Académique Documents

Professionnel Documents

Culture Documents

Design and Optimization of Exhaust Muffler

Transféré par

Benjamín AlainDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Design and Optimization of Exhaust Muffler

Transféré par

Benjamín AlainDroits d'auteur :

Formats disponibles

DESIGN & OPTIMIZATION OF EXHAUST MUFFLER &

DESIGN VALIDATION

1

RAHUL D. NAZIRKAR, 2S.R.MESHRAM, 3AMOL D. NAMDAS, 4SURAJ U. NAVAGIRE,

5

SUMIT S. DEVARSHI

1,2,3,4,5

Department of Mechanical Engineering, Sinhgad Institute of Technology, Lonavala-410401, India

Abstract- For an automotive exhaust system the noise level, transmission loss & back pressure are the most important

parameters for the driver & engine performance. In order to improve the design efficiency of muffler, resonating of the

exhaust muffler should be avoided by its natural frequency. Mufflers are most important part of the engine system and it is

commonly used in the exhaust system to minimize the sound transmission level which is caused by exhaust gases. The design

of muffler becomes more and more important for noise reduction. The solid modeling of exhaust muffler is created by

CATIA-V5 and modal analysis is carried out by ANSYS to study the vibration and natural frequency of muffler. So as to

differentiate between the working frequency from natural frequency and avoid resonating..

Keywords- Exhaust muffler; Creating 3-D model in CATIA-V5; Modal analysis; Mode shape

constant source of trouble to the environment.

Significantly, the exhaust noise in terms of

pressure is about 10 times all the other noises

(structural noise) combined. So the problems of

reducing engine noise consist, mainly in attenuating

exhaust noise.

I. INTRODUCTION

Expansion chambers are effective tools for

reducing noise in several applications. The most

familiar example is probably the automotive muffler,

where a single tuned expansion chamber is utilized.

Therefore, automotive exhaust system is a significant

part of exhaust system. There are several parameters

that describe the acoustic performance of a muffler

and/or its associated piping. These include the

noise reduction (NR), the insertion loss(IL), and the

transmission loss (TL). The NR is the sound

pressure level difference across the muffler.

Though the NR can be easily measured, it is

not particularly helpful for muffler design. The IL

is the sound pressure level difference at a point,

usually outside the system, without and with the

muffler present. Though the IL is very useful to

industry, it is not so easy to calculate since it

depends not only on the muffler geometry itself

but

also

on

the source impedance and the

radiation impedance.

The design of mufflers has been a topic of

great interest for many years and hence a great deal of

understanding

has been gained. Most of the

advances in the theory of acoustic filters and exhaust

mufflers have come about in the last four

decades. Hence good design of the muffler

should give the best noise reduction

and

offer

optimum backpressure for the engine. Moreover, for

a given internal configuration mufflers have to work

for a broad range of engine speed.

III. DESIGN

There are numerous variations of the two main types

of muffler designs commonly used, namely absorptive

and reactive. Generally automotive mufflers will have

both reactive and absorptive properties. [3]

The TL is the difference in the sound power

level between the incident wave entering and the

transmitted wave exiting the muffler when the

muffler termination is anechoic; the TL is a property

of the muffler only. The muffler TL may be

calculated from models but is difficult to

measure. This paper will focus on measuring the

muffler TL. [1]

A. Benchmarking

The first step in any design is to set a target by doing

the benchmarking. The same will be applicable for the

silencer here, to set a target in terms of transmission

loss.

B. Target Frequencies

After doing benchmarking exercise, there is needs to

calculate the target frequencies to give more

concentration of higher transmission loss. For

calculating the target frequencies engine max power

rpm is required and calculation follows,

II. BASIC THEORY

Since the invention of the internal combustion

engine in the latter part of the nineteenth

century, the noise created by it has been a

Proceedings of 10th IRF International Conference, 01st June-2014, Pune, India, ISBN: 978-93-84209-23-0

31

Design & Optimization of Exhaust Muffler & Design Validation

Theoretical Computation:

The exhaust tones are calculated using the following

Formulae:

CFR = Engine Speed in RPM/60 . For a two stroke

engine

(1)

= Engine Speed in RPM/120 .For a four-stroke

engine

(2)

EFR = n X (CFR)

(3)

C. Muffler Volume Calculation Volume Of the

muffler (Vm):

D. Internal Configuration And Concept Design

Based on the benchmarking transmission loss and

target frequencies the designer draws the few concept

of the internal configuration.

