Académique Documents

Professionnel Documents

Culture Documents

G80SO63XX11P3

Transféré par

ThirukkumaranBalasubramanianCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

G80SO63XX11P3

Transféré par

ThirukkumaranBalasubramanianDroits d'auteur :

Formats disponibles

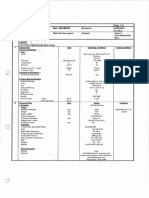

AgipGas BV

WESTERN LIBYA GAS PROJECT

LIBYAN BRANCH

Snamprogetti Lummus Gas Ltd

AGBV Doc. No.

0177/NC/02

G-80-S-O-63XX 11

CTR Job No.

CTR Doc. No.

310300

5E-631-PA-E-86627

Plant

MELLITAH PLANT

Snamprogetti

ABB Lummus Malta

AGBV Job No.

Location

Sh. 1 of 13

GSPLAJ

Rev.

P1 P2 P3

PROCESS DUTY SPECIFICATION FOR

SULPHUR SOLIDIFIER UNIT, SOLID SULPHUR STORAGE,

CONVEYING AND METERING FACILITIES

P3

07/07/03 Approved for Design General Revision

A.Angelucci

G.M.Bosi

C.Stocco

P2

21/02/03 Approved for Design

A.Angelucci

G.M.Bosi

C.Stocco

P1

18/12/02 Issued for Approval

A.Angelucci

G.M.Bosi

C.Stocco

Prep.

Check.

Appr.

Rev.

Date

Description

PMS Rev.

AGBV Appr.

Form code: MDT.GG.QUA.0004 Sh. 01/Rev. 3.96

Data file:330287973.doc

This document is CONFIDENTIAL and the sole property of the AGIP GAS BV. It shall neither be shown to third parties nor used for other purposes than those for

which it has been issued/sent. Any unauthorized attempt to reproduce it, in any form, is strictly prohibited.

AgipGas BV

WESTERN LIBYA GAS PROJECT

LIBYAN BRANCH

Snamprogetti Lummus Gas Ltd

Plant

MELLITAH PLANT

Snamprogetti

ABB Lummus Malta

AGBV Job No.

AGBV Doc. No.

0177/NC/02

G-80-S-O-63XX 11

CTR Job No.

CTR Doc. No.

310300

5E-631-PA-E-86627

Location

GSPLAJ

Sh. 2 of 13

Rev.

P1 P2 P3

Index

SCOPE

GENERAL

2.1

Material

PROCESS REQUIREMENTS

EQUIPMENT REQUIREMENTS

SYSTEM DESCRIPTION

5.1

Cooling water system description

5.2

Exhaust air system description

5.3

Design Basis

INSTRUMENTATION

6.1

Solidifier Units

6.2

Belt Conveyor to Warehouse

6.3

Portal Reclaimer

6.4

Tripper

6.5

Truck loading station

6.6

Control Scheme Architecture

ELECTRICAL

GUARANTEE REQUIREMENTS

UTILITIES COMSUMPTIONS

10

REFERENCE DOCUMENTS

_______________________________

Form code: MDT.GG.QUA.0004 Sh. 01/Rev. 3.96

Data file:330287973.doc

This document is CONFIDENTIAL and the sole property of the AGIP GAS BV. It shall neither be shown to third parties nor used for other purposes than those for

which it has been issued/sent. Any unauthorized attempt to reproduce it, in any form, is strictly prohibited.

AgipGas BV

WESTERN LIBYA GAS PROJECT

LIBYAN BRANCH

Snamprogetti Lummus Gas Ltd

Plant

MELLITAH PLANT

Snamprogetti

ABB Lummus Malta

AGBV Job No.

AGBV Doc. No.

0177/NC/02

G-80-S-O-63XX 11

CTR Job No.

CTR Doc. No.

310300

5E-631-PA-E-86627

Location

GSPLAJ

Sh. 3 of 13

Rev.

P1 P2 P3

SCOPE

This specification outlines the process requirements for the design of one sulphur solidifier

system (based on solid sulphur pastilles process) and relevant solid sulphur storage and

metering facilities. The system will be installed at Mellitah Plant.

The solid sulphur transportation from the Metering System to the berth and the Ship Loading

system are outside this scope of work.

For scope of work Battery Limit refer to para 9.

GENERAL

For climate, ambient conditions and utilities characteristics refer to G-65-S-Z-0001 00 Design

Premises for Mellitah Plant.

2.1

Material

Materials shall be suitable for the fluid handled and shall be subject to the Owner approval.

The spray system will utilize as cooling medium water which has a chloride content of about

140 ppm as NaCl.

The material of the Belt Cooler shall be suitable for cooling water with the above mentioned

characteristics.

