Académique Documents

Professionnel Documents

Culture Documents

W L 1176

Transféré par

shama093Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

W L 1176

Transféré par

shama093Droits d'auteur :

Formats disponibles

US

Classified by

Underwriters Laboratories, Inc.

to UL 1479 and CAN/ULC-S115

WL 1176

CL

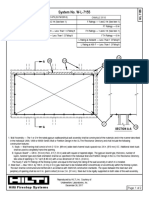

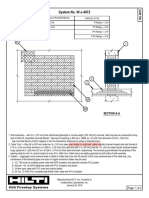

System No. W-L-1176

ED

SI

AS F I

ANSI/UL1479 (ASTM E814)

CAN/ULC S115

F Rating 1 and 2 Hr (See Items 1 and 3A)

F Rating 1 and 2 Hr (See Items 1 and 3A)

T Rating 1/2 Hr

FT Rating 1/2 Hr

FH Rating 1 and 2 Hr (See Itema 1 and 3A)

FTH Rating 1/2 Hr

A

3A

3B

SECTION A-A

1. Wall Assembly The 1 or 2 hr fire rated wallboard/stud wall assembly shall be constructed of the materials and in the manner specified in the

individual U300, U400, V400 or W400 Series Wall and Partition Designs in the UL Fire Resistance Directory and shall include the following

construction features.

A. Studs Wall framing shall consist of either wood studs or steel channel studs. Wood studs to consist of nom 2 by 4 in. (51 by 102 mm)

lumber spaced 16 in. (406 mm) OC. Steel studs to be min 2-1/2 in. (64 mm) wide and spaced max 24 in. (610 mm) OC.

B. Gypsum Board* The gypsum board type, thickness, number of layers, fastener type and sheet orientation shall be as specified in the

individual Wall and Partition Design. Max area of opening is 180 sq. in. (0.116 m2) with max dimension of 18 in. (457 mm). Max width of

openings in wood stud walls is limited 14-1/2 in. (368 mm).

The hourly F, FH Ratings of the firestop system are equal to the hourly fire rating of the wall assembly in which it is installed.

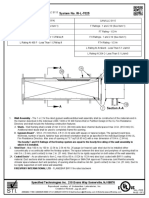

2. Through Penetrant One or more steel electrical metallic tubing to be installed within the opening. The space between tubing shall be min 1/2

in. (13 mm) and max 5/8 in. (16 mm). Tubing to be rigidly supported on both sides of wall assembly. The space between tubing and periphery

of opening shall be min 1/2 in. (13 mm) to max 2-3/8 in. (60 mm). The following types and sizes of metallic tube may be used:

A. Conduit Nom 2 in. (51 mm) diam (or smaller) steel electrical metallic tubing or 2 in. (51 mm) diam steel conduit.

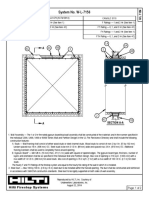

3. Firestop System The firestop system shall consist of the following:

A. Packing Material Min 2-1/2 or 3-3/4 in. (64 or 95 mm) thickness of min 4 pcf (64 kg/m3) mineral wool batt insulation, firmly packed into

the opening as a permanent form for 1 or 2 hr rated walls, respectively. Mineral wool to be recessed from both sides of the assembly to

accommodate the required thickness of fill material (Item 3B).

B. Fill, Void or Cavity Material* Sealant Min 5/8 in. (16 mm) thickness of fill material applied within the annulus, flush with both surfaces

of wall.

HILTI INC FS-ONE Sealant or FS-ONE MAX Intumescent Sealant.

* Indicates such products shall bear the UL or cUL Certification Mark for jurisdictions employing the UL or cUL Certification (such as Canada),

respectively.

Hilti Firestop Systems

Reproduced by HILTI, Inc. Courtesy of

Underwriters Laboratories, Inc.

