Académique Documents

Professionnel Documents

Culture Documents

07.Spr - Serial Vs Direct Dilution. Time To Apply New Thinking To Ic50 Determination and Dose Response Analysis

Transféré par

BhojTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

07.Spr - Serial Vs Direct Dilution. Time To Apply New Thinking To Ic50 Determination and Dose Response Analysis

Transféré par

BhojDroits d'auteur :

Formats disponibles

Serial vs direct:Layout 1

3/4/07

11:08

Page 36

Liquid Handling

SERIAL vs DIRECT

DILUTION

Time to apply new thinking

to IC50 determination and

dose-response analysis?

By Dr John Comley

36

The serial dilution method is standard practice in the preparation of doseresponse series for IC50 determination. However, it is well recognised that

inadequacies in the liquid handling or mixing technique will affect the dilution

ratio and hence the compound concentration and any errors will be

compounded during each successive serial dilution, mix and transfer. A recent

poll of end users ranked better precision, particularly at lower drug

concentrations, and the reduction in compound precipitation as the

improvements in dose-response analysis they most desired. In addition, it is now

suspected that hydrophobic compounds may be lost from solution during

aqueous serial dilutions and absorbed to intermediate plastic surfaces. This in

turn adds to concern over the reliability of the results generated and the extent

to which they are a true reflection of the potency of the compounds being

evaluated. As part of the general drive to enhance the quality of screening data

generated researchers are investigating strategies based on the direct dilution of

micro-volumes of compound (ie on a volumetric basis). These investigations

have been aided by the availability of low volume dispensing systems with good

precision at low nL dispense volumes and a relatively wide dynamic range. Some

groups are now reporting that IC50 values of compounds tend to be lower

(more active) when the concentrations are made via direct dilutions. It is

increasingly evident that direct dilution has a future role to play in doseresponse analysis and where acoustic droplet ejection is preferentially deployed

additional benefits will be derived in terms of reduced waste stream generated,

less source material used and no cross-contamination.

Drug Discovery World Spring 2007

Serial vs direct:Layout 1

3/4/07

11:08

Page 37

Liquid Handling

he uptake and use of nanolitre dispensing

within drug discovery is now widespread,

with nearly two-thirds of all groups

involved in dispensing activities having access to

nanolitre (nL) volumes today and most of the

remainder considering or planning to acquire a nL

capability in the future (Figure 1)1.

Although plate replication and compound reformatting still represent the main applications for

nanolitre dispensing in drug discovery today, there

is increasing use being made of cherry picking low

volumes both for, or directly used in the set up of,

IC50 or dose-response analysis (57% now using)

(Figure 2).

Most of the nL dispenser offerings available

today (eg Beckman PicoRAPTR, CyBi-NanoJet

or Labcyte Echo, etc) are standalone and typically have only a small amount of automation built

into them. However, in order to fully automate the

main applications of nL dispensing it is evident that

users will need to integrate these systems with other

components (eg input or output plate

stacking/hotel; robotic plate handler; bulk reagent

dispenser; and controlling software) and possibly

other non-essential plate processing peripherals (eg

incubator; mixer; lidder/delidder; sealer; reader,

etc). When interest to purchase a standardised fully

automated nL dispensing system for the main applications of nL systems was investigated it was apparent that most end users would like to access a system that is flexible enough to be able to perform

multiple applications, ie compound reformatting

combined with dose-response and IC50 preparation

in the same system (Figure 3).

Serial dilutions

The generation of dose-response curves requires

the preparation of solutions of compound at var-

Figure 1: Uptake of nanolitre in drug discovery

dispensing today

NO, but we are considering

or plan to acquire a nL

dispensing capability in

the future

30%

YES, currently using

nL dispensing

67%

NO, we dont have a current or

foreseeable future requirement

for low (nL) volume dispensing

3%

HTStec 2007

ious concentrations over a wide range, often covering six logs of magnitude. These concentrations

have more traditionally been made by a serial

dilution technique in which a stock solution of

the active compound of interest, typically in

100% DMSO, is cherry picked. This may take the

form of aspirating an aliquot from a selected well

in a source library plate or by punching out a prealiquoted volume stored in mini-tube. In either

case, the aliquot is then diluted with aqueous

diluent or buffer at a fixed ratio (eg 1 into 3) and

mixed thoroughly, often by repeat aspirate and

dispense cycles within the pipette tip. An aliquot

of diluted drug is then removed and added to a

volume of new aqueous diluent at the same ratio

as the first dilution. Typically dilutions are performed in adjacent wells along the row or column

of the plate, with successive serial dilutions made

until the dose response range required in the

series is achieved. When this intermediate plate is

Figure 2: Main applications of nanolitre dispensing in drug discovery

Plate replication

Compound reformatting to dry plates

Just-in-time compound reformatting to plates containing liquid or cell layers

Cherry picking for, or direct use in, IC50 or dose-response analysis

Cherry picking for single concentration small focused sets

Cherry picking for single concentration hit confirmation

Spotting to microplate arrays

Microarraying

0% 10% 20% 30% 40% 50% 60% 70% 80% 90%

HTStec 2007

Drug Discovery World Spring 2007

% Using nanolitre dispensing for the particular applications

37

Serial vs direct:Layout 1

3/4/07

11:08

Page 39

Liquid Handling

complete, it can be reformatted or replicated to

multiple assay plates. The key point with serial

dilution being that it has been standard practise

to dilute drug stocks that were initially prepared

and solubilised with 100% DMS0, with aqueous

solutions to minimise the final DMSO concentration in the assay. In addition, it is usual to prepare

relatively large (L) volumes of a dilution series in

a separate intermediate plate or series of tubes,

distinct from the ones in which the assay(s) will

be undertaken, contributing to the overall greater

use of compound than is necessary for the setup

of multiple assay dose-response curves. (Figures 4

and Figure 5).

Figure 3: Interest in purchasing a standardised fully

automated nL dispensing system for specific

applications

Two or more of the below

applications in the same system

Compound reformatting only

Dose-response and IC50 preparation

only

Cherry picking only

0%

10%

20%

30%

40%

50%

60%

70%

80%

% Respondents who would consider purchasing such systems

HTStec 2007

Direct dilutions

The alternative approach to serial dilution is the

direct dilution of micro-volumes of compound (ie on

a volumetric basis). In this case the volume actually

dispensed is directly proportional to the amount of

compound required to give the desired concentration in the chosen final assay volume. Although the

concept of direct dilution has been around and discussed for many years, the recent availability of low

volume dispensing systems able to deliver with better precision a minimum volume dispense in the

region of 1 to 10nL and a relatively wide dynamic

range, has resulted in the approach finally being

investigated more widely, with the practicalities of

how the technique might be routinely implemented

considered and the benefits realised. As with most of

the recent changes adopted in drug discovery processing, many improvements have been driven by

the desire to enhance the quality of data generated.

