Académique Documents

Professionnel Documents

Culture Documents

1

Transféré par

Parash LoyaTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

1

Transféré par

Parash LoyaDroits d'auteur :

Formats disponibles

Development of a Three-Dimensional

Bioprinter: Construction of Cell

Supporting Structures Using Hydrogel

and State-Of-The-Art Inkjet

Technology

Yuichi Nishiyama

Kanagawa Academy of Science and Technology,

Think-E Building, 1-23, Minamiwatarida,

Kawasaki-ku, Kawasaki 210-0855, Japan

Makoto Nakamura1

Graduate School of Science and Engineering for Research

Engineering,

University of Toyama,

3190, Gofuku, Toyama 930-8555, Japan;

Kanagawa Academy of Science and Technology,

Kanagawa, Japan

e-mail: maknaka@eng.u-toyama.ac.jp

Chizuka Henmi

Kumiko Yamaguchi

Shuichi Mochizuki

Hidemoto Nakagawa

Koki Takiura

Kanagawa Academy of Science and Technology,

Think-E Building, 1-23, Minamiwatarida,

Kawasaki-ku, Kawasaki 210-0855, Japan

We have developed a new technology for producing threedimensional (3D) biological structures composed of living cells

and hydrogel in vitro, via the direct and accurate printing of cells

with an inkjet printing system. Various hydrogel structures were

constructed with our custom-made inkjet printer, which we termed

3D bioprinter. In the present study, we used an alginate hydrogel

that was obtained through the reaction of a sodium alginate solution with a calcium chloride solution. For the construction of the

gel structure, sodium alginate solution was ejected from the inkjet

nozzle (SEA-Jet, Seiko Epson Corp., Suwa, Japan) and was

mixed with a substrate composed of a calcium chloride solution.

In our 3D bioprinter, the nozzle head can be moved in three dimensions. Owing to the development of the 3D bioprinter, an innovative fabrication method that enables the gentle and precise

fixation of 3D gel structures was established using living cells as

a material. To date, several 3D structures that include living cells

have been fabricated, including lines, planes, laminated structures, and tubes, and now, experiments to construct various hydrogel structures are being carried out in our laboratory.

DOI: 10.1115/1.3002759

1

Corresponding author.

Contributed by the Bioengineering Division of ASME for publication in the JOURNAL OF BIOMECHANICAL ENGINEERING. Manuscript received March 6, 2007; final manuscript received May 16, 2008; published online December 31, 2008. Review conducted by Cheng Zhu.

Journal of Biomechanical Engineering

Introduction

We have developed a new technology for producing living tissues in vitro, utilizing the direct and accurate printing of cells with

an inkjet printing system. Organ transplantation is one of the ultimate medical treatments, however, the shortage of donor organs

is an urgent and serious problem because waiting periods for donor organs have become longer and longer, and a number of million patients have died during the waiting period every year. Tissue engineering is one of the promising approaches to solve such

problems, and many researchers have addressed the development

of available tissues and organs by engineering approaches. To

date, engineered epithelium, cornea, and cartilage have been developed and applied clinically and successfully; however, any effective methods to produce complicated tissues and organs have

not been established, especially in composite tissues composed of

multitype cells. Then, we have speculated and addressed the development a new technology to manipulate individual cells and to

construct and regenerate composite biological tissues.

The main technique used in our approach is the direct and accurate printing of living cells using the inkjet technique. We previously confirmed that the cells ejected from an inkjet nozzle were

alive and able to proliferate 1. In addition, we were able to eject

the growth factor and other chemicals along with the cells by the

inkjet technique. These results indicate that the cells precisely

placed using the inkjet technique have a potential to attach to each

other, and the regenerative tissues can be engineered through the

culturing process. However, with this method using the inkjet

technique, the cells must be fixed onto the printed position in

order to prevent blotting and migration, and we aimed to construct

3D structures using liquid materials such as cell suspended media.

Thus, we employed some liquid materials that have an ability to

solidify after ejection, such as sodium alginate solution and fibrinogen solution, which gelate after mixing with calcium chloride solution and thrombin solution, respectively. With these materials, we were able to control the position of the ejected cells

and precisely form 3D structures. These gels are biocompatible

and can be formed in a liquid substrate to prevent the cells from

drying. Similar techniques have been reported in other works

16.

