Académique Documents

Professionnel Documents

Culture Documents

2011 02 PotM Testing of - Electromechanical Relays PDF

Transféré par

reza515heiTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

2011 02 PotM Testing of - Electromechanical Relays PDF

Transféré par

reza515heiDroits d'auteur :

Formats disponibles

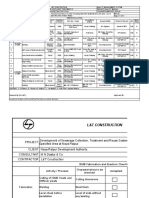

Presentation 8.

Efficient, Easy and Standardized Testing of Electromechanical Relays by Using a Library of Test

Templates

Peter Fong, Sequence Instruments, Canada

Michael Albert, OMICRON, Germany

Abstract

Standardized testing of protection relays is a big

challenge for electric utilities. But the importance and

the need for establishing a testing standard are

increasing more and more. For modern relays with its

hundreds of relay parameters and its increasing number

of protection functions the standardization seems to be

a must. The use of modern technologies is mandatory.

But how does a test for a single function relay e.g. an

electromechanical relay fit to this approach. Normally

there is a need of having a powerful test set,

information about the specialties of the dedicated relay

and the knowledge about testing this kind of protection

relays. And in the end this test has to be stored in a

database. In many cases the tests of the

electromechanical relay is fulfilled with an older test set.

That means manually testing and of course the test

report has to be written by hand, too.

OMICRON provides a library of test plans for years.

This library is called PTL (Protection Testing Library)

and it uses the newest software features of the Test

Universe software and supports test plans for single

function protection relays. This paper describes the idea

of these templates and points out the advantages and

the differences of the test plan for single function relays

to the test plans of multifunctional relays of the PTL.

Keywords

single function relay, protection testing, automatic

testing, standardized testing.

Introduction

In 2008, electric utilities worldwide purchase up to $850

million of protective relays each year. Although much of

these relays are numerical relays, still up to 10% of

these are electromechanical relays. North American

utilities account for up to $35 million in annual

purchases of electromechanical relays [4].

Although electromechanical relays are normally single

function devices, testing of these relays poses special

challenges due to the behavior of the electromechanical

movements. With many utilities losing testing expertise,

knowledge of testing these relays are also lost.

The benefits of having automatic test plans for different

electromechanical relays that are intuitive and userinteractive help the utilities to train new employees for

relay testing and as well to maintain a high level of

quality assurance for their relay testing program.

Automatic testing also ensures repeatability and allows

for proper comparison or trending of relay behavior.

All the test templates are supported by the

manufacturer of the relay test set, so that utilities do not

need to be concerned about maintenance of the test

templates over time.

Figure 1: Test setup for testing EM relay (Transformer

differential relay BDD from GE)

A standardized testing approach

The need for standardization has increased during the

last years. Due to the fact that over the years different

testing philosophies and different testing approaches

have been evolved and not at least different knowledge,

opinions and skills of testing people are recognized, it is

getting more and more important to standardize the

testing procedure. This standardization leads to

The test person saves time for developing a test.

As all the plans include the same tests, the testing

quality can be better controlled and improved.

Working together as a team is easier.

Company know-how can be added to the standard.

It is possible to test all generations of protection

devices with the same test equipment.

In general there are a lot of possibilities establishing

testing standards. Two main types of standardization

are [2]:

Standard for testing a dedicated protection function

OMICRON electronics GmbH 2010 International Protection Testing Symposium

Presentation 8.2

Standard for testing a dedicated protection

application (e.g. line protection for highest voltage).

An example of a standard for testing a dedicated

protection function is the definition of a test plan for

testing the transformer differential protection function:

Configuration or stabilization test

Pickup test

Operating characteristic test

Trip time test

Harmonic blocking test

The standard should also include which fault loops are

used and e.g. defines the number and position of the

test shots.

Once these steps are defined and the tests are

standardized it is possible to increase the automation

level of relay testing.

Multi function vs. single function relays

There are some essential differences between modern

numerical relays and electromechanical relays:

The number of protection functions is extremely

different

The number of parameters is extremely different

The application range of electromechanical relays

is limited

Due to these limitations it is possible to cover 100% of

needed tests of a single function relay in an automated

test template. The PTL items for single function relays

are designed for the most common application. That

means that is possible to have these relays tested in a

fully automated way.

