Académique Documents

Professionnel Documents

Culture Documents

General Specifications: Model DVM, 3VM Model IM Three-Valve Manifolds

Transféré par

apisituTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

General Specifications: Model DVM, 3VM Model IM Three-Valve Manifolds

Transféré par

apisituDroits d'auteur :

Formats disponibles

<<Contents>> <<Index>>

General

Specifications

Model DVM, 3VM

Model IM

Three-Valve Manifolds

GS22B01C01-00E

The three-valve manifold is a device in which one equalizing valve and two stop valves are assembled together (one

unit). The manifolds are available in either carbon steel or

stainless steel and, when mounted differential pressure

transmitters, form a compact unit. It is available for use

with all Y/15, Y/13, Y/13H, Y/11DM, EJ110, EJ120, EJ130,

EJX110, EJA110, and EJA120 Differential Pressure

Transmitters.

IM

MODEL DVM

STANDARD SPECIFICATIONS

DVM

Applicable Instruments: Refer to Table 1.

3VM

Valve Material: JIS S35C carbon steel valves or JIS SUSF

316 stainless steel valves.

Tubing Material: JIS SUS316TP.

IM

Maximum Working Pressure: Refer to Table 1.

Maximum Operating Temperature: 120C (250F).

Process Connections: JIS Rc1/2(PT1/2) or 1/2NPT female,

whichever specified. For DVM40B, used 1/2 inch pipe welded end.

Instrument Connections: JIS R1/2 (PT1/2) or 1/2NPT

male, whichever specified.

Direction of Process Connections: Vertical.

OPTIONS

Degrease Cleansing Treatment for Oxygen Service

Preparation: Use SUSF316 stainless steel manifold.

Option code: /OSW.

Stainless Steel Tag Plate: Wired onto instrument.

Option Code: /TP-W.

Process side connection and Instrument side connection.

DVM - - - *B

Process side connection

Rc1/4 female : 2

1/4 NPT female : 3

Rc1/2 female : 4

* 1/2 NPT female : 5

1/4 inch pipe welded end : A (Note1)

* 1/2 inch pipe welded end : B (Note1)

Instrument side connection

R1/4 male : 6

1/4 NPT male : 7

* 1/2 NPT male : 8

R1/2 male : N

Direction of process connection

Side process connection : S

* Vertical process connection : N

(Note1) Code B or A will be specified for Y/13HA.

* marks indicate the typical selection.

Table 1. Model DVM Suffix Codes and Specifications

Applicable

Instrument

*1:

Maximum Working

Pressure

Model and Suffix Codes

Valve Material *1

Y/15A

DVM-20 --N *B

JIS SUSF316

Y/13A

DVM-10 --N *B

JIS SUSF316

Y/13HA

DVM-40 B-N-N *B

JIS SUSF316

41.1 MPa, 420 kgf/cm2,

412 bar or 5970 psi

Y/11DM

DVM-80 --N *B

JIS SUSF316

14.7 MPa, 150 kgf/cm2,

148 bar or 2130 psi

14.7 MPa, 150 kgf/cm2,

148 bar or 2130 psi

Users must consider the characteristics of selected wetted parts material and the influence of process fluids. The use of inappropriate

materials can result in the leakage of corrosive process fluids and cause injury to personnel and/or damage to plant facilities. It is also

possible that the instrument itself can be damaged and that fragments from the instrument can contaminate the user's process fluids.

Be very careful with highly corrosive process fluids such as hydrochloric acid, sulfuric acid, hydrogen sulfide, sodium hypochlorite, and

high-temperature steam (150C [302F] or above). Contact Yokogawa for detailed information of the wetted parts material.

Yokogawa Electric Corporation

2-9-32 Nakacho, Musashino-shi, Tokyo, 180-8750

Phone: 81-422-52-5690 Fax.: 81-422-52-2018

Japan

GS 22B01C01-00E

Copyright Dec. 1976

11th Edition Aug. 2007

<<Contents>> <<Index>>

OPTIONS

MODEL IM

STANDARD SPECIFICATIONS

Material: JIS S35C carbon steel or JIS SUSF316 stainless

steel.