With conventional rapid-prototyping techniques, it is possible

to fabricate 3D structures using resin, plaster, and molten-metal

using inkjet technology. However, these methods are not capable

of fabricating structures using living cells and biological materials. In contrast, our method was designed to fabricate some living

tissue structures, and to also be able to utilize cells and biomaterials simultaneously. Furthermore, hydrogel 3D structures have

been successfully constructed using our novel technique described

in this paper.

Herein, we present our technique for fabricating 3D cell supporting structures using the inkjet technique and hydrogels. First,

we describe our custom-made 3D bioprinter, which is able to eject

cells and other liquid materials with precise positioning. Next, our

new method of fabrication of 3D gel structures is presented, in

which soft fixation with improved viscosity is used to construct

gel structures precisely. We mainly used alginate gel in the present

study, as it is inexpensive and easy to handle. Nevertheless, we

intend to discuss details of gel structures formed from other materials that have better biocompatibility at the next stage of our

research. We have investigated a number of different gel materials; however, only the combination of fibrinogen and hyaluronan

is described in this study.

Experiments and Results

2.1 Materials. Three kinds of materials, sodium alginate, calcium chloride, and polyvinyl alcohol PVA, were used in this

study. The sodium alginate was the precursor of the gel and calcium chloride was used as the substrate. Alginate gel was obtained

by mixing them. PVA was used as a viscosity enhancer for the

Copyright 2009 by ASME

MARCH 2009, Vol. 131 / 035001-1

Downloaded From: http://biomechanical.asmedigitalcollection.asme.org/ on 08/11/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

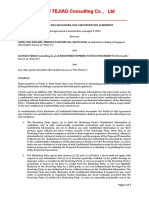

Fig. 1 Alginate gel beads

substrate. When the sodium alginate solution was ejected from the

inkjet nozzle into a substrate of calcium chloride, alginate gel

beads with the same size as the droplets supplied by the inkjet

were obtained, as shown in Fig. 1. The bead was the minimum

unit of gel structure used in this study. Since the beads suspended

in a low viscosity substrate moved freely, a gel structure could not

be formed with precise positioning. Therefore, we mixed the substrate with PVA to increase its viscosity. Both the alginate gel and

the PVA are known to have good biocompatibility. For example,

the alginate gel was used for the matrix material of cell transplantation and the PVA was applied for the soft contact lens material

79. Figure 2 shows living HeLa cells in alginate gel beads. The

viability of ejected cells was confirmed by time lapse monitoring,

which showed that cells were moving in the alginate gel beads.

For improved biocompatibility, fibrinogen and hyaluronan

could also be used for the gel precursor and substrate viscosity

enhancer, respectively. The fibrinogen is contained in the blood. If

necessary, it can be harvested from each patient. However, alginate gel and PVA were mainly used in order to study their feasibility with our 3D bioprinter, as they are inexpensive and adequate

materials.

Fig. 3 Comparison of inkjet droplets and bovine endothelial

cells

droplets ejected from the inkjet nozzles ranges from

1 pl to 100 pl. Figure 3 shows a comparison of the inkjet droplets

by a commercial inkjet printer and the suspended cells. The size

of the droplets was nearly equal to that of the cells 1. Therefore,

the inkjet printer has a potential to form 2D biological tissues at a

similar resolution with the cells.

We used an EPSON SEA-Jet inkjet nozzle head static electricity actuated inkJet, SEA-Jet, Seiko Epson Corp., Suwa, Japan, as shown in Fig. 4 10. It is driven by electrostatic force

using different electrical potentials and does not use any heat generation. Thus, it was able to eject cells through the inside capillary

without heating the droplets, which were sized at 8 160 pl, at a

frequency of 2 kHz or less. Although the inkjet nozzle head has

12 channels, each nozzle head is able to eject only a single kind of

fluid because the inlets of the channels connect to the same tank of

materials.