October 14, 2015

Vous aimerez peut-être aussi

- UL-1297 Firestop SystemDocument1 pageUL-1297 Firestop Systemshama093Pas encore d'évaluation

- W L 1054Document2 pagesW L 1054shama093Pas encore d'évaluation

- System No. W-L-2274: F Rating - 1 and 2 HR (See Item 1) T Rating - 1 and 2 HR (See Item 1)Document2 pagesSystem No. W-L-2274: F Rating - 1 and 2 HR (See Item 1) T Rating - 1 and 2 HR (See Item 1)Lea Rebeca Tuesta Gonzales ZuñigaPas encore d'évaluation

- System No. W-L-2458: F Ratings - 1 and 2 HR (See Item 1) T Rating - 0 HRDocument2 pagesSystem No. W-L-2458: F Ratings - 1 and 2 HR (See Item 1) T Rating - 0 HRLea Rebeca Tuesta Gonzales ZuñigaPas encore d'évaluation

- UntitledDocument2 pagesUntitledandy_ramblaPas encore d'évaluation

- C Aj 1609Document2 pagesC Aj 1609vhin84Pas encore d'évaluation

- HW D 0187Document2 pagesHW D 0187Luiggi Zuñiga BarahonaPas encore d'évaluation

- System No. C-AJ-8175: F Rating - 2 HR T Rating - 0 HRDocument2 pagesSystem No. C-AJ-8175: F Rating - 2 HR T Rating - 0 HRLea Rebeca Tuesta Gonzales ZuñigaPas encore d'évaluation

- System No. C-AJ-1480: F Rating - 2 HR T Rating - 0 HRDocument2 pagesSystem No. C-AJ-1480: F Rating - 2 HR T Rating - 0 HRArulPas encore d'évaluation

- CAD Details PDF For Architectural Firestop CAD BIM Typicals ASSET DOC LOC 1577626Document8 pagesCAD Details PDF For Architectural Firestop CAD BIM Typicals ASSET DOC LOC 1577626shama093Pas encore d'évaluation

- System No. W-L-2199 Firestop SystemDocument2 pagesSystem No. W-L-2199 Firestop SystemDatPas encore d'évaluation

- System PDF Files - 1. UL and cUL Systems - cws0002Document2 pagesSystem PDF Files - 1. UL and cUL Systems - cws0002Emanuel Almeida PastlPas encore d'évaluation

- System No. W-L-2276: F Rating - 2 HR T Rating - 2 HRDocument2 pagesSystem No. W-L-2276: F Rating - 2 HR T Rating - 2 HRDatPas encore d'évaluation

- CAJ1353Document1 pageCAJ1353Anonymous PCsoNCt0mFPas encore d'évaluation

- CAJ1317Document1 pageCAJ1317Luis AlbertoPas encore d'évaluation

- System No. W-L-2240: F Rating - 1 HR T Rating - 1 HRDocument2 pagesSystem No. W-L-2240: F Rating - 1 HR T Rating - 1 HRDatPas encore d'évaluation

- Firestopping System Applications AND Standard Application - Ul ListedDocument5 pagesFirestopping System Applications AND Standard Application - Ul ListedAry TubagusPas encore d'évaluation

- System No. F-A-1008: F Ratings - 2 and 3 HR (See Item 3B) T Rating - 0 HRDocument2 pagesSystem No. F-A-1008: F Ratings - 2 and 3 HR (See Item 3B) T Rating - 0 HRAnonymous PCsoNCt0mFPas encore d'évaluation

- System PDF Files - 1. UL and cUL Systems - wl7025 - DLDocument2 pagesSystem PDF Files - 1. UL and cUL Systems - wl7025 - DLEmanuel PastlPas encore d'évaluation

- Retain: Spare PartsDocument1 pageRetain: Spare PartsAhmed Mohamed Abd ElhakamPas encore d'évaluation

- System PDF Files - 1. UL and cUL Systems - Caj8113 - DLDocument4 pagesSystem PDF Files - 1. UL and cUL Systems - Caj8113 - DLEmanuel PastlPas encore d'évaluation

- F-Rating 2 Hr, T-Rating 1 Hr Firestop SystemDocument2 pagesF-Rating 2 Hr, T-Rating 1 Hr Firestop SystemArulPas encore d'évaluation

- FP Specs Outdoor EnclosureDocument3 pagesFP Specs Outdoor Enclosureahmadove1100% (1)

- Firestop System for Concrete WallsDocument2 pagesFirestop System for Concrete WallshossamPas encore d'évaluation

- HWD0134Document2 pagesHWD0134Edwin Jalanoca LlaulliPas encore d'évaluation

- HWD0194Document2 pagesHWD0194Ever Nina LauraPas encore d'évaluation

- CWD1004 - Curtain Wall Design - Firestopping - STIDocument2 pagesCWD1004 - Curtain Wall Design - Firestopping - STIMDPas encore d'évaluation

- Bandeja - Concreto - W-J-4031Document2 pagesBandeja - Concreto - W-J-4031cesar walter salazar garciaPas encore d'évaluation

