shoulder Information

Box OD

Elevator Capacity

(least accurate)

(gal/ft)

Note: The maximum make-up torque should be applied when possible.

Note: To maximize connection operational tensile, a MUT (T4) = 51,700 (ft-lbs) should be applied.

Tool Joint Torsional Strength

Tool Joint Tensile Strength

Nominal

(with Coating)

Note: Oil field barrel equals 42 US gallons.

Note: Drill pipe assembly values are best estimates and may vary due to pipe body mill tolerance, internal plastic coating, and other factors.

Connection Performance

Maximum Make-up Torque

Minimum Make-up Torque

Range2

1,590,400

210,000

0.47

168,000

22,288

23,069

6.625

0.625

5.375

11.781

34.472

22.691

16.178

32.356

6.625 (in) OD

95 % Inspection Class

1,503,000

198,100

0.50

158,500

24,198

22,218

6.562

0.594

5.375

11.134

33.824

22.691

15.260

30.520

0.625 (in) Wall

S-135 )

API Premium Class

1,245,800

163,300

0.60

130,700

20,377

18,341

6.375

0.500

5.375

9.228

31.919

22.691

12.582

25.163

Note: Nominal Burst

calculated at 87.5% RBW

per API.

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully

responsible for the accuracy and suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied

warranty is intended. Drill pipe assembly properties are calculated based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear

conditions (remaining body wall) is for information only and does not represent or imply acceptable operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance

ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the application. For API connections that have different pin and box IDs, tool joint ID refers to

the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

www.NOV.com/GrantPrideco/CustomerFeedback

Customer Created 09-06-2013

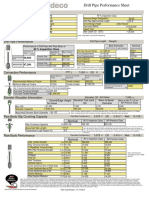

Operational Limits of Drill Pipe

Connection

Pipe Body

GTM69

95 % Inspection Class

Tool Joint OD

(in)

8.500

Tool Joint ID

Pipe Body OD

(in)

6.625

Wall Thickness (in) 0.625

(in)

Combined Loading for Drill Pipe at

(ft-lbs)

0

3,100

6,200

9,300

12,500

15,600

18,700

21,800

24,900

28,000

31,200

34,300

37,400

40,500

43,600

46,700

49,900

53,000

56,100

59,200

(lbs)

1,478,000

1,478,000

1,478,000

1,478,000

1,478,000

1,478,000

1,478,000

1,478,000

1,478,000

1,478,000

1,478,000

1,478,000

1,476,000

1,471,300

1,466,200

1,460,700

1,454,600

1,448,300

1,441,500

1,434,400

S-135

Minimum Make-up Torque = 49,300

(ft-lbs)

Connection Max

Pipe Body

Max Tension Tension

(lbs)

Pipe Body Grade

Combined Loading for Drill Pipe at

Maximum Make-up Torque = 59,200

Operational Assembly

Torque

Max Tension

Tool Joint Specified Minimum

120,000

(psi)

Yield Strength

5.250

Operationa Assembly

l Torque

Max Tension

(ft-lbs)

(lbs)

(lbs)

Pipe Body

Max Tension

(lbs)

(ft-lbs)

Connection

Max Tension

(lbs)