PROCESS REQUIREMENTS

The system is designed to receive molten sulphur, to solidify it in pastilles form, to store them

in warehouse stockpile and to handle the product in bulk for metering.

The design capacity of the solidification system is 530 t/day of solid sulphur 99.5 wt % purity.

The system will include 6 units of 6 t/hr (four units will be in operation, one in stand-by and the

other one in maintenance).

The duty cycle is 24 hr/day.

The Solid Sulphur Storage and Metering System is designed considering to export the product

with ship vessels of 15.000 tons (Cargo capacity).

The liquid sulphur is available from two storage tanks (outside of the scope of work).

Provisions to be also provided for future local truck loading facilities.

_______________________________

Form code: MDT.GG.QUA.0004 Sh. 01/Rev. 3.96

Data file:330287973.doc

This document is CONFIDENTIAL and the sole property of the AGIP GAS BV. It shall neither be shown to third parties nor used for other purposes than those for

which it has been issued/sent. Any unauthorized attempt to reproduce it, in any form, is strictly prohibited.

AgipGas BV

WESTERN LIBYA GAS PROJECT

LIBYAN BRANCH

Snamprogetti Lummus Gas Ltd

Plant

MELLITAH PLANT

Snamprogetti

ABB Lummus Malta

AGBV Job No.

AGBV Doc. No.

0177/NC/02

G-80-S-O-63XX 11

CTR Job No.

CTR Doc. No.

310300

5E-631-PA-E-86627

Location

GSPLAJ

Sh. 4 of 13

Rev.

P1 P2 P3

EQUIPMENT REQUIREMENTS

The system will consist of the following main equipment.

Solidification Part

5E-632-CK-001 A/B

5E-632-XX-003

5E-632-HA-001

5E-632-HA-002

5E-632-HA-003

5E-632-PA-002 A/B

5E-632-VB-001

5E-632-XX-001 A-F

5E-632-KE-001 A/B

5E-632-XX-002

5E-632-TA-001

5E-632-PA-003

Sulphur Filters

Sulphur Preconditioning System, consisting of:

Sulphur Cooling Heat Exchanger

Thermalfluid Cooling Heat Exchanger

Thermalfluid Heating Heat Exchanger

Thermalfluid Pumps

Thermalfluid Expansion Vessel

Sulphur Solidifier Units

Exhaust Air Fans

Release Agent System, consisting of:

Release Agent Tank, including Stirrer

Release Agent Pump

Handling Part

5E-632-YH-001

5E-632-YH-002

5E-632-YH-003

5E-632-YH-004

Feeding Belt Conveyor

Tripper Car

Portal/Scraper Reclaimer

Reclaimer Product Conveyor

Metering Stations

5E-632-JM-001

5E-632-JM-002

Feeding Metering Station

Reclaiming Metering Station

Buildings

5E-632-ZP-001

5E-632-ZP-002

Shelter for Solidification Unit

Warehouse

_______________________________

Form code: MDT.GG.QUA.0004 Sh. 01/Rev. 3.96

Data file:330287973.doc

This document is CONFIDENTIAL and the sole property of the AGIP GAS BV. It shall neither be shown to third parties nor used for other purposes than those for

which it has been issued/sent. Any unauthorized attempt to reproduce it, in any form, is strictly prohibited.

AgipGas BV

WESTERN LIBYA GAS PROJECT

LIBYAN BRANCH

Snamprogetti Lummus Gas Ltd

Plant

MELLITAH PLANT

Snamprogetti

ABB Lummus Malta

AGBV Job No.

AGBV Doc. No.

0177/NC/02

G-80-S-O-63XX 11

CTR Job No.

CTR Doc. No.

310300

5E-631-PA-E-86627

Location

GSPLAJ

Sh. 5 of 13

Rev.

P1 P2 P3

SYSTEM DESCRIPTION

Sulphur pastilles will be obtained feeding liquid sulphur to a solidification system, where six

Solidifier Units are provided (four operating, one standby and one in maintenance) each one

with a design capacity of 6 t/hr. The liquid sulphur is stored at about 135 C in the tanks 5E631-TA-001 and 5E-631-TA-002 and it is transferred to the Sulphur Pit 5E-632-TH-001 by

means of two centrifugal horizontal pumps 5E-632-PA-001 A/B (one spare). The sulphur is

maintained in the pit at about 135 C using low pressure steam as heating medium. From the

Pit the liquid sulphur is fed continuously to the solidification units by means of two vertical type

Liquid Sulphur Pumps 5E-632-PH-001 A/B (one in operation and one standby), one additional

pump 5E-632-PH-001 C will be provided as capital spare and it will be stored in the spare

parts warehouse building. Liquid sulphur transfer pumps, sulphur pit and sulphur pumps are

outside scope of work.

