Académique Documents

Professionnel Documents

Culture Documents

D 1 Low Smoke Zero Halogen Cables

Transféré par

Pratham KashyapTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

D 1 Low Smoke Zero Halogen Cables

Transféré par

Pratham KashyapDroits d'auteur :

Formats disponibles

Low Smoke Zero Halogen Wire and Cable

Low Smoke Zero

Halogen Cables

Eric Wall

Anixter Inc.

US Wire and Cable

2010 IEEE PES-ICC Fall Meeting

Fountain Hills, Arizona

1

Low Smoke Zero Halogen Wire and Cable

Defining Low Smoke Zero Halogen

Cable that burns cleanly and does not contain

halogens

No true official LSZH definition

Low Smoke is officially defined in several standards

LS (low smoke), ST1 (smoke test), plenum (NFPA 262)

Zero Halogen not clearly defined

Some Toxicity and Corrosivity tests

No UL recognized zero halogen cable designation

Low Smoke Zero Halogen Wire and Cable

Common LSZH Terms

LSZH

Low Smoke Zero Halogen

LSF

Low Smoke and Fume

NHFR

Non Halogen Flame Retardant

HFFR

Halogen Free Flame Retardant

FRNC

Fire Retardant Non Corrosive

FRLS

Fire Resistant Low Smoke

LC

Low Corrosivity

LH

Low Halogen

Low Smoke Zero Halogen Wire and Cable

LSZH Cables Available

Control Cable

Shielded Control Cable

Instrumentation Cable

Thermocouple Extension

Fiber Optic

Security Cable

Industrial Ethernet

Building Wire

VFD Cable

600V Power Cable

Low Smoke Zero Halogen Wire and Cable

Defined UL Low Smoke Types

ST1

UL 83 Single Thermoplastic Wire (THHN, THWN, etc)

UL 44 Single Thermoset Wire (RHH, RHW, etc)

UL 719 Non-metallic sheathed cable (NM-B, NMC-B)

LS

Type AC

Type CMx

Type DP

Type ITC

Type MC

Flexible Motor Supply

Type BLx/BMx

Type OFx

Type TC

Wind Turbine Tray Cable (WTTC)

Low Smoke Zero Halogen Wire and Cable

Why zero halogen?

Halogens are prevalent in wire cable as part of

common polymers and flame retardants

Halogens used in cable:

Fluorine in polymer (e.g. FEP, PTFE)

Chlorine in polymer (e.g. PVC, CSPE, CPE)

Bromine used as flame retardant additive (e.g. PBDE)

Halogens function by free radical reduction

Acid gases (e.g. HCl) are produced which can harm

people and damage equipment

Incomplete combustion results in thick, dark smoke

Part of the reason the terms are combined

6

Low Smoke Zero Halogen Wire and Cable

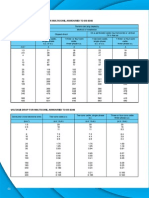

Halogen Content of W&C

Polymer

Halogen Content (% by weight)

XLP (cross-linked polyethylene)

with halogen-free flame retardants

with halogenated flame retardants

<0.02

<0.02

717

EPR (ethylene propylene rubber)

with halogenated flame retardants

<0.02

914

PU (polyurethane)

<0.02

PE (polyethylene)

with halogen-free flame retardants

<0.02

<0.02

CSPE (chlorosulfonated polyethylene)

1326

CPE (chlorinated polyethylene)

1428

PVC (polyvinyl chloride)

2229

FEP (fluorinated ethylene propylene)

6278

(<0.02 generally considered zero halogen)

7

Low Smoke Zero Halogen Wire and Cable

How do LSZH Products work?

Most common method is used of inorganic hydrated

mineral fillers

Aluminum Trihydrate (ATH) and Magnesium Hydroxide (MDH)

Three modes of flame retardance

Water vapor formed during combustion

Reduces available organic fuel load

Protective char layer formed

Main disadvantage is high loading levels need (>60%)