1,503,000 1,478,000

1,503,000

1,503,000

1,679,100

1,502,900 1,478,000

2,600

1,502,900

1,502,900

1,679,100

1,502,300 1,478,000

5,200

1,502,500

1,502,500

1,679,100

1,679,100

1,501,400 1,478,000

7,800

1,501,900

1,501,900

1,500,000 1,478,000

10,400

1,501,000

1,501,000

1,679,100

1,498,400 1,478,000

13,000

1,499,800

1,499,800

1,679,100

1,496,300 1,478,000

15,600

1,498,400

1,498,400

1,679,100

1,493,900 1,478,000

18,200

1,496,700

1,496,700

1,679,100

1,491,100 1,478,000

20,800

1,494,700

1,494,700

1,679,100

1,488,000 1,478,000

23,400

1,492,500

1,492,500

1,679,100

1,679,100

1,484,300 1,478,000

25,900

1,490,100

1,490,100

1,480,300 1,478,000

28,500

1,487,400

1,487,400

1,679,100

1,476,000 1,478,000

31,100

1,484,400

1,484,400

1,679,100

1,471,300 1,478,000

33,700

1,481,100

1,481,100

1,679,100

1,466,200 1,478,000

36,300

1,477,600

1,477,600

1,679,100

1,460,700 1,478,000

38,900

1,473,800

1,473,800

1,679,100

1,469,700

1,469,700

1,679,100

1,679,100

41,500

1,454,600 1,478,000

1,448,300 1,478,000

44,100

1,465,300

1,465,300

1,441,500 1,478,000

46,700

1,460,700

1,460,700

1,679,100

1,434,400 1,478,000

49,300

1,455,800

1,455,800

1,679,100

Operational drilling torque is limited by the Make-up Torque.

Operational drilling torque is limited by the Make-up Torque.

Connection

Make-up Torque Range

Make-up Torque

(ft-lbs)

Min MUT

Max MUT

49,300

50,400

51,500

52,600

53,700

54,800

55,900

57,000

58,100

59,200

Connection Max

Tension

(lbs)

1,679,100

1,716,600

1,754,000

1,725,400

1,684,200

1,643,000

1,601,700

1,560,500

1,519,300

1,478,000

Note: Recommended MUT should always be used when possible. If not possible, MUT should be as close to Recommended MUT as possible.

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully responsible for the accuracy and

suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated

based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable

operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the

application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

09-06-2013

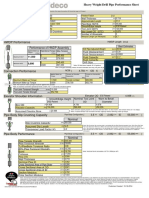

Connection Wear Table

Connection

GTM69

Tool Joint OD

Connection

Wear

Tool

Joint OD

New OD

(in)

8.5

8.438

8.376

8.313

8.251

8.189

8.127

8.065

8.003

7.94

7.878

7.816

Worn OD

(in)

8.500

Tool Joint ID

(in)

Tool Joint Specified Minimum

120,000

(psi)

Yield Strength

5.250

Connection Max

Tension

Connection

Torsional

Strength (ft-lbs)

Max

MUT

98,600

98,600

97,500

91,700

86,200

80,700

75,200

69,800

64,500

59,100

53,900

48,800

59,200

59,200

58,500

55,000

51,700

48,400

45,100

41,900

38,700

35,500

32,400

29,300

(ft-lbs)

Connection Max

Tension

Min MUT

(lbs)

(lbs)

(ft-lbs)

1,478,000

1,438,500

1,423,200

1,500,100

1,565,000

1,624,300

1,678,200

1,673,400

1,610,300

1,467,500

1,334,400

1,206,700

49,300

1,679,100

49,300

1,722,100

48,800

1,752,400

45,800

1,697,800

43,100

1,652,600

40,400

1,606,800

37,600

1,556,200

34,900

1,464,900

32,200

1,339,800

29,600

1,223,600

27,000

1,112,000

24,400

1,004,900

Pipe Body

Combined Loading Table (Torque-Tension)

Pipe Body

95 % Inspection Class

Pipe Body Torque

Pipe Body OD

18,000

36,000

(in)

6.625

54,000

72,000

Wall Thickness (in) 0.625

90,100

108,100

126,100

Pipe Body Grade

144,100

S-135

162,100

180,100

198,100

Pipe Body Max

1,503,000 1,496,800 1,478,000 1,446,100 1,400,300 1,338,600 1,259,600 1,159,200 1,031,500 864,100

Tension

(lbs)

626,200

16,500

(ft-lbs)

