Académique Documents

Professionnel Documents

Culture Documents

DESIGN - Heat Load Calculation: Sub: Comments On Plants Study Report

Transféré par

venkatspinnerDescription originale:

Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

DESIGN - Heat Load Calculation: Sub: Comments On Plants Study Report

Transféré par

venkatspinnerDroits d'auteur :

Formats disponibles

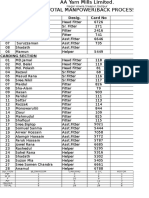

HUMIDIFICATION PLANT AT PRECOT-A

Sub: COMMENTS ON PLANTS STUDY REPORT

DESIGN Heat load calculation

S.N

01

02

Description

Radiation thro roof

Our Design

Kcal/hr

100440

Airtek

calculation

91450

No details given

124X40.5X1.0X(58.38)

Radiation thro Wall

10000

21153

No details given

1559000

2123538

Heat load thro wall is negligible

because of the following reasons

>North & South side:75% covered by

Plant houses

>East&West side departments

03

>Enclosed wall is 450mm thk stone

masonry

However we have taken 10%

Machine load

M/c

04

05

06

KWX No.machinesX KcalXLoad factor

----------------------------Efficiency of motor

(details not

given)

OHC

-do-

50500

Pnumafil motor

-do-

126000

50% to be considered as it is

discharged into trench

Occupancy 80X150

Lighting

50X860

Other

source

heat

like

belt,

bearing etc are due to motor only

and hence separately not to be

taken.

Total

12000

43000

-

10000

43000

210000

1900940

2499141

Air Quantity Calculations

Volume of Air quantity required should be calculated from the following

formula:

Head load X Safety Factor

----------------------------------Specific Heat X Density of Air X t

t : (Department temp Air temp leaving Air washer)

(36 29)

According above formula

1057720 Cmh

(622000 Cfm) = No of Air charge : 44

Since Kanjikode is a very humid place, we allowed more number of Air

changes of 46. Capacity of plant is 650000 cfm.

Present supply air capacity

- 650000 cfm

Present Exhaust air capacity - 672000 cfm (V filters fully clean

condition)

Room condition Assumption

Outside Dry Bulb

:

Corresponding wet Bulb

:

40O C

28O C

RH of dept

D.B of dept

55

- 34O C

The above assumption is wrong

As per Psychometric chart

For outside dry bulb 40O C & wet bulb 28O C

We can achieve DB of department 37O C for RH of 55%

Exhaust Air

We always keep exhaust capacity slightly more than the supply quantity.

The reason being all our plants are having V filters, which will

chocked soon after cleaning.

In that case capacity gets reduced and maintaining 95-100% of supply

capacity.

Regarding exhaust air calculation by AirTek, capacity of 750000 cfm

seems wrong, as most of our plants are old with efficiency 85%.

NO

new/Old fan will deliver morethan the designed capacity. We feel the

method of calculation of exhaust will be wrong.

SITRA has made an elaborate study and arrived at 672000 cfm of exhaust.

Exhaust Vs Supply

The contention exhaust 85% of supply is an old theory for window

construction building.

As per the latest technology, exhaust are

designed for 100% of supply because of windowless construction & closed

chamber department.

Floating Fluff

Normally slit grills are prevailed to take care of floating fluff.

contention of closing slit grill will aggregate the problem.

reason for floating fluff may be due to some other problems.

Plant Efficiency

Plant No.5 is having ABC fan.

Plant No.7 is of

static AF 20 fan and Cfm should be high. Your

in above fan is incorrect as fan in plant No.13

No.6 gives more Cfm.

The method of conducting

The

The

Batliboi 8 bladed high

contention of less Cfm

which is same as plant

study may be wrong.

Energy Efficient Motor

Old plant house motors are normal motors and we are replacing with

energy efficient during replacement.

But recent supply of Batliboi motors are flange mounted 960 RPM ABB

make motors, which are having efficiency

of morethan 88%.

The same

type motors are available in all our MIL plants and its performance is

satisfactory.

Spray Nozzles:

Recent supply of new plants are of Polycarbonate. Only old plants are

having PVC nozzles and will be replaced with polycarbonate at the time

of replacement.

Precot A Humidification plants comprises of the following make

1. Duvent System

2. Old Batliboi

3. ABC System

Recently we are doing the replacement of 3 fan Duvent system with

Batliboi High efficiency 8 bladed fans.