In the case of dose-response analysis, the concern

has been the reliability of the results generated and

the extent to which they are a true reflection of the

potency of the compounds being evaluated. The

Source Plate

Cherry pick from source

X8

X96

Serially dilute

compounds

Assay Plate

Intermediate Buffer Dilution Plate

Transfer from

intermediate plate

to assay plates

Figure 4 (above)

Traditional serial dilution

technique used in IC50 and

dose-response analysis

Figure 5 (left)

Serial dilution of dye down the

rows of microplate

Drug Discovery World Spring 2007

39

Serial vs direct:Layout 1

3/4/07

11:08

Page 41

Liquid Handling

Figure 6: Improvements desired when undertaking dose response analysis today

Better precision (%CV) particularly at lower drug concentrations

Reduction in compound precipitation (poor aqueous solubility may lead to false negatives)

Significantly less source material (compound) used

Less accumulated error (that may arise from multiple dilution steps)

Less loss of hydrophobic compounds sticking to pipette tips or intermediate dilution plates

Reduction in consumable costs (pipette tips, plates and DMSO)

Less 'bolus effect' on DMSO addition to aqueous*

Reduction in waste generated

* Notes on the Bolus Effect Acoustic droplet ejection adds solutions of drug candidates to cells with the cell-containing microplate in an inverted position. This leads to a major benefit

for cell-based analyses. Typically when DMSO solutions are added to microplates containing cells, a bolus of DMSO containing test compound sinks through the surrounding cell medium

and is in contact with the cells at far higher concentrations than the final equilibrium concentration. This can lead to cell damage or death and make it difficult to determine the actual

effect of the test compound. When DMSO is added to an inverted plate, the DMSO spreads out across the meniscus and only after the plate is returned to its upright position does the

DMSO begin to drop through the solution. By this time, the DMSO has spread over the entire meniscus and the distributed solution diffuses smoothly through the cell medium.

HTStec 2007

relative ranking of the importance of improvements

desired when undertaking dose-response analysis

today are presented in Figure 6. This shows that better precision (%CV) particularly at lower drug concentrations and the reduction in compound precipitation (induced by poor solubility in aqueous solution which could lead to false negatives) were

ranked as the improvements respondents most

desired. Interestingly, progress towards addressing

this entire list of improvements could be expected to

be derived from the application of direct dilution

approaches. With this in mind, interest in performing automated IC50 and dose-response analysis by

direct dilution was investigated1. It was found that

around 1 in 5 (19%) current users of nL dispensing

are already using direct dilution strategies today and

a further 45% are considering it (Figure 7), suggesting that the expectation is that tangible benefits will

be derived from the direct approach.

Vendor updates

In the following vendor updates we will learn

about some of the current approaches to serial and

direct dilution for IC50 determination and doseresponse analysis. In particular, we will examine

the role that low volume and nanolitre dispensing

can make to such activities; whether positive displacement micropipettes or piezo dispensing holds

the key to direct dilution; how new automated,

including microfluidic, systems could significantly

Drug Discovery World Spring 2007

improve such activities; where new tracking

methodology is being applied to enhance the quality of dose-response data; where optimisation of

dispensing and mixing parameters has yielded

faster processing and superior data; and whether

the IC50 is affected by the dilution strategy.

Artel (www.artel-usa.com) has enhanced its MVS

(Multichannel Verification System) to provide laboratories with the first standardised technology to

verify the accuracy of dilution ratios in serial dilution protocols. This new capability is essential for

drug discovery and other laboratories that rely on

data generated from dilution-based liquid delivery

procedures. To generate a proper serial dilution

methodology, during which a sample solution is

Figure 7: Interest in performing automated IC50

and dose-response analysis by direct dilution

YES, we are considering it

45%

HTStec 2007

YES, we are already using it

19%

NO, prefer conventional

serial dilution

36%

41

Serial vs direct:Layout 1

3/4/07

11:08

Page 43

Liquid Handling

diluted across a microtiter plate, accurate and

repeatable volume transfer and efficient solution

mixing are critical. It is also imperative that the sample concentration in the initial solution be known so

that the decreasing concentrations of sample across

the plate can be correctly determined. Because sample concentration is directly affected by starting concentration and the amount of transferred volume, an

inaccurate liquid handler can cause unseen, compounding errors in serial dilution applications,

which can void the integrity of the dilution assay.

Previously, the only option available for laboratories

to measure dilution ratios in serial dilution protocols

were home-brewed methods requiring internally

developed sample solutions. This time-consuming

process does not allow for inter-laboratory comparability or traceability. By contrast, the MVS technology and range of standardised solutions allow for

rapid verification of dilution ratios and provide

traceable results for compliance and reproducibility.

The MVS verifies target volumes via ratiometric

photometry, which uses the absorbance values of

two proprietary dye solutions to calculate dispensed

volume. The enhanced MVS now provides traceable

measurements for single- or multiple-point dilutions

to a concentration endpoint ratio of 1:2000 of the

starting material (Figure 8).

Beckman

Coulters

(www.beckman.com)

PicoRAPTR (Picolitre Rapid Transfer Robot)

offers ultra-low volume aspirate and dispense operations. The system consists of an eight tip piezo head

with eight independent fluid paths and dual plate

carrier stage which allows for high speed aspiration

(1L to 100L) and dispense (1nL to 100L) volumes. The ultra clean sonication wash, inert fluid

pathways, precise spatial positioning and 100%

DMSO compatibility enables high-quality dose

response curves using direct or serial dilution. With

DMSO correction of liquid and the extended pipetting dispense range you are able to achieve a 5 log

concentration giving a percentage bias within 10%

and precision %CV of less than 10%. 90% of the

aspirated solution is available with using an air gap

resulting in reagent cost savings and allowing for the

filling of an entire microplate from a single aspirate.

The system will accommodate source plates of 96,

384, 1536 well microplates and destination plates of

96, 384, 1536, 3456 well microplates. Beckman

Coulter also offers selective tip loading for the

Biomek FXP Laboratory Automation Workstation

multichannel pipetting head. This allows for serial

dilutions to be performed by configuring the loading

of tips for any row(s) or column(s) the user needs to

work with (Figure 9).