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully responsible for the accuracy and

suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated

based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable

operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the

application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

09-06-2013

Vous aimerez peut-être aussi

- How to prepare Welding Procedures for Oil & Gas PipelinesD'EverandHow to prepare Welding Procedures for Oil & Gas PipelinesÉvaluation : 5 sur 5 étoiles5/5 (1)

- DrillPipe, 80%, 3.500 OD, 0.449 Wall, EU, G-105.. XT39 (4.938 X 2.563) PDFDocument3 pagesDrillPipe, 80%, 3.500 OD, 0.449 Wall, EU, G-105.. XT39 (4.938 X 2.563) PDFGarcia C L Alberto100% (1)

- DrillPipe, 80%, 5.000 OD, 0.500 Wall, IEU, S-135.. XT50 (6.625 X 3.750Document3 pagesDrillPipe, 80%, 5.000 OD, 0.500 Wall, IEU, S-135.. XT50 (6.625 X 3.750Инженер Луис А. ГарсиаPas encore d'évaluation

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance Sheetjinyuan74Pas encore d'évaluation

- DrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Document3 pagesDrillPipe, 80%, 4.000 OD, 0.330 Wall, IU, G-105.. XT39 (4.875 X 2.563)Johann ZabaletaPas encore d'évaluation

- Drill Pipe Performance Sheet 5.875 XT57 G105Document3 pagesDrill Pipe Performance Sheet 5.875 XT57 G105Garcia C L AlbertoPas encore d'évaluation

- LandingString, 80%, 5.875 OD, 0.750 Wall, IEU, S-135.. XT57 (7.250 X 3.500)Document3 pagesLandingString, 80%, 5.875 OD, 0.750 Wall, IEU, S-135.. XT57 (7.250 X 3.500)Garcia C L AlbertoPas encore d'évaluation

- DrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Document3 pagesDrillPipe, 80%, 5.000 OD, 0.362 Wall, IEU, X-95.. XT50 (6.625 X 3.938)Johann ZabaletaPas encore d'évaluation

- Drill Pipe Performance SheetDocument3 pagesDrill Pipe Performance SheetGarcia C L AlbertoPas encore d'évaluation

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 pagesDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaPas encore d'évaluation

- DrillPipe, 80%, 5.875 OD, 0.500 Wall, IEU, S-135.. XT57 (7.000 X 4.250)Document3 pagesDrillPipe, 80%, 5.875 OD, 0.500 Wall, IEU, S-135.. XT57 (7.000 X 4.250)Garcia C L AlbertoPas encore d'évaluation

- DrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Document3 pagesDrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Garcia C L AlbertoPas encore d'évaluation

- HeavyWeight 3.5 25.58lbs NC-38Document3 pagesHeavyWeight 3.5 25.58lbs NC-38Инженер Луис А. ГарсиаPas encore d'évaluation

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoPas encore d'évaluation

- Drill CollarDocument1 pageDrill CollarGuillermo Rangel AvalosPas encore d'évaluation

- 2.500 X 1.375 DC With MW20 SlickDocument1 page2.500 X 1.375 DC With MW20 SlickHadi Bapir SlemanPas encore d'évaluation

- 4.000in 0.330wall IU CYX105-120 XT39 (4.875 X 2.688 TJ) 12P 15BDocument3 pages4.000in 0.330wall IU CYX105-120 XT39 (4.875 X 2.688 TJ) 12P 15BjohangomezruizPas encore d'évaluation

- Trispiral XT39Document1 pageTrispiral XT39Cerón Niño SantiagoPas encore d'évaluation

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoPas encore d'évaluation

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Drill Pipe: Pipe Body: Tubular Assemblymsm.ele2009Pas encore d'évaluation

- Xt39 Spec SheetDocument3 pagesXt39 Spec SheetjdcomptonPas encore d'évaluation

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoPas encore d'évaluation

- 5.000in 0.362wall IEU S135 NC50 (6.625 X 3.250 TJ) 9P 12BDocument3 pages5.000in 0.362wall IEU S135 NC50 (6.625 X 3.250 TJ) 9P 12BJeaneth HerreraPas encore d'évaluation