- UL HWD 0209Document2 pagesUL HWD 0209jlledwinestebanPas encore d'évaluation

- System PDF Files - 1. UL and cUL Systems - fc2253 - DL PDFDocument2 pagesSystem PDF Files - 1. UL and cUL Systems - fc2253 - DL PDFEmanuel PastlPas encore d'évaluation

- BXUV.G256 - Fire-Resistance Ratings - ANSI - UL 263 - UL Product IQDocument6 pagesBXUV.G256 - Fire-Resistance Ratings - ANSI - UL 263 - UL Product IQEmanuel Ciprian CiucurPas encore d'évaluation

- Electric-Resistance-Welded Ferritic Alloy-Steel Boiler and Superheater TubesDocument4 pagesElectric-Resistance-Welded Ferritic Alloy-Steel Boiler and Superheater TubesVishal SharmaPas encore d'évaluation

- BXUV.P213 - Fire-Resistance Ratings - ANSI - UL 263 - UL Product IqDocument4 pagesBXUV.P213 - Fire-Resistance Ratings - ANSI - UL 263 - UL Product IqEmanuel Ciprian CiucurPas encore d'évaluation

- Specification For Chain Link Fence and GatesDocument8 pagesSpecification For Chain Link Fence and GatesSuresh BabuPas encore d'évaluation

- HILTI - Approval-document-ASSET-DOC-LOC-722Document1 pageHILTI - Approval-document-ASSET-DOC-LOC-722david messierPas encore d'évaluation

- Ks1150 TC 100 Ipn Fire Resistance Classification ProtocolDocument8 pagesKs1150 TC 100 Ipn Fire Resistance Classification ProtocolBinh HuynhPas encore d'évaluation

- Approval Document ASSET DOC LOC 953Document2 pagesApproval Document ASSET DOC LOC 953andy_ramblaPas encore d'évaluation

- XHEZ.f-a-2043 - Through-Penetration Firestop Systems - UL Product IQDocument4 pagesXHEZ.f-a-2043 - Through-Penetration Firestop Systems - UL Product IQMd. Atiqul IslamPas encore d'évaluation

- System PDF Files - 1. UL and cUL Systems - cwd1033Document3 pagesSystem PDF Files - 1. UL and cUL Systems - cwd1033Emanuel Almeida PastlPas encore d'évaluation

- M2 - Manual PDFDocument0 pageM2 - Manual PDFFlorinHanu100% (1)

- Fire Stop Design 673Document4 pagesFire Stop Design 673raviPas encore d'évaluation

- Design No. D759: October 31, 2003Document9 pagesDesign No. D759: October 31, 2003souravrobinPas encore d'évaluation

- WL1167Document1 pageWL1167Juvenal GutierrezPas encore d'évaluation

- Design Number 3MU/BPF 180-01: Perimeter Fire BarriersDocument2 pagesDesign Number 3MU/BPF 180-01: Perimeter Fire BarriersAbram SelimPas encore d'évaluation

- System WJ 2256Document1 pageSystem WJ 2256Manoj SamPas encore d'évaluation

- Cold-Formed Welded and Seamless High-Strength, Low-Alloy Structural Tubing With Improved Atmospheric Corrosion ResistanceDocument5 pagesCold-Formed Welded and Seamless High-Strength, Low-Alloy Structural Tubing With Improved Atmospheric Corrosion ResistanceJosé Ramón GutierrezPas encore d'évaluation

- ASTM A 178 Specification For ERW Carbon Steel and Carbon Manganese Steel Boiler and Superheater TubesDocument4 pagesASTM A 178 Specification For ERW Carbon Steel and Carbon Manganese Steel Boiler and Superheater TubesAnibal QuezadaPas encore d'évaluation

- A178A178M.21771 Norma ERW CalderasDocument4 pagesA178A178M.21771 Norma ERW CalderasCristian Eduardo Ortega MoragaPas encore d'évaluation

- Electric-Resistance-Welded Carbon Steel and Carbon-Manganese Steel Boiler and Superheater TubesDocument4 pagesElectric-Resistance-Welded Carbon Steel and Carbon-Manganese Steel Boiler and Superheater TubesSriniramu SriniramuPas encore d'évaluation

- BXUV.P204 Fire Resistance Ratings - ANSI/UL 263Document5 pagesBXUV.P204 Fire Resistance Ratings - ANSI/UL 263AlexPas encore d'évaluation