The diameter of the hole to be drilled on the pipe is

calculated as;

In matlab simulation the value of transmission loss

becomes 6.078 db and by using mathematical equation

transmission loss becomes 6.04 db. So, the MATLAB

simulation model is validated and percentage error in

between this is 0.625 %.

G. Single Expansion Chamber

The measured natural frequency of muffler of mode

shape 1 is 562.9 Hz.

Proceedings of 10th IRF International Conference, 01st June-2014, Pune, India, ISBN: 978-93-84209-23-0

32

Design & Optimization of Exhaust Muffler & Design Validation

The measured natural frequency of muffler of mode

shape 5 is 1529.2 Hz.

H. Double Expansion Chamber

The measured natural frequency of muffler of mode

shape 2 is 765.9 Hz.

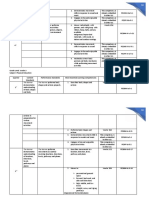

Fig.7

Modal Analysis

The measured natural frequency of muffler of mode

shape 3 is 765.21 Hz.

The measured natural frequency of muffler of mode

shape 1 is 583.62 Hz.

The measured natural frequency of muffler of mode

shape 4 is 1029.7 Hz.

The measured natural frequency of muffler of mode

shape 2 is 637.7 Hz.

Proceedings of 10th IRF International Conference, 01st June-2014, Pune, India, ISBN: 978-93-84209-23-0

33

Design & Optimization of Exhaust Muffler & Design Validation

The measured natural frequency of muffler of mode

shape 3 is 650.72 Hz.

In this model the first protrusion i.e., inlet pipe is

included 100mm inside the muffler and then analysis

is carried out.

The measured natural frequency of muffler of mode

shape 4 is 650.72 Hz.

The TL result for given model is 19.62 db.

The measured natural frequency of muffler of mode

shape 5 is 1001.1 Hz.

Transmission loss should be more than 30 db. In this

muffler, transmission loss becomes 19.62 db. So it is

not satisfying condition.

IV. OPTIMIZATION

(A) Single Expansion Chamber

The different transmission loss of single expansion

chamber is at different protrusion. These different

models are as below;

I. Single Expansion Chamber with First Protrusion

II. Single Expansion Chamber with Front And Back

Protrusion Muffler

Proceedings of 10th IRF International Conference, 01st June-2014, Pune, India, ISBN: 978-93-84209-23-0

34

Design & Optimization of Exhaust Muffler & Design Validation

In this double expansion chamber the inlet protrusion

is increased by 100mm and outlet protrusion is

increased by 50mm and then analysis is done.

Transmission loss should be more than 30 db. In this

muffler, transmission loss becomes 21.24 db. So it is

not satisfying condition.

The transmission loss of single expansion chamber is

6.04 db which is less than requirement i.e., 30 db and

it is not satisfactory. So, it is not satisfying condition.

Therefore, for the better sound quality and

transmission loss we are doing optimization in the

double expansion chamber.

(B) Double expansion chamber

Transmission loss should be more than 30 db. In this

muffler, transmission loss becomes 42.48 db. So, it is

satisfying condition. So, it is optimized condition in

the consideration of transmission loss.

V. RESULTS

The results of modal analysis for the six natural

frequencies of single expansion chamber of muffler is

in Table I

Proceedings of 10th IRF International Conference, 01st June-2014, Pune, India, ISBN: 978-93-84209-23-0

35

Design & Optimization of Exhaust Muffler & Design Validation

TABLE I. COMPARISON OF MEASURED AND

EXPERIMENTAL NATURAL FREQUENCY

The results of modal analysis for double expansion

chamber of inlet and outlet at different fixing positions

are shown in tabulated form;

TABLE II. FIXED AT FRONT END

TABLE III. FIXED AT FIRST AND LAST END

TABLE IV. FIXED AT MIDDLE PIPE

Proceedings of 10th IRF International Conference, 01st June-2014, Pune, India, ISBN: 978-93-84209-23-0

36

Design & Optimization of Exhaust Muffler & Design Validation

CONCLUSION

Double expansion chamber gives better results as

compared to single expansion chamber. Transmission

loss of double expansion chamber is 42.48 which is

more than requirement and satisfactory. Also Natural

frequency of double expansion chamber is within

range of 583.62 to 1001.1 Hz resulting in no

resonance. By fixing the muffler at first and double

expansion chamber we can increase the frequency and

avoid the resonance. Transmission loss of the muffler

can be increased by adding protrusion pipe at inlet and

outlet. It can be seen that the finite element modal

analysis has certain significance in the study of

vibration characteristics of the muffler. The time

required for optimization of muffler using ANSYS

and MATLAB is very short and can be repeated

simply after changing the input parameters which

provides an easy way to find an optimum solution for

muffler design.