- 5 7/8" VM-165 R2 Pipe SpecsDocument2 pages5 7/8" VM-165 R2 Pipe SpecsTiffany DacinoPas encore d'évaluation

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoPas encore d'évaluation

- 5 7/8" 23.4 PPF S135 Pipe SpecsDocument2 pages5 7/8" 23.4 PPF S135 Pipe SpecsTiffany DacinoPas encore d'évaluation

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJohann ZabaletaPas encore d'évaluation

- Section 19 - Appendix C - FormsDocument52 pagesSection 19 - Appendix C - Formsfivehours5Pas encore d'évaluation

- Beam End Connection ReportDocument6 pagesBeam End Connection ReportHibri HalimPas encore d'évaluation

- Landing String 6.625 .938 v150 FH Slip Proof 95rbw PDFDocument4 pagesLanding String 6.625 .938 v150 FH Slip Proof 95rbw PDFMarcelo VeronezPas encore d'évaluation

- Pipe Rack Hilti Bolt CalculationsDocument6 pagesPipe Rack Hilti Bolt CalculationsAnonymous MAQrYFQDzVPas encore d'évaluation

- ITEM 564.00010001 - Bridge Hanger Fabrication and InstallationDocument14 pagesITEM 564.00010001 - Bridge Hanger Fabrication and InstallationKY PengPas encore d'évaluation

- 1 Input Data: Profis Anchor 2.4.6Document6 pages1 Input Data: Profis Anchor 2.4.6Naresh KumarPas encore d'évaluation

- 250x16 Shs Column Base - Pa2123Document5 pages250x16 Shs Column Base - Pa2123ihpeterPas encore d'évaluation

- Principle of Operation: Target Inline FlowmeterDocument7 pagesPrinciple of Operation: Target Inline Flowmeterابزار دقیقPas encore d'évaluation

- Application Example: Pneumatic 2-Finger Parallel GripperDocument35 pagesApplication Example: Pneumatic 2-Finger Parallel GripperBaltazar EspinosaPas encore d'évaluation

- DTW 1213 Protective Fabric Sleeve For Single Hydraulic HosesDocument6 pagesDTW 1213 Protective Fabric Sleeve For Single Hydraulic HosesRaymundo68Pas encore d'évaluation

- Fabrication Inspection ProcedureDocument11 pagesFabrication Inspection Procedurewill_herry100% (6)

- Type 501 453 UniversalDocument1 pageType 501 453 Universalrambala123Pas encore d'évaluation

- 6-15-0003 Rev 4Document9 pages6-15-0003 Rev 4cynidePas encore d'évaluation

- Shear Load CalculationDocument8 pagesShear Load Calculationvinny1978Pas encore d'évaluation

- Oil Sands Fact SheetDocument47 pagesOil Sands Fact SheetAnonymous B7pghhPas encore d'évaluation

- Crimp HandbookDocument24 pagesCrimp Handbookrony_lesbtPas encore d'évaluation

- PV Elite Vessel Analysis Program: Input DataDocument90 pagesPV Elite Vessel Analysis Program: Input DatajahiranazriPas encore d'évaluation

- Local Stress Calculation Sheet - Edition 4-July-15Document20 pagesLocal Stress Calculation Sheet - Edition 4-July-15Prashant AgrawalPas encore d'évaluation

- AA SPEC 371001 - Conveyor Pulleys and ShaftsDocument14 pagesAA SPEC 371001 - Conveyor Pulleys and Shaftsjonodo89Pas encore d'évaluation

- Astm Lupoy ns5000c - EngDocument2 pagesAstm Lupoy ns5000c - EngJosh DineshPas encore d'évaluation

