Académique Documents

Professionnel Documents

Culture Documents

EMD Millipore FTPF12590 - AFS-8D-16D - Manual - V1-0 - 05-2012 - EN PDF

Transféré par

Anonymous APKSWlyTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

EMD Millipore FTPF12590 - AFS-8D-16D - Manual - V1-0 - 05-2012 - EN PDF

Transféré par

Anonymous APKSWlyDroits d'auteur :

Formats disponibles

User Manual

AFS® 8D, 16D

Preface

Congratulations!

Thank you for purchasing our Water Purification System.

For any questions or requests, please use the contact information provided below.

By Internet

The Internet Site can be used to find addresses, telephone/fax numbers and other

information.

Internet Site Address:

www.millipore.com

www.millipore.com/techservice

www.millipore.com/lab_water

Manufacturing Site

Millipore SAS

67120 Molsheim

France

AFS® 8D, 16D 1

Preface

Safety information

Your water system should be operated according to the instructions in this manual. In

particular, the hydraulic and electrical specifications should be followed and met. It is

important to use this equipment as specified in this manual; using this equipment in a

different manner may impair the safety precautions of the water system.

This ATTENTION symbol is used to refer to instructions in this manual that need

to be done carefully.

These symbols are used to indicate that proper safety equipment has to be used.

Protective glasses and gloves must be worn.

This UV RADIATION sticker is used to refer to a position on the water system

Cabinet or inside of it where exposure to UV light is possible.

This DANGER sticker is used to refer to a position on the water system Cabinet or

inside of it that could be hazardous.

This ELECTRICAL GROUND sticker is used to refer to a position on the water

system Cabinet or inside where an electrical ground connection is made.

This ELECTRICAL DANGER sticker is used to refer to a position on the water

system Cabinet or inside where an electrical danger could exist.

IMPORTANT!

Your water system should be installed and operated in a clean and dry area. Please refer to

the environment requirements page at the end of this manual.

Your water system is not designed for domestic use.

Powering off the water system for a long period of time can discharge the battery

used by the time keeper: time and date can be lost. If the water system is shut off for

a long period of time, use the lab closed mode or go through an installation procedure

of the water system. Contact your Service Representative.

Save the system’s history frequently – every 3 or 6 months.

2 AFS® 8D, 16D

Preface

Documentation usage

The instruction manual found with your water purification system is important for a good

usage and the maintenance in compliance with the manufacturer specifications.

Your water system is delivered with two documents, and these are:

x A user manual which describes all specifications, operations and functions of the water

system.

x A quick guide that describes quick access to maintenance and operating information.

It may be necessary for to reference these documents for maintenance or other procedures

with the water system. It is recommended to store these documents in such way that they

can be quickly located and where they will not be damaged.

A plastic folder is provided with the water system. Use this to safety store the documents.

You can stick the side of the plastic folder on the side of the water system and place the

documents in there if desired.

AFS® 8D, 16D 3

Preface

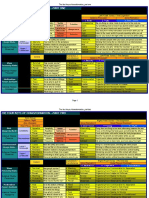

System overview

The water system and its different modules are shown here.

Item Description Item Description

1 System name and type 7 System’s hydraulic connections

2 Display and keypad 8 System ID and serial number

3 Progard® Pretreatment Pack location 9 External power supply*

4 Locking handle 10 Q-Gard® Pack location

5 Sanitization/cleaning port 11 Vacuum level gauge and adjustment

6 Electrical connections screw

* For powering off the system, disconnect the power cord from the power socket. The power cord should be

plugged into a wall outlet that is accessible.

4 AFS® 8D, 16D

Preface

Keypad usage

The keypad and its usage are explained below.

Item Function

1 MODE key

This button is used to switch between different system modes: Standby or

maintenance mode, Ready or tank filling mode and Configuration mode.

x From Standby, press twice to go to Ready.

x From Ready, press once to go to Standby.

2 LEFT or RIGHT key

These buttons are used to navigate in the user interface software. They are also used

to change configuration or set point values.

3 VALIDATE key

This button is used to confirm a change or an action required by the water system. It

is also used to save any changes made in configuration.

4 HELP INDICATOR icon

There are up to 3 of these icons on the display depending upon the software mode.

These indicators are here to tell the user which keypad button is available and active.

See the examples below:

3 help indicators:

x Press on (Mode key) to switch system mode.

x Press on to navigate in the software branch.

x Press on (Validate key) to configure ECO mode.

2 help indicators:

x Press on (Mode key) to switch system mode.

x Press on to navigate in the software branch.

1 help indicator:

x Press on (Mode key) to switch system mode.

2 AFS® 8D, 16D

Table of contents

Table of contents

Items needed ............................................................................................................................ 7

Items checklist ......................................................................................................................................... 8

Millitrack® Software - option.............................................................................................................. 9

System ....................................................................................................................................11

Display icons ........................................................................................................................................... 12

Software modes ..................................................................................................................................... 13

Operating principle and status .......................................................................................................... 14

Maintenance information ........................................................................................................... 15

Configure system parameters .................................................................................................... 16

View operation parameters ................................................................................................................ 18

Software navigation map ................................................................................................................... 19

Consumables replacement ....................................................................................................21

Replacing Progard® Pack .................................................................................................................... 22

Replacing Q-Gard® Pack ..................................................................................................................... 24

Replacing final filter .................................................................................................................... 26

Sanitization and cleaning .....................................................................................................29

Sanitizing RO membranes with chlorine ................................................................................ 30

Cleaning RO membranes with acid/base (pH) .............................................................................. 31

Other functions .....................................................................................................................33

Saving display energy - ECO mode .................................................................................................. 34