All exhaust trenches were designed by ABC without

running perpendicular to machine at particular interval.

slit

trench,

Also plants were added then and there and planning of trench is not

perfect.

Regarding distribution of supply air, we have planned to introduce

linear diffuser system perpendicular to machine 5 lines.

In addition, slit trench parallel to machine will also be designed at

every 4th machine.

We will make a perfect planning and implement the same in the coming

years.

Vous aimerez peut-être aussi

- 2011 Product Catalogue-Air Cooled Screw Chiller (M Type)Document37 pages2011 Product Catalogue-Air Cooled Screw Chiller (M Type)Diêm Công Việt100% (2)

- 038 - EVO235 & 270 LiteratureDocument26 pages038 - EVO235 & 270 LiteratureFabio BosioPas encore d'évaluation

- Labconco-7115900 Rev A Intelli-Sense Multi-Speed BlowersDocument58 pagesLabconco-7115900 Rev A Intelli-Sense Multi-Speed Blowersgeovany_villagraPas encore d'évaluation

- LG MultiV III - CatalogueDocument13 pagesLG MultiV III - CatalogueMuhidin KozicaPas encore d'évaluation

- Introduction of High Output Engine SAA12V140 For Generator: Key WordsDocument5 pagesIntroduction of High Output Engine SAA12V140 For Generator: Key WordsGustavoPas encore d'évaluation

- Enclosed Genset Experience 201809Document5 pagesEnclosed Genset Experience 201809Franklin FernandezPas encore d'évaluation

- Rotary Heat ExchangerDocument32 pagesRotary Heat Exchangerntt_121987Pas encore d'évaluation

- GE's New Gas Turbine System: Designed To Change The Game in Power GenerationDocument12 pagesGE's New Gas Turbine System: Designed To Change The Game in Power GenerationHeryanto SyamPas encore d'évaluation

- Transformador Pad Mounted ABBDocument12 pagesTransformador Pad Mounted ABBJuan E Torres MPas encore d'évaluation

- 1-4 Start Up Boost LeafletDocument4 pages1-4 Start Up Boost LeafletsdiamanPas encore d'évaluation

- Diverter Damper Systems - BrochureDocument8 pagesDiverter Damper Systems - Brochuregionizz100% (1)

- 741 VLB BrochureDocument4 pages741 VLB BrochureMohammad Ali ZamanPas encore d'évaluation

- F Advanced Heller System Technical 2005 Good OneDocument53 pagesF Advanced Heller System Technical 2005 Good Onesubru1980Pas encore d'évaluation

- Nampally Hyd. Since 26 Years: Volume - IiiDocument17 pagesNampally Hyd. Since 26 Years: Volume - IiiAnkush NayarPas encore d'évaluation

- Simens Combine CycleDocument12 pagesSimens Combine CycleMuhammad JafarPas encore d'évaluation

- AC DC Kilns (Drives, Cement Plant)Document10 pagesAC DC Kilns (Drives, Cement Plant)RajuPas encore d'évaluation

- Turbina Gas LM-2500Document275 pagesTurbina Gas LM-2500Alexander Monroy Martinez100% (2)

- Why YORK Switched To Open Drive Motor:: Now Let's Examine Five Specific Points Raised by CompetitorsDocument15 pagesWhy YORK Switched To Open Drive Motor:: Now Let's Examine Five Specific Points Raised by CompetitorsImran GhafoorPas encore d'évaluation

- Rosenberg CatalogueDocument24 pagesRosenberg CatalogueFu AunPas encore d'évaluation

- 08 AjaxDocument19 pages08 AjaxJ ParraPas encore d'évaluation

- Proposal For Biomass Based Power Project: Capacity 1.0 MweDocument10 pagesProposal For Biomass Based Power Project: Capacity 1.0 MweSaalai K ManiPas encore d'évaluation

- AerzenDocument20 pagesAerzenmih4iPas encore d'évaluation

- Evolving Design Chiller PlantDocument7 pagesEvolving Design Chiller PlantMohsin KhanPas encore d'évaluation

- 5 - Turbine Generator Upgrades & MaintenanceDocument30 pages5 - Turbine Generator Upgrades & Maintenancerashm006ranjan100% (1)

- KR - Single Package - R410A - 60Hz - CO - Saudi - MFL67452905 - 6CUK0-01B - 130916-10TRDocument58 pagesKR - Single Package - R410A - 60Hz - CO - Saudi - MFL67452905 - 6CUK0-01B - 130916-10TR1969MAZHARPas encore d'évaluation