VII. FUTURE WORK

The muffler which we are going to create that is little

big in size. So, in future the size of muffler can be

minimize to a proper size which can be suitable for the

motorcycle. Also there is a scope to calculate back

pressure. Also because of reduction in size of muffler

the manufacturing cost of muffler can also be reduce.

Due to reduction in the muffler the requirement of

space is also less.

REFERENCES

[1]

Z. Tao & A.F.Seybert, A Review Of Current Techniques For

Measuring Muffler Transmission Loss, Society Of

Automotive Engineers (SAE), 2003

[2]

Shital Shah, Saisankaranarayana K, Kalyankumar S. Hatti, &

Prof. D.G.Thombare, A Practical Approach Towards Muffler

Design, Development and Prototype Validation, 2010

[3]

Potente, Daniel, General Design Principles For an Automotive

Muffler, Proceedings of Acoustics, 2005

[4]

Tetsuo Kaneda, Mitsuaki Oda, Prediction of Transmission

Loss for Motorcycle Muffler, Society Of Automotive

Engineers (SAE), 1999

[5]

Sachin Wagh,Development of Exhaust Silencer for Improved

Sound Quality, Society Of Automotive Engineers (SAE),

2010

[6]

I. J. Lee and A. Selamet, Acoustic Characteristics of

Coupled Dissipative and Reactive Silencers, Society Of

Automotive

Engineers

(SAE),

2003.

Proceedings of 10th IRF International Conference, 01st June-2014, Pune, India, ISBN: 978-93-84209-23-0

37

Vous aimerez peut-être aussi

- Design and Comparison of Mufflers Having Different Arrangements For Diesel EngineDocument8 pagesDesign and Comparison of Mufflers Having Different Arrangements For Diesel EngineWaruna PasanPas encore d'évaluation

- Muffler Design For Automotive Exhaust Noise Attenuation - A ReviewDocument4 pagesMuffler Design For Automotive Exhaust Noise Attenuation - A ReviewStylishrockerPradeepPas encore d'évaluation

- Exhaust Design by University of Maine FSAEDocument7 pagesExhaust Design by University of Maine FSAEMichael Matthews0% (1)

- 2014 Design Principles For An Automotive MufflerDocument8 pages2014 Design Principles For An Automotive MufflerSurendrakumar BindPas encore d'évaluation

- 7th Sem ProjectDocument68 pages7th Sem ProjectKumar SiddhanthPas encore d'évaluation

- A Review Paper On Design of Muffler Toward Reduce Sound in Exhaust System of IC EngineDocument6 pagesA Review Paper On Design of Muffler Toward Reduce Sound in Exhaust System of IC EngineJose PradoPas encore d'évaluation

- Transmission Losses in Reactive MufflerDocument6 pagesTransmission Losses in Reactive MufflerVignesh PadmanabhanPas encore d'évaluation

- MufflerDocument6 pagesMufflerDhurai Raj100% (2)

- Exhaust Muffler Design PrinciplesDocument9 pagesExhaust Muffler Design Principlespaulomareze67% (3)

- Muffler Design, Development and ValidationDocument17 pagesMuffler Design, Development and ValidationAmos OchienoPas encore d'évaluation

- Design and Fabrication of Reactive MufflerDocument8 pagesDesign and Fabrication of Reactive MufflermacsacPas encore d'évaluation

- An Overview of Automobile Noise and Vibration ControlDocument11 pagesAn Overview of Automobile Noise and Vibration ControlMathews P Reji100% (1)

- Exhaust Muffler Design PDFDocument2 pagesExhaust Muffler Design PDFAlexPas encore d'évaluation

- Active Noise Control in A Luxury VehicleDocument247 pagesActive Noise Control in A Luxury VehicleMizioPas encore d'évaluation

- Design Principles and Optimization of Exaust Reactive MufflerDocument6 pagesDesign Principles and Optimization of Exaust Reactive MufflerBenjamín Alain100% (1)

- 615 Fullpaper 1238981371122068 PDFDocument15 pages615 Fullpaper 1238981371122068 PDFlucaPas encore d'évaluation