System is not used for a long time - Lab Closed ......................................................................... 35

Dissolved gas based upon the measured O2 level content ........................................................ 36

Emergency procedure........................................................................................................................... 38

Error messages .......................................................................................................................41

Error codes .............................................................................................................................................. 42

Basic troubleshooting .......................................................................................................................... 43

Chemical and technical specifications .................................................................................45

Specifications and requirements ...................................................................................................... 46

Legal information ..................................................................................................................49

Notice ....................................................................................................................................................... 50

Copyright ................................................................................................................................................. 50

Trademarks .............................................................................................................................................. 50

Product warranty and limitation of liability ................................................................................. 51

4 AFS® 8D, 16D

Table of contents

Recycling ................................................................................................................................................. 51

Item catalog numbers ........................................................................................................... 53

Consumables catalog numbers ......................................................................................................... 54

Optional consumables catalog numbers ........................................................................................ 54

Optional equipment catalog numbers ............................................................................................ 55

System’s catalog numbers .................................................................................................................. 55

AFS® 8D, 16D 5

Items needed

Items needed

Items checklist

Verify that all items are available before beginning the installation.

x Water system unit (A)

x User manual and Quick Reference Guide (B)

x External power supply (C)

x Progard® Pack and Q-Gard® Pack (D)

x BioPak® C final filter (E)

x Accessories bag with:

x Tubings

x Fittings

x Power cord

x Tubing guides

8 AFS® 8D, 16D

Items needed

Millitrack® Software - option

Millitrack® Software is an embedded GUI (graphical user interface) developed with AJAX

(Asynchronous JavaScript and XML) techniques that generate interactive web pages

through a point-to-point computer or direct network connection using TCP/IP Ethernet

protocol.

Millitrack® Software allows a lab user to download or view instantaneously quality data

through their internet browser for rapid monitoring of his water purification system.

Millitrack® Software users have also real–time remote access to interactive web pages

through a standard TCP/IP network describing water purification system status,

configuration, instant quality parameters, settings, identification and Dashboard.

Key Benefits:

x Native Web graphical user interface.

x Real-time and remote Dashboard of water systems.

x XML data format available for printing or downloading to any spreadsheet database.

x Compatible with any lab data management system such as LIMS, ELN, SDMS/ECM.

Choose the data range and the events you want to download or print.

AFS® 8D, 16D 9

System

System

Display icons

Know how to interpret each icon displayed. These are displayed below.

Item Description Item Description

1 System status indication are: 3 Values area is used to display

x Maintenance or tool: x Water quality measures

the system is in Standby or x Software menu and

maintenance can be started. configuration values

x Configuration or gears: x Error code numbers

configuration parameters such 4 Units are:

as set points can be changed. x ‘ or minutes

x Process or hour glass: x Mȍ.cm or megOhm

the system is busy. No action centimeter.

can be done. x µS/cm or micro siemens by

2 Warning maintenance or alarm (from centimeter

left to right) are displayed to indicate x °C or temperature degree

that: Celsius

x CL2 sanitization is required: x % or percentage.

perform the sanitization of the 5 x Consumables status icons are

RO cartridge. used to indicate that a

x Final filter replacement is maintenance action is

required (if option activated) required.

x For more information, refer to

x System sanitization is required.

the Quick Guide or the

x Product water resistivity is Consumables Replacement

below set point. section in this document.

x Low feed water pressure is 6 x Tank filling is represented by

detected. the top bar.

x Water is detected (if water x When the top bar is blinking,

sensor installed). the system fills the tank. When

x

it’s not blinking, the tank full

Contact Technical Service. level is reached.

12 AFS® 8D, 16D

System

Software modes

The different software modes are described below with some examples.

x System is in Standby or maintenance.

x Tool icon indicates maintenance.

x System is in Standby or maintenance.

x Tool icon indicates maintenance

x Values area indicates Cl2 sanitization start.

x System is in Configuration.

x Gears icon indicates parameters.

x Values area indicates ECO mode setting.

x System is in Ready or in Tank Filling or in distribution.

x Distribution product water resistivity is 15 Mȍ.cm.

x Distribution product water resistivity is 15 Mȍ.cm.

x The Progard pack must be changed within 15 days: order a new

Progard pack.

x Yellow color display and : the Progard pack must be changed.

x Distribution product water resistivity is 15 Mȍ.cm.

x Yellow color display and : the CL2 cleaning must be started.

x Distribution product water resistivity is 15 Mȍ.cm.

x Yellow color display, Er:20 and .

x The system has detected a minor problem that does not affect

the normal operation. Refer to section Error codes at page 42.

x Red color display and .

x The system has detected a dysfunction when operating in

normal conditions. In this example, system has detected a low

feed water pressure and has stopped. More investigation is

required.

x Red color display, Er:02 and .

x The system has detected a dysfunction when operating in

normal conditions. Refer to section Error codes at page 42.

x Red color display and : the Progard pack has been removed or

a wrong pack is installed.

x Tool icon indicates maintenance.

AFS® 8D, 16D 13

System

Operating principle and status

An Analyzer Feed System (“AFS®”) is a water system designed to automatically feed an

analyzer. The AFS® D (or Degasser) includes a degassing device which is used to remove air

from the product water delivered to the analyzer.

As a summary, the system purifies tap water using the Progard® Pack and Reverse Osmosis.

A tank and pump are used to store and distribute the product water to the Analyzer. A

sensor is used to determine if the Analyzer needs water. This water is further purified by

ion exchange before going to the Analyzer.

Understanding the terminalogy of operating status.

DISTRIBUTION The system has detected that the analyzer needs water. Thus the

distribution part of the system is producing water and sends that water

to the analyzer.