- Catalogo Extractores SQBSQDocument48 pagesCatalogo Extractores SQBSQNarcisoPas encore d'évaluation

- 2011 R22 DX Type Screw ChillerDocument41 pages2011 R22 DX Type Screw ChillerDiêm Công ViệtPas encore d'évaluation

- T15 BrochureDocument8 pagesT15 BrochuretrxrhcpPas encore d'évaluation

- Hıtachi GeneratörDocument8 pagesHıtachi Generatörmkk326Pas encore d'évaluation

- ANP Observation MOLDocument4 pagesANP Observation MOLAmarnath PandeyPas encore d'évaluation

- 5 Development and Operating Experience PDFDocument10 pages5 Development and Operating Experience PDFVijaya100% (2)

- Engineering Letter: IntegralmotorsforcentrifugalfansDocument4 pagesEngineering Letter: IntegralmotorsforcentrifugalfansjameeloPas encore d'évaluation

- Performance of Fans After at Various Plants: RetrofittingDocument19 pagesPerformance of Fans After at Various Plants: RetrofittingmkpqPas encore d'évaluation

- Semco Enthalpy Wheel Technical ManualDocument37 pagesSemco Enthalpy Wheel Technical ManualjvalkenburgPas encore d'évaluation

- 4052 - Mcquay MNG 115.2 PDFDocument88 pages4052 - Mcquay MNG 115.2 PDFFarrukhAhmedKhanPas encore d'évaluation

- Cooling Tower Fans and DrivesDocument3 pagesCooling Tower Fans and DrivesAnonymous NwnJNOPas encore d'évaluation

- Coolex Catalog Concealed Ducted Split Units R22Document20 pagesCoolex Catalog Concealed Ducted Split Units R22Mohammad Abdul Aziz40% (5)

- EAG2020-541 E575R 8000 LPH Paras Pakistan Revision ADocument3 pagesEAG2020-541 E575R 8000 LPH Paras Pakistan Revision AArun BajajPas encore d'évaluation

- Sgt-600 GT Mechdrive enDocument4 pagesSgt-600 GT Mechdrive enRoozbeh PPas encore d'évaluation

- Siemens Steam Turbine SST-150Document4 pagesSiemens Steam Turbine SST-150G.Ramesh100% (1)

- 9e ChinaDocument7 pages9e Chinanabil160874Pas encore d'évaluation

- Siemens HedrichDocument51 pagesSiemens HedrichpabloalienadoPas encore d'évaluation

- INTRODUCING AQUAFAN - Motorless Hydro-Powered Cooling Tower TechnologyDocument16 pagesINTRODUCING AQUAFAN - Motorless Hydro-Powered Cooling Tower TechnologyWatco GroupPas encore d'évaluation

- Spec Sheet - 3306 250 KVA PrimeDocument4 pagesSpec Sheet - 3306 250 KVA PrimeAsantony Raj100% (1)

- ZA5D Installation in Lotus-Mugen-Honda Type 109BDocument7 pagesZA5D Installation in Lotus-Mugen-Honda Type 109BDeepak MurthyPas encore d'évaluation

- ECODAN AtW Split WWW - ZubadanDocument2 pagesECODAN AtW Split WWW - ZubadanFlorentin GheorghitaPas encore d'évaluation

- CPac (Mr. Slim) R410a CatalogDocument15 pagesCPac (Mr. Slim) R410a CataloghivnPas encore d'évaluation

- Aerzen Delta Blowers Overpressure G1 068 03 enDocument0 pageAerzen Delta Blowers Overpressure G1 068 03 engarisa1963Pas encore d'évaluation

- EC Medium Pressure Axial Fans 2014-02Document8 pagesEC Medium Pressure Axial Fans 2014-02spscribd1Pas encore d'évaluation

- Auxillary Power ConsumptionDocument47 pagesAuxillary Power ConsumptionMohit KumarPas encore d'évaluation

- Turbine Inlet CoolingDocument6 pagesTurbine Inlet Coolingankarao1969Pas encore d'évaluation

- MCW Cooling Tower: Engineering Data & SpecificationsDocument36 pagesMCW Cooling Tower: Engineering Data & SpecificationsRajendran SrnPas encore d'évaluation