Drug Discovery World Spring 2007

Figure 8: Artels MVS (Multichannel Verification System)

Figure 9: Beckmans PicoRAPTR dispenser

43

Serial vs direct:Layout 1

3/4/07

11:08

Page 44

Liquid Handling

serial dilutions and other multiparameter experiments at very high throughput. For example, to

perform a single step serial dilution, a volume file

in an Excel format of 96 volumes of dilution buffer

is given to the head followed by a file of 96 complementary volumes of target compound. Two

aspiration steps, first of the buffer then the target

compound, are followed by a single dispense step

to create a plate with 96 different concentrations of

the compound with a dilution factor of 1:200

across the plate. If required, this plate could be further diluted in a second step for a total dilution

range of 1:40,000 (Figure 10).

Figure 10

Variable volume aspiration on

the Caliper Life Sciences

Sciclone i1000

The Intelligent Sciclone i1000 from Caliper Life

Sciences (www.caliperLS.com) offers for the very

first time independent pipetting control over each

channel in a 96 channel pipetting head meaning

that each channel can pipette its own unique fluid

volume. The heart of the system is the real-time

feedback, self-diagnosing and adaptive control

enabled by the proprietary MEMS micro flow

meters built in to each of the 96 independent channels. One hundred and nine micro-processors monitor performance parameters in real time and facilitate on the fly adjustments to compensate for

variations like temperature and viscosity. In addition, each channel has the ability to pipette across

an extremely wide dynamic range from 5 to 1,000

microlitres. With this capability, researchers can do

one-step plate normalisations, IC50 experiments,

For dilution operations in the low volume range

CyBio (www.cybio-ag.com) provides two dedicated instruments. For serial dilutions the CyBiDiluSpro can be used, for direct dilutions the

CyBi-NanoJet is the instrument of choice. The

CyBi-DiluSpro is an economically priced 8-channel pipettor which is perfectly designed for the

automatic preparation of serial dilutions. The large

volume range (250L head: 0.5-250L; 25L

head: 0.1-25L) allows the execution of serial dilution as well as the direct dilution in a special range

(1:500) depending on the dispense volume. The

CyBi-DiluSpro is a modular device. The user has

the choice of three different carriage systems (4-, 5place linear carriage and 10-place circular system),

three different tip types for a single device and two

different software packages (either optimised programs/graphical user interface or a Scripting Studio

for creating own programs) depending on the

requirements of the customer (Figure 11). The

Figure 11 (above): CyBios CyBi-DiluSpro

Figure 12 (left): CyBios CyBi-NanoJet

44

Drug Discovery World Spring 2007

Serial vs direct:Layout 1

3/4/07

11:08

Page 46

Liquid Handling

CyBi-NanoJet is a very flexible, bulk dispensing

instrument operating in the low volume range from

50nL to 20uL per shot. The pressure/valve based

system can handle up to 16 independent reagent

lines and can access every well individually in any

SBS plate format. Reagents, cells or beads can be

dispensed with a nearly unmatched precision.

Direct dilutions can be performed using the instrument stand alone by adding two different reagents

into single wells, which allows dilution rates of

more than 1,000 (eg 50nL in 60uL). Depending on

the operation mode the CyBi-NanoJet can be

used as a flexible assay workstation or as a fast

HTS assay processor (Figure 12).

Figure 13: Genaptas direct dilution IC50 engine. Compounds are introduced as single

samples in the milli-molar regime. They are diluted and assayed automatically by the system

without the intervention of any external sample handling or automation. The device is

capable of producing a 100-200 point IC50 curve in 30 minutes using just a few microlitres of

reagent. (Photo courtesy Ley Group, Dept of Chemistry, Univ of Cambridge)

First Step

Transfer 75, 25, 7.5 and

2.5 nL of each hit to four

consecutive wells (30,

10, 3 and 1 droplets,

respectively).

Source Plate

Assay Plate

Second Step

Transfer 250 and 2.5 nL to

two wells in an

intermediate plate

Fourth Step

Transfer 75, 25, 7.5 and 2.5 nL of

each diluted sample to four

consecutive wells of the assay plate

(30, 10, 3 and 1 droplets, respectively.

Fifth Step

Back fill wells to maintain DMSO

constant at 75 nL per well.

Third Step

Dilute intermediate

plate with 25 mL DMSO

in each well

Intermediate Plate

Figure 14: Acoustic droplet ejection (ADE) allows for an efficient direct dilution technique.

Active compounds are cherry-picked from source plates at four volumes directly to an assay

plate (Step 1). These same compounds are transferred to an intermediate plate at two

volumes and diluted with 25L DMSO to provide dilutions of 100:1 and 10,000:1 (Step 2).

Dilution directly into DMSO eliminates the potential for compound precipitation and

reduces absorbance to the plate (Step 3). Each of these diluted solutions is transferred to

the assay plate in four volumes as indicated (Step 4). DMSO is back-filled using ADE to

maintain an equal amount of DMSO (75nL) in each well (Step 5). A 10L assay will have a

total concentration of 0.75% DMSO

46

Genapta (www.genapta.com) has been designing

and building direct dilution potency systems in collaboration with a major pharma partner for the

past five years. Its current product development

(the PIC50 system) is for enzymatic assays, and

later in 2007 will pick up cell based assays with the

instrument being released on to the open market

Q3, 2007. Direct dilution, rather than a well by

well discrete approach, has mostly become a reality because of the availability of high quality pumping systems. In particular the advent of nanoscale

HPLC systems, has allowed the ability to control

liquid flows down to a few nL per minute, which

in turn enables detailed external control of the mixing conditions on a microfluidic chip. Thus it is

possible to create a dynamic and varying concentration gradient against which to perform a competitive binding assay by controlling flow rates

rather than trying to dispense and mix metered volumes of reagents into a well. This approach has a

number of advantages that include repeatability

and ease of set up. In addition to the flow control,

a miniaturised spectrometer is used to assay the

reaction. Together these elements form a miniaturised-screening platform. As the system takes a

single slug of compound that is diluted as it is

measured, the use of microwell plates as a carrier

medium is greatly reduced, and the device needs little or no external automation to generate potency

data for the medicinal chemist. As such it allows

this potency to be generated alongside basic toxicity in timescales of hours rather than weeks. Such a

reduction in assay time increases the potential for

iteration during discovery 10-fold, allowing many

more elements in a candidate series to be characterised at the crucial later stages (Figure 13).