- Noise Reduction in Centrifugal Fans: A Literature SurveyDocument29 pagesNoise Reduction in Centrifugal Fans: A Literature SurveyPooria1989Pas encore d'évaluation

- LMS Solutions For NVH Acoustics and Comfort BrochureDocument20 pagesLMS Solutions For NVH Acoustics and Comfort BrochurejohnndoeePas encore d'évaluation

- Muffler BasicsDocument10 pagesMuffler BasicsGianluca Sala100% (1)

- Ashrae 48Document63 pagesAshrae 48Mohamed Aboobucker Mohamed IrfanPas encore d'évaluation

- KTM Technical Handbook 7.3Document13 pagesKTM Technical Handbook 7.3roderickmodePas encore d'évaluation

- Magic Roma User Manual1Document8 pagesMagic Roma User Manual1Sledge HammerPas encore d'évaluation

- Donaldson - Silencer Exhaust SystemDocument25 pagesDonaldson - Silencer Exhaust SystemBenjamín AlainPas encore d'évaluation

- Developing Sound Package Treatments For A Vehicle PDFDocument7 pagesDeveloping Sound Package Treatments For A Vehicle PDFmicky1389Pas encore d'évaluation

- Ngineering ATA: Fan Sound & Sound RatingsDocument8 pagesNgineering ATA: Fan Sound & Sound RatingsRavi DeshmukhPas encore d'évaluation

- Exhaust Muffler Design Principles PDFDocument2 pagesExhaust Muffler Design Principles PDFWesley0% (1)

- Volumetric Efficiency of Engines Definitions/Terminology: Induction ProcessDocument6 pagesVolumetric Efficiency of Engines Definitions/Terminology: Induction ProcessWasi UddinPas encore d'évaluation

- acoustic Plenum - Pressure - Drop - & - Acoustic - GuidelinesجيدDocument35 pagesacoustic Plenum - Pressure - Drop - & - Acoustic - GuidelinesجيدAli Habib0% (1)

- Design and Analysis of Muffler To Reduce The Back PressureDocument5 pagesDesign and Analysis of Muffler To Reduce The Back PressureijsretPas encore d'évaluation

- Fsae Exhaust ReportDocument8 pagesFsae Exhaust ReportGodwin JerryPas encore d'évaluation

- FSAE Muffler DesignDocument1 pageFSAE Muffler DesignBambang MurtjahjantoPas encore d'évaluation

- FSAE Intake ManifoldDocument10 pagesFSAE Intake Manifoldbestie123456789Pas encore d'évaluation

- Building Acoustic Suspension Subwoofer BoxesDocument12 pagesBuilding Acoustic Suspension Subwoofer BoxesDavid Perez0% (1)

- Muffler DesignDocument8 pagesMuffler Designjeyaselvanm0% (1)

- Spring Materials PDFDocument25 pagesSpring Materials PDFyatin chhabra0% (1)

- Fundamentals of Acoustics & Practical HVAC Design Considerations. Demir Doken Acoustic EngineerDocument25 pagesFundamentals of Acoustics & Practical HVAC Design Considerations. Demir Doken Acoustic Engineertruong sanh NguyenPas encore d'évaluation

- GL Harmony Class - Noise and Vibration CargoDocument22 pagesGL Harmony Class - Noise and Vibration CargoantonPas encore d'évaluation

- Oise Ibration and Arshness: by C.Venkatanarayana 163701Document27 pagesOise Ibration and Arshness: by C.Venkatanarayana 163701prasanthPas encore d'évaluation

- Vespa Service Manual 08-04-2021Document322 pagesVespa Service Manual 08-04-2021Julio Borrero100% (1)

- Noise Control: Determining The Best OptionDocument5 pagesNoise Control: Determining The Best OptionCarlos SantosPas encore d'évaluation

- Flow in The CylinderDocument24 pagesFlow in The CylinderFernando AndradePas encore d'évaluation

- Comparing and Evaluating Supercharger Impellers: Carl Fausett Member S.A.E. 928 Motorsports, LLCDocument12 pagesComparing and Evaluating Supercharger Impellers: Carl Fausett Member S.A.E. 928 Motorsports, LLCRodPas encore d'évaluation

- Fast Car - December 2014 UKDocument116 pagesFast Car - December 2014 UKPaul KarijaPas encore d'évaluation

- AUDI OptimizationDocument37 pagesAUDI OptimizationKiran DamaPas encore d'évaluation

- Aqua Silencer Report 2Document25 pagesAqua Silencer Report 2avikashPas encore d'évaluation