2.2 Inkjet Nozzle. In general, inkjet nozzles have originally

been developed for the printer heads. The very high resolution

print can be outputted by the recent inkjet printers. The size of the

Fig. 2 Gel beads including HeLa cells

035001-2 / Vol. 131, MARCH 2009

Fig. 4 EPSON SEA-Jet inkjet nozzle head

Transactions of the ASME

Downloaded From: http://biomechanical.asmedigitalcollection.asme.org/ on 08/11/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Table 1 Specification of the 3D bioprinter

Nozzle

Maximum ejecting frequency

Dimensions W D H

Positioning resolution

Positioning repeatability

Maximum feed speed

Effective feed stroke all axis

Epson SEA-Jet

2 kHz

400 300 380 mm3

0.2 m

4 m

130 mm/ s

100 mm

bead. Although the bead sizes varied depending on the nozzles

and the fluid type, they were approximately 10 60 m in diameter in our examination. In this study, several gel structures were

constructed by precisely distributing beads.

Figure 6 describes the method used to fabricate gel structures.

Droplets ejected from the inkjet nozzle are gelated by the contact

with the substrate surface. Therefore, 2D gel structures with arbitrary patterns were able to be formed on the surface of the substrate. 3D gel structures were obtained by stacking 2D gel structures and allowing them to sink into the substrate.

2.4.1 Fabrication of a Gel Line. Figure 7a shows a gel line

made by the continuous operation of the EPSON SEA-Jet. The

substrate was a 2% calcium chloride solution on a slide glass, and

the droplets ejected from the nozzle were a 0.8% solution of sodium alginate. The nozzle was easily able to eject up to 1% solution of sodium alginate. In this case, the line had no gap and had

a constant diameter, while lines with other configurations, such as

a broken line, were also fabricated by the same nozzle head, as

shown in Fig. 7b. The line shapes varied depending on the ejection frequency and the nozzle speed, and the results are shown in

Table 2. Although solid lines were formed under the condition of

high ejection frequency and low nozzle speed, a more refined line

was formed at lower ejection frequency and higher nozzle speed

limits.

2.4.2 Fabrication of a Gel Sheet. A gel sheet that formed a

plain gel structure was made by the parallel arrangement of gel

lines, as shown in Fig. 8. In this case, a 2% calcium chloride

solution was used as the substrate, and the ejection frequency and

nozzle speed were set to 800 Hz and 20 mm/ s, respectively.

Fig. 5 Newly developed bioprinter: a 3D bioprinter developed in our laboratory and b 3D bioprinter in a bioclean

bench environment

2.3 Our 3D Bioprinter. Our 3D bioprinter was manufactured

to be capable of operating the inkjet nozzle head and fabricating

3D structures Fig. 5a. We found that the printer had a positioning accuracy of less than a few micrometers and could operate in

a bioclean bench setting Fig. 5b. The actuators of the printer

are equipped with a feed mechanism of ball screws with stepping

motors ASC36AK, Oriental Motor Co., Ltd., Tokyo, Japan,

which are controlled by a closed-loop control method. The printing process is controlled by a Windows PC.

We also developed power and signal sources for the nozzle

using a signal generator H8/3052 microprocessor, Renesas Technology Corp., Tokyo, Japan and amplifier PA92 Operational

Amplifier, Apex Microtechnology Corp, Tucson, AZ, respectively. With this system, a signal of 0 2 V is amplified up to 20

times of the original voltage. We drove the EPSON SEA-Jet

nozzles by a rectangular waveform using this custom-made controller. Table 1 shows the fundamental specification of the 3D

bioprinter.

2.4 Fabrication of Gel Structures. The minimum gel structure printed by our bioprinter is a bead, as shown in Fig. 1, thus

the resolution of the gel structure was as small as the size of the

Journal of Biomechanical Engineering

2.4.3 Fabrication of 3D Gel Structures. 3D gel structures

were constructed by the lamination of some gel sheets. However,

the initial trials ultimately failed because the 3D gel structures

were not fixed firmly and easily broken down. Therefore, several

other materials were examined to construct firmer 3D gel structures. After several exploring tests, we found that the use of calcium chloride mixed with some viscosity improver was effective.

Then, we tried various viscosity enhancers, such as dextran, xanthan gum, guar, carrageenan, tragacanth gum, and pectin, and

Fig. 6 Illustration of the gel structure fabrication method

MARCH 2009, Vol. 131 / 035001-3

Downloaded From: http://biomechanical.asmedigitalcollection.asme.org/ on 08/11/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Fig. 8 Gel sheet nozzle head speed: 25 mm/ s, ejecting frequency: 800 Hz

the 3D gel structures, while 10% calcium chloride in the substrate

was the most suitable for the firm gelation of the sodium alginate.