Can lead to reduction in physical properties

Synergistic additives and coatings used to improve performance

8

Low Smoke Zero Halogen Wire and Cable

Advantages of LSZH

Less smoke generated allowing for safe

evacuation and fire suppression

Potential for less secondary equipment damage

from corrosive smoke

Potentially lower total life cycle environmental

impact

Low Smoke Zero Halogen Wire and Cable

Disadvantages of LSZH

Potential Reduction in physical properties

Reduced Tensile Strength and Elongation

Increased Moisture Absorption

Reduced insulation resistance and dielectric strength

Less resistant to oil and chemicals

Need for LSZH cable when other halogenated materials

present

Need for LSZH when environment is well ventilated

Special Pulling Lubricant Needed

Halogenated materials have longer track record

10

Low Smoke Zero Halogen Wire and Cable

LSZH Applications

Confined spaces with high cable density and human

inhabitants or sensitive equipment

Shipboard Navy specified LSZH in middle of 1980s

Public Transit Kings cross fire in Europe

Europe

Central Offices / Data Centers

Latest generation of nuclear plants

Other US applications?

Automotive

Specified for other public areas?

Arenas, shopping malls, houses of worship

11

Low Smoke Zero Halogen Wire and Cable

Applications with minimum benefit?

Installations with low concentration of cables

relative to other materials (e.g. residential)

Where exposed to chemicals or oils

Installations with physical stress

Non-confined areas

Direct burial

12

Low Smoke Zero Halogen Wire and Cable

Future of LSZH

Environmental / Green aspects of materials

increasingly important

LSZH cables will continue to improve

Adoption as industry becomes more comfortable

with LSZH material

What happens if a significant failure occurs in the

field?

Or if a significant non-LSZH failure occurs?

13

Low Smoke Zero Halogen Wire and Cable

Questions?

Thank you!

14

Vous aimerez peut-être aussi

- No Smoke Without FireDocument1 pageNo Smoke Without FireArdi Do0% (1)

- Prysmian Draka Cable Catalogue NEK606 BFOU RFOUDocument82 pagesPrysmian Draka Cable Catalogue NEK606 BFOU RFOUmr3478Pas encore d'évaluation

- 2192Y / H03VVH2-F BS EN 50525-2-11 Flexible CableDocument2 pages2192Y / H03VVH2-F BS EN 50525-2-11 Flexible CableVictor Manayay ChamayaPas encore d'évaluation

- Of Strand Diameter and Conductor Resistance As Per IS 694 and IS 8130 Are MetDocument4 pagesOf Strand Diameter and Conductor Resistance As Per IS 694 and IS 8130 Are MetShubhranshu SumanPas encore d'évaluation

- EDC-DTS-LV002 - Electrical Accessories For LV ABCDocument34 pagesEDC-DTS-LV002 - Electrical Accessories For LV ABCJoe biloutePas encore d'évaluation

- Cable Fire Behaviour (Compatibility Mode)Document34 pagesCable Fire Behaviour (Compatibility Mode)elvikaPas encore d'évaluation

- High-Voltage Bridge For Cable Fault Location, Sheath Testing, Sheath Fault Prelocation and PinpointingDocument4 pagesHigh-Voltage Bridge For Cable Fault Location, Sheath Testing, Sheath Fault Prelocation and PinpointingPetru VirgilPas encore d'évaluation

- 09 PDFDocument19 pages09 PDFHesham FandyPas encore d'évaluation

- 2.3 Cable de Guardia - OPGW SPEC (15-53931)Document9 pages2.3 Cable de Guardia - OPGW SPEC (15-53931)xcazor morayPas encore d'évaluation

- 24 Fiber OPGW ANDES PDFDocument7 pages24 Fiber OPGW ANDES PDFMAN TPas encore d'évaluation

- 2.1. Technical Specification For OPGW NZ (91271A (Rev.3) )Document9 pages2.1. Technical Specification For OPGW NZ (91271A (Rev.3) )Samiksha BhattacharyaPas encore d'évaluation

- Aluminum Cables For Power Distribution AECH - Chapter - 10Document22 pagesAluminum Cables For Power Distribution AECH - Chapter - 10Anonymous XgX8kTPas encore d'évaluation

- TempRise IEC61439 07112018Document7 pagesTempRise IEC61439 07112018Anonymous JDWNC4ZDMUPas encore d'évaluation

- 27 HV XLPErformance Cable TechnologyDocument6 pages27 HV XLPErformance Cable TechnologyRanaSinhaPas encore d'évaluation

- Nhxmh-O-J 300-500VDocument4 pagesNhxmh-O-J 300-500VA. HassanPas encore d'évaluation

- OLX Handbook 2013 V1 - 2.1Document114 pagesOLX Handbook 2013 V1 - 2.1IhaszPas encore d'évaluation