RECIRCULATION The system is periodically recirculating water in the distribution portion

of the system but no water is being delivered to the analyzer.

TANK FILLING The distribution tank is being filled by RO Water. A sensor starts and

stops this mode.

FLUSH A periodic flush of the RO portion of the system is done. This refreshes

the water in this part of the system if they are not being used to produce

water.

RINSING A sensor has determined that the RO portion needs to rinse itself before

sending water to the tank.

SANITIZATION There are different types of sanitization that can be done. See the

maintenance section in this document for more information.

CLEANING An acid or base cleaning can be done. A packaged chemical is available

for this type of cleaning. See the Item Catalogue Numbers section at the

end of this document.

14 AFS® 8D, 16D

System

Maintenance information

Some information can be shown on the display.

CL2

In this view, the chlorine sanitization can be performed.

PH

In this view, the acid or base cleaning can be performed.

SAN

In this view, the system’s sanitization can be performed by a

qualified service representative.

LF 01

In this view, the final filter lifetime can be reset once it has been

changed.

LF 02

In this view, the UV Lamp 254 nm lifetime can be reset once it

has been changed by a qualified service representative.

LAb C

In this menu, the Lab Closed mode can be activated.

AFS® 8D, 16D 15

System

Configure system parameters

Access and configure all system parameters.

SP 01

This setting is not used and not accessible.

SP 02

Set point for the RO % Rejection. Below this set point, an alarm

is indicated. This measurement indicates the percent of ions

removed by the RO relative to the amount of ions entering the

system.

SP 03

Set point for the water resistivity being sent to the analyzer.

Below this set point, an alarm is indicated.

DATE

Menu where date and time can be adjusted.

IP AD – used with Millitrack® software

Menu where the actual used IP address can be viewed.

IP DF - used with Millitrack® software

Menu where the actual IP address can be reset and switch to the

default one.

ECO

Menu where the display energy saving mode can be activated or

deactivated.

C---

Restricted menu accessible with a code and used for Service.

16 AFS® 8D, 16D

System

An example of a configuration change: the DATE (YYYY, MM, DD) and TIME (00:00).

1- System is in STANDBY 2- In maintenance menu, 3- Press on right arrow

mode. Press on right arrow press . until the date menu is

. displayed.

4- Press to enter dAtE 5- Change year with arrows 6- Change month with arrows

menu. and press . and press .

7- Change day with arrows 8- The date is set now.

and press .

9- Set the time. Press . 10- Change with arrows 11- Change with arrows

and press . and press .

AFS® 8D, 16D 17

System

View operation parameters

In Ready or Tank filling, press and hold 2 sec on left or right arrow to access

operation parameters.

Tap water feed conductivity value can

be displayed by pressing .

Press to go back to d1 view.

RO feed water conductivity value can

be displayed by pressing .

Press to go back to d2 view.

RO water temperature value can be

displayed by pressing .

Press to go back to d3 view.

RO pump pressure value can be

displayed by pressing .

Press to go back to d4 view.

RO % rejection value can be displayed

by pressing .

Press to go back to d5 view.

RO permeate water conductivity value

can be displayed by pressing .

Press to go back to d6 view.

18 AFS® 8D, 16D

System

Software navigation map

The software map below shows the main menus available in the system.

Standby or maintenance

Press

to navigate…

Press

to navigate…

Ready or Tank Filling

AFS® 8D, 16D 19

Consumables replacement

Consumables replacement

Replacing Progard® Pack

x When the system shows the icon , order a new pack.

x When the system displays the yellow alert , replace the pack.

Note:

it is recommended to replace the Vent Filter at this time. Additionally, it is

recommended to clean the feed water strainer.

Removing exhausted pack

Verify or put the system in Standby by pressing - MODE key.

1 Unlock the locking handle by pulling up.

2 Pull out the pack.

Note:

when the pack is removed, a red color display appears. This is normal. This will go

away when a new pack is installed.

22 AFS® 8D, 16D

Consumables replacement

Placing new pack

Remove the new pack from its shipping box. Remove the 2 protective caps from the

ports at the top of the pack.

Locate the o-ring inside each port. Make sure the o-rings are push inside

against the inner edge of the ports.

1 Mount the bottom of the pack onto the small hole in the cabinet.

Swing the rest of the pack so that the top of the Pack aligns with pack locking handle

and the cabinet ports.

2 Push the top of the pack in-place.

3 Push the pack locking handle down to secure the pack.

x The new pack is detected.

x The display prompts you to start a “Progard flush”: press for 1 second.

x The “Progard flus”h lasts 15 min.

x System goes in Tank Filling automatically.

AFS® 8D, 16D 23

Consumables replacement

Replacing Q-Gard® Pack

x When the system shows the icon , order a new pack.

x When the system displays the yellow alert , replace the pack.

x Before replacing the pack, verify that the tank is full.

Removing exhausted pack

Verify or put the system in Standby by pressing - MODE key.

If system is connected to PE 30,60,100 tanks: close the valves underneath the tank.

1 Locate the Sampling Port. It is typically located downstream of the final filter. Place a

container under to collect any water that will come out when it's opened.

Open the valve. Wait until water stops flowing out.

2 Detach the tubing from the final filter inlet. Place this tubing end into a drain or sink.

3 Pull up the locking handle.

4 Pull out the entire pack.

Note:

when the pack is removed, an alarm appears. This is normal. The alarm will go away

when a new pack is installed.

24 AFS® 8D, 16D

Consumables replacement

Placing new pack

Remove the new pack from its shipping box. Remove the 2 protective caps from the

ports at the top of the pack.

1 Mount the bottom of the pack onto the small hole in the cabinet.

Swing the rest of the pack so that the top of the pack aligns with pack locking handle

and the cabinet ports.