Acoustic droplet ejection (ADE) on the Labcyte

Echo (www.labcyte.com) has been used to investigate direct dilutions of small volumes. Using the

Drug Discovery World Spring 2007

Serial vs direct:Layout 1

3/4/07

11:09

Page 47

Liquid Handling

The need for high quality dose response data continues to drive the demand for serial dilution, especially in the area of low volume dispensing. This is

reflected in a continued level of interest for serial

dilution functionality in the fully integrated liquid

handling systems that RTS Life Science

(www.rtslifescience.com) produces. A system

recently developed for one client utilised twin

Velocity11 VPrep liquid handlers installed within

an automated robotic cell. One of the key challenges that RTS had to overcome was the need to

dynamically generate custom plate well information so as to ensure that the correct serial dilution

was performed for specific plates being processed

through the system. Key to this was the tight integration afforded by RTS d-Sprint and Sprint

software platforms. A custom developed Sprint

device driver allowed the dynamic population, via

JavaScript, of the parameters required for the dilution into the PrepWorks protocol template. This

Drug Discovery World Spring 2007

50

Direct dilution IC50 M

protocol outlined in Figure 14, 12-point direct

dilutions over six orders of magnitude can be prepared. Recently researchers at Bristol-Myers

Squibb have reported2 that the IC50 values of compounds tend to be significantly lower (more active)

when the concentrations are made via direct dilutions of small volumes than when the concentrations are achieved with serial dilution (Figure 15).

It has been postulated that this was due to compounds adsorbing to the solid surfaces of the dilution plate wells and to the pipette tips used to

transfer the fluids. Hydrophobic compounds suffered the most loss during serial dilutions. Recent

work using mass spectroscopy to measure the concentrations of solutions has provided independent

analytical support to the hypothesis that significant

amounts of compound are lost during serial dilution. The actual concentration of analyte in serially diluted solutions can be far less than anticipated,

and may cause false negatives in primary screening

tests for potency as well as inaccurate IC50 values.

In addition to the loss of high value hits, these false

negatives also create difficulties for medicinal

chemists and chemo-informatics programmes

attempting to draw conclusions about structureactivity relationships. The recently launched

Labcyte POD 810 plate assembler (Figure 16)

robotically integrates an Echo liquid handler for

ADE with plate storage, a bulk filler for reagents

or diluents, and software designed to optimise

direct dilution techniques for dose-response curves.

The POD plate assembler takes source plates and

optimises the throughput of ADE to provide destination plates ready for assay or further storage.

40

30

20

10

0

0

10

20

30

40

50

Serial dilution IC50 M

Figure 15: Comparison of IC50 values generated via direct dilution using acoustic droplet

ejection (ADE) vs serial dilution. Researchers at BMS measured the IC50 values of more than

1,000 compounds over a six-log range of concentrations. The only difference between both

sets of experiments was that the different concentrations were prepared either by direct

dilution with ADE or serial dilution. The horizontal axis shows the IC50 value determined via

serial dilution while the vertical axis gives the value determined via direct dilution.

Compounds that had IC50 values greater than 20mM were considered ineffective.

Compounds in the lower left, highlighted by a purple square, are hits by both techniques. The

110 compounds (>10% of total) in the yellow area were measured as ineffective by the

traditional serial dilution technique but were active with direct dilution of ADE transferred

volumes. The compounds circled in red are very potent candidates that had been falsely

identified as inactive when the dose-response curves were generated via serial dilution. The

true IC50 values of some of these compounds were two orders of magnitude lower than

suggested by serial dilution. Recently, a second major pharmaceutical company confirmed

these trends. They showed, using mass spectrometric analysis, that many hydrophobic

compounds are lost during serial dilutions and that the actual concentration of the

compound may be 10 to 100 times lower than expected. Figure modified with permission2

Figure 16

The Labcyte POD 810 plate

assembler is optimised for

direct dilution by acoustic

drop ejection

47

Serial vs direct:Layout 1

3/4/07

11:09

Page 48

Liquid Handling

Figure 17

An integrated liquid handling

cell on an RTS Life Science

robot with high throughput

serial dilution capability

functionality enabled individual dilutions to be

performed on a plate by plate basis, as part of a

fully automated process under the control of dSprint. Features such as multiple copies, different concentrations and custom dilution patterns

can all be specified. In addition to the VPreps, the

system includes two Thermo Cytomat storage

units (one with assisted thawing capability), a plate

sealer and piercer from Abgene, RTS own-design

384 tube sealer/cutter instrument, as well as

numerous lid handlers and barcode readers etc, all

of which are controlled via RTS Sprint scheduling software. Directly fed from an RTS SampleStore, itself running d-Sprint, via the integrated high-speed 384 Multi-Pix picking station, this

system provides users with highly functional serial

Figure 18

TTP LabTechs mosquito

nanolitre pipettor uses

disposable positive

displacement microplates for

compound dilution

dilution capabilities capable of operating 24/7

(Figure 17).

Siliflow (www.siliflow.com) designs, manufactures

and integrates liquid handling solutions. Its proprietary Nanodrop module is based on a piezo-actuated dispenser which allows ejection of droplets in

the nanolitre to picolitre range (50pl to 10nl per

drop). So far CVs of less than 3% have been

achieved for nanolitre drops. Dispense frequency

can be adjusted from 0.1 to 1Khz and exact number of drops (burst) can also be defined. The drop

size is defined by the nozzle diameter while various

electronic parameters allow to accurately adjust

this drop size. Drop volume can be calculated

thanks to a synchronised stroboscopic vision system combined with a proper calculation algorithm.

Combining these items Siliflow aims to fully automate the direct dilution process. Siliflow will integrate these functions together with an agitation

module, in a 3-axis robot in order to launch a commercial direct dilution system in mid-2007.