Maximum Working Pressure: 14.7 MPa, 150 kgf/cm2,

148 bar or 2130 psi.

Maximum Operating Temperature: 150C(300F)

Process Connection: Refer to Table 2.

Degrease Cleansing Treatment for Oxygen Service

Preparation: Use SUSF316 stainless steel manifold.

Option code: /OSW.

Stainless Steel Hardware: JIS SUS 630 cap screw for the

Models IM-300.

Option code: /SSB.

Vent Plug: Available for IM-300 and IM-400.

Option code: /VNT.

Stainless Steel Tag Plate: Wired onto instrument.

Option Code: /TP-W.

Instrument Connection: Refer to Table 2.

Table 2. Model IM Suffix Codes and Specifications

Applicable

Instrument

Y/15A, Y/13A

EJ110, EJ120,

EJA110, EJA120

EJX110

*1:

Model and Suffix

Codes

Material *1

IM-300*B

JIS SUSF316

IM-400*B

JIS S35C

IM-100*B

JIS SUSF316

Available Directly

Mounted to

Instrument

Yes

No

Connection

Process

Instrument

Instrument process

connector

Direct connection

with bolts

JIS Rc1/2 (PT1/2) female

Users must consider the characteristics of selected wetted parts material and the influence of process fluids. The use of inappropriate

materials can result in the leakage of corrosive process fluids and cause injury to personnel and/or damage to plant facilities. It is also

possible that the instrument itself can be damaged and that fragments from the instrument can contaminate the user's process fluids.

Be very careful with highly corrosive process fluids such as hydrochloric acid, sulfuric acid, hydrogen sulfide, sodium hypochlorite, and

high-temperature steam (150C [302F] or above). Contact Yokogawa for detailed information of the wetted parts material.

MODEL 3VM

STANDARD SPECIFICATIONS

Process side connection and Instrument side connection.

Valve Material: JIS S35C carbon steel valves or JIS SUSF

316 stainless steel valves. (For tubing

material, see Table 3 below.)

3VM - - - *B

Process side correction

Rc1/4 female : J1

Rc1/2 female : J2

1/4 NPT female : N1

* 1/2 NPT female : N2

1/4 inch pipe welded end : W1 (Note1)

* 1/2 inch pipe welded end : W2 (Note1)

Instrument side connection

R1/4 male : 1

R1/2 male : 2

1/4 NPT male : 3

* 1/2 NPT male : 4

Direction of process connection

Side process connection : S

* Vertical process connection : N

Maximum Working Pressure: Refer to Table 3.

Maximum Operating Temperature: 120C (250F).

Process Connections: JIS Rc1/2(PT1/2) or 1/2NPT female.

For 3VM-3S, used 1/2 inch pipe

welded end.

Instrument Connections: JIS R1/2(PT1/2) or 1/2NPT male.

Direction of Process Connections: Vertical.

OPTIONS

Degrease Cleansing Treatment for Oxygen Service

Preparation: Use SUSF316 stainless steel manifold.

Option code: /OSW.

(Note1) Code W2 or W1 will be specified for EJ130.

* marks indicate the typical selection.

Vent Plug: Available for 3VM-1. Option Code: /VNT.

Stainless Steel Tag Plate: Wired onto instrument.

Option Code: /TP-W.

All Rights Reserved. Copyright 1976, Yokogawa Electric Corporation

GS 22B01C01-00E

Mar. 01, 2006-00

<<Contents>> <<Index>>

Table 3. Model 3VM Suffix Codes and Specifications

Tubing

Maximum Working

Pressure

3VM-1S-N24-N*B

JIS SUSF316

JIS SUS 316TP

14.7 MPa {150 kgf/cm2}

3VM-3S-W22-N*B

JIS SUSF316

JIS SUS 316TP

41.1 MPa {420 kgf/cm2}

Model and Suffix Codes

EJ110, EJ120,

EJA110, EJA120, EJX110

EJ130

*1:

Material *1

Valve

Applicable Instrument

Users must consider the characteristics of selected wetted parts material and the influence of process fluids. The use of inappropriate

materials can result in the leakage of corrosive process fluids and cause injury to personnel and/or damage to plant facilities. It is also

possible that the instrument itself can be damaged and that fragments from the instrument can contaminate the user's process fluids.