2 Push the top of the pack in-place.

Locate the o-ring inside each port. Make sure the o-rings are push inside

against the inner edge of the ports.

If system is connected to PE Reservoir: open the valves underneath the tank.

3 Push the pack locking handle down to secure the pack.

x The new pack is detected.

x The display prompts you to start a polisher rinse: press next for 1 second.

x Wait for 2-3 minutes.

x Put the system in Standby.

4 Reconnect the tubing on the final filter inlet.

5 Close the sampling valve. Press to put the system in Ready or Tank filling.

AFS® 8D, 16D 25

Consumables replacement

Replacing final filter

x When the system shows , order a new final filter.

x When the system displays the yellow alert , replace the final filter.

x Before replacing the final filter verify that the tank is at least half full.

Note:

do not rinse the final filter with a pack that has not been rinsed out.

Removing final filter

x Verify or put the system in Standby by pressing .

x The system displays LF: 01.

1 Open the sampling valve to remove the pressure in the distribution product line.

2 Disconnect the final filter from the distribution product line.

3 Unscrew the fittings from both ends of the filter.

4 Remove the final filter.

26 AFS® 8D, 16D

Consumables replacement

Placing new final filter

Remove the new filter from its shipping box.

1 Screw the fittings on both ends.

2 x Connect the new filter on the distribution product line, and

x Open or verify that the sampling valve is opened.

3 Press for 1 second to put the system in Tank filling and to reset the life time.

x Remove air from the final filter by unscrewing the air vent cap.

x Close it once it is air purged.

x The display prompts you to start a final filter rinse: press next for 1 second.

x Wait for 2-3 minutes.

x Put the system in Standby.

4 Close the sampling valve.

AFS® 8D, 16D 27

Sanitization and cleaning

Sanitization and cleaning

Sanitizing RO membranes with chlorine

x A chlorine tablet is periodically used to reduce or remove a layer of bio film on the feed

water side of the RO membrane.

x When the system shows the yellow alert , put the system in Standby by

pressing .

1- Using the tool, unscrew 2- Remove the plug and insert 3- Screw the plug back: make

the sanitation port cap. the tablet in the port. sure the o-ring is in place.

Use proper safety

equipment.

Starting CL2 sanitization

1- Press for 1 second to 2- The sanitization lasts 3- System goes in Ready or

start CL2 sanitization. 19 min. Tank filling.

Note: The sanitization can be cancelled in emergency case or when started by mistake.

Press during the cycle to abort sanitization.

30 AFS® 8D, 16D

Sanitization and cleaning

Cleaning RO membranes with acid/base (pH)

x It may become necessary to remove any built up layer of mineral scale or organic

material. This is done with a pH Cleaner. Contact your Service Representative for more

information about their use.

x To start the cleaning, make sure the system is in Standby or put the system in Standby by

pressing .

1- Using the tool, unscrew 2- Remove the plug and insert 3- Screw the plug back: make

the sanitation port cap. the tablet in the port. sure the o-ring is in place.

Starting pH cleaning

1- Put the system in Standby 2- Press on right arrow 3- Press for 1 second to

by pressing . to go to next view. start pH cleaning.

4- The cleaning lasts 5- Once the cleaning is

82 minutes. finished, press to put

the system in Standby.

6- Unscrew the plug and 7- Screw the plug back and

remove the empty pouch put the system in Tank

from the cleaning port. filling by pressing twice .

AFS® 8D, 16D 31

Other functions

Other functions

Saving display energy - ECO mode

When this function is activated, the ECO mode is used to save energy when the display is

not used. It shuts down the system’s display backlight after a 15 min period of non-use.

The ECO mode is disabled by pressing a keypad button or when a warning message is

displayed by the system (error code or warning symbol).

Configuring ECO mode

1- Put the system in Standby 2- Press once again. 3- You are in configuration

by pressing . mode. Press on right

arrow until you

reach…

4- Press to enter ECO 5- Press to change the 6- NO. Press to confirm

menu. setting between YES or… the setting and exit.

34 AFS® 8D, 16D

Other functions

System is not used for a long time - Lab Closed

You can use the Lab Closed function whenever the system is not be used for a long time.

In this mode, water quality is maintained by periodic automatic flushing.

Do not power off the system! The system time and date can be lost as a

result. If the system is shut off for a long period of time, contact your

service representative for an installation procedure in compliance with the

manufacturer specifications.

Detach the product tubing to the tank.

If required, empty the tank using the front valve

1- Unscrew the nut from the bottom connection

of the tank.

2- Remove the tubing. Put this tubing in a sink

or drain

Configuring Lab Closed mode

1- Verify the system in 2- Press on right arrow 3- Press to activate the

Standby. until you reach… Lab Closed mode.

Exiting Lab Closed Mode

1- Reconnect tubing to the tank.

2- From lab closed mode: 3- The system goes in Tank

press for 1 second. filling.

AFS® 8D, 16D 35

Other functions

Dissolved gas based upon the measured O2 level content

By adjusting the vacuum level in the system, it is possible to control the level of dissolved

gas based upon the measured O2 level content.

Principle: using an external O2 meter, measure the level of O2 in the product water

sampled in a small beaker. Repeat this operation several times and calculate the average

level of O2 in the product water. Then adjust the vacuum level according to the measured

level.

If a specific level of O2 is required, the air diffuser can be used to saturate the tank water

with O2.

Adjusting vacuum level

Verify that you have at least 10 L of water in the tank..

1 Put the system in Standby or Maintenance.

Open the Distribution sampling valve to depressurize.

2 Remove the Q-Gard® pack.

Wait for the degassing level to drop down completely.