Special solution for single function relays

Automated Relay Testing (Protection Testing

Library)

The OMICRON Protection Testing Library (PTL)

provides a good basis for designing testing standards.

The PTL contains of many small items, which are

designed to test protection devices in an easy and

automated manner.

The first release of the PTL was in spring 2007 and the

focus was on providing testing solutions for numerical

relays. Additionally to the standardization approach the

idea was to help the users analyzing the relay behavior.

But with the experiences of the last years there is a very

good chance of having the same testing tools working

in different worlds, the protection world of the numerical

relays with their huge number of settings and the

electromechanical relay world with a handful number of

relay parameters and a fixed setup.

A PTL item contains of (no matter if it is for a testing a

single function or multifunctional relay):

One test template to support many different relay

variants. Results in this test template are

automatically assessed based on tolerances as

suggested by the relay manufacturer.

Automatic calculation of the tripping characteristic

regarding to the relay settings.

A test report is generated automatically.

A user manual with useful information for testing

the dedicated relay.

For numerical relays the main protection functions and

some of the most important functions are covered in the

PTL.

In contrast to test templates developed for multifunction

numerical relays single function relays require the

following features:

Easy and logical entry of setting parameters (in

difference to numerical relays it is not possible to

emulate the relay manufacture software). The

challenge is to digitize the potentiometers or

jumpers in meaningful way.

Pop-up dialog boxes with instructions to help guide

the tester through the procedure as well as wiring

connections.

Instructions on what to do when a test fails.

Support variants of the same relay with different

setting parameters, operating characteristics, and

wiring connections.

A typical GE type IAC overcurrent relay has over 60

variants. The test template for the IAC relay allows the

user to select the variant from a list box (see figure 2).

Once selected, the appropriate wiring diagram and

characteristics are automatically selected.

Figure 2: Selecting the relay model

The workflow for testing single function relays consists

of the following easy and logic steps:

OMICRON electronics GmbH 2010 International Protection Testing Symposium

Presentation 8.3

1.

2.

3.

4.

5.

Entering/Checking the relay settings

Wiring/Connections

Pre-test instructions

Test and assessment

Report generation

Figure 5: Entering relay settings

It is possible to navigate through the dialog boxes and

switch between the multiple setting screens by using

the next or previous buttons.

In addition to the relay settings some more parameters

are important for the creation of a proper test plan.

Therefore relay general information (e.g. serial no.,

location, etc.) and tolerance for the test (a default value

is given from relay specification) has to be entered or

has to be confirmed.

Figure 3: Workflow for testing single function relays

At the beginning the test template has to be opened.

From this point on the automatism of the test template

is running and the guidance for the user is active. The

experienced user can cancel the guidance through the

entire test (see figure 4).

Figure 6: Additional information (relevant for the test template)

These settings are used to set up the tolerances in the

test modules or for creating the test report.

Step 2: Wiring/Connections

The wiring diagram is shown with some instructions

how to connect the relay and the test set (see figure 7).

Figure 4: Using the template with/without guidance

The confirmation of this information window with OK

starts to the five steps workflow for testing single

function relays.

Step 1: Entering/Checking the relay settings

The setting screen will start automatically. The user can

easily enter the relay settings. If there are many settings

on the relay, the setting screen may be distributed over

two or more dialog boxes.

Figure 7: Wiring diagram

OMICRON electronics GmbH 2010 International Protection Testing Symposium

Presentation 8.4

After the wiring the setup of the hardware has to be

checked. The information window guides to the

hardware configuration of the test plan (see figure 8).

Figure 10: Pre-test information window

Figure 8: Pre-Configurated 125V WET contacts

The test plan is pre-configured for e.g. 125V wet

contacts. This can be adapted to the conditions of the

actual substation.

The tests can be performed all at once, or can be

executed one by one.

With these explanations the know-how of the templates

designer is passed over to the template user. The

information is shown right before the dedicated test

module. These pause modules can also be used to

store company's know-how in an easy way and teach

the next generation of testers.