Be very careful with highly corrosive process fluids such as hydrochloric acid, sulfuric acid, hydrogen sulfide, sodium hypochlorite, and

high-temperature steam (150C [302F] or above). Contact Yokogawa for detailed information of the wetted parts material.

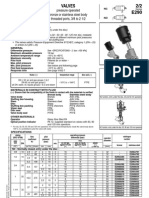

DIMENSIONS

UNIT: mm

Model DVM-10

Model DVM-40B

Model 3VM-3S

All Rights Reserved. Copyright 1976, Yokogawa Electric Corporation

GS 22B01C01-00E

Mar. 01, 2006-00

<<Contents>> <<Index>>

Model IM-100

Models IM-300 and IM-400

Model 3VM1

All Rights Reserved. Copyright 2005, Yokogawa Electric Corporation

Subject to change without notice.

GS 22B01C01-00E

Aug. 01, 2007-00

Vous aimerez peut-être aussi

- General Specifications: Model DVM, 3VM Model IM Three-Valve ManifoldsDocument4 pagesGeneral Specifications: Model DVM, 3VM Model IM Three-Valve ManifoldsBao Nguyen DinhPas encore d'évaluation

- ASCONDocument6 pagesASCONNithyAPas encore d'évaluation

- Manual Reset Construction 1/4 To 1/2: No Voltage Release (Lever Type)Document6 pagesManual Reset Construction 1/4 To 1/2: No Voltage Release (Lever Type)dharmendrabholePas encore d'évaluation

- Solenoid Valves 3 - 2 General Service 327 CAT 80402GBDocument6 pagesSolenoid Valves 3 - 2 General Service 327 CAT 80402GBsaifulPas encore d'évaluation

- Solenoid Valves 3/2 551 553Document12 pagesSolenoid Valves 3/2 551 553frghertyertyergfhdftyertyPas encore d'évaluation

- Asco Direct Acting Solenoid Valve - 320Document6 pagesAsco Direct Acting Solenoid Valve - 320SatyamEng100% (1)

- 12 400E 2MC FinalDocument4 pages12 400E 2MC FinalthadanivishalPas encore d'évaluation

- (Level Switch) DS - MS50-EN - X - 07 - 2016Document8 pages(Level Switch) DS - MS50-EN - X - 07 - 2016galih santosoPas encore d'évaluation

- Manual Actuator: Code: FR2:LB700050008 Reference: CM16Document2 pagesManual Actuator: Code: FR2:LB700050008 Reference: CM16rafa100% (1)

- AG Quick Release ENProDocument4 pagesAG Quick Release ENProNatalia WinataPas encore d'évaluation

- Test-Report-Iec-60335-2 Usisivac PDFDocument35 pagesTest-Report-Iec-60335-2 Usisivac PDFSana IvanovicPas encore d'évaluation

- 5 3 Way Ss ValveDocument12 pages5 3 Way Ss ValveGopinath GunasekaranPas encore d'évaluation

- Pressure Control BrochureDocument12 pagesPressure Control Brochurebkpaul3107Pas encore d'évaluation

- SBM TECHNOLOGY - Advanced High Pressure Cooling ValveDocument8 pagesSBM TECHNOLOGY - Advanced High Pressure Cooling ValveEricsson BotchweyPas encore d'évaluation

- Solenoid Valves 3/2 131: Direct Operated 3 Mounting Holes in The Body 1/4Document2 pagesSolenoid Valves 3/2 131: Direct Operated 3 Mounting Holes in The Body 1/4sks1969Pas encore d'évaluation