Liquid sulphur preconditioning unit, including sulphur filters, is provided to keep under control

liquid sulphur temperature at the inlet of solidifier unit.

In the Solidifier Units the sulphur is produced in the form of pastilles and cooled down by

means of cooling water. Uniformly sized drops of sulphur product are continuously deposited

onto a stainless steel Cooling Conveyor Belt. The uniform drops, once in contact with the belt,

form into 3 to 6 mm diameter pastilles.

The pastilles are indirectly cooled as they travel the length of the belt by sprying cooling water

underneath.

Once the pastilles have traveled the length of the conveyor, they are in solid form at about 70

C. A release agent (Diasil SRA, Tegopren 5863 or equivalent) is applied, before the sulphur

product is deposited on the belt to ensure trouble free product discharge.

The solidified pastilles are sent to the warehouse, by means of the one Belt Conveyors 5E632-YH-001 and the Tripper Car 5E-632-YH-002. A continuous belt weigher 5E-632-JM-001

fitted into the belt conveyor 5E-632-YH-001 will record rate of feed and total capacity of

material delivered to the store. Because of its particle size in the range of few millimeters the

sulphur pastilles have good flow behaviour, as long as they are not stored for a longer period

at compressive stress. However, storage periods of some days up to few weeks in the

warehouse cannot be avoided, as the warehouse serves for the storage of sulphur until a

sufficient quantity is available for ship loading. This led to the formation of columns of caked

sulphur pastilles.

Solid Sulphur is reclaimed from the store by a portal reclaimer 5E-632-YH-003 at capacity of

430 tons/h onto a belt conveyor 5E-632-YH-004 running the full length of the store at ground

level. This conveyor has a capacity of 430 tons/h and is equipped with a moveable/emergency

hopper for emergency by-pass feed in the event of portal scraper stoppage; the backup hoppers

will be loaded by front loaders in case of break-down of the portal scraper. In addition,

provisions for future local truck loading shall be provided.

A continuous belt weigher 5E-632-JM-002 fitted into the belt conveyor 5E-632-YH-004 will

record rate of feed and total capacity of material delivered to the Pipe Conveyor (about 2.3 km

long, not included in the scope of work of Contractor) and routed to the Jetty for ship loading.

The design capacity of the shiploading system is 430 ton/hr of solid sulphur and it allows to

load a ship vessel of 15.000 tons (Cargo Capacity) in about 2 days.

_______________________________

Form code: MDT.GG.QUA.0004 Sh. 01/Rev. 3.96

Data file:330287973.doc

This document is CONFIDENTIAL and the sole property of the AGIP GAS BV. It shall neither be shown to third parties nor used for other purposes than those for

which it has been issued/sent. Any unauthorized attempt to reproduce it, in any form, is strictly prohibited.

AgipGas BV

WESTERN LIBYA GAS PROJECT

LIBYAN BRANCH

Snamprogetti Lummus Gas Ltd

Plant

MELLITAH PLANT

Snamprogetti

ABB Lummus Malta

5.1

AGBV Job No.

AGBV Doc. No.

0177/NC/02

G-80-S-O-63XX 11

CTR Job No.

CTR Doc. No.

310300

5E-631-PA-E-86627

Location

GSPLAJ

Sh. 6 of 13

Rev.

P1 P2 P3

Cooling water system description

The cooling medium foreseen for sulphur soldifier is open loop type. In fact the water sprayed

is collected underneath the cooling belt conveyors in the collecting hoppers under the solidifier

units and sent to the Cooling Water Return Pit 5E-632-TH-002. Two pumps (5E-632-PH-002

A/B) are provided to transfer the cooling water from the Pit to the cooling water return system.

Manufacturer shall prevent any cooling water contamination. Both cooling water pit and

cooling water pumps are outside Manufacturer scope of work.

5.2

Exhaust air system description

Exhaust air, including H2S and sulphur fumes from liquid sulphur during solidification is sucked

by the exhaust fan 5E-632-KE-001 A/B (one in operation and one spare) and is led to the

atmosphere outside the shelter. Manufacturer will consider provisions to control the air

discharge to the atmosphere in order to avoid environmental impact and pollution. Due to

presence of the sulphur fumes, corrosion resistant exhaust fans shall be provided.

_______________________________

Form code: MDT.GG.QUA.0004 Sh. 01/Rev. 3.96

Data file:330287973.doc

This document is CONFIDENTIAL and the sole property of the AGIP GAS BV. It shall neither be shown to third parties nor used for other purposes than those for

which it has been issued/sent. Any unauthorized attempt to reproduce it, in any form, is strictly prohibited.

AgipGas BV

WESTERN LIBYA GAS PROJECT

LIBYAN BRANCH

Snamprogetti Lummus Gas Ltd

Plant

MELLITAH PLANT

Snamprogetti

ABB Lummus Malta

5.3

AGBV Job No.