- Inverter Air Cooled Screw Chillers: Product ManualDocument52 pagesInverter Air Cooled Screw Chillers: Product ManualKyaw San OoPas encore d'évaluation

- CEB1053Document30 pagesCEB1053oscar horacio floresPas encore d'évaluation

- Ecblue: Movement by PerfectionDocument20 pagesEcblue: Movement by PerfectionpradojuanPas encore d'évaluation

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsD'Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsÉvaluation : 4 sur 5 étoiles4/5 (1)

- Boarding PassDocument3 pagesBoarding PassvenkatspinnerPas encore d'évaluation

- Honey Dew TestDocument4 pagesHoney Dew TestvenkatspinnerPas encore d'évaluation

- BagtagDocument2 pagesBagtagvenkatspinnerPas encore d'évaluation

- D 24 SpareDocument395 pagesD 24 SparevenkatspinnerPas encore d'évaluation

- Health FormDocument2 pagesHealth FormvenkatspinnerPas encore d'évaluation

- MVS Machine and Clearer SettingDocument18 pagesMVS Machine and Clearer SettingvenkatspinnerPas encore d'évaluation

- OE TwistDocument3 pagesOE TwistvenkatspinnerPas encore d'évaluation

- CBR Vs CDGDocument1 pageCBR Vs CDGvenkatspinnerPas encore d'évaluation

- Thrace Spinning MillsDocument10 pagesThrace Spinning MillsvenkatspinnerPas encore d'évaluation

- OE DraftDocument3 pagesOE DraftvenkatspinnerPas encore d'évaluation

- Trash Count DetailsDocument14 pagesTrash Count DetailsvenkatspinnerPas encore d'évaluation

- Choice of TravellersDocument14 pagesChoice of TravellersvenkatspinnerPas encore d'évaluation

- MSRDocument1 pageMSRvenkatspinnerPas encore d'évaluation

- Steel Ring TravellersDocument12 pagesSteel Ring TravellersvenkatspinnerPas encore d'évaluation

- 12 VT Ex 6942 To 6948 Spain All Counts 12 07 07Document6 pages12 VT Ex 6942 To 6948 Spain All Counts 12 07 07venkatspinnerPas encore d'évaluation

- Full Text 01Document54 pagesFull Text 01venkatspinnerPas encore d'évaluation

- Krar Unit 54Document41 pagesKrar Unit 54venkatspinnerPas encore d'évaluation

- The Usterized Difference: Become A USTERIZED MemberDocument4 pagesThe Usterized Difference: Become A USTERIZED MembervenkatspinnerPas encore d'évaluation

- Variety Wise Fibre Test Results (Length and Neps - Tested at SITRA, Trash% Tested at PD)Document1 pageVariety Wise Fibre Test Results (Length and Neps - Tested at SITRA, Trash% Tested at PD)venkatspinnerPas encore d'évaluation

- PM CustomisationDocument109 pagesPM CustomisationvenkatspinnerPas encore d'évaluation

- Blowroom SL No Name Desig. Card No Remarks: Nagar Howla, Sreepur, GazipurDocument8 pagesBlowroom SL No Name Desig. Card No Remarks: Nagar Howla, Sreepur, GazipurvenkatspinnerPas encore d'évaluation

- Tenso RapidDocument12 pagesTenso Rapidvenkatspinner100% (1)

- Test Results With Techno Cradles in R/FDocument1 pageTest Results With Techno Cradles in R/FvenkatspinnerPas encore d'évaluation

- Units of Electrical Energy Consumed by Common Domestic Appliances/equipmentDocument2 pagesUnits of Electrical Energy Consumed by Common Domestic Appliances/equipmentvenkatspinnerPas encore d'évaluation

- 55 CHT (37kw Motor) 55 CHT (34 KW Motor)Document4 pages55 CHT (37kw Motor) 55 CHT (34 KW Motor)venkatspinnerPas encore d'évaluation

- Schlafhorst Texlab: Catalogue of ServicesDocument27 pagesSchlafhorst Texlab: Catalogue of ServicesvenkatspinnerPas encore d'évaluation

- 01 Bräcker PerformanceDocument5 pages01 Bräcker PerformancevenkatspinnerPas encore d'évaluation

- Elite TrailDocument6 pagesElite TrailvenkatspinnerPas encore d'évaluation

- Temperature Conditions: Type of Solar ModuleDocument2 pagesTemperature Conditions: Type of Solar ModuleEhsan Ur RehmanPas encore d'évaluation