Step 4: Test and assessment

The relay function is tested using the standard Test

Universe test modules. These modules allow testing to

be visual and interactive during the test. Test points are

assessed at the time of the test. If a test points fails, the

user can stop the test right away and corrects the error

(e.g. setting error) without having to wait until the entire

test is completed. Figure 11 shows a test of the trip

times for an overcurrent relay.

Figure 9: Single tests or test all

Figure 11: Testing the trip times

Step 3: Pre-test instructions

Step 3 of the workflow provides pre-test instructions

and references to the tester.

The test module contains preconfigured test shots

which are set by the template designer. Because of the

open structure of all the templates of the PTL, it is very

easy to change the test shots to the own test

philosophy.

OMICRON electronics GmbH 2010 International Protection Testing Symposium

Presentation 8.5

Step 5: Report generation

All test shots are assessed automatically to pass or fail

based on the given tolerances and the report is

generated. Tools such as time-signal diagrams and

characteristic view can help with trouble-shooting if

needed. On the one hand the test report can be defined

in a long form which contains all test information from

the set up of test modules to test results and the final

assessment. On the other hand a short form of the

report can be created with only a short information if

test has passed or failed.

This paper has shown the possibility of speedy tests for

conventional single function protection relays in a

standardized way, by using the newest test equipment

with the latest test templates of the PTL.

Because of the following aspects

Pre-configured for routine E/M testing for the most

common application

Speedy tests possible of conventional protection

devices

Automatic assessment based on manu-facturing

recommendations

User configurable and adaptable

the use of these templates has a lot of benefits.

These PTL templates for testing single function relays

are also part of standard delivery and available for free

download.

References

[1] Karl

Zimmerman,

David

Costello:

Lessons Learned From Commissioning Protective

Relaying Systems. OMICRON IPTS 2009, Vienna

Figure 12: Test report

This 5 steps workflow demonstrates the principle, the

idea and the realization of the standardized automatic

test plans for single function relays. Based on this idea

a lot of electromechanical relays will be integrated in the

PTL. All of these test plans will follow this principle and

for this it will be more clear and traceable by another

person.

[2] Eugenio Carvalheira, Michael Albert, Oliver Janke:

PTL: A solid basis for building customized line

protection test standards. OMICRON IPTS 2009,

Vienna

Conclusion

[4] Worldwide Study of the Protective Relay

Marketplace in Electric Utilities 2006-2008

Energy Business Reports

Most of the protection engineers have to test all

generations of protection relays electromechanical

relays, electrostatic and of course digital relays.

Therefore they have to have a good knowledge about

the different kinds of relays. For these people it will be a

tremendous help to have only one test equipment to

use. This means the same hardware, software for

testing all these relays. The difference of the test plans

is only based on the protection relay.

OMICRON provides within its Protection Testing Library

a lot of these test plans using the same hardware and

the newest software for all kind of protection relays.

Single function relays, mostly electromechanical relays

are recognized by its variants and by its specialties. The

small functional range allows a 100% automated test

plan. The user is guided through the template and gets

valuable information important for the test, e.g. wiring

the relay contacts or setting up the test device.

[3] B. Bastigkeit: How a library of relay specific test

templates can support the protection engineer.

OMICRON IPTS 2007, Bregenz

OMICRON electronics GmbH 2010 International Protection Testing Symposium

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- E1 30 PDFDocument7 pagesE1 30 PDFreza515heiPas encore d'évaluation

- The First Voyage Round The World by MageDocument405 pagesThe First Voyage Round The World by MageGift Marieneth LopezPas encore d'évaluation

- ISH-2011 Requirements For-Testing HV-DC Equipment PDFDocument6 pagesISH-2011 Requirements For-Testing HV-DC Equipment PDFreza515heiPas encore d'évaluation

- Versatile AC Test System PDFDocument2 pagesVersatile AC Test System PDFreza515heiPas encore d'évaluation

- Shunt Reactor PaperDocument6 pagesShunt Reactor Paperbukit_guestPas encore d'évaluation

- TP - 101.01 - Short Circuit Impedance With Midas - 1110 PDFDocument4 pagesTP - 101.01 - Short Circuit Impedance With Midas - 1110 PDFreza515heiPas encore d'évaluation