AGBV Doc. No.

0177/NC/02

G-80-S-O-63XX 11

CTR Job No.

CTR Doc. No.

310300

5E-631-PA-E-86627

Location

GSPLAJ

Sh. 7 of 13

Rev.

P1 P2 P3

Design Basis

5.3.1

Liquid Sulphur conditions at B.L.

Temperature

Pressure

Purity

Ash Content

Hydrocarbons

Acidity

H2S

5.3.2

Cooling Water Supply conditions at B.L.

Temperature

Pressure

5.3.3

: 32 C

: 5 barg

Cooling Water Return conditions at B.L.

Temperature

Pressure

5.3.4

: 135 C min

: 3 barg

: > 99.5 %

: < 500 ppmw

: < 500 ppmw

: < 300 ppmw

: < 10 ppm

: 44 C, maximum return temperature from individual user.

: ATM

Product Characteristics (Pastilles)

Solid Sulphur Temperature

Solid Sulphur purity

Shape, Size and Size Distribution

diameter.

Compaction

Bulk Density

Moisture content

Angle of repose

Dust (as produced)

Friability

: 70 C

: 99.5 %

: Generically semispherical, between 1 mm and 6 mm in

Less than 5% is retained on a 6.3 mm screen.

A minimum of 75% of materials is retained a N 31/2 U.S.

Screen (5.6 mm).

A minimum of 75% of materials is retained a N 7 U.S.Screen

(2.8 mm).

Less than of 2% of materials is retained a N16 U.S. Screen

(1.00 mm).

Less than of 0.5% of materials is retained a N 50 U.S.

Screen (300 microns).

: Fines generated after direct shear test under static loading

of 165 KPa (approximate 15 m stockpile) not to exceed 0.2%

fines by weight.

Fines generated after direct shear test under dynamic loading

at 165 KPa, not to exceed 0.5% by weight.

: 1100 kg/m3

: < 0.5% wt

: > 25

: < 0.5%

: < 2% (stress level II after 1 day)

_______________________________

Form code: MDT.GG.QUA.0004 Sh. 01/Rev. 3.96

Data file:330287973.doc

This document is CONFIDENTIAL and the sole property of the AGIP GAS BV. It shall neither be shown to third parties nor used for other purposes than those for

which it has been issued/sent. Any unauthorized attempt to reproduce it, in any form, is strictly prohibited.

AgipGas BV

WESTERN LIBYA GAS PROJECT

LIBYAN BRANCH

Snamprogetti Lummus Gas Ltd

Plant

MELLITAH PLANT

Snamprogetti

ABB Lummus Malta

5.3.5

AGBV Job No.

AGBV Doc. No.

0177/NC/02

G-80-S-O-63XX 11

CTR Job No.

CTR Doc. No.

310300

5E-631-PA-E-86627

Location

Sh. 8 of 13

GSPLAJ

Rev.

P1 P2 P3

Capacity of the system

Solidification units capacity (six units in total)

Working hours

Warehouse Stockpile net capacity

Reclaimer design capacity

Conveyor from warehouse to pipe conveyor

Conveyor from Solidification units to warehouse

Feeding Metering Station

Reclaiming Metering Station

: 6 t/hr each

: 24 hr/day

: 1 x 25000 tons

: 430 t/hr

: 430 t/hr

: 28 t/hr

: 28 t/hr

: 430 t/hr

_______________________________

Form code: MDT.GG.QUA.0004 Sh. 01/Rev. 3.96

Data file:330287973.doc

This document is CONFIDENTIAL and the sole property of the AGIP GAS BV. It shall neither be shown to third parties nor used for other purposes than those for

which it has been issued/sent. Any unauthorized attempt to reproduce it, in any form, is strictly prohibited.

AgipGas BV

WESTERN LIBYA GAS PROJECT

LIBYAN BRANCH

Snamprogetti Lummus Gas Ltd

Plant

MELLITAH PLANT

Snamprogetti

ABB Lummus Malta

6

6.1

AGBV Job No.

AGBV Doc. No.

0177/NC/02

G-80-S-O-63XX 11

CTR Job No.

CTR Doc. No.

310300

5E-631-PA-E-86627

Location

GSPLAJ

Sh. 9 of 13

Rev.

P1 P2 P3

INSTRUMENTATION

Solidifier Units

The control of molten sulphur flow shall be precisely monitored and automatically controlled by

means of a vortex flow meter associated with variable frequency pump drivers and by a

pressure control on the liquid sulphur return line.

A series of thermocouples shall be provided to monitor the process temperatures the necessity

of any adjustment or an upset condition by using preconditioning unit.

Temperature, pressure, flow and levels parameters throughout the system are monitored along

with other information.