- 12-385 Item 01 - MonitorDocument20 pages12-385 Item 01 - Monitorleokareyxoxoers100% (1)

- Wika Pressure SensorDocument102 pagesWika Pressure SensorOmkar ThakurPas encore d'évaluation

- NAMUR High Flow CatalogDocument7 pagesNAMUR High Flow CatalogSandi AslanPas encore d'évaluation

- Pioneer VSX D307 Audio Video Receiver Service ManualDocument56 pagesPioneer VSX D307 Audio Video Receiver Service ManualRuben NavaPas encore d'évaluation

- Protect pressure gauges with BDT42/43 syphonsDocument2 pagesProtect pressure gauges with BDT42/43 syphonsSandi AslanPas encore d'évaluation

- Pressure Control Valves: Backpressure Regulators UV 1.6, 2.6Document2 pagesPressure Control Valves: Backpressure Regulators UV 1.6, 2.6cartarPas encore d'évaluation

- Burmad 400 Series-Globe Type Deluge ValveDocument8 pagesBurmad 400 Series-Globe Type Deluge Valvenastyn-1Pas encore d'évaluation

- Pic 05 0033 GBDocument14 pagesPic 05 0033 GBLis LisPas encore d'évaluation

- Valvulas Sole No Ides IsDocument12 pagesValvulas Sole No Ides Isaaa3131Pas encore d'évaluation

- ZR22G ZR22S ZR402G - Bulletin11M12A01-01E - 100Document13 pagesZR22G ZR22S ZR402G - Bulletin11M12A01-01E - 100Bhaskar KumarPas encore d'évaluation

- 2100 Rev H English ManualDocument2 pages2100 Rev H English ManualJuan HernándezPas encore d'évaluation

- Proportional Reducing ValveDocument8 pagesProportional Reducing ValvediabalziabPas encore d'évaluation

- Valves 2/2 E290: Pressure Operated Bronze or Stainless Steel Body Threaded Ports, 3/8 To 2 1/2Document4 pagesValves 2/2 E290: Pressure Operated Bronze or Stainless Steel Body Threaded Ports, 3/8 To 2 1/2Velpuri RameshBabuPas encore d'évaluation

- TSF-13CF Manual enDocument18 pagesTSF-13CF Manual entienPas encore d'évaluation

- Catalago PDFDocument12 pagesCatalago PDFGregory StewartPas encore d'évaluation

- LS200 Series Liquid Level SwitchesDocument4 pagesLS200 Series Liquid Level SwitchesJavy PantojaPas encore d'évaluation

- จำหน่าย Danfoss Type RTDocument11 pagesจำหน่าย Danfoss Type RTParinpa KetarPas encore d'évaluation

- Asco Series 210 General Service CatalogDocument6 pagesAsco Series 210 General Service CatalogEric ToroPas encore d'évaluation

- WIKA - Data Sheet For SnubberDocument2 pagesWIKA - Data Sheet For Snubberyasser hamzaPas encore d'évaluation

- Catalogo ASCODocument4 pagesCatalogo ASCOIkaro MatosPas encore d'évaluation

- Abb Rotametro Que NecesitoDocument21 pagesAbb Rotametro Que Necesitomonyk_2442411Pas encore d'évaluation

- Pioneer VSX-D810 - RRV2446 Service ManualDocument78 pagesPioneer VSX-D810 - RRV2446 Service ManualArif786xPas encore d'évaluation

- Panasonic Service Manual DMR-ES15EBDocument84 pagesPanasonic Service Manual DMR-ES15EBGavtechdocsPas encore d'évaluation

- Manson Engineering NP-9912 Service ManualDocument12 pagesManson Engineering NP-9912 Service ManualDa ElPas encore d'évaluation

- Brooks Rotameter Variable AreaDocument22 pagesBrooks Rotameter Variable Areamhidayat108Pas encore d'évaluation