3 Unscrew – by turning counter-clock wise, the vacuum level adjustment screw.

To prevent regulator damage, do not force or over-turn adjustment screw.

4 Insert the Q-Gard® pack. And put the system in Ready or Tank Filling.

Let system produces water for a few minutes..

Note:

Wait for Rinsing mode to finish if necessary.

5 Turn the adjustment screw clock-wise to increase the vacuum level: turn one or two

turns and wait for the value to stabilize on the gauge.

Repeat the operation until desired vacuum level is reached.

36 AFS® 8D, 16D

Other functions

AFS® 8D, 16D 37

Other functions

Emergency procedure

38 AFS® 8D, 16D

Other functions

Emergency by pass kit installation

Make sure the system is in Standby

Power OFF the system by unplugging the power cord from the wall outlet.

1 Open the sampling valve to depressurize.

2 Close the manual valve on the tubing located at the bottom of the tank.

x Remove the Q-Gard® pack. Install a new one (see replacement procedure for the Q-Gard®

pack).

3 Disconnect the quick fitting on the feed water tube.

Disconnect the quick fitting on the tank and the bottom OUT 5 port.

4 Detach the by pass and connect it on the feed tube and on the bottom tube of the

system. Follow the water flow direction indicated on the bypass.

x Rinse the pack for 3 min. While rinsing the pack, go to next step.

5 Adjust the value of the pressure regulator at 1.5 bar.

x Replace final filter if necessary.

6 Close the sampling valve.

x The system is ready to feed the analyzer. Depending on the feedwater quality, the capacity

of the pack can vary. Contact your service representative for more information.

AFS® 8D, 16D 39

Error messages

Error messages

Error codes

An error code is always displayed with and can be displayed in two different ways:

Yellow display alert error: Red display alarm error:

The list of error codes is presented below.

Code Meaning What to do?

Er:01 Tap feed water conductivity > set point Contact your service representative.

Er:02 Feed water temperature > set point See next page.

Er:03 RO permeate conductivity > set point Contact your service representative.

Er:04 RO % rejection < set point Contact your service representative.

Er:05 RO Feed water conductivity < min Contact your service representative.

Er:06 RO Feed water conductivity > max Contact your service representative.

Er:07 RO permeate temperature < min Contact your service representative.

Er:08 RO permeate temperature > max Contact your service representative.

Er:09 RO permeate conductivity < min Contact your service representative.

Er:10 RO permeate conductivity > max Contact your service representative.

Er:15 Distribution water temperature < min Contact your service representative.

Er:16 Distribution water temperature > max Contact your service representative.

Er:17 Distribution water resistivity < min Contact your service representative.

Er:18 Distribution water resistivity > max Contact your service representative.

Er:19 Distribution auto stop timer See next page.

Er:20 Network cable is unplugged See next page.

Er:21 No response from DHCP server Contact your network administrator.

Er:22 Incorrect IP address Contact your network administrator.

Er:23 Distribution pressure sensor failure Contact your service representative.

Er:24 Replace UV lamp 254 nm See next page.

Er:28 Replace distribution pump Contact your service representative.

Er:30 No response from cold fire Contact your service representative.

microprocessor

Er:31 Distribution pressure too high Contact your service representative.

42 AFS® 8D, 16D

Error messages

Basic troubleshooting

Icon or error What to do?

x Distribution product water resistivity < set point.

x Verify the consumables have been replaced.

x Open the sampling valve to let water flow out for a minute.

x Low feed water pressure is detected (0.5 bar).

x Verify the feed water faucet is opened.

x Verify the feed water pressure is in specification.

x Verify the feed water pressure regulator is well adjusted or is working

properly (if installed).

x Water is detected – if leak detector installed.

x Verify if there is any water leaking from the system.

x Verify if there is any water around the water sensor.

Er:02 x Feed water temperature > 35°C.

x Verify that the feed water temperature is really greater than 35 °C. See the

feed water quality requirements to operate the system in compliance with

the manufacturer specifications.

Er:19 x Distribution auto stop timer is elapsed.

x Wait for the system to fill the tank totally. Er: 19 will disappear when tank

is full.

x Confirm that the analyzer needs 18 continuous minutes of distribution.

Er:20 x Network cable is unplugged.

x Cancel the error by pressing for more than 1 second or plug the Ethernet

cable.

Er:24 x Replace UV lamp 254 nm: the UV lamp is exhausted.

x Contact your Service Representative for replacing the UV Lamp 254 nm.

AFS® 8D, 16D 43

Chemical and technical specifications

Chemical and technical specifications

Specifications and requirements

Distribution product water specifications (CLRW)

Resistivity > 10 Mȍ.cm @ 25 °C

Conductivity < 0.1 µS/cm @ 25 °C

Total Organic Carbon (TOC) < 500 ppb

Micro organisms < 10 cfu/mL

Dissolved silica < 100 µg/L

Dispensing water flow rate to analyzer Up to 0.6 L/min for 18 min

Dispensing pressure to analyzer 1-2 bar (adjustable)

System and reservoir max length tubing 3 m (8 mm diameter tubing)

Distribution max length tubing 10 m (8 mm diameter tubing)

Dissolved gas based on measured O2 Down to approx. 3 ppm

Feed water quality requirements

Pressure 1.5 – 3 bar

Flow rate > 5 L/min at 2 bar

Type Potable

Temperature 5 – 35 °C

Conductivity 100 – 2000 µS/cm at 25 °C

pH 4- 10

Langelier Saturation Index (LSI) < 0.3

Free total chlorine < 3 ppm

Flow rates to tank

Type 3 water AFS 8D 8 L/h (can be lowered to 5.6 L/h)

Type 3 water AFS 16D 16 L/h

Water system weight

Dry weight (AFS 8D) 14 kg

Operating weight (AFS 8D) 21 kg

Dry weight (AFS 16D) 15.3 kg

Operating weight (AFS 16D) 22.2 kg

46 AFS® 8D, 16D

Chemical and technical specifications

Water system dimensions

Electrical specifications

Voltage 100-240 VAC ± 10%

Frequency 50-60 Hz ± 10%

Power consumption 200 W or 250 VA

Input 24 VDC, 8.33 A

Environmental requirements

Altitude < 2000 m

Ambient operating temperature 5 – 40 °C

Ambient storage temperature 5 – 40 °C

Installation category I

Pollution degree 2

Relative humidity during Maximum relative humidity 80% for

storage and operation temperature up to 31°C decreasing

linearly to 50% relative humidity at 40°C.