- A 135 - 97 Qtezns1sruqDocument11 pagesA 135 - 97 Qtezns1sruqfadjarPas encore d'évaluation

- Ameristar Reja 2Document1 pageAmeristar Reja 2MIHAEL CRUZPas encore d'évaluation

- Approval Document ASSET DOC LOC 716Document2 pagesApproval Document ASSET DOC LOC 716fazil yoosufPas encore d'évaluation

- UL-certified firestop system for concrete floorsDocument2 pagesUL-certified firestop system for concrete floorsvikaspisalPas encore d'évaluation

- Firestop System for Nonmetallic PipeDocument2 pagesFirestop System for Nonmetallic PipeDatPas encore d'évaluation

- A252Document7 pagesA252Luz DuartePas encore d'évaluation

- Diffuser ConnectionDocument4 pagesDiffuser Connectionbsh1978Pas encore d'évaluation

- C-AJ-2834 - Through-Penetration Firestop Systems - UL Product IqDocument3 pagesC-AJ-2834 - Through-Penetration Firestop Systems - UL Product Iqchatgpt MohitPas encore d'évaluation

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsD'Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsÉvaluation : 4 sur 5 étoiles4/5 (1)

- ISLAM Its Foundation and ConceptsDocument226 pagesISLAM Its Foundation and Conceptsfaisal al otaibiPas encore d'évaluation

- Pandas DataFrame NotesDocument13 pagesPandas DataFrame Notesalainvalois67% (3)

- Introductory Notes: Matplotlib: PreliminariesDocument11 pagesIntroductory Notes: Matplotlib: PreliminariesJohnyMacaroniPas encore d'évaluation

- Python Notes/Cheat Sheet: Operator FunctionalityDocument7 pagesPython Notes/Cheat Sheet: Operator FunctionalityJohnyMacaroniPas encore d'évaluation

- Product Data Sheet For CP 680-P and CP 680-M Cast-In Firestop Devices Technical Information ASSET DOC LOC 1540966Document1 pageProduct Data Sheet For CP 680-P and CP 680-M Cast-In Firestop Devices Technical Information ASSET DOC LOC 1540966shama093Pas encore d'évaluation

- W J 2120Document2 pagesW J 2120shama093Pas encore d'évaluation

- Approval Document ASSET DOC LOC 2134219Document1 pageApproval Document ASSET DOC LOC 2134219shama093Pas encore d'évaluation

- Unlimited Memory: Kali Yantra by Pennylea MorrisDocument3 pagesUnlimited Memory: Kali Yantra by Pennylea Morrisshama093Pas encore d'évaluation

- F C 7042Document2 pagesF C 7042shama093Pas encore d'évaluation

- F A 1017Document3 pagesF A 1017shama093Pas encore d'évaluation

- Handout - 2852 - AU - 2012 - CR2852 - Autodesk Navisworks Practical Tips and Tricks From Seven Years in The Construction IndustryDocument20 pagesHandout - 2852 - AU - 2012 - CR2852 - Autodesk Navisworks Practical Tips and Tricks From Seven Years in The Construction Industryshama093Pas encore d'évaluation

- Unlimited Memory: Kali Yantra by Pennylea MorrisDocument3 pagesUnlimited Memory: Kali Yantra by Pennylea Morrisshama093Pas encore d'évaluation

- CAD Details PDF For Architectural Firestop CAD BIM Typicals ASSET DOC LOC 1577626Document8 pagesCAD Details PDF For Architectural Firestop CAD BIM Typicals ASSET DOC LOC 1577626shama093Pas encore d'évaluation

- PETE 662 Final Project - Cumulative Gas Production Rates from Transverse FracturesDocument1 pagePETE 662 Final Project - Cumulative Gas Production Rates from Transverse Fracturesshama093Pas encore d'évaluation

- Prayer TimesDocument2 pagesPrayer Timesshama093Pas encore d'évaluation

- Cts4Un: 4 SQ - MM Standard Feed Through Terminal BlocksDocument3 pagesCts4Un: 4 SQ - MM Standard Feed Through Terminal BlocksNgoãn Nguyễn ĐứcPas encore d'évaluation

- Lecore Manual PV Breather ValvesDocument14 pagesLecore Manual PV Breather Valveskeshri roushanPas encore d'évaluation

- The Painful TruthDocument4 pagesThe Painful TruthazharPas encore d'évaluation

- Mini Track Loaders: MT55 and MT100Document8 pagesMini Track Loaders: MT55 and MT100Abhinandan Padha100% (1)