- Ras-10ukv-E SVM-020007Document79 pagesRas-10ukv-E SVM-020007Para Club MilazzoPas encore d'évaluation

- Rexroth Bomba HidraulicaDocument52 pagesRexroth Bomba HidraulicaHernan LopezPas encore d'évaluation

- VSX-407RDS, - 607RDSDocument58 pagesVSX-407RDS, - 607RDSmichal_lysyPas encore d'évaluation

- Panasonic PT-53WX42F Service Repair Manual - Ep824Document130 pagesPanasonic PT-53WX42F Service Repair Manual - Ep824Larry LeavittPas encore d'évaluation

- Wika Pressure TransmiterDocument4 pagesWika Pressure TransmitercuongPas encore d'évaluation

- Pressure Transmitter For General Applications Model S-10, Standard Version Model S-11, Flush DiaphragmDocument4 pagesPressure Transmitter For General Applications Model S-10, Standard Version Model S-11, Flush Diaphragminfo5280Pas encore d'évaluation

- Test Pressure GaugeDocument2 pagesTest Pressure GaugerodcavicchioniPas encore d'évaluation

- Pressure Transmitter Data SheetDocument2 pagesPressure Transmitter Data Sheetneurolepsia3790Pas encore d'évaluation

- Tel TruDocument28 pagesTel TruVeronica MendosaPas encore d'évaluation

- Ode - 21a2kv25Document2 pagesOde - 21a2kv25meomimi9457Pas encore d'évaluation

- Valvula Reductora de Presion Bermad Area 675 720-ULDocument4 pagesValvula Reductora de Presion Bermad Area 675 720-ULChristian FherPas encore d'évaluation

- OverpressureDocument2 pagesOverpressureampowersidPas encore d'évaluation

- Proportional pressure relief valve model DBET and DBEMTDocument10 pagesProportional pressure relief valve model DBET and DBEMTrafarodrig6Pas encore d'évaluation

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsD'EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsÉvaluation : 3 sur 5 étoiles3/5 (2)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsD'EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsPas encore d'évaluation

- Instrumentation and Test Gear Circuits ManualD'EverandInstrumentation and Test Gear Circuits ManualÉvaluation : 5 sur 5 étoiles5/5 (1)

- The Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsD'EverandThe Technology of Instrument Transformers: Current and Voltage Measurement and Insulation SystemsPas encore d'évaluation

- Packscan InfoDocument4 pagesPackscan InfosathyasingPas encore d'évaluation

- Pakscan CatalogueDocument32 pagesPakscan CatalogueragulPas encore d'évaluation

- Pub059-023!00!1100 (Pakscan Paktester Field Test Unit Technical Manual)Document82 pagesPub059-023!00!1100 (Pakscan Paktester Field Test Unit Technical Manual)apisituPas encore d'évaluation

- Pub059-020-00 - 0100 (Pakscan Integral FCU (Field Control Unit) Technical Manual) PDFDocument34 pagesPub059-020-00 - 0100 (Pakscan Integral FCU (Field Control Unit) Technical Manual) PDFapisituPas encore d'évaluation

- PUB060-001-00 - 1110 RCL NetworksDocument8 pagesPUB060-001-00 - 1110 RCL NetworksapisituPas encore d'évaluation

- HPSTerminal Automation Brochure 020910 Rev 4 EopDocument8 pagesHPSTerminal Automation Brochure 020910 Rev 4 Eopgtimber99Pas encore d'évaluation

- Pakscan CatalogueDocument32 pagesPakscan CatalogueragulPas encore d'évaluation

- PUB060-001-00 - 1110 RCL NetworksDocument8 pagesPUB060-001-00 - 1110 RCL NetworksapisituPas encore d'évaluation

- Pakscan CatalogueDocument32 pagesPakscan CatalogueragulPas encore d'évaluation

- HPSTerminal Automation Brochure 020910 Rev 4 EopDocument8 pagesHPSTerminal Automation Brochure 020910 Rev 4 Eopgtimber99Pas encore d'évaluation