- ISH 2011 - The Achievable Voltage Measurement Uncertainty of The Bushing Tap Method During The Induced Voltage Test of Power Transformers PDFDocument7 pagesISH 2011 - The Achievable Voltage Measurement Uncertainty of The Bushing Tap Method During The Induced Voltage Test of Power Transformers PDFreza515heiPas encore d'évaluation

- TransformerDocument6 pagesTransformerrasheed313Pas encore d'évaluation

- E1 38 PDFDocument7 pagesE1 38 PDFreza515heiPas encore d'évaluation

- Testing Power Quality Meters Using A CMC Test Set: SituationDocument8 pagesTesting Power Quality Meters Using A CMC Test Set: Situationreza515heiPas encore d'évaluation

- ISH 2011 - Paper Winding Resistance PDFDocument8 pagesISH 2011 - Paper Winding Resistance PDFreza515heiPas encore d'évaluation

- E1 34 PDFDocument7 pagesE1 34 PDFreza515heiPas encore d'évaluation

- Tettex Information: Measuring Ratio On Power Transformers With Higher Test VoltagesDocument12 pagesTettex Information: Measuring Ratio On Power Transformers With Higher Test Voltagesreza515heiPas encore d'évaluation

- E1 04 PDFDocument7 pagesE1 04 PDFreza515heiPas encore d'évaluation

- ISH-2011 Overview of Test Requirements on-HVDC-apparatus PDFDocument7 pagesISH-2011 Overview of Test Requirements on-HVDC-apparatus PDFreza515heiPas encore d'évaluation

- E1 37 PDFDocument8 pagesE1 37 PDFreza515heiPas encore d'évaluation

- E1 10 PDFDocument7 pagesE1 10 PDFreza515heiPas encore d'évaluation

- E1 28 PDFDocument8 pagesE1 28 PDFreza515heiPas encore d'évaluation

- E1 17 PDFDocument4 pagesE1 17 PDFreza515heiPas encore d'évaluation

- E1 18 PDFDocument5 pagesE1 18 PDFreza515heiPas encore d'évaluation

- E1 19 PDFDocument5 pagesE1 19 PDFreza515heiPas encore d'évaluation

- E1 08 PDFDocument11 pagesE1 08 PDFreza515heiPas encore d'évaluation

- E1 09Document6 pagesE1 09bukit_guestPas encore d'évaluation

- Increasing The Trigger Range: Translated From ETZ-A, Vol. 92 (1971) Nr. 1, P. 56. - .57Document3 pagesIncreasing The Trigger Range: Translated From ETZ-A, Vol. 92 (1971) Nr. 1, P. 56. - .57Anil SinghPas encore d'évaluation

- E1 27Document11 pagesE1 27Neel GalaPas encore d'évaluation

- E1 11Document6 pagesE1 11madhukarreddy2811Pas encore d'évaluation

- DSWpaper PDFDocument18 pagesDSWpaper PDFreza515heiPas encore d'évaluation

- 2013 03 PotM Monitoring of 420 KV XLPE Cable System in Underground Tunnel ENU PDFDocument5 pages2013 03 PotM Monitoring of 420 KV XLPE Cable System in Underground Tunnel ENU PDFreza515heiPas encore d'évaluation

- 2013 02 PotM ENU Performance Measurement PDFDocument6 pages2013 02 PotM ENU Performance Measurement PDFreza515heiPas encore d'évaluation

- E1 03 PDFDocument8 pagesE1 03 PDFreza515heiPas encore d'évaluation

- 2013 05 PotM Tuned Medium Band UHF PD Measurement Method For GIS ENU PDFDocument9 pages2013 05 PotM Tuned Medium Band UHF PD Measurement Method For GIS ENU PDFreza515heiPas encore d'évaluation

- Enzymes IntroDocument33 pagesEnzymes IntropragyasimsPas encore d'évaluation

- Hannah Mancoll - Research Paper Template - 3071692Document14 pagesHannah Mancoll - Research Paper Template - 3071692api-538205445Pas encore d'évaluation

- Enrile v. SalazarDocument26 pagesEnrile v. SalazarMaria Aerial AbawagPas encore d'évaluation