- What Is Cross Linked PolyethyleneDocument14 pagesWhat Is Cross Linked PolyethyleneYongki Yo'el Gibranto100% (1)

- Compact Round Concentric-Lay-Stranded Aluminum 1350 ConductorsDocument6 pagesCompact Round Concentric-Lay-Stranded Aluminum 1350 ConductorsThanh DangPas encore d'évaluation

- Doha Cables Profile 2015Document15 pagesDoha Cables Profile 2015Ahmed Farouk100% (1)

- Iec 62219Document31 pagesIec 62219boopathy1705Pas encore d'évaluation

- Dow TR Xlpe CompoundDocument4 pagesDow TR Xlpe CompoundraghavPas encore d'évaluation

- APECB 245 - 300 Instructions NKT 4280,0122,0CDocument40 pagesAPECB 245 - 300 Instructions NKT 4280,0122,0CWenceslao EscorzaPas encore d'évaluation

- ACCCDocument6 pagesACCCDong BachPas encore d'évaluation

- AEI LinkeX Cross-Linked Polyethylene Insulated Power CablesDocument42 pagesAEI LinkeX Cross-Linked Polyethylene Insulated Power Cablesjohn9999999Pas encore d'évaluation

- Thermal Characteristics: Continuous Current Carrying CapacityDocument1 pageThermal Characteristics: Continuous Current Carrying CapacityLucian2001Pas encore d'évaluation

- Sector Die CatalogueDocument3 pagesSector Die CatalogueAHMED YOUSEF100% (1)

- Cara Nak Pasang Wayar Cats Eye Utk NetworkDocument15 pagesCara Nak Pasang Wayar Cats Eye Utk NetworkKrull Hzm100% (1)

- 08.instrumentation CablesDocument5 pages08.instrumentation CablesChandu ReddyPas encore d'évaluation

- Transition Joint EHV - Oil To XLPE NKT Cable JointDocument11 pagesTransition Joint EHV - Oil To XLPE NKT Cable Jointwaqas_a_shaikh4348100% (1)

- GTP For DPDC HTDocument2 pagesGTP For DPDC HTjamilPas encore d'évaluation

- 500kV Aluminum-Sheathed XLPE Cable in A 96m Vertical ShaftDocument6 pages500kV Aluminum-Sheathed XLPE Cable in A 96m Vertical ShaftshahpinkalPas encore d'évaluation

- Olex Arial CatalogueDocument15 pagesOlex Arial CatalogueMike WesleyPas encore d'évaluation

- Termination KitDocument18 pagesTermination KitJan Glen MenesesPas encore d'évaluation

- TAN DELTA PrincipleDocument3 pagesTAN DELTA PrincipleRahul PhadakePas encore d'évaluation

- Cathodic Protection Systems and The NECDocument9 pagesCathodic Protection Systems and The NECAnonymous uxilzxUkaIPas encore d'évaluation

- Electron Beam Crosslinking TechnologyDocument14 pagesElectron Beam Crosslinking TechnologyChaitanya ShakyaPas encore d'évaluation

- LS EHV Cable System: 66 500kV XLPE Cable & AccessoriesDocument64 pagesLS EHV Cable System: 66 500kV XLPE Cable & AccessoriesRachid HamianiPas encore d'évaluation

- TDS Fosroc Conbextra Cable Grout HS India3Document4 pagesTDS Fosroc Conbextra Cable Grout HS India3RAJKUMAR CHATTERJEE. (RAJA.)Pas encore d'évaluation

- ZTT Adss 20-113931 - BDocument11 pagesZTT Adss 20-113931 - BervanPas encore d'évaluation

- IEC 62491-2008 Labelling of Cables and CoresDocument64 pagesIEC 62491-2008 Labelling of Cables and CoresTu Nguyen TraiPas encore d'évaluation

- HVDCDocument21 pagesHVDCsubhankarprusty5259Pas encore d'évaluation

- ABI High Voltage Engineering and Testing 3rd EditionDocument1 pageABI High Voltage Engineering and Testing 3rd EditionJames Ernes Llacza CarmeloPas encore d'évaluation

- 10 MeV Electron Beam Cross-Linking of Plasticized PVCDocument6 pages10 MeV Electron Beam Cross-Linking of Plasticized PVCDuc Nguyen HuuPas encore d'évaluation

- FRP Rods For Brittle Fracture ResistantDocument9 pagesFRP Rods For Brittle Fracture Resistantdmsoares1989Pas encore d'évaluation