Each Solidification Units will have a Local Operator Panel for local maintenance operations of

the unit(s).

6.2

Belt Conveyor to Warehouse

All instrumentation and control system required for safe and efficient operation of the unit shall

be provided by the Manufacturer.

The instrumentation shall include at least the following:

Limit switches to indicate any belt failure and to stop the flow of liquid sulphur to the

solidifiers.

A zero speed switch or other suitable device shall be designed for sequential control and to

sense belt breakage, belt slippage or belt stoppage of the feed conveyors to the

Warehouse

A safety system (consisting of an emergency shut-down push button installed on local

panel) shall be provided to stop the operation of solidifier and the feed conveyor to

Warehouse.

6.3

Portal Reclaimer

The operation and control of the portal scraper reclaimer can be effected in three different

modes as follows:

Non-interlocked Manual Mode: this mode is used during maintenance, trouble-shooting and

repair to control each individual drive at their respective location without any inter-locking

effect from the PLC controls.

Interlocked Manual Mode: this mode of operation has all inter-locking functions in active

mode, mainly for the safe operation of the equipment by the local operator.

_______________________________

Form code: MDT.GG.QUA.0004 Sh. 01/Rev. 3.96

Data file:330287973.doc

This document is CONFIDENTIAL and the sole property of the AGIP GAS BV. It shall neither be shown to third parties nor used for other purposes than those for

which it has been issued/sent. Any unauthorized attempt to reproduce it, in any form, is strictly prohibited.

AgipGas BV

WESTERN LIBYA GAS PROJECT

LIBYAN BRANCH

Snamprogetti Lummus Gas Ltd

Plant

MELLITAH PLANT

Snamprogetti

ABB Lummus Malta

AGBV Job No.

AGBV Doc. No.

0177/NC/02

G-80-S-O-63XX 11

CTR Job No.

CTR Doc. No.

310300

5E-631-PA-E-86627

Location

GSPLAJ

Sh. 10 of 13 Rev.

P1 P2 P3

Automatic Mode: the scraper reclaimer is electrically interlocked with the discharging

conveyor; the scraper reclaimer operates automatically until the stockpiled material is

completely reclaimed or a command to stop reclaiming is received from the remote

control in DCS Control Room. However, the operator can also stop the reclaimer locally

by the key-switch control on the operators panel.

6.4

Tripper

Travelling tripper is motorized type travelling on rails including drive unit complete with selfbreaking gear reducer, hanging flat cable for power supply and control to tripper.

The operation and control of the tripper can be effected in two different modes as follows:

Manual Mode: tripper is operated from local panel through pushbutton by putting

Remote/Local switch in local mode

Automatic Mode: before putting tripper in operation, working zone for tripper is selected and

tripper is positioned at beginning of working zone from DCS Control Room; tripper

discharges material at a particular position till stockpile level reaches high, then tripper

moved to a predetermined distance until the stockpile is full in the working zone.

6.5

Truck loading station

No controls shall be provided for future local truck loading.

6.6

Control Scheme Architecture

Controls will be divided in two sections:

a) One PLC for Solidification Units and Warehouse loading.

b) One PLC on Reclaimer for Warehouse Product Transfer to Pipe Conveyor.

The PLC for Solidification Units and Tripper Car will be located at the Electrical Substation

S/S-6 as remote I/O; controls shall be designed to provide fully automated operation and

complete status monitoring of the Solidification Units and Warehouse Loading from DCS

Operator.

The DCS Operator will be responsible:

1) to transfer the Liquid Sulphur from the Storage Tank 5E-631-TA-001/002 the Liquid

Sulphur Pit 5E-631-TH-001.

2) to transfer the Liquid Sulphur from the Liquid Sulphur Pit 5E-631-TH-001 to the

Solidification Units.

3) cooling water system.

4) to load product into warehouse.

_______________________________

Form code: MDT.GG.QUA.0004 Sh. 01/Rev. 3.96

Data file:330287973.doc

This document is CONFIDENTIAL and the sole property of the AGIP GAS BV. It shall neither be shown to third parties nor used for other purposes than those for

which it has been issued/sent. Any unauthorized attempt to reproduce it, in any form, is strictly prohibited.

AgipGas BV

WESTERN LIBYA GAS PROJECT

LIBYAN BRANCH

Snamprogetti Lummus Gas Ltd

Plant

MELLITAH PLANT

Snamprogetti

ABB Lummus Malta

AGBV Job No.

AGBV Doc. No.

0177/NC/02

G-80-S-O-63XX 11

CTR Job No.

CTR Doc. No.

310300

5E-631-PA-E-86627

Location

GSPLAJ

Sh. 11 of 13 Rev.