2.4.4 Fabrication of Gel Tubes Containing HeLa Cells. By

means of the method described above, the 3D gel structures containing living cells can be fabricated. Figure 11 shows a representative 3D gel tube containing HeLa cells, which was fabricated by

the use of sodium alginate solution containing HeLa cells 6

106 / ml as ink, and 10% calcium chloride solution with 15%

PVA as a substrate, respectively. In these 3D structures, hydrogel

functioned well as a morphological cell supporting structure.

Fig. 7 Gel lines formed using the 3D bioprinter nozzle head

speed: 35 mm/ s, ejecting frequency: 500 Hz: a alginate gel

solid line nozzle head speed: 40 mm/ s, ejecting frequency:

1 kHz and b alginate gel broken line

found that PVA and hyaluronan are the best candidates with acceptable properties, such as biocompatibility, homogeneous solubility, and stability. Finally, 3D gel structures by the lamination of

gel sheets were successfully formed using a substrate, whose viscosity was enhanced by PVA, as shown in Fig. 9. In addition, gel

rings were formed by drawing circles and 3D gel tubes were successfully made by continuously drawing a circle at the same position, as the gel rings were stacked to form a 3D tube, which sank

into the substrate Fig. 10. We found that the substrate mixed

with greater than 15% PVA showed good supporting properties for

2.5 Viscosity. The viscosity of the liquid materials, such as

the sodium alginate solution, is an important factor for our fabrication methods. The inkjet nozzles are not capable of ejecting a

high viscosity solution, while the substrate could not fix the gel

structure effectively with a low viscosity solution. Then, the viscosities of the liquid materials were measured using a rotational

viscometer LVDV-II+ PRO CP, Brookfield Engineering Laboratories, Inc., Middleboro, MA, and the results are shown in Figs.

12a and 12b. The viscosities of the fibrinogen and the hyaluronan solutions were compared to those of the sodium alginate

and PVA solutions, with the results shown in Figs. 13a and

13b.

Discussion

3.1 Gel Structure Formation Using 3D Bioprinter. The

main objective of this study was to demonstrate the fabrication of

3D gel structures as cell supporting structures, which have the

potential to grow and develop to regenerative tissues with cultured

living cells. Although the gel structures produced in our laboratory

were not as complex as actual tissues, basic 3D forms, such as

fibers, sheets, laminated sheets, and tubes, were able to be fabricated using our 3D bioprinter and our method of fixing the gel

Table 2 Conditions necessary for forming gel lines. Gel line could formed. A part of

the gel line could not be formed continuously. Gel line could not be formed continuously.

Nozzle head speed mm/s

Shooting

frequency

Hz

100

500

1000

1500

2000

10

15

20

25

30

35

40

45

50

75

100

125

035001-4 / Vol. 131, MARCH 2009

Transactions of the ASME

Downloaded From: http://biomechanical.asmedigitalcollection.asme.org/ on 08/11/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Fig. 9 Gel lamination nozzle head speed: 25 mm/ s, ejecting

frequency: 800 Hz

Fig. 11 Gel tube including HeLa cells nozzle head speed:

25 mm/ s, ejecting frequency: 800 Hz

structure Figs. 810. They were directly fabricated in the liquid

substrate. Then, if the gel structure includes the cells, the cells

inside of the gel are not desiccated and are protected from the

impact shock due to the shock absorption characteristics of the

liquid. Furthermore, since the gel structures were comprised of the

gel bead 10 60 m in diameter, they were formed in minimum

resolution of the bead size, whose size was the same as the usual

cell size, using the 3D bioprinter. Therefore, our custom-made 3D

bioprinter showed sufficient potential to fabricate cell supporting

structures, such as 3D gel structures and precise cell positioning,

which were able to provide protection for the cells by the use of

hydrogel materials. In addition, we demonstrated that a tubular gel

structure was able to be fabricated as a cell supporting structure

by our method, as shown in Fig. 11, and confirmed that a number

of cells embedded in the gel tube were alive. We speculated that if

a gel tube containing vascular endothelial cells, vascular smooth

muscle cells, and fibroblast cells was fabricated by the present

method, and the cells inside the gel attached to each other and

self-assembled, a tubular tissue with a similar construction as a

blood vessel could be obtained.

nozzles, as shown in Fig. 12a. Although we have yet to evaluate

only in terms of viscosity, viscosity is an important property to

consider from the aspect of the ejecting ability and ejection stability of the nozzles. A substrate with more than 15% PVA showed

a good ability to support the gel structures and had a viscosity of

about 400 mPa Fig. 12b.