TTP LabTechs mosquito product family

(www.ttplabtech.com/mosquito) facilitates assay

miniaturisation through precise compound dilution

on a nL scale in microplates containing up to 1536

wells. At the core of mosquito is a continuous reel

of disposable, positive displacement micropipettes

which can aspirate, dispense and even mix. The

narrow bore pipettes can sample from the bottom

of each well, ensuring negligible dead volume. Since

each micropipette is disposable, the instrument

48

Drug Discovery World Spring 2007

Serial vs direct:Layout 1

3/4/07

11:09

Page 49

Liquid Handling

guarantees zero cross-contamination of samples

and removes the need for unreliable, time-consuming and expensive solvent wash cycles. This means

compound dilutions can be produced directly from

high-concentration DMSO stock solutions with

confidence. Mosquito has two formats applicable

to compound dilution: mosquito X1 is a single

micropipette hit picking version for precision sampling of any individual well; while the mosquito

HTS uses 8 or 16 pipettes in a columnar format for

more rapid pipetting. A key application of mosquito is the preparation of assay-ready plates within

HTS departments. These plates contain test compounds prepared from library stocks ahead of time

at the correct concentrations. DMSO is routinely

used for compound dissolution, but its presence at

concentrations above 1% can markedly affect assay

performance. Thus, accurate nanolitre quantities of

DMSO-based stock solution are required to keep

concentrations low when preparing assay-ready

plates. On mosquito, serial dilutions are commonly

performed in a 500nL total volume using an aspirate, dispense and mix cycle. Where compound

carry-over is an issue, tips can be changed for each

dilution step. Alternatively, direct dilution can be

achieved by pipetting stock solutions throughout

the instruments volumetric range. Routinely, this

involves the repeat pipetting of 3-4 stock solutions

at volumes between 50 and 1,200nL (Figure 18).

Standard serial dilution methods are tedious, timeconsuming, and often inaccurate at high dilutions

due to the propagation of errors. Velocity11s

(www.velocity11.com) Bravo Liquid Handling

platform is capable of performing serial dilution by

row or by column. Coupled with the VWorks

software package, parameters such as mix height,

tip retraction, mixing speed and mixing cycles can

cut the time to perform an accurate and precise

serial dilution by 75%. The software tools ensure

that the serial dilution can be tailored to specific

applications. The ability of one pipette head to perform both serial dilution and full 96- or 384- well

dispensing, from low (2L) high (200L) volumes

means that only one instrument is required to perform backfilling of plates and the serial dilution

operation in a single protocol, with no head swap

required. In a case study, we performed a standard

1:2 serial dilution by column across a 96 well

plate. Using non-optimised parameters, 20 mix

cycles were required to achieve satisfactory precision (average CVs under 3%, and accuracy >99%).

The drawback was that this would require 20 minutes to process an individual 96-well plate. After

utilising the capabilities of VWorks software platDrug Discovery World Spring 2007

form to optimise parameter values for mix height,

speed of mixing, and tip retraction, essentially

identical accuracy and precision results with just

three mix cycles was achieved; this reduced the

time for a serial dilution operation to 5 minutes

(Figure 19).

Figure 19

The Velocity11 Bravo Liquid

Handling Platform. Tips can be

loaded in single row or

column and the full head mode

Summary

In Table 1 we attempt to draw a comparison

between the serial and direct dilution developments reviewed above. It also serves to highlight

how direct dilution approaches can reduce or minimise the perceived inadequacies of current dose

response analysis techniques. It is well recognised

that even minor problems in the liquid handling or

mixing technique will affect the dilution ratio and

hence the compound concentration, and these

errors will be compounded during the serial dilution process increasing with each successive dilution and transfer. It is, however, less appreciated

that hydrophobic compounds may be readily lost

49

Serial vs direct:Layout 1

3/4/07

11:09

Page 50

Liquid Handling

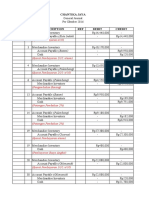

Table 1: Comparison of serial and direct dilution techniques

SERIAL DILUTION

INADEQUACIES OF

DOSE-RESPONSE

ANALYSIS TECHNIQUE

DISPOSABLE

PIPETTE TIPS

DIRECT DILUTION

WASHABLE

FIXED TIPS

USING

ACOUSTIC

DROPLET

EJECTION (ADE)

USING

OTHER FIXED

NOZZLE

NANOLITRE

DISPENSERS

Accumulated error

YES

YES

NO

NO

Hydrophobic compounds lost

YES

not known

NO

not known

Potential for cross contamination

NO

HIGH

NO

HIGH

Wash waste

LOW

HIGH

NONE

HIGH

Consumables (tips) waste

HIGH

NONE

NONE

NONE

Source material required (volume)

nL

nL

References

1 Automated Low Volume

Dispensing Trends 2006, 44pp,

published by HTStec Limited,

Cambridge, UK, June 2006.

2 Spicer, J et al.

Pharmacological Evaluation of

Different Compound Dilution

and Transfer Paradigms on an

Enzyme Assay in Low Volume

384-well Format. Drug

Discovery Technology Meeting,

Boston, August 2005.

50

from solution during aqueous serial dilutions with

as much as 90-99% of the material absorbed to

intermediate surfaces including disposable pipette

tips and dilution wells. Direct dilution using ADE

eliminates compound absorbance and adherence

(sticking) since the sample does not encounter the

pipette tips. It is not known the extent to which

hydrophobic compounds might adhere to the inner

surfaces of fixed tip pipettors or the nozzles of

nanolitre dispensers, some of which may have specialised non-stick surface coatings. If disposable

tips are used only one time, there is no chance of

cross-contamination, although repeated use would

increase the chance of carryover. As fixed tips

pipettors or the nozzles of nanolitre dispensers

come in contact with many different compounds

on multiple occasions, even with the most stringent

washing, there is the potential for cross contamination. To reduce carryover to an acceptable level

it is routine to wash fixed tips or nozzles more

thoroughly or frequently, and as a result the liquid

waste stream generated will be high. If disposable

tips are used only once, without washing, then the

plastic waste stream also increases. By adopting a

direct dilution strategy significantly less source

material and less solvent are required to make sample concentrations than traditional techniques

employing serial dilutions. Overall, the case for

considering direct dilution would seem to be selfevident, particularly if by using ADE the quality of

hits could be improved and their true potency

revealed. However, it remains to be seen what

value the groups responsible for making dose

response comparisons will place on these benefits

and whether direct dilution will be adopted further,

particularly if this involves the purchase of new

DDW

ADE liquid handler.

Dr John Comley is Managing Director of HTStec

Limited, an independent market research consultancy whose focus is on assisting clients delivering

novel enabling platform technologies (liquid handling, laboratory automation, detection instrumentation and assay reagent technologies) to drug discovery. Since it formation in 2003, HTStec has

published 23 market reports on drug discovery

technologies and Dr Comley has authored 17

review articles in Drug Discovery World. Further

information on accessing the market report

Automated Low Volume Dispensing Trends 2006

can be obtained by visiting www.htstec.com or by

emailing john.comley@htstec.com to receive a free

copy of the Reports Executive Summary and Table

of Contents.