- Weld Like a Pro: Beginning to Advanced TechniquesD'EverandWeld Like a Pro: Beginning to Advanced TechniquesÉvaluation : 4.5 sur 5 étoiles4.5/5 (6)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsD'EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsÉvaluation : 4.5 sur 5 étoiles4.5/5 (10)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AD'EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&APas encore d'évaluation

- All-in-One Manual of Industrial Piping Practice and MaintenanceD'EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceÉvaluation : 5 sur 5 étoiles5/5 (1)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerD'EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerÉvaluation : 5 sur 5 étoiles5/5 (1)

- Process Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationD'EverandProcess Control for Sheet-Metal Stamping: Process Modeling, Controller Design and Shop-Floor ImplementationPas encore d'évaluation

- SyllabusDocument1 pageSyllabusSaurav SenguptaPas encore d'évaluation

- SyllabusDocument1 pageSyllabusSaurav SenguptaPas encore d'évaluation

- SyllabusDocument1 pageSyllabusSaurav SenguptaPas encore d'évaluation

- Environmental Protection Agency: Federal FundsDocument18 pagesEnvironmental Protection Agency: Federal FundsSaurav SenguptaPas encore d'évaluation

- NED CertificateDocument1 pageNED CertificateSaurav SenguptaPas encore d'évaluation

- Performa For Teaching SchemeDocument13 pagesPerforma For Teaching SchemeSaurav SenguptaPas encore d'évaluation

- Teaching SchemeDocument10 pagesTeaching SchemeSaurav SenguptaPas encore d'évaluation

- IIT (ISM) SyllabusDocument34 pagesIIT (ISM) SyllabusSaurav SenguptaPas encore d'évaluation

- Oil and Gas Well TestingDocument1 pageOil and Gas Well TestingSaurav SenguptaPas encore d'évaluation

- 11 Chapter 1Document56 pages11 Chapter 1Saurav SenguptaPas encore d'évaluation

- Q. 1 - Q. 5 Carry One Mark EachDocument19 pagesQ. 1 - Q. 5 Carry One Mark EachSaurav Sengupta0% (1)

- Lecture 5 Drill Bit Types and Their ApplicationsDocument8 pagesLecture 5 Drill Bit Types and Their ApplicationsSaurav SenguptaPas encore d'évaluation

- Sensitivities of The States Which Fear That Once A District Is Taken Off The List Financial Aid Which Is MadeDocument1 pageSensitivities of The States Which Fear That Once A District Is Taken Off The List Financial Aid Which Is MadeSaurav SenguptaPas encore d'évaluation

- Mechanical Behavior of Concentric & Eccentric Casing, Cement & Formation Using Analytical & Numerical MethodDocument15 pagesMechanical Behavior of Concentric & Eccentric Casing, Cement & Formation Using Analytical & Numerical MethodSaurav SenguptaPas encore d'évaluation

- Gas LoopDocument18 pagesGas LoopSaurav SenguptaPas encore d'évaluation

- HVAC Loren Cook FansDocument28 pagesHVAC Loren Cook FansExcelPas encore d'évaluation

- TC1 ModDocument1 pageTC1 ModAlexander SverdlovPas encore d'évaluation

- fa4c-2pd-FAN COIL UNITDocument15 pagesfa4c-2pd-FAN COIL UNITAhmed KhattabPas encore d'évaluation

- Flange Weight Charts Asme B16.5Document7 pagesFlange Weight Charts Asme B16.5lupiPas encore d'évaluation

- ALLSTYLE CatalogwebDocument48 pagesALLSTYLE CatalogwebjorgegalezoPas encore d'évaluation

- Factored Load Factored StrengthDocument12 pagesFactored Load Factored Strengthhello whelloPas encore d'évaluation

- Dyna Lift Flyer - 500 FL 000010 en (1) ELECTRICO CYLINDERDocument20 pagesDyna Lift Flyer - 500 FL 000010 en (1) ELECTRICO CYLINDERMARCO HernándezPas encore d'évaluation