Noise level < 50 db at 1 meter

Indoor use only

AFS® 8D, 16D 47

Legal information

Legal information

Notice

The information in this document is subject to change without notice and should not be

construed as a commitment by Millipore S.A.S. Millipore S.A.S. assumes no responsibility

for any errors that might appear in this document. This manual is believed to be complete

and accurate at the time of publication. In no event shall Millipore S.A.S. be liable for

incidental or consequential damages in connection with or arising from the use of this

manual.

We manufacture and sell water purification systems designed to produce pure or ultra pure

water with specific characteristics (PS/cm, T, TOC, CFU/ml, Eu/ml) when it leaves the water

purification system provided that it’s fed with water quality within specifications, and

properly maintained as required by the supplier.

We do not warrant these systems for any specific applications. It is up to the end user to

determine if the quality of the water produced by our systems matches his expectations,

fits with norms/legal requirements and to bear responsibility resulting from the usage of

the water.

Copyright

¤ 2012 Millipore S.A.S.. Printed in France. All rights reserved. This book or parts thereof

may not be reproduced in any form without the written permission of the publishers. The

photos are non-contractual.

Trademarks

AFS, Progard, Q-Gard, Biopak, Millipak and Millitrack are registered trademarks of

Merck KGaA.

The “M” Mark is a trademark of Merck KGaA.

All other trademarks are trademarks of their respective manufacturers.

50 AFS® 8D, 16D

Legal information

Product warranty and limitation of liability

The applicable warranty and limitation of liability for the products listed in this publication

may be found at http://www.millipore.com/ec/cp3/terms within the "Terms and Conditions

of Sale" applicable to your purchase transaction.

Recycling

Directive 2002/96 EC: For European users only

The symbol “crossed bin” on a product or its packaging indicates that

the product should not be treated like household waste when

discarded. Instead the product should be disposed of at a location

that handles discarded electric or electronic equipment.

Proper disposal of equipment containing electric or electronic

components will help to reduce pollution effects to the environment

or to human health. Proper recycling of these products helps in

environmental preservation and helps to protect natural resources.

For more information about recycling of products containing electric

or electronic components, please contact your local recycling

representative or organization.

Use appropriate means for lifting and carrying.

Pay special attention to how you handle the system in order not to damage your back.

Lift by straightening your legs. Let your leg muscles, not your back muscles, do the work.