Considering the effects of viscosity, we propose here the fibrinogen solution and hyaluronan as other candidates of available

biocompatible materials for the gel precursor and substrate, re-

3.2 Effects of Viscosity. The nozzles were able to eject easily

up to a 1% solution of sodium alginate. Hence, a solution with

components sized up to 10 mPa could also be ejected by the

Fig. 10 Gel tube with enlarged view of the opening at the tip of

the tube nozzle head speed: 25 mm/ s, ejecting frequency:

800 Hz

Journal of Biomechanical Engineering

Fig. 12 Viscosity of the sodium alginate and PVA solutions

determined using a viscometer: a sodium alginate solution

and b PVA solution

MARCH 2009, Vol. 131 / 035001-5

Downloaded From: http://biomechanical.asmedigitalcollection.asme.org/ on 08/11/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

and hyaluronan solution are thought to be promising candidates

for gel and viscosity regulator, respectively. Applying such gels

and substrate materials, we may avoid such harmful conditions.

Nevertheless, it is considered that viable 3D tissues can be engineered and developed, if living cells in the 3D biocompatible

gel structures adhere to each other and proliferate in a 3D environment after fabrication. Such potential was demonstrated in the

present study.

Conclusion

We have developed a 3D bioprinter using state-of-the-art inkjet

technology and its feasibility was shown in this study. Using our

bioprinter, several simple 3D cell supporting structures, such as

fibers, 2D sheets, multilayered sheets, and 3D tubes, were constructed in a liquid substrate. Our results also show that viscosity

control had a critical effect on stabilizing the 3D cell supporting

structures in the fluid. Our bioprinter also showed a potential to

simultaneously eject multiple materials, including hydrogel precursor, living cells, growth factors, and nutrients. Presently, we are

developing a second generation bioprinter that can organize 3D

gel structures by embedding different types of living cells inside

or outside. We are aiming at the establishment of an effective

bioprinter that can fabricate 3D structures comprised of living

cells, toward the final goal of engineering living tissues and organs in the future.

Acknowledgment

Fig. 13 Viscosity of the fibrinogen and hyaluronan solutions

determined using a viscometer: a fibrinogen solution and b

hyaluronan solution

spectively. According to preliminary experiments on viscosity, a

fibrinogen solution of up to 0.8% can be ejected by the inkjet

nozzles Fig. 13a, while a greater than a 0.5% solution of hyaluronan can be used as the substrate, as well as 15% of PVA Fig.

13b.

3.3 Biocompatibility of the Materials. The biocompatibility

of the materials was not evaluated completely in the present study.

Although alginate hydrogel itself is known to be biocompatible

and we have also confirmed that the cells in alginate gel beads

were living by time lapse monitoring, a 10% calcium chloride

solution was used in some experiments in this study to make the

hydrogel stiffer. In this case, we examined the viability of the cells

by trypan blue staining after dissolving of the alginate gel, and

confirmed that 70% of the cells were alive. However, such high

osmotic solutions must have some adverse effects on the cells.

Therefore, further additional exploration of more suitable materials and further development of gelation techniques are needed.

This is one of the important issues at the next stage of development of this technology. According to our experiments on the

effects of viscosity, as discussed above, we found that fibrin gel

035001-6 / Vol. 131, MARCH 2009

We thank Seiko Epson Corp. for their kind support in regard to

the inkjet head and Dr. K. Suyama for the expert technical assistance. This work was supported by Kanagawa Academy of Science and Technology and grants-in-aid for Scientific Research

Grant Nos. 17300146, 18760518, and 18880042 from Japan Society for the Promotion of Science.

References

1 Nakamura, M., Kobayashi, A., Takagi, F., Watanabe, A., Hiruma, Y., Ohuchi,

K., Iwasaki, Y., Horie, M., Morita, I., and Takatani, S., 2005, Biocompatible

Inkjet Printing Technique for Designed Seeding of Individual Living Cells,

Tissue Eng., 11, pp. 16581666.