- First - Second and Third Class Levers in The Body - Movement Analysis in Sport - Eduqas - Gcse Physical Education Revision - Eduqas - BBC BitesizeDocument2 pagesFirst - Second and Third Class Levers in The Body - Movement Analysis in Sport - Eduqas - Gcse Physical Education Revision - Eduqas - BBC BitesizeyoyoyoPas encore d'évaluation

- Chapter 5 - CheerdanceDocument10 pagesChapter 5 - CheerdanceJoana CampoPas encore d'évaluation

- PreviewpdfDocument29 pagesPreviewpdfSoemarlan ErlanPas encore d'évaluation

- 1500 Series: Pull Force Range: 10-12 Lbs (44-53 N) Hold Force Range: 19-28 Lbs (85-125 N)Document2 pages1500 Series: Pull Force Range: 10-12 Lbs (44-53 N) Hold Force Range: 19-28 Lbs (85-125 N)Mario FloresPas encore d'évaluation

- PGCRSM-01-BLOCK-03 Research Design ExperimentalDocument29 pagesPGCRSM-01-BLOCK-03 Research Design ExperimentalVijilan Parayil VijayanPas encore d'évaluation

- Computer System Servicing 1 NC-II MODULE 8A (Second Semester: Week 6 - 7)Document19 pagesComputer System Servicing 1 NC-II MODULE 8A (Second Semester: Week 6 - 7)Carl John GomezPas encore d'évaluation

- 35 Electrical Safety SamanDocument32 pages35 Electrical Safety SamanSaman Sri Ananda RajapaksaPas encore d'évaluation

- Roles and Responsibilities of An InstructorDocument4 pagesRoles and Responsibilities of An InstructorMohanlal SainiPas encore d'évaluation

- Low Voltage Switchgear Specification: 1. ScopeDocument6 pagesLow Voltage Switchgear Specification: 1. ScopejendrikoPas encore d'évaluation

- William Hallett - BiographyDocument2 pagesWilliam Hallett - Biographyapi-215611511Pas encore d'évaluation

- 9881 enDocument345 pages9881 enSaid BenPas encore d'évaluation

- The Great Muslim Scientist - Imam Jaffer Sadiq (ADocument78 pagesThe Great Muslim Scientist - Imam Jaffer Sadiq (ASalman Book Centre100% (2)

- Homeopatija I KancerDocument1 pageHomeopatija I KancermafkoPas encore d'évaluation

- (Isaac Asimov) How Did We Find Out About AntarcticDocument24 pages(Isaac Asimov) How Did We Find Out About AntarcticDrBabu PSPas encore d'évaluation

- Calculus For The Life Sciences 2nd Edition Greenwell Solutions ManualDocument26 pagesCalculus For The Life Sciences 2nd Edition Greenwell Solutions ManualSharonPerezozqy100% (56)

- KCG-2001I Service ManualDocument5 pagesKCG-2001I Service ManualPatrick BouffardPas encore d'évaluation

- Soundarya Lahari Yantras Part 6Document6 pagesSoundarya Lahari Yantras Part 6Sushanth Harsha100% (1)

- Ismb ItpDocument3 pagesIsmb ItpKumar AbhishekPas encore d'évaluation

- ACCA F2 2012 NotesDocument18 pagesACCA F2 2012 NotesThe ExP GroupPas encore d'évaluation

- CCDocument5 pagesCCnazmulPas encore d'évaluation

- Procter and Gamble - MarketingDocument10 pagesProcter and Gamble - MarketingIvana Panovska100% (5)

- 1 PBDocument7 pages1 PBIndah Purnama TaraPas encore d'évaluation

- Final Self Hypnosis Paperback For PrintDocument150 pagesFinal Self Hypnosis Paperback For PrintRic Painter100% (12)

- Brosur YSIO X.preeDocument20 pagesBrosur YSIO X.preeRadiologi RSUD KilisuciPas encore d'évaluation

- IOT Architecture IIDocument29 pagesIOT Architecture IIfaisul faryPas encore d'évaluation

- John Wren-Lewis - NDEDocument7 pagesJohn Wren-Lewis - NDEpointandspacePas encore d'évaluation