Drug Discovery World Spring 2007

Vous aimerez peut-être aussi

- 439 PDFDocument11 pages439 PDFsonyagustynPas encore d'évaluation

- Diafiltration For Desalting or Buffer ExchangeDocument6 pagesDiafiltration For Desalting or Buffer Exchangesharfina02Pas encore d'évaluation

- International Journal of Research in Controlled ReleaseDocument8 pagesInternational Journal of Research in Controlled ReleaseMohd ShoaibPas encore d'évaluation

- IJRPR1589Document6 pagesIJRPR1589Adriansyah AdriPas encore d'évaluation

- Dissolution Testing and Drug Release StudiesDocument11 pagesDissolution Testing and Drug Release StudiesAbdu K. ÊlmankoryPas encore d'évaluation

- Am 22 4 659-665 1971Document7 pagesAm 22 4 659-665 1971Sophie KimPas encore d'évaluation

- TFF for biomolecule separation and purificationDocument7 pagesTFF for biomolecule separation and purificationPrashant Patil100% (1)

- IJN 19021 Application of Supercritical Antisolvent Method in Drug Enca 070511Document14 pagesIJN 19021 Application of Supercritical Antisolvent Method in Drug Enca 070511Poovanaan Sathiya SeelanPas encore d'évaluation

- Tangential Flow Filtration BasicsDocument19 pagesTangential Flow Filtration BasicsKarthik VijayakumarPas encore d'évaluation

- The Effect of Pharmaceuticals On The Nanoscale Structure of PEO-PPO-PEO MicellesDocument8 pagesThe Effect of Pharmaceuticals On The Nanoscale Structure of PEO-PPO-PEO MicellesヨトミヒトPas encore d'évaluation

- Dialysis and reverse osmosis technologies explainedDocument9 pagesDialysis and reverse osmosis technologies explainedK.D. PatelPas encore d'évaluation

- In Vitro Methods For Detecting Cytotoxicity: UNIT 2.6Document27 pagesIn Vitro Methods For Detecting Cytotoxicity: UNIT 2.6hiền nguyễnPas encore d'évaluation

- A Prolonged Release Parenteral Drug Delivery System - An OverviewDocument11 pagesA Prolonged Release Parenteral Drug Delivery System - An Overviewcristian135Pas encore d'évaluation

- Ijpbs 5ed9073caa323Document11 pagesIjpbs 5ed9073caa323Dr. Nilesh JainPas encore d'évaluation

- Bio AvailabilityDocument12 pagesBio AvailabilityGnan ChanduPas encore d'évaluation

- 9456-Article Text-23945-1-10-20101216Document18 pages9456-Article Text-23945-1-10-20101216fitri wahyuniPas encore d'évaluation

- Formulation and Evaluation of Sustained Release Tablet of Aceclofenac by Film CoatingDocument9 pagesFormulation and Evaluation of Sustained Release Tablet of Aceclofenac by Film CoatingQoriPas encore d'évaluation

- BCS REg ApproachDocument7 pagesBCS REg Approachvg_vvgPas encore d'évaluation

- Practical 12Document7 pagesPractical 125408 ManshaPas encore d'évaluation

- TFF SystemDocument13 pagesTFF SystemG_RanjithPas encore d'évaluation

- Nanoparticles in Drug Delivery Potential Green Nanobiomedicine ApplicationsDocument24 pagesNanoparticles in Drug Delivery Potential Green Nanobiomedicine ApplicationstaufikPas encore d'évaluation

- Other CategoriesDocument10 pagesOther Categoriesnosila_oz854Pas encore d'évaluation

- European Journal of Pharmaceutics and Biopharmaceutics: Yanzhuo Zhang, Tongying Jiang, Qiang Zhang, Siling WangDocument7 pagesEuropean Journal of Pharmaceutics and Biopharmaceutics: Yanzhuo Zhang, Tongying Jiang, Qiang Zhang, Siling WangrajeshPas encore d'évaluation

- Dissolution Testing (Kel 3)Document28 pagesDissolution Testing (Kel 3)Anonymous QEVAyPMPas encore d'évaluation

- Computational ModelDocument12 pagesComputational Modelrvscdri1Pas encore d'évaluation

- Topical and Transdermal Drug Products-Product Quality Tests 3 Drug Release 724Document14 pagesTopical and Transdermal Drug Products-Product Quality Tests 3 Drug Release 724Rara WulansariPas encore d'évaluation

- Capitulo 4 Basic Techniques For MicrobialDocument10 pagesCapitulo 4 Basic Techniques For MicrobialLuis RodriguezPas encore d'évaluation

- Preparation and Evaluation of Ethyl Cellulose Micro SpheresDocument5 pagesPreparation and Evaluation of Ethyl Cellulose Micro SpheresnavinchellaPas encore d'évaluation

- How I Personalize Fluid Therapy in Septic Shock?: Review Open AccessDocument11 pagesHow I Personalize Fluid Therapy in Septic Shock?: Review Open AccessGian CarloPas encore d'évaluation

- A Prolonged Release Parenteral Drug Delivery SystemDocument11 pagesA Prolonged Release Parenteral Drug Delivery SystemronnymcmPas encore d'évaluation

- NanosuspensionDocument16 pagesNanosuspensionthasneemPas encore d'évaluation

- A Antimicrobial Susceptibility TestingDocument13 pagesA Antimicrobial Susceptibility TestingkurfaPas encore d'évaluation

- Article 012Document8 pagesArticle 012Esha JainPas encore d'évaluation

- InVitro Drug Release Profile StudiesDocument18 pagesInVitro Drug Release Profile Studieswahid hussainPas encore d'évaluation

- Article in Press: Colloids and Surfaces B: BiointerfacesDocument10 pagesArticle in Press: Colloids and Surfaces B: BiointerfacesVander JuniorPas encore d'évaluation

- Water Treatment ArticleDocument7 pagesWater Treatment ArticleeladrozinPas encore d'évaluation

- Methods To Enhance BADocument38 pagesMethods To Enhance BAAamir NawazPas encore d'évaluation

- 1 s2.0 S0378517311000226 MainDocument9 pages1 s2.0 S0378517311000226 MainFIRMAN MUHARAMPas encore d'évaluation