- Gpcdoc Gtds Shell Omala s4 GX 220 (En) TdsDocument3 pagesGpcdoc Gtds Shell Omala s4 GX 220 (En) Tdsmuhammed hasbyPas encore d'évaluation

- CF750Document9 pagesCF750Shilpi VirmaniPas encore d'évaluation

- 1. المضخهDocument20 pages1. المضخهالمهندسوليدالطويلPas encore d'évaluation

- Working and Maintenance of Crushing EquipmentDocument53 pagesWorking and Maintenance of Crushing EquipmentKeshav ChhawchhariaPas encore d'évaluation

- Essentials of Economics, 10th Edition (2016)Document468 pagesEssentials of Economics, 10th Edition (2016)Luis EstradaPas encore d'évaluation

- Hydrogen BombDocument3 pagesHydrogen BombirfuuPas encore d'évaluation

- Fallsem2016-17 1286 RM001 27-Jul-2016 Mee1003 THDocument74 pagesFallsem2016-17 1286 RM001 27-Jul-2016 Mee1003 THaman agarwalPas encore d'évaluation

- Multec 3.5 PDFDocument178 pagesMultec 3.5 PDFRogério MorenoPas encore d'évaluation

- 5-Transmission and DistributionDocument38 pages5-Transmission and DistributionCaribPas encore d'évaluation

- MOI - Riyadh-UL Control Panel With VFD (2 Duty + 1 Standby)Document17 pagesMOI - Riyadh-UL Control Panel With VFD (2 Duty + 1 Standby)Emad AbushrarPas encore d'évaluation

- France en Dec. 2022 v3Document37 pagesFrance en Dec. 2022 v3Tarek OsmanPas encore d'évaluation

- Moduł Igbt Mg25j2ys40 25a 600v Toshiba DatasheetDocument4 pagesModuł Igbt Mg25j2ys40 25a 600v Toshiba Datasheetmouelhi karimPas encore d'évaluation

- 42NQV050 060 SVMDocument102 pages42NQV050 060 SVMRob KoopmanPas encore d'évaluation

- Illumination MCQDocument5 pagesIllumination MCQBhalchandra SwamiPas encore d'évaluation

- AV65WP74Document19 pagesAV65WP74ElectroCenterPas encore d'évaluation

- Well Failure Model - Example: Mitigating Action Matrix - Key To Numbers Entered in Matrix AboveDocument20 pagesWell Failure Model - Example: Mitigating Action Matrix - Key To Numbers Entered in Matrix Aboveeng7mohamed7hashimPas encore d'évaluation

- 01 VRF 011 01 PDFDocument60 pages01 VRF 011 01 PDFMechanical PowerPas encore d'évaluation

- Advanced Motion Controls FC1010Document7 pagesAdvanced Motion Controls FC1010Servo2GoPas encore d'évaluation

- SREA-ECET (Mechanical) 8 Years Topic Wise Bit Bank-1 PDFDocument68 pagesSREA-ECET (Mechanical) 8 Years Topic Wise Bit Bank-1 PDFDhanunjay JaguPas encore d'évaluation

- Casing ScrapersDocument2 pagesCasing ScrapersthetrevanianPas encore d'évaluation

- Gastron BDM Sarawak Summary 16.05.2023Document5 pagesGastron BDM Sarawak Summary 16.05.2023yusuf mohd sallehPas encore d'évaluation

- PrefaceDocument45 pagesPrefaceaddy_callsoutPas encore d'évaluation

- Bombardier¿ and Challenger¿ Are Trademarks of Bombardier, IncDocument5 pagesBombardier¿ and Challenger¿ Are Trademarks of Bombardier, IncMiguel Andres Esparragoza CeballosPas encore d'évaluation

- (Walter J. Maciel (Auth.) ) Astrophysics of The IntDocument271 pages(Walter J. Maciel (Auth.) ) Astrophysics of The IntLuis Fernando Mejia0% (1)

- D11RDocument24 pagesD11RRicardo Contreras B100% (2)

- Venturimeter ProjectDocument43 pagesVenturimeter ProjectPangambam Suman100% (1)

- Energy, Work & Power QPDocument8 pagesEnergy, Work & Power QPSalman Farsi TaharatPas encore d'évaluation

- CAT - C15 (Prefix SDP) .Prefix SDP1-822Document14 pagesCAT - C15 (Prefix SDP) .Prefix SDP1-822Phil B.100% (2)