- Bosch Fuel LubricityDocument4 pagesBosch Fuel LubricityvictorpoedePas encore d'évaluation

- Formula SAE Performance Exhaust DesignDocument65 pagesFormula SAE Performance Exhaust Designpaulo negaoPas encore d'évaluation

- Analysis of Change in Intake Manifold Length and Development of Variable Intake SystemDocument6 pagesAnalysis of Change in Intake Manifold Length and Development of Variable Intake SystemDarius TothPas encore d'évaluation

- Installation Guide & Operators ManualDocument132 pagesInstallation Guide & Operators ManualMauricio OlayaPas encore d'évaluation

- Damper DynoDocument3 pagesDamper DynoEoin MurrayPas encore d'évaluation

- Puma Race Engines - Cylinder Head Modifications - Part 1: Valve SeatsDocument4 pagesPuma Race Engines - Cylinder Head Modifications - Part 1: Valve SeatsRobert DennisPas encore d'évaluation

- Automotive Engine Valve RecessionDocument135 pagesAutomotive Engine Valve RecessionFGarcia92100% (1)

- Toyota Motorsport GMBH - The Home of High PerformanceDocument27 pagesToyota Motorsport GMBH - The Home of High PerformanceMarcos SoarPas encore d'évaluation

- Design Principles For An Automotive Muffler: Vinod Sherekar and P. R. DhamangaonkarDocument7 pagesDesign Principles For An Automotive Muffler: Vinod Sherekar and P. R. DhamangaonkartanasaPas encore d'évaluation

- Acoustic Performance Designof Automotive MufflerDocument6 pagesAcoustic Performance Designof Automotive MufflerCosmin DxiPas encore d'évaluation

- Design and Construction of A Reactive Type Muffler For A Fsae CarDocument11 pagesDesign and Construction of A Reactive Type Muffler For A Fsae CarYuvaraj BadigerPas encore d'évaluation

- Product Design of MufflerDocument16 pagesProduct Design of MufflernaniPas encore d'évaluation

- Vibration Analysis of An Automotive Silencer For Reduced Incidence of FailureDocument6 pagesVibration Analysis of An Automotive Silencer For Reduced Incidence of FailureerpublicationPas encore d'évaluation

- Design and Analysis of Muffler For Two-Wheeler: Tejas J. KalangeDocument9 pagesDesign and Analysis of Muffler For Two-Wheeler: Tejas J. KalangeDeepak ChaurasiaPas encore d'évaluation

- Design and Construction of A Muffler For Engine Exhaust Noise ReductionDocument6 pagesDesign and Construction of A Muffler For Engine Exhaust Noise ReductionFallo SusiloPas encore d'évaluation

- Duct Silencer: Application NotesDocument4 pagesDuct Silencer: Application NotesBenjamín AlainPas encore d'évaluation

- Reshetki Dlya Zabora Naruzhnego Vozduha EalDocument3 pagesReshetki Dlya Zabora Naruzhnego Vozduha EalBenjamín AlainPas encore d'évaluation

- HTM 08-01Document48 pagesHTM 08-01Benjamín AlainPas encore d'évaluation

- Flaktwoods SilencersDocument14 pagesFlaktwoods SilencersBenjamín AlainPas encore d'évaluation

- Design Principles and Optimization of Exaust Reactive MufflerDocument6 pagesDesign Principles and Optimization of Exaust Reactive MufflerBenjamín Alain100% (1)

- Donaldson - Silencer Exhaust SystemDocument25 pagesDonaldson - Silencer Exhaust SystemBenjamín AlainPas encore d'évaluation

- Noiseblock InstallDocument12 pagesNoiseblock InstallBenjamín AlainPas encore d'évaluation

- Catalogue Axces Silenciadores de EscapeDocument47 pagesCatalogue Axces Silenciadores de EscapeBenjamín AlainPas encore d'évaluation

- Catalogo Trox PDFDocument500 pagesCatalogo Trox PDFBenjamín AlainPas encore d'évaluation

- AAAC Guideline For Apartment and Townhouse Acoustic Rating 2010Document10 pagesAAAC Guideline For Apartment and Townhouse Acoustic Rating 2010Benjamín AlainPas encore d'évaluation

- Babe Ruth Saves BaseballDocument49 pagesBabe Ruth Saves BaseballYijun PengPas encore d'évaluation

- Importance of Communications 05sept2023Document14 pagesImportance of Communications 05sept2023Sajib BhattacharyaPas encore d'évaluation