- Resume MuzammilDocument1 pageResume MuzammilMine FollowerPas encore d'évaluation

- Relief Valve (Line) - Test and Adjust - Hydraulic Hammer PDFDocument4 pagesRelief Valve (Line) - Test and Adjust - Hydraulic Hammer PDFjuan castaedaPas encore d'évaluation

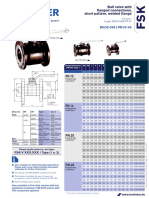

- Ball Valves with Flanged Connections for Various Pipe Sizes and Pressure RatingsDocument1 pageBall Valves with Flanged Connections for Various Pipe Sizes and Pressure Ratingsabdelkader benabdallahPas encore d'évaluation

- Gymna Handpiece ManualDocument29 pagesGymna Handpiece ManualGuan JiangPas encore d'évaluation

- FLO DS 0111 V Belt Pulley SPBDocument4 pagesFLO DS 0111 V Belt Pulley SPBYohanes Joko TriyantoPas encore d'évaluation

- Uh - 700 Manual de Servicio Taladro HiltiDocument7 pagesUh - 700 Manual de Servicio Taladro HiltiBenya MinPas encore d'évaluation

- Fike Impulse Valve OverviewDocument34 pagesFike Impulse Valve OverviewEmre ErdemPas encore d'évaluation

- Mechanical Engineering Department Unit Test ScheduleDocument3 pagesMechanical Engineering Department Unit Test ScheduleMohammedIkramUddinSohailPas encore d'évaluation

- XEROX 6204 Parts ListsDocument50 pagesXEROX 6204 Parts ListsAnonymous gn8qxx0% (1)

- Bill of Materials Two-Storey ApartmentDocument15 pagesBill of Materials Two-Storey ApartmentJames Patrick Galvez GonzalesPas encore d'évaluation

- Interpretations ASME B16.34-1998Document21 pagesInterpretations ASME B16.34-1998Claudenir AlvesPas encore d'évaluation

- Level 8 Loading Part Plan: H J K L M N P QDocument1 pageLevel 8 Loading Part Plan: H J K L M N P QGeethika SandaruwanPas encore d'évaluation

- Structural Repair ManualDocument29 pagesStructural Repair Manualjjrelucio3748100% (3)

- 13-D-Purchases N TacklesDocument7 pages13-D-Purchases N TacklesRohit SinghPas encore d'évaluation

- Manual: Original InstructionsDocument71 pagesManual: Original InstructionsMelanie GerdesPas encore d'évaluation

- Bravo Distributor Manual (English)Document12 pagesBravo Distributor Manual (English)Tam Jia TernPas encore d'évaluation

- Tension Members - Notes Mohit JaiswalDocument5 pagesTension Members - Notes Mohit JaiswalPiyush GuptaPas encore d'évaluation

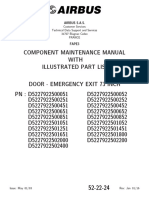

- @airbus: Airbus S.A.SDocument627 pages@airbus: Airbus S.A.Sjoker hotPas encore d'évaluation

- Component Maintenance Manual Cargo Hook Suspension SystemDocument30 pagesComponent Maintenance Manual Cargo Hook Suspension SystemAlireza Samavati.H100% (1)

- HWork03 SolDocument7 pagesHWork03 SolBen CarltonPas encore d'évaluation

- 2.4 Precaution of Usage For Anti Backlash Spur GearsDocument2 pages2.4 Precaution of Usage For Anti Backlash Spur Gearsnay hlaing SoePas encore d'évaluation

- GTP 127 Asdarp Engineering Development R1Document18 pagesGTP 127 Asdarp Engineering Development R1andiee traderPas encore d'évaluation

- HydraulicsDocument8 pagesHydraulicsAlper SakalsizPas encore d'évaluation

- CES Emergency and Segment Stops by Room and MachineDocument2 pagesCES Emergency and Segment Stops by Room and MachineSaurabh YadavPas encore d'évaluation

- Design Calc - Cooling Tower Sizing - R1 - 15.10.2011Document1 pageDesign Calc - Cooling Tower Sizing - R1 - 15.10.2011AliAliPas encore d'évaluation

- Guiberson Swab Cup Type TADocument1 pageGuiberson Swab Cup Type TAAgus HaryadiePas encore d'évaluation