AFS® 8D, 16D 51

Item catalog numbers

Item catalog numbers

Consumables

Name Description Reference

PROGARD T2 Pre-treatment pack PR0G0T0S2

PROGARD T2 WITHOUT SILVER Pre-treatment pack PR0G0T0S2US

PROGARD T2 WITHOUT POLYPHOSPHATE Pre-treatment pack PR0G0TNP2

PROGARD T2 WITHOUT POLYPHOSPHATE

Pre-treatment pack PR0G0TNP2US

WITHOUT SILVER

Q-GARD A2 Polishing pack CP2ALLREST

SANITIZATION TABLETS Chlorine tablets (50/pack) ZWCL01F50

SANITIZATION TABLETS – US only Chlorine tablets (24/pack) 5874316024

SANITIZATION TABLETS – Canada only Chlorine tablets (24/pack) 5874316024C

RO ACID CLEANER Acid pouch (12/pack) ZWACID012

RO BASE CLEANER Base pouch (12/pack) ZWBASE012

MILLEX VENT FILTER (0.45 µm) 10L tank vent filter (10/pack) SLFH02510

PE RESERVOIR VENT FILTER SODA LIME For 30, 60, 100 PE reservoir TANKMPK01

VENT FILTER FOR SDS For SDS 200-350 ZFRE012FC

UV LAMP UV 254 nm ZLXUVLPL1

BIOPAK CLINICAL Final filter (ALP free water) CDUFBC001

MILLIPAK 100 Final filter (0.22 µm) MPGLI0ZW1

Optional consumables

Name Description Reference

PACK SUPPORT Ext. pre-treatment bracket ZFPACKSP2

PREPAK Ext. pre-treatment pack PRPK00001

PREPAK WITHOUT SILVER Ext. pre-treatment pack PRPK00001US

54 AFS® 8D, 16D

Item catalog numbers

Accessories and options

Name Description Reference

10 L PE TANK Square polyethylene reservoir TANKAFS10

PE RESERVOIR 30 Round polyethylene reservoir TANKPE030

30 L PE UNDERBENCH TANK Round under bench reservoir TANKBI030

PE RESERVOIR 60 Round polyethylene reservoir TANKPE060

PE RESERVOIR 100 Round polyethylene reservoir TANKPE100

100 L PE UNDERBENCH TANK Square under bench reservoir ZBITANK01

SDS 200 200 L SDS tank alone TANK00200

TANK CONNECTION KIT Connection kit to SDS SDSAFSCKT

TANK LEVEL SPLITTER Tank level display splitter ZSTWINLX2

AERATION PUMP KIT 230 V Air diffuser with 230 V pump ZAFS5AKIT

AERATION PUMP KIT 120 V Air diffuser with 120 V pump ZAFS6AKIT

ASM 120 V Automatic sanitization module TANKS60UV

ASM 230 V Automatic sanitization module TANKS50UV

WATER SENSOR Water leak detector ZFWATDET4

WALL MTG BRACKET System wall mounting bracket SYSTFIX01

OPTICAP WALL MTG BRACKET Final filter wall mounting bracket M0PMNTKIT

BIOPAK WALL MTG BRACKET Final filter wall mounting bracket MBPKMNKIT

MILLIPAK WALL MTG BRACKET Final filter wall mounting bracket MPKMNTKIT

ESP INSTALL KIT 8MM TUBING Sanitary sampling valve ZSSV008T1

EMERGENCY BYPASS KIT Bypass function ZBYPASSKT

SANITIZATION KIT System’s sanitization SANKIT004

Systems

Name Description Reference

AFS® 8 D Analyzer Feed System with degasser ZAFS08DWW

AFS® 16 D Analyzer Feed System with degasser ZAFS16DWW

AFS® 8D, 16D 55

AFS® 8D, 16D – FTPF12590 – V1.0 – 05/2012

Vous aimerez peut-être aussi

- AU680 AU480 OnlineSpecification Oct15-2010v8Document55 pagesAU680 AU480 OnlineSpecification Oct15-2010v8nooruzamanPas encore d'évaluation

- AU680 AU480 Instrument Online Specification Jan1-2011v9Document55 pagesAU680 AU480 Instrument Online Specification Jan1-2011v9Phat Luong100% (3)

- AU680 - AU480 Online LAN Specification - Ver.1Document94 pagesAU680 - AU480 Online LAN Specification - Ver.1gustavodlrPas encore d'évaluation

- Access Immunoassay System ManualDocument310 pagesAccess Immunoassay System ManualKaushik Bhuva100% (3)

- PROCEDURE MANUALS - (Materials and Process Specifications Manual) - (07-01)Document15 pagesPROCEDURE MANUALS - (Materials and Process Specifications Manual) - (07-01)RickyPas encore d'évaluation

- Sysmex KX21N Service Manual-SchematicDocument39 pagesSysmex KX21N Service Manual-Schematichatem mohammedPas encore d'évaluation

- Domina Plusb Premium Line Eng Rev5 OpDocument35 pagesDomina Plusb Premium Line Eng Rev5 OpSergiu Si Renata Bancos100% (1)

- Marine Hvac SystemDocument58 pagesMarine Hvac SystemSiti Aishah Hussien100% (3)

- Heat StressDocument22 pagesHeat StressnasirfahimPas encore d'évaluation

- Service Manual Tosoh Aia360Document4 pagesService Manual Tosoh Aia360OmerPas encore d'évaluation

- KX 21Document18 pagesKX 21Kang OpikPas encore d'évaluation

- Sysmex KX21N Service Manual-MaintenDocument22 pagesSysmex KX21N Service Manual-Maintenhatem mohammedPas encore d'évaluation

- Host Manual SysmexDocument30 pagesHost Manual SysmexMarité VizgarraPas encore d'évaluation

- Beckman Coulter AcT 5 Diff - Instructions For UseDocument468 pagesBeckman Coulter AcT 5 Diff - Instructions For UseHenry Velásquez0% (1)

- Cobas e 411 - Host Interface ManualDocument65 pagesCobas e 411 - Host Interface ManualMaratYakupov100% (2)

- Users Manual Elyte-1Document68 pagesUsers Manual Elyte-1tamiratPas encore d'évaluation

- DS2 Service ManualDocument320 pagesDS2 Service ManualVolodymyr100% (1)

- Bayer Clinitek - Service ManualDocument172 pagesBayer Clinitek - Service ManualAngeles Lagunes100% (2)

- Beckman Coulter ACT - Service Manual PDFDocument514 pagesBeckman Coulter ACT - Service Manual PDFKader SmailiPas encore d'évaluation

- Thermo Sorvall T3 Centrifuge - Service ManualDocument44 pagesThermo Sorvall T3 Centrifuge - Service Manualluroguita100% (1)

- Clinitek 500 (Bayer) CT 500 Service Manual PDFDocument322 pagesClinitek 500 (Bayer) CT 500 Service Manual PDFSwami Meera100% (1)

- Konelab PRIME 30 Service ManualDocument282 pagesKonelab PRIME 30 Service ManualWiener cesar RodriguezPas encore d'évaluation

- HM-325-Service Guide (01-14)Document14 pagesHM-325-Service Guide (01-14)Carlos Rea100% (1)

- XS Series E Appen 7 Installation PDFDocument101 pagesXS Series E Appen 7 Installation PDFJesusPas encore d'évaluation

- BioTechnica OperatorManualsSW21.0Document311 pagesBioTechnica OperatorManualsSW21.0Delan YusonPas encore d'évaluation

- Millipore Afs 16 Service ManualDocument2 pagesMillipore Afs 16 Service ManualMoheeb Kamal0% (5)

- ERBA XL ASTM HOST ManualDocument48 pagesERBA XL ASTM HOST ManualЯрослав Письменный100% (3)

- Chapter 1-Safety: Contraindications, Warnings, Cautions, PrecautionsDocument68 pagesChapter 1-Safety: Contraindications, Warnings, Cautions, PrecautionsLion Micheal OtitolaiyePas encore d'évaluation

- Sysmex Xs 800i Series Astm Specs PDFDocument36 pagesSysmex Xs 800i Series Astm Specs PDFArchil KapanadzePas encore d'évaluation