2 Goldmann, T., and Gonzalez, J. S., 2000, DNA-Printing: Utilization of a

Standard Inkjet Printer for the Transfer of Nucleic Acids to Solid Supports, J.

Biochem. Biophys. Methods, 42, pp. 105110.

3 Campbell, P. G., Miller, E. D., Fisher, G. W., Walker, L. M., and Weiss, L. E.,

2005, Engineered Spatial Patterns of FGF-2 Immobilized on Fibrin Direct

Cell Organization, Biomaterials, 26, pp. 67626770.

4 Miller, E. D., Fisher, G. W., Weiss, L. E., Walker, L. M., and Campbell, P. G.,

2006, Dose-Dependent Cell Growth in Response to Concentration Modulated

Patterns of FGF-2 Printed on Fibrin, Biomaterials, 27, pp. 22132221.

5 Roth, E. A., Xu, T., Das, M., Gregory, C., Hickman, J. J., and Boland, T.,

2004, Inkjet Printing for High-Throughput Cell Patterning, Biomaterials,

25, pp. 37073715.

6 Xu, T., Jin, J., Gregory, C., Hickman, J. J., and Boland, T., 2005, Inkjet

Printing of Viable Mammalian Cells, Biomaterials, 26, pp. 9399.

7 Lim, F., and Sun, A. M., 1980, Microencapsulated Islets as Bio Artificial

Endocrine Pancreas, Science, 210, pp. 908910.

8 Chrisine, W., Erich, K. O., Jorg, K., Zofia, F., Tim, W., and Dorothee, F., 2004,

PolyVinyl Alchol Membranes for Adhesion Prevention, J. Biomed. Mater.

Res., Part B: Appl. Biomater., 70B, pp. 191202.

9 Hyon, S. H., Cha, W. I., Ikada, Y., Kita, M., Ogura, Y., and Honda, Y., 1994,

PolyVinyl Alcohol Hydrogels as Soft Contact Lens Material, J. Biomater.

Sci., Polym. Ed., 5, pp. 397406.

10 Kamisuki, S., Hagata, T., Tezuka, C., Fjii, M., and Atobe, M., 1988, A Low

Power, Small, Electrostatically-Driven Commercial Inkjet Head, Proceedings

of MEMS 98, pp. 6368.

Transactions of the ASME

Downloaded From: http://biomechanical.asmedigitalcollection.asme.org/ on 08/11/2016 Terms of Use: http://www.asme.org/about-asme/terms-of-use

Vous aimerez peut-être aussi

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Statistical Methods For High Dimensional Biology: Stat/Biof/Gsat 540Document63 pagesStatistical Methods For High Dimensional Biology: Stat/Biof/Gsat 540Parash LoyaPas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- BiopolymerDocument21 pagesBiopolymerParash LoyaPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Signals and Systems 2nd (Simon Haykin)Document820 pagesSignals and Systems 2nd (Simon Haykin)Jane Hung82% (17)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- Instructions For Filling of Passport Application Form and Supplementary FormDocument18 pagesInstructions For Filling of Passport Application Form and Supplementary FormJessicaSouzaPas encore d'évaluation

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Parash LoyaDocument0 pageParash LoyaParash LoyaPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- BioenergyDocument4 pagesBioenergyParash LoyaPas encore d'évaluation

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Controle de Abastecimento e ManutençãoDocument409 pagesControle de Abastecimento e ManutençãoHAROLDO LAGE VIEIRAPas encore d'évaluation

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- FS2004 - The Aircraft - CFG FileDocument5 pagesFS2004 - The Aircraft - CFG FiletumbPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- 2010 - Impact of Open Spaces On Health & WellbeingDocument24 pages2010 - Impact of Open Spaces On Health & WellbeingmonsPas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- Account Statement From 30 Jul 2018 To 30 Jan 2019Document8 pagesAccount Statement From 30 Jul 2018 To 30 Jan 2019Bojpuri OfficialPas encore d'évaluation

- NLL - Elementary - Coursebook 2019 PDFDocument24 pagesNLL - Elementary - Coursebook 2019 PDFgilmolto100% (1)