- Endodontic Irrigation Techniques and DevicesDocument6 pagesEndodontic Irrigation Techniques and DevicesSilviu3103Pas encore d'évaluation

- tmpD1B TMPDocument8 pagestmpD1B TMPFrontiersPas encore d'évaluation

- Delapril and Indapamide: Development and Validation of A Stability-Indicating Core-Shell LC Method and Its Application For Simultaneous Tablets AssayDocument5 pagesDelapril and Indapamide: Development and Validation of A Stability-Indicating Core-Shell LC Method and Its Application For Simultaneous Tablets AssaykarimPas encore d'évaluation

- Lysing Methods and Reagents For Flow Cytometry Immunophenotyping - Very Important PDFDocument9 pagesLysing Methods and Reagents For Flow Cytometry Immunophenotyping - Very Important PDFSubhajitHajraPas encore d'évaluation

- Pharma Particle Analysis with Acorn Area NMRDocument3 pagesPharma Particle Analysis with Acorn Area NMRprakush01975225403Pas encore d'évaluation

- 7-MS 1403Document7 pages7-MS 1403anthonyPas encore d'évaluation

- (Auda Et Al, 2015) - Niosomes As Transdermal Drug Delivery System For CelecoxibDocument17 pages(Auda Et Al, 2015) - Niosomes As Transdermal Drug Delivery System For Celecoxibabdulloh suyutiPas encore d'évaluation

- International Journal of Innovative Pharmaceutical Research: Ophthalmic Delivery System For Dexamethasone: An OverviewDocument5 pagesInternational Journal of Innovative Pharmaceutical Research: Ophthalmic Delivery System For Dexamethasone: An OverviewGufron MustofaPas encore d'évaluation

- Bacterial Enumeration: Standard Plate Count (Viable Counts)Document7 pagesBacterial Enumeration: Standard Plate Count (Viable Counts)Meshal NoorPas encore d'évaluation

- Scintillation Cocktail Using MicroFill 5994 3417EN AgilentDocument4 pagesScintillation Cocktail Using MicroFill 5994 3417EN AgilentAngin MalamPas encore d'évaluation

- Accepted Manuscript: Ommling SeixasDocument17 pagesAccepted Manuscript: Ommling SeixasMoran PepePas encore d'évaluation

- Drug Release Kinetics ModelsDocument7 pagesDrug Release Kinetics ModelsSajid Khan SadozaiPas encore d'évaluation

- 2011_Mach_J_Pharm_Sci_Use_Flow_Cytometry_Detection_SVP_Therapeutic_Protein_FormulationsDocument8 pages2011_Mach_J_Pharm_Sci_Use_Flow_Cytometry_Detection_SVP_Therapeutic_Protein_FormulationslienhartviktorPas encore d'évaluation

- Introduction To Tableting by Direct CompressionDocument12 pagesIntroduction To Tableting by Direct CompressionSonal KasbePas encore d'évaluation

- Pharmaceutical Dosage Forms Disperse Systems Volume 2Document489 pagesPharmaceutical Dosage Forms Disperse Systems Volume 2Mariana RibeiroPas encore d'évaluation

- Dispersi Padat PDFDocument14 pagesDispersi Padat PDFdian oktavianiPas encore d'évaluation

- Flow Injection AnalysisDocument15 pagesFlow Injection Analysisnishadh1Pas encore d'évaluation

- Parenteral Products: The Preparation and Quality Control of Products for InjectionD'EverandParenteral Products: The Preparation and Quality Control of Products for InjectionPas encore d'évaluation

- Oral Formulation Roadmap from Early Drug Discovery to DevelopmentD'EverandOral Formulation Roadmap from Early Drug Discovery to DevelopmentElizabeth KwongPas encore d'évaluation

- Experimental approaches to Biopharmaceutics and PharmacokineticsD'EverandExperimental approaches to Biopharmaceutics and PharmacokineticsPas encore d'évaluation

- Nanoparticulate Drug Delivery Systems: Strategies, Technologies, and ApplicationsD'EverandNanoparticulate Drug Delivery Systems: Strategies, Technologies, and ApplicationsYoon YeoPas encore d'évaluation

- Bioprocessing for Cell-Based TherapiesD'EverandBioprocessing for Cell-Based TherapiesChe J. ConnonPas encore d'évaluation

- JIPMER Entrance Examination & Counseling Schedule 2018 - TentativelyDocument1 pageJIPMER Entrance Examination & Counseling Schedule 2018 - TentativelyBhojPas encore d'évaluation

- QedDocument1 pageQedBhojPas encore d'évaluation

- Feynman x27 S Tips On Physics Reflections AdviceDocument2 pagesFeynman x27 S Tips On Physics Reflections AdviceBhojPas encore d'évaluation

- KinematicsDocument30 pagesKinematicsSanjeev KumarPas encore d'évaluation

- Btech Merit 1516Document103 pagesBtech Merit 1516at35Pas encore d'évaluation

- ProjectDocument72 pagesProjectBhojPas encore d'évaluation

- Capacitors & Energy StorageDocument44 pagesCapacitors & Energy StoragearuunrsPas encore d'évaluation

- AMU Engineering Entrance Exam Physics Solved Paper 2010Document4 pagesAMU Engineering Entrance Exam Physics Solved Paper 2010BhojPas encore d'évaluation

- KinematicsDocument30 pagesKinematicsSanjeev KumarPas encore d'évaluation

- (WWW - Entrance-Exam - Net) - Important Books For IITDocument3 pages(WWW - Entrance-Exam - Net) - Important Books For IITBhojPas encore d'évaluation

- ProjectDocument72 pagesProjectBhojPas encore d'évaluation

- Notification ImplementationofAct8of2006Document20 pagesNotification ImplementationofAct8of2006BhojPas encore d'évaluation

- 1 PDFDocument1 page1 PDFBhojPas encore d'évaluation

- Solving 04Document13 pagesSolving 04BhojPas encore d'évaluation

- BPLDocument3 pagesBPLBhojPas encore d'évaluation

- NABARD Broiler Farming ProjectDocument10 pagesNABARD Broiler Farming ProjectGrowel Agrovet Private Limited.Pas encore d'évaluation

- A. Process of Counseling (Flow Chart) : Scheme of Online All India Quota UG CounselingDocument21 pagesA. Process of Counseling (Flow Chart) : Scheme of Online All India Quota UG CounselingBhojPas encore d'évaluation