- Pub059-031!00!0811 (Pakscan P3 Hot Standby Master Station Change Over Times)Document5 pagesPub059-031!00!0811 (Pakscan P3 Hot Standby Master Station Change Over Times)apisituPas encore d'évaluation

- Spds Electronic SealDocument4 pagesSpds Electronic SealapisituPas encore d'évaluation

- Pub059-035!00!1116 (Pakscan FCU (Field Control Unit) Technical Manual For IQ3 CVA CMA)Document52 pagesPub059-035!00!1116 (Pakscan FCU (Field Control Unit) Technical Manual For IQ3 CVA CMA)apisituPas encore d'évaluation

- Lightning and Surge Protection Methods for Pakscan SystemsDocument2 pagesLightning and Surge Protection Methods for Pakscan SystemsapisituPas encore d'évaluation

- 95 8526 20.3 - (Pirecl)Document80 pages95 8526 20.3 - (Pirecl)apisituPas encore d'évaluation

- Case Study ABB enDocument3 pagesCase Study ABB enapisituPas encore d'évaluation

- Bartec AUTDocument12 pagesBartec AUTapisituPas encore d'évaluation

- Pub059-023!00!1100 (Pakscan Paktester Field Test Unit Technical Manual)Document82 pagesPub059-023!00!1100 (Pakscan Paktester Field Test Unit Technical Manual)apisituPas encore d'évaluation

- 980501Document21 pages980501apisituPas encore d'évaluation

- New Generation Pakscan Master Station: Key BenefitsDocument8 pagesNew Generation Pakscan Master Station: Key BenefitsapisituPas encore d'évaluation

- OrbitX - Remote Assistance SetupDocument136 pagesOrbitX - Remote Assistance SetupapisituPas encore d'évaluation

- PUB060-001-00 - 1110 RCL NetworksDocument8 pagesPUB060-001-00 - 1110 RCL NetworksapisituPas encore d'évaluation

- OrbitX - Remote Assistance Setup PDFDocument10 pagesOrbitX - Remote Assistance Setup PDFapisituPas encore d'évaluation

- Omni Flow Computer Modbus: DatabaseDocument12 pagesOmni Flow Computer Modbus: DatabaseapisituPas encore d'évaluation

- Peer-to-Peer Basics: Date: 05 22 03 Author(s) : Kenneth D. ElliottDocument12 pagesPeer-to-Peer Basics: Date: 05 22 03 Author(s) : Kenneth D. ElliottapisituPas encore d'évaluation

- 980402Document8 pages980402apisituPas encore d'évaluation

- 970803Document4 pages970803apisituPas encore d'évaluation

- 960701Document12 pages960701apisituPas encore d'évaluation

- 960702Document4 pages960702apisituPas encore d'évaluation

- General Specifications: YokogawaDocument16 pagesGeneral Specifications: YokogawaapisituPas encore d'évaluation

- Chapter 1Document27 pagesChapter 1Junaid KhaliqPas encore d'évaluation

- Masatoshi Imada, Atsushi Fujimori and Yoshinori Tokura - Metal-Insulator TransitionsDocument225 pagesMasatoshi Imada, Atsushi Fujimori and Yoshinori Tokura - Metal-Insulator TransitionsPo48HSDPas encore d'évaluation

- Synthesis of Para-Red and 1-Iodo-4-Nitrobenzene ExperimentDocument2 pagesSynthesis of Para-Red and 1-Iodo-4-Nitrobenzene ExperimentMaryPas encore d'évaluation

- Earthing CalculationDocument4 pagesEarthing CalculationNipuna Thushara WijesekaraPas encore d'évaluation

- ISO 4406 Fluid Cleanliness GuideDocument1 pageISO 4406 Fluid Cleanliness GuideJai BhandariPas encore d'évaluation

- Photosynthesis Lab: Leaf Disk Floating RatesDocument9 pagesPhotosynthesis Lab: Leaf Disk Floating RatesNakuru SandwichPas encore d'évaluation