- Gutter DesignDocument6 pagesGutter Designtawas200% (1)

- Fitting Lab ReportDocument15 pagesFitting Lab ReportMUHAMMAD AMIRUL HANIF AHMADPas encore d'évaluation

- Air Arms TX200Document8 pagesAir Arms TX200kurakPas encore d'évaluation

- CEMA Standard 501.1-2015Document16 pagesCEMA Standard 501.1-2015MPas encore d'évaluation

- BS 1868, BS 1873 MSS SP80 / BS 5154 BS 5154 Api 600, Api 6D Api 603 BS 5351 MSS SP-71Document1 pageBS 1868, BS 1873 MSS SP80 / BS 5154 BS 5154 Api 600, Api 6D Api 603 BS 5351 MSS SP-71sajanchaudhariPas encore d'évaluation

- TC1569 Drilling Choke Control System Model CW Control PanelDocument74 pagesTC1569 Drilling Choke Control System Model CW Control PanelrolandPas encore d'évaluation

- Short Answers of ATDDocument8 pagesShort Answers of ATDPunith YadavPas encore d'évaluation

- 21 Scrap Cutter MSCDocument4 pages21 Scrap Cutter MSCCorporación NSI, C.A. Corporación NSI, C.A.Pas encore d'évaluation

- MOC-0116 Piping Material Take Off For 20" Pipe Line From Ds5 To New Produced Water Evaporation PondDocument3 pagesMOC-0116 Piping Material Take Off For 20" Pipe Line From Ds5 To New Produced Water Evaporation PondMurtadda MohammedPas encore d'évaluation

- Price Master ListDocument20 pagesPrice Master ListKaren Balisacan Segundo Ruiz100% (1)

- PTC Inspector Training Manual Spark MindaDocument20 pagesPTC Inspector Training Manual Spark MindaYogiPas encore d'évaluation

- Spare Parts List CP100-400Document7 pagesSpare Parts List CP100-400Gaëlle HennebelPas encore d'évaluation

- Jaw Fassi Grabber - Parts CatalogueDocument1 pageJaw Fassi Grabber - Parts CatalogueHarun OrionPas encore d'évaluation

- Model 5803 Advance Control Base For The Modular Table System Maintenance and Repair ManualDocument43 pagesModel 5803 Advance Control Base For The Modular Table System Maintenance and Repair ManualSergio MontesPas encore d'évaluation

- Asko Dryer Spare Parts Catalog 2003 EditionDocument12 pagesAsko Dryer Spare Parts Catalog 2003 EditionTom SenbergPas encore d'évaluation

- School Form 1 School Register For Senior High School (SF1-SHS)Document4 pagesSchool Form 1 School Register For Senior High School (SF1-SHS)dominic dalton calingPas encore d'évaluation

- Fisher EZ Sliding - Stem Control Valve: The Easy - Et Valve FamilyDocument20 pagesFisher EZ Sliding - Stem Control Valve: The Easy - Et Valve FamilyAlberto GuillenPas encore d'évaluation

- 20engine PDFDocument18 pages20engine PDFKEVINPas encore d'évaluation

- American Society of Heating, Refrigerating and Air-Conditioning EngineersDocument3 pagesAmerican Society of Heating, Refrigerating and Air-Conditioning EngineersMohammed YasserPas encore d'évaluation

- Attachment 1 API SC6 Plenary 6DDocument33 pagesAttachment 1 API SC6 Plenary 6Dderinn_cPas encore d'évaluation

- Iso 261-1998Document8 pagesIso 261-1998Pippo LandiPas encore d'évaluation

- Propane Reflux PumpDocument6 pagesPropane Reflux PumpBT20MEC047 Jeet BhaktaPas encore d'évaluation

- Workshop 1 Welding : Arc Welding & Spot WeldingDocument2 pagesWorkshop 1 Welding : Arc Welding & Spot Weldingsherif115040 BuePas encore d'évaluation