- Current-Carrying Capacity For Multicore, Armoured To Bs 6346Document1 pageCurrent-Carrying Capacity For Multicore, Armoured To Bs 6346lkt_pestechPas encore d'évaluation

- 600 / 1000v Stranded Copper Conductors PVC Insulated With Steel Wire Amour and PVC Sheathed Overall. (BS 6346: 1997)Document8 pages600 / 1000v Stranded Copper Conductors PVC Insulated With Steel Wire Amour and PVC Sheathed Overall. (BS 6346: 1997)Himdad TahirPas encore d'évaluation

- Opgw Fiber Spec Dno 91391Document5 pagesOpgw Fiber Spec Dno 91391carlos diazPas encore d'évaluation

- Description: Cu/Mica/Xlpe/Oscr/Lszh/Gswa/LszhDocument4 pagesDescription: Cu/Mica/Xlpe/Oscr/Lszh/Gswa/LszhTarek FawzyPas encore d'évaluation

- EMEA WC Sec 6Document55 pagesEMEA WC Sec 6andy175Pas encore d'évaluation

- Siemens Sentron BuswayDocument2 pagesSiemens Sentron Buswayduyan1987Pas encore d'évaluation

- Fire Resistant 08Document36 pagesFire Resistant 08mehdi227Pas encore d'évaluation

- Leader XLPE VisualDocument64 pagesLeader XLPE VisualMohd Izham IdrisPas encore d'évaluation

- Trfricate Kit For 3C Cold Shrink TerminationDocument4 pagesTrfricate Kit For 3C Cold Shrink Terminationdes1982Pas encore d'évaluation

- NCI - LV Cables CatalogueDocument55 pagesNCI - LV Cables Catalogues50% (2)

- Compact Round Stranded Aluminum Conductors Using Single Input Wire ConstructionDocument4 pagesCompact Round Stranded Aluminum Conductors Using Single Input Wire ConstructionHanh-Trang DangPas encore d'évaluation

- 12F0003X00 Anixter LSZH WP W&C EN US PDFDocument6 pages12F0003X00 Anixter LSZH WP W&C EN US PDFPratham KashyapPas encore d'évaluation

- Flame Resistant Cable LSZHDocument2 pagesFlame Resistant Cable LSZHshinojbaby4148Pas encore d'évaluation

- Low Smoke Zero Halogen Wire and Cable Best Practices: Products. Technology. Services. Delivered GloballyDocument6 pagesLow Smoke Zero Halogen Wire and Cable Best Practices: Products. Technology. Services. Delivered GloballyHashimAmrPas encore d'évaluation

- Cable TerminologyDocument5 pagesCable TerminologyVinay MandiPas encore d'évaluation

- Cable LSZHDocument1 pageCable LSZHGabetsos KaraflidisPas encore d'évaluation

- Acknowledgement: Signature Mr. Pratham Kumar (IV B. Tech., VIII Sem.)Document1 pageAcknowledgement: Signature Mr. Pratham Kumar (IV B. Tech., VIII Sem.)Pratham KashyapPas encore d'évaluation

- Low Smoke Zero Halogen Cable: Seminar ReportDocument1 pageLow Smoke Zero Halogen Cable: Seminar ReportPratham KashyapPas encore d'évaluation

- Table of Content: Title Page No. Chapter 1: Introduction of LSZH Cable 1 1Document2 pagesTable of Content: Title Page No. Chapter 1: Introduction of LSZH Cable 1 1Pratham KashyapPas encore d'évaluation

- 12F0003X00 Anixter LSZH WP W&C EN US PDFDocument6 pages12F0003X00 Anixter LSZH WP W&C EN US PDFPratham KashyapPas encore d'évaluation

- Halogen ADocument25 pagesHalogen APratham KashyapPas encore d'évaluation

- Master's Degree Programme in Sociology: Assignment July 2015 and January 2016 SessionsDocument6 pagesMaster's Degree Programme in Sociology: Assignment July 2015 and January 2016 SessionsPratham KashyapPas encore d'évaluation

- Master's Degree Programme in Sociology: Assignment July 2015 and January 2016 SessionsDocument6 pagesMaster's Degree Programme in Sociology: Assignment July 2015 and January 2016 SessionsPratham KashyapPas encore d'évaluation