- Soal BIOKIM Nomor 3Document4 pagesSoal BIOKIM Nomor 3Siti RositahPas encore d'évaluation

- PROBLEMS Holtz and KovacsDocument3 pagesPROBLEMS Holtz and KovacsDaniel L. Blanco Pérez0% (2)

- 7 Paint DefectsDocument29 pages7 Paint DefectsMohamed Nouzer100% (2)

- DPR Nag River Volume IIIDocument290 pagesDPR Nag River Volume IIIashutosh_shahu1Pas encore d'évaluation

- 8629 - 1t3 Protection of Steel From CorrosionDocument50 pages8629 - 1t3 Protection of Steel From Corrosionkranthi kumarPas encore d'évaluation

- The Triple Point of Water (TPW)Document24 pagesThe Triple Point of Water (TPW)vebriyantiPas encore d'évaluation

- Chemistry May:June 2015 Paper 43Document9 pagesChemistry May:June 2015 Paper 43Kamini Maria SaldanhaPas encore d'évaluation

- Comparison of Several Glycerol Reforming Methods For Hydrogen and Syngas Production Using Thermodynamic AnalysisDocument8 pagesComparison of Several Glycerol Reforming Methods For Hydrogen and Syngas Production Using Thermodynamic AnalysisPanagiotis GkezerlisPas encore d'évaluation

- Stowa 2002-11B PDFDocument155 pagesStowa 2002-11B PDFKahl YeongPas encore d'évaluation

- 11 Chapter Reaction Kinetics Text Book Exercise PDFDocument14 pages11 Chapter Reaction Kinetics Text Book Exercise PDFBilal KhanPas encore d'évaluation

- Hydrocarbon Migration and Trapping MechanismsDocument51 pagesHydrocarbon Migration and Trapping MechanismsReddy Setyawan100% (3)

- Corrosion Behavior of Stainless Steel in Hydrochloric Acid and Nitric Acid SolutionsDocument5 pagesCorrosion Behavior of Stainless Steel in Hydrochloric Acid and Nitric Acid SolutionsantonytechnoPas encore d'évaluation

- Chapter-2-LEVEL MEASUREMENTDocument26 pagesChapter-2-LEVEL MEASUREMENTMohammed YusufPas encore d'évaluation

- Valvoline Lithium Ep2 GreaseDocument1 pageValvoline Lithium Ep2 GreaseDicky PratamaPas encore d'évaluation

- Évfolyam Dolgozat - Peterke ReginaDocument6 pagesÉvfolyam Dolgozat - Peterke ReginaRegina PeterkePas encore d'évaluation

- Masterfiber: Monofilament Polypropylene Fibres For Cementitious SystemDocument2 pagesMasterfiber: Monofilament Polypropylene Fibres For Cementitious SystemHsaam Hsaam100% (1)

- IIT-JEE Syllabus: RSM79 PH I PP CH 1Document34 pagesIIT-JEE Syllabus: RSM79 PH I PP CH 1NayanKishorkumarThakkerPas encore d'évaluation

- Rainbow FireDocument4 pagesRainbow FireSilvia MariaPas encore d'évaluation

- CASSIDA FLUID GL 220 SDSDocument5 pagesCASSIDA FLUID GL 220 SDSFajar EkoPas encore d'évaluation

- U4 - WeldingDocument59 pagesU4 - WeldingAnonymous LM9RaUA4yPas encore d'évaluation

- Chemistry Five YearDocument9 pagesChemistry Five YeararslsaadPas encore d'évaluation

- Chem 210 Lab Report 1Document6 pagesChem 210 Lab Report 1Mxokzah Cmoh100% (1)

- ApplicationNote PH Measurement JamJellies EN 30538204Document4 pagesApplicationNote PH Measurement JamJellies EN 30538204MarcinPas encore d'évaluation

- How To Observe The SunDocument3 pagesHow To Observe The Sunnkvd134Pas encore d'évaluation