- Iso 9001 CRMDocument6 pagesIso 9001 CRMleovencePas encore d'évaluation

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Federal Complaint of Molotov Cocktail Construction at Austin ProtestDocument8 pagesFederal Complaint of Molotov Cocktail Construction at Austin ProtestAnonymous Pb39klJPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Sysmex Xs-800i1000i Instructions For Use User's ManualDocument210 pagesSysmex Xs-800i1000i Instructions For Use User's ManualSean Chen67% (6)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Contact and Profile of Anam ShahidDocument1 pageContact and Profile of Anam ShahidSchengen Travel & TourismPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Rubber Chemical Resistance Chart V001MAR17Document27 pagesRubber Chemical Resistance Chart V001MAR17Deepak patilPas encore d'évaluation

- Non Circumvention Non Disclosure Agreement (TERENCE) SGDocument7 pagesNon Circumvention Non Disclosure Agreement (TERENCE) SGLin ChrisPas encore d'évaluation

- Katie Tiller ResumeDocument4 pagesKatie Tiller Resumeapi-439032471Pas encore d'évaluation

- Report Emerging TechnologiesDocument97 pagesReport Emerging Technologiesa10b11Pas encore d'évaluation

- Astera Data Integration BootcampDocument4 pagesAstera Data Integration BootcampTalha MehtabPas encore d'évaluation

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- Lecture02 NoteDocument23 pagesLecture02 NoteJibril JundiPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- Instrumentation Positioner PresentationDocument43 pagesInstrumentation Positioner PresentationSangram Patnaik100% (1)

- Circular Flow of Process 4 Stages Powerpoint Slides TemplatesDocument9 pagesCircular Flow of Process 4 Stages Powerpoint Slides TemplatesAryan JainPas encore d'évaluation

- Algorithms For Image Processing and Computer Vision: J.R. ParkerDocument8 pagesAlgorithms For Image Processing and Computer Vision: J.R. ParkerJiaqian NingPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- 5511Document29 pages5511Ckaal74Pas encore d'évaluation

- Gas Dehydration (ENGINEERING DESIGN GUIDELINE)Document23 pagesGas Dehydration (ENGINEERING DESIGN GUIDELINE)Tu Dang TrongPas encore d'évaluation

- Inside Animator PDFDocument484 pagesInside Animator PDFdonkey slapPas encore d'évaluation

- WSP Global EnvironmentDocument20 pagesWSP Global EnvironmentOrcunPas encore d'évaluation

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- GLF550 Normal ChecklistDocument5 pagesGLF550 Normal ChecklistPetar RadovićPas encore d'évaluation

- Do You Agree With Aguinaldo That The Assassination of Antonio Luna Is Beneficial For The Philippines' Struggle For Independence?Document1 pageDo You Agree With Aguinaldo That The Assassination of Antonio Luna Is Beneficial For The Philippines' Struggle For Independence?Mary Rose BaluranPas encore d'évaluation

- Data Sheet: Experiment 5: Factors Affecting Reaction RateDocument4 pagesData Sheet: Experiment 5: Factors Affecting Reaction Ratesmuyet lêPas encore d'évaluation

- DMDW Mod3@AzDOCUMENTS - inDocument56 pagesDMDW Mod3@AzDOCUMENTS - inRakesh JainPas encore d'évaluation

- Archlinux 之 之 之 之 Lmap 攻 略 ( 攻 略 ( 攻 略 ( 攻 略 ( 1 、 环 境 准 备 ) 、 环 境 准 备 ) 、 环 境 准 备 ) 、 环 境 准 备 )Document16 pagesArchlinux 之 之 之 之 Lmap 攻 略 ( 攻 略 ( 攻 略 ( 攻 略 ( 1 、 环 境 准 备 ) 、 环 境 准 备 ) 、 环 境 准 备 ) 、 环 境 准 备 )Goh Ka WeePas encore d'évaluation

- Math5 Q4 Mod10 DescribingAndComparingPropertiesOfRegularAndIrregularPolygons v1Document19 pagesMath5 Q4 Mod10 DescribingAndComparingPropertiesOfRegularAndIrregularPolygons v1ronaldPas encore d'évaluation

- Simply Put - ENT EAR LECTURE NOTESDocument48 pagesSimply Put - ENT EAR LECTURE NOTESCedric KyekyePas encore d'évaluation

- The European Journal of Applied Economics - Vol. 16 #2Document180 pagesThe European Journal of Applied Economics - Vol. 16 #2Aleksandar MihajlovićPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)