P1 P2 P3

The PLC of reclaimer will be located inside Reclaimer operating cabin; controls shall be

designed to provide fully automated operation of warehouse unloading from Shiploader

Operator.

The Shiploader Operator will be responsible to perform a limited number of operations as

follows:

1) to reclaim the solidified sulphur pastilles from the Warehouse.

2) to load the ship vessels by means the pipe Conveyor and Shiploader.

Shiploader, Pipe Conveyor, Transfer Belt Conveyor and Reclaimer will automatically initiate a

controlled auto-sequence start-up and/or auto-sequence shutdown.

Shiploader Operator will have the overall control of the product Transfer Belt Conveyor,

Reclaimer and Shiploading System.

_______________________________

Form code: MDT.GG.QUA.0004 Sh. 01/Rev. 3.96

Data file:330287973.doc

This document is CONFIDENTIAL and the sole property of the AGIP GAS BV. It shall neither be shown to third parties nor used for other purposes than those for

which it has been issued/sent. Any unauthorized attempt to reproduce it, in any form, is strictly prohibited.

AgipGas BV

WESTERN LIBYA GAS PROJECT

LIBYAN BRANCH

Snamprogetti Lummus Gas Ltd

Plant

MELLITAH PLANT

Snamprogetti

ABB Lummus Malta

AGBV Job No.

AGBV Doc. No.

0177/NC/02

G-80-S-O-63XX 11

CTR Job No.

CTR Doc. No.

310300

5E-631-PA-E-86627

Location

GSPLAJ

Sh. 12 of 13 Rev.

P1 P2 P3

ELECTRICAL

The electrical equipment of Solidification Units and Metering System shall be selected

according to the Hazardous Area Classification. As a minimum, all electrical equipment shall

be suitable for installation in Zone 22 areas as per IEC 61241-3.

GUARANTEE REQUIREMENTS

Manufacturer shall guarantee the satisfactory operation of the system, the performance of

each equipment of the entire system. In addition, Manufacturer shall guarantee the product

quality according to the requirements of this specification with the system operated at the

design capacity.

The following figures will be guaranteed:

Pastilles dimensions

Solidification unit capacity

Pastilles temperature outlet

Solid Sulphur reclaiming rate

Conveyors capacity

H2S emission limit

Dust emission limit

SO2 emission limit

Water

Friability

: As per Industry Adopted Modified Sudic

: 6 t/hr each

: 70 C

: 430 t/h

: according to the para 5.3.5 of this spec.

: Refer to Health, Safety,

Enviromental Project Plan

: Refer to Health, Safety,

Enviromental Project Plan

: Refer to Health, Safety, Enviromental Project Plan

: no contamination

: < 2% (stress level II after 1 day)

UTILITIES COMSUMPTIONS

Expected consumption, based on four units in operations, of the following utilities has been

calculate during bidding phase:

Heating medium LP steam, 4,0 bar g, 152C

Consumption:

for operation:

for start-up:

100 kg/h

300 kg/h

Cooling water max. 32C, 3 bar

Consumption:

approx. 100 m/h (for 4 units)

Make-up water for release agent:

12 l/h (3 l/h per unit)

CL- content of water:

max. 140 ppm

_______________________________

Form code: MDT.GG.QUA.0004 Sh. 01/Rev. 3.96

Data file:330287973.doc

This document is CONFIDENTIAL and the sole property of the AGIP GAS BV. It shall neither be shown to third parties nor used for other purposes than those for

which it has been issued/sent. Any unauthorized attempt to reproduce it, in any form, is strictly prohibited.

AgipGas BV

WESTERN LIBYA GAS PROJECT

LIBYAN BRANCH

Snamprogetti Lummus Gas Ltd

Plant

MELLITAH PLANT

Snamprogetti

AGBV Job No.

AGBV Doc. No.

0177/NC/02

G-80-S-O-63XX 11

CTR Job No.

CTR Doc. No.

310300

5E-631-PA-E-86627

Location

ABB Lummus Malta

GSPLAJ

Sh. 13 of 13 Rev.

P1 P2 P3

Electric energy

Capacity installed:

Solidification units

Handling conveyors

Reclaimer

40 kW (without spare units)

40 kW

less than 150 kW

Instrument air (de-oiled and dry) Pressure 7 bar

Consumption:

approx. 0,5 Nm/h

Release agent Water/Tegopren, mixture 97 % water, 3 % Tegopren

Consumption:

0,015 kg Tegopren per ton of sulphur

Final consumptions list shall be defined during detail engineering and will be in the range of

+

/- 10% accurancy of the above expected consumptions.