- Chunking Chunking Chunking: Stator Service IssuesDocument1 pageChunking Chunking Chunking: Stator Service IssuesGina Vanessa Quintero CruzPas encore d'évaluation

- Hydraulics and PneumaticsDocument6 pagesHydraulics and PneumaticsRyo TevezPas encore d'évaluation

- Design Practical Eden Swithenbank Graded PeDocument7 pagesDesign Practical Eden Swithenbank Graded Peapi-429329398Pas encore d'évaluation

- Heirs of Vinluan Estate in Pangasinan Charged With Tax Evasion For Unsettled Inheritance Tax CaseDocument2 pagesHeirs of Vinluan Estate in Pangasinan Charged With Tax Evasion For Unsettled Inheritance Tax CaseAlvin Dela CruzPas encore d'évaluation

- Jurnal 1 Ieevee LPF PDFDocument4 pagesJurnal 1 Ieevee LPF PDFNanda SalsabilaPas encore d'évaluation

- Parts Manual: Generator SetDocument118 pagesParts Manual: Generator SetAhmed Kamal100% (2)

- AMO Exercise 1Document2 pagesAMO Exercise 1Jonell Chan Xin RuPas encore d'évaluation

- Atom SDDocument5 pagesAtom SDatomsa shiferaPas encore d'évaluation

- Datos Adjuntos Sin Título 00013Document3 pagesDatos Adjuntos Sin Título 00013coyana9652Pas encore d'évaluation

- FKTDocument32 pagesFKTNeeraj SharmaPas encore d'évaluation

- Sample Interview Questions For Planning EngineersDocument16 pagesSample Interview Questions For Planning EngineersPooja PawarPas encore d'évaluation

- Furnace Temperature & PCE ConesDocument3 pagesFurnace Temperature & PCE ConesAbdullrahman Alzahrani100% (1)

- JBF Winter2010-CPFR IssueDocument52 pagesJBF Winter2010-CPFR IssueakashkrsnaPas encore d'évaluation

- Interbond 2340UPC: Universal Pipe CoatingDocument4 pagesInterbond 2340UPC: Universal Pipe Coatingnoto.sugiartoPas encore d'évaluation

- ASHRAE Elearning Course List - Order FormDocument4 pagesASHRAE Elearning Course List - Order Formsaquib715Pas encore d'évaluation

- MOS - Steel StructureDocument15 pagesMOS - Steel StructuredennisPas encore d'évaluation

- K MCQsDocument6 pagesK MCQsF ParikhPas encore d'évaluation

- BSDDocument26 pagesBSDEunnicePanaliganPas encore d'évaluation

- DLI Watchman®: Vibration Screening Tool BenefitsDocument2 pagesDLI Watchman®: Vibration Screening Tool Benefitssinner86Pas encore d'évaluation

- Waswere Going To Waswere Supposed ToDocument2 pagesWaswere Going To Waswere Supposed ToMilena MilacicPas encore d'évaluation

- KiSoft Sort & Pack Work Station (User Manual)Document41 pagesKiSoft Sort & Pack Work Station (User Manual)Matthew RookePas encore d'évaluation

- Beautiful SpotsDocument2 pagesBeautiful SpotsLouise Yongco100% (1)

- MPT EnglishDocument5 pagesMPT Englishkhadijaamir435Pas encore d'évaluation

- Zambia National FormularlyDocument188 pagesZambia National FormularlyAngetile Kasanga100% (1)

- Cosmic Handbook PreviewDocument9 pagesCosmic Handbook PreviewnkjkjkjPas encore d'évaluation

- ATS2017 ProspectusDocument13 pagesATS2017 ProspectusGiri WakshanPas encore d'évaluation

- Case Study To Find Tank Bulging, Radial Growth and Tank Settlement Using API 650Document15 pagesCase Study To Find Tank Bulging, Radial Growth and Tank Settlement Using API 650Jafer SayedPas encore d'évaluation

- Medabots-Rokusho Version (European) - Medal Codes (Part 1) (GBA Cheats) - CodeTwink ForumsDocument5 pagesMedabots-Rokusho Version (European) - Medal Codes (Part 1) (GBA Cheats) - CodeTwink Forumsdegraded 4resterPas encore d'évaluation

- SXV RXV ChassisDocument239 pagesSXV RXV Chassischili_s16Pas encore d'évaluation

- Slides - SARSDocument191 pagesSlides - SARSCedric PoolPas encore d'évaluation