- EdisDocument227 pagesEdisThong Chan100% (1)

- A Noble Noose of Methods - ExtendedDocument388 pagesA Noble Noose of Methods - ExtendedtomasiskoPas encore d'évaluation

- Acc116 Dec 2022 - Q - Test 1Document6 pagesAcc116 Dec 2022 - Q - Test 12022825274100% (1)

- E-Versuri Ro - Rihana - UmbrelaDocument2 pagesE-Versuri Ro - Rihana - Umbrelaanon-821253100% (1)

- DMIT - Midbrain - DMIT SoftwareDocument16 pagesDMIT - Midbrain - DMIT SoftwarevinPas encore d'évaluation

- T5 B11 Victor Manuel Lopez-Flores FDR - FBI 302s Re VA ID Cards For Hanjour and Almihdhar 195Document11 pagesT5 B11 Victor Manuel Lopez-Flores FDR - FBI 302s Re VA ID Cards For Hanjour and Almihdhar 1959/11 Document Archive100% (2)

- Csu Cep Professional Dispositions 1Document6 pagesCsu Cep Professional Dispositions 1api-502440235Pas encore d'évaluation

- Product Manual 26086 (Revision E) : EGCP-2 Engine Generator Control PackageDocument152 pagesProduct Manual 26086 (Revision E) : EGCP-2 Engine Generator Control PackageErick KurodaPas encore d'évaluation

- Agency Canvas Ing PresentationDocument27 pagesAgency Canvas Ing Presentationkhushi jaiswalPas encore d'évaluation

- Mozal Finance EXCEL Group 15dec2013Document15 pagesMozal Finance EXCEL Group 15dec2013Abhijit TailangPas encore d'évaluation

- Disclosure To Promote The Right To InformationDocument11 pagesDisclosure To Promote The Right To InformationnmclaughPas encore d'évaluation

- Guidelines For Prescription Drug Marketing in India-OPPIDocument23 pagesGuidelines For Prescription Drug Marketing in India-OPPINeelesh Bhandari100% (2)

- Surgery - 2020 With CorrectionDocument70 pagesSurgery - 2020 With CorrectionBaraa KassisPas encore d'évaluation

- DS Agile - Enm - C6pDocument358 pagesDS Agile - Enm - C6pABDERRAHMANE JAFPas encore d'évaluation

- Seabank Statement 20220726Document4 pagesSeabank Statement 20220726Alesa WahabappPas encore d'évaluation

- PE MELCs Grade 3Document4 pagesPE MELCs Grade 3MARISSA BERNALDOPas encore d'évaluation

- List of Sovereign States and Dependent Territories by Birth RateDocument7 pagesList of Sovereign States and Dependent Territories by Birth RateLuminita CocosPas encore d'évaluation

- Individual Career Plan: DIRECTIONS: Answer The Following Questions in Paragraph Form (3-4 Sentences) Per QuestionDocument2 pagesIndividual Career Plan: DIRECTIONS: Answer The Following Questions in Paragraph Form (3-4 Sentences) Per Questionapi-526813290Pas encore d'évaluation

- HFE0106 TraskPart2Document5 pagesHFE0106 TraskPart2arunkr1Pas encore d'évaluation

- ADC of PIC MicrocontrollerDocument4 pagesADC of PIC Microcontrollerkillbill100% (2)

- Walking in Space - Lyrics and Chord PatternDocument2 pagesWalking in Space - Lyrics and Chord Patternjohn smithPas encore d'évaluation

- 1.water, Acids, Bases, Buffer Solutions in BiochemistryDocument53 pages1.water, Acids, Bases, Buffer Solutions in BiochemistryÇağlaPas encore d'évaluation

- Module6 Quiz1Document4 pagesModule6 Quiz1karthik1555Pas encore d'évaluation

- Toh MFS8B 98B 003-11114-3AG1 PDFDocument92 pagesToh MFS8B 98B 003-11114-3AG1 PDFDmitry NemtsoffPas encore d'évaluation

- in 30 MinutesDocument5 pagesin 30 MinutesCésar DiazPas encore d'évaluation

- Mosharaf HossainDocument2 pagesMosharaf HossainRuhul RajPas encore d'évaluation

- Business-Communication Solved MCQs (Set-3)Document8 pagesBusiness-Communication Solved MCQs (Set-3)Pavan Sai Krishna KottiPas encore d'évaluation

- Ci Thai RiceDocument4 pagesCi Thai RiceMakkah Madina ricePas encore d'évaluation