10 REFERENCE DOCUMENTS

Heat Material Balance N:

Process Flow Diagram N:

G-80-Y-O-0002 00

G-80-D-O-1163 02

_______________________________

Form code: MDT.GG.QUA.0004 Sh. 01/Rev. 3.96

Data file:330287973.doc

This document is CONFIDENTIAL and the sole property of the AGIP GAS BV. It shall neither be shown to third parties nor used for other purposes than those for

which it has been issued/sent. Any unauthorized attempt to reproduce it, in any form, is strictly prohibited.

Vous aimerez peut-être aussi

- CEIL Engineering FinHR Advt 202324 02Document6 pagesCEIL Engineering FinHR Advt 202324 02ThirukkumaranBalasubramanianPas encore d'évaluation

- Job Description-Process EngineerDocument1 pageJob Description-Process EngineerThirukkumaranBalasubramanianPas encore d'évaluation

- PALL FILTER - Process Data SheetDocument2 pagesPALL FILTER - Process Data SheetThirukkumaranBalasubramanianPas encore d'évaluation

- Visual Inspection WeldDocument53 pagesVisual Inspection Weldshifa100% (1)

- DS 7502Document4 pagesDS 7502ThirukkumaranBalasubramanianPas encore d'évaluation

- Mellitah Oil & Gas BV: Welding Procedure Specification For Stainless Steel PipingDocument9 pagesMellitah Oil & Gas BV: Welding Procedure Specification For Stainless Steel PipingThirukkumaranBalasubramanianPas encore d'évaluation

- D2-001-AM Part 1Document118 pagesD2-001-AM Part 1ThirukkumaranBalasubramanianPas encore d'évaluation

- Job Description-Piping EngineerDocument1 pageJob Description-Piping EngineerThirukkumaranBalasubramanianPas encore d'évaluation

- Job Description-Mechanical EngineerDocument1 pageJob Description-Mechanical EngineerThirukkumaranBalasubramanianPas encore d'évaluation

- Summarized Technical - Information Data'sDocument1 pageSummarized Technical - Information Data'sThirukkumaranBalasubramanianPas encore d'évaluation

- CUI Risk Factors on Insulated PipingDocument21 pagesCUI Risk Factors on Insulated PipingRenan Soares KieferPas encore d'évaluation

- Final Report TOTAL EP MYANMARDocument24 pagesFinal Report TOTAL EP MYANMARThirukkumaranBalasubramanianPas encore d'évaluation

- Mellitah Oil & Gas BV: Field Bending OF LinepipeDocument4 pagesMellitah Oil & Gas BV: Field Bending OF LinepipeThirukkumaranBalasubramanianPas encore d'évaluation

- Guide to Failure Analysis in Oil and Gas IndustryDocument6 pagesGuide to Failure Analysis in Oil and Gas IndustryThirukkumaranBalasubramanian100% (1)

- Cold CuttingDocument2 pagesCold CuttingThirukkumaranBalasubramanianPas encore d'évaluation

- Execution of Tie-Ins Without A Plant ShutdownDocument3 pagesExecution of Tie-Ins Without A Plant ShutdownThirukkumaranBalasubramanianPas encore d'évaluation

- Mellitah Oil & Gas BV: Wafa Gathering ProcedureDocument19 pagesMellitah Oil & Gas BV: Wafa Gathering ProcedureThirukkumaranBalasubramanianPas encore d'évaluation

- INITIAL RISK REVIEW - WAFA Cold CutDocument6 pagesINITIAL RISK REVIEW - WAFA Cold CutThirukkumaranBalasubramanianPas encore d'évaluation

- Mellitah Oil & Gas BV: Wafa Gathering ProcedureDocument583 pagesMellitah Oil & Gas BV: Wafa Gathering ProcedureThirukkumaranBalasubramanian0% (1)

- Mellitah Oil & Gas BVDocument12 pagesMellitah Oil & Gas BVThirukkumaranBalasubramanianPas encore d'évaluation

- PSG 15 Repairs or Modifications Dated 13th Nov 2013 PDFDocument13 pagesPSG 15 Repairs or Modifications Dated 13th Nov 2013 PDFThirukkumaranBalasubramanianPas encore d'évaluation

- Non Oily Wastewater To The SeaDocument1 pageNon Oily Wastewater To The SeaThirukkumaranBalasubramanianPas encore d'évaluation

- JERES-D-001 Design Criteria For Pressure VesselsDocument37 pagesJERES-D-001 Design Criteria For Pressure VesselsThirukkumaranBalasubramanianPas encore d'évaluation

- Atlas Grade Datasheet - All Datasheets Rev Aug 2013 PDFDocument57 pagesAtlas Grade Datasheet - All Datasheets Rev Aug 2013 PDFMikku KattaPas encore d'évaluation

- Installation PlanDocument28 pagesInstallation PlanThirukkumaranBalasubramanianPas encore d'évaluation