- Bansal Classes 11th Standard Physics DPPsDocument148 pagesBansal Classes 11th Standard Physics DPPsAnilKumar Jupalli100% (2)

- How Is A CT Scan Done?Document4 pagesHow Is A CT Scan Done?BhojPas encore d'évaluation

- A. Process of Counseling (Flow Chart) : Scheme of Online All India Quota UG CounselingDocument21 pagesA. Process of Counseling (Flow Chart) : Scheme of Online All India Quota UG CounselingBhojPas encore d'évaluation

- BSC Ams I YearDocument20 pagesBSC Ams I YearBhojPas encore d'évaluation

- Unit-III Chapter-10 Cell Structure: Important PointsDocument13 pagesUnit-III Chapter-10 Cell Structure: Important PointsBhojPas encore d'évaluation

- AIPMT 2016 Physics Paper With Ans & Solution by Allen KotaDocument10 pagesAIPMT 2016 Physics Paper With Ans & Solution by Allen KotaMohitPas encore d'évaluation

- Ionic Equilibrium Study PackageDocument24 pagesIonic Equilibrium Study PackageManpreet SinghPas encore d'évaluation

- Practice Test 1 1dmotionDocument11 pagesPractice Test 1 1dmotionLynn Hollenbeck BreindelPas encore d'évaluation

- ThalsfDocument1 pageThalsfBhojPas encore d'évaluation

- D BankDocument1 pageD BankBhojPas encore d'évaluation

- Leader Online Test Series For Jee Main Plus Advanced 2018Document2 pagesLeader Online Test Series For Jee Main Plus Advanced 2018Girdhari Lal SainiPas encore d'évaluation

- JKKLMNNNNDocument1 pageJKKLMNNNNBhojPas encore d'évaluation

- Homework 7 Traffic Accident Data AnalysisDocument5 pagesHomework 7 Traffic Accident Data AnalysisRagini P0% (1)

- Natural DyeDocument21 pagesNatural Dyesanjay shettiPas encore d'évaluation

- Barbara S. Hutchinson, Antoinette Paris-Greider Using The Agricultural, Environmental, and Food Literature Books in Library and Information Science 2002Document491 pagesBarbara S. Hutchinson, Antoinette Paris-Greider Using The Agricultural, Environmental, and Food Literature Books in Library and Information Science 2002Paramitha TikaPas encore d'évaluation

- Energy and Memory Efficient Clone Detection in WSN AbstractDocument4 pagesEnergy and Memory Efficient Clone Detection in WSN AbstractBrightworld ProjectsPas encore d'évaluation

- الصراع التنظيمي وأثره...Document25 pagesالصراع التنظيمي وأثره...mohmod moohPas encore d'évaluation

- 2390A Series Spectrum AnalyzersDocument6 pages2390A Series Spectrum AnalyzersElizabeth FaulknerPas encore d'évaluation

- 00 2 Physical Science - Zchs MainDocument4 pages00 2 Physical Science - Zchs MainPRC BoardPas encore d'évaluation

- DRS User ManualDocument52 pagesDRS User Manualwmp8611024213100% (1)

- Proceedings of The Third International Conference On Computational Intelligence and InformaticsDocument881 pagesProceedings of The Third International Conference On Computational Intelligence and InformaticsJanes DstPas encore d'évaluation

- RLE Journal CoverDocument2 pagesRLE Journal Coverrchellee689Pas encore d'évaluation

- 2 Jurnal Internasional (2019) PDFDocument9 pages2 Jurnal Internasional (2019) PDFDwi KrisnawatiPas encore d'évaluation

- Prop. Solution For India Asset and Tax DepreciationDocument8 pagesProp. Solution For India Asset and Tax DepreciationJit Ghosh100% (1)

- Repair Guides - Wiring Diagrams - Wiring DiagramsDocument18 pagesRepair Guides - Wiring Diagrams - Wiring DiagramsAlvaro PantojaPas encore d'évaluation

- Amado Vs Salvador DigestDocument4 pagesAmado Vs Salvador DigestEM RGPas encore d'évaluation

- Leak Proof Engineering I PVT LTDDocument21 pagesLeak Proof Engineering I PVT LTDapi-155731311Pas encore d'évaluation

- Design and Implementation of Automated Student School Fees PaymentDocument11 pagesDesign and Implementation of Automated Student School Fees PaymentTony Omorotionmwan Airhiavbere75% (4)

- Smartaisle Containment Brochure EnglishDocument32 pagesSmartaisle Containment Brochure EnglishAsad NizamPas encore d'évaluation

- Dr. Mian Ashfaq Ali: Mechanical Vibrations ME-421Document14 pagesDr. Mian Ashfaq Ali: Mechanical Vibrations ME-421Talha MohsinPas encore d'évaluation

- Safety Breach NoticeDocument3 pagesSafety Breach NoticeMohamed HadjkacemPas encore d'évaluation

- ACCT601 Australian Auditing and Assurance Services 201660Document15 pagesACCT601 Australian Auditing and Assurance Services 201660Rafayel MarufPas encore d'évaluation

- Domestic Ro Price List 2021Document6 pagesDomestic Ro Price List 2021den onePas encore d'évaluation

- Module Combustion Engineering-1-2Document13 pagesModule Combustion Engineering-1-2Julie Ann D. GaboPas encore d'évaluation

- Oracle Payslip PDFDocument2 pagesOracle Payslip PDFVaishnavi DappurePas encore d'évaluation

- Mr. Gopikrishna - CH: Career ObjectiveDocument3 pagesMr. Gopikrishna - CH: Career ObjectiveGopi KrishnaPas encore d'évaluation

- Donate Your Corneas PleaseDocument19 pagesDonate Your Corneas PleaseRahul PinnamaneniPas encore d'évaluation

- PT Amar Sejahtera General LedgerDocument6 pagesPT Amar Sejahtera General LedgerRiska GintingPas encore d'évaluation

- Enter The Data Below: Sample PDF Only From Excel CalculationDocument1 pageEnter The Data Below: Sample PDF Only From Excel CalculationWilson (Electrical Engineer)Pas encore d'évaluation

- Seminar On Biodegradable PolymersDocument19 pagesSeminar On Biodegradable Polymerskeyur33% (3)

- Aurora Fire Pump SpecsDocument16 pagesAurora Fire Pump SpecsJosé Martín Meza CabillasPas encore d'évaluation

- Module 1 The Nature of Strategic Management2Document8 pagesModule 1 The Nature of Strategic Management2Julienne LobchoyPas encore d'évaluation