- DataSheet 105723Document2 pagesDataSheet 105723ThirukkumaranBalasubramanianPas encore d'évaluation

- Aspee Hi-Tech: Knapsack SprayerDocument2 pagesAspee Hi-Tech: Knapsack SprayerThirukkumaranBalasubramanianPas encore d'évaluation

- JERES-D-001 Design Criteria For Pressure VesselsDocument37 pagesJERES-D-001 Design Criteria For Pressure VesselsThirukkumaranBalasubramanianPas encore d'évaluation

- Reference ListDocument28 pagesReference ListThirukkumaranBalasubramanianPas encore d'évaluation

- DataSheet 105723Document2 pagesDataSheet 105723ThirukkumaranBalasubramanianPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (119)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- The Invisible Hero Final TNDocument8 pagesThe Invisible Hero Final TNKatherine ShenPas encore d'évaluation

- Choose the Best WordDocument7 pagesChoose the Best WordJohnny JohnnieePas encore d'évaluation

- Classification of Textile Testing - OrDNURDocument6 pagesClassification of Textile Testing - OrDNURKazi ShorifPas encore d'évaluation

- Vintage Style Indonesian Geography Lesson For High School by SlidesgoDocument56 pagesVintage Style Indonesian Geography Lesson For High School by Slidesgoohd InstalasicontrolPas encore d'évaluation

- CHEM206 Answers 1Document3 pagesCHEM206 Answers 1Shiro UchihaPas encore d'évaluation

- STEM Spring 2023 SyllabusDocument5 pagesSTEM Spring 2023 SyllabusRollins MAKUWAPas encore d'évaluation

- 01 Design of Flexible Pavement Using Coir GeotextilesDocument126 pages01 Design of Flexible Pavement Using Coir GeotextilesSreeja Sadanandan100% (1)

- EcohistDocument3 pagesEcohistRkmv EconPas encore d'évaluation

- LAC-Documentation-Tool Session 2Document4 pagesLAC-Documentation-Tool Session 2DenMark Tuazon-RañolaPas encore d'évaluation

- Principles of SamplingDocument15 pagesPrinciples of SamplingziggerzagPas encore d'évaluation

- Raychem Price ListDocument48 pagesRaychem Price ListramshivvermaPas encore d'évaluation

- Electrophoresis and Fractionation of Wheat GlutenDocument14 pagesElectrophoresis and Fractionation of Wheat GlutensecucaPas encore d'évaluation

- A.2.3. Passive Transport Systems MCQsDocument3 pagesA.2.3. Passive Transport Systems MCQsPalanisamy SelvamaniPas encore d'évaluation

- Understand Azure Event HubsDocument12 pagesUnderstand Azure Event HubselisaPas encore d'évaluation

- Types of LogoDocument3 pagesTypes of Logomark anthony ordonioPas encore d'évaluation

- Bethany Getz ResumeDocument2 pagesBethany Getz Resumeapi-256325830Pas encore d'évaluation

- Lesson 5 CMADocument10 pagesLesson 5 CMAAssma SabriPas encore d'évaluation

- Marijuana Grow Basics - Jorge CervantesDocument389 pagesMarijuana Grow Basics - Jorge CervantesHugo Herrera100% (1)

- Quality CircleDocument33 pagesQuality CircleSudeesh SudevanPas encore d'évaluation

- Exam Ref AZ 305 Designing Microsoft Azure Infrastructure Sol 2023Document285 pagesExam Ref AZ 305 Designing Microsoft Azure Infrastructure Sol 2023maniPas encore d'évaluation

- Using Snapchat For OSINT - Save Videos Without OverlaysDocument12 pagesUsing Snapchat For OSINT - Save Videos Without OverlaysVo TinhPas encore d'évaluation

- 153C Final Exam Study Guide-2Document6 pages153C Final Exam Study Guide-2Soji AdimulaPas encore d'évaluation

- Denodo Job RoleDocument2 pagesDenodo Job Role059 Monisha BaskarPas encore d'évaluation

- Obsolescence 2. Book Value 3. Depreciation 4. Depletion EtcDocument9 pagesObsolescence 2. Book Value 3. Depreciation 4. Depletion EtcKHAN AQSAPas encore d'évaluation

- Research Paper On Organ DonationDocument8 pagesResearch Paper On Organ Donationsheeliya whitePas encore d'évaluation

- Solr 3000: Special Operations Long Range Oxygen Supply 3,000 PsigDocument2 pagesSolr 3000: Special Operations Long Range Oxygen Supply 3,000 Psigмар'ян коб'ялковськийPas encore d'évaluation

- E PortfolioDocument76 pagesE PortfolioMAGALLON ANDREWPas encore d'évaluation

- Levels of Attainment.Document6 pagesLevels of Attainment.rajeshbarasaraPas encore d'évaluation