- Orphee Mythic 22 Hematology Analyzer - User ManualDocument99 pagesOrphee Mythic 22 Hematology Analyzer - User Manualelemenat75% (4)

- Humastar 80Document101 pagesHumastar 80Nelson Santos83% (6)

- Human Desing-Phs-Chart - Bilinmeyen PDFDocument2 pagesHuman Desing-Phs-Chart - Bilinmeyen PDFMu Tana100% (16)

- Cooling TowerDocument8 pagesCooling TowerNeal JohnsonPas encore d'évaluation

- BT3000 PLUS Service-Manual ING Rev.0-Ver.8!05!10-04Document184 pagesBT3000 PLUS Service-Manual ING Rev.0-Ver.8!05!10-04Lucas Janiares50% (2)

- DXH 600 - 800 Hardware CTSDocument52 pagesDXH 600 - 800 Hardware CTSReynaldo Macario100% (1)

- MC-600 CBC AnalyzerDocument16 pagesMC-600 CBC AnalyzerBeenish MirzaPas encore d'évaluation

- ICorr CED CT06 ApplicationOfIntumescentCoatings Issue1 PDFDocument17 pagesICorr CED CT06 ApplicationOfIntumescentCoatings Issue1 PDFJoe Gaffney100% (1)

- XP-Series ASTM Communication Specifications en Ver.1.0 (R312006)Document18 pagesXP-Series ASTM Communication Specifications en Ver.1.0 (R312006)Aron Raymond0% (1)

- Miura - Host Interface ManualDocument22 pagesMiura - Host Interface Manualgustavodlr100% (1)

- Human HumaClot Junior - Service ManualDocument28 pagesHuman HumaClot Junior - Service ManualHirabteb Arshia Co. IVD ManufacturerPas encore d'évaluation

- kx-21n SysmexDocument359 pageskx-21n SysmexAhmed Tawfik67% (3)

- Lesson Plan in Science IV (Weather On Earth PT - Kcis)Document23 pagesLesson Plan in Science IV (Weather On Earth PT - Kcis)Charm PosadasPas encore d'évaluation

- 30i - Service Manual - V1.2 PDFDocument374 pages30i - Service Manual - V1.2 PDFJulio Cesar100% (1)

- Brosur ERBA Electrolyte Analyzer Lyte Pro Plus PDFDocument2 pagesBrosur ERBA Electrolyte Analyzer Lyte Pro Plus PDFAnonymous LVTVdJG9XPas encore d'évaluation

- Vitalab LIS2-A HostDocument30 pagesVitalab LIS2-A HostRonan ColobongPas encore d'évaluation

- Biofuge Fresco 100V-120V Green EnglishDocument70 pagesBiofuge Fresco 100V-120V Green EnglishAndrew Holmes80% (5)

- ECL 412 Đông MáuDocument97 pagesECL 412 Đông MáuNguyễn Phú50% (2)

- Микропланшетная Ифа Система Evolis (Bio-rad) СиDocument472 pagesМикропланшетная Ифа Система Evolis (Bio-rad) СиОлег Васюк100% (1)

- HumaLyte Plus ServiceDocument26 pagesHumaLyte Plus ServiceAyaovi Jorlau100% (1)

- Appendix B: Technical InformationDocument11 pagesAppendix B: Technical InformationOnTa OnTa60% (5)

- Micro Lab 300 User ManualDocument2 pagesMicro Lab 300 User Manualmuhammad wajahatPas encore d'évaluation

- Guia de Mantenimiento HS200Document20 pagesGuia de Mantenimiento HS200luisoft88Pas encore d'évaluation

- Randox Interface ManualDocument32 pagesRandox Interface ManualReach Business Software Pvt LtdPas encore d'évaluation

- Ebg SVC Manual 6502 PDFDocument48 pagesEbg SVC Manual 6502 PDFNGUYEN MEDICALPas encore d'évaluation

- U120 Ultra Data Transfer Package Insert With Bluetooth Instructions 112...Document3 pagesU120 Ultra Data Transfer Package Insert With Bluetooth Instructions 112...Eddie ZambranaPas encore d'évaluation

- Wondfo BiotechDocument19 pagesWondfo Biotechhca_12Pas encore d'évaluation

- Xc-A30 Esr Service ManualDocument14 pagesXc-A30 Esr Service ManualNurlita FtmPas encore d'évaluation

- Host Communication EX-D JokohDocument7 pagesHost Communication EX-D JokohJoko Susetyo100% (1)

- Biorad PW40 PW41 Manual ENGDocument80 pagesBiorad PW40 PW41 Manual ENGLucila Figueroa Gallo100% (2)

- B - Series User's ManualDocument15 pagesB - Series User's ManualNikolay PenevPas encore d'évaluation

- Robonik - Readwell TOUCHDocument2 pagesRobonik - Readwell TOUCHRaja Mohan GopalakrishnanPas encore d'évaluation

- User Manual For PR SeriesqDocument46 pagesUser Manual For PR SeriesqTulu TvPas encore d'évaluation

- Elix Essential Manual Millipore - Water-PurificationDocument54 pagesElix Essential Manual Millipore - Water-PurificationDino Sk100% (1)

- Elix Essential - ManualDocument54 pagesElix Essential - ManualDavid LePas encore d'évaluation

- Application Notes Rudder Angle Indication System - 10... 0... 10 V Voltage Input 4189350048 UKDocument15 pagesApplication Notes Rudder Angle Indication System - 10... 0... 10 V Voltage Input 4189350048 UKSyam NairPas encore d'évaluation

- Legacy - IOM-LDS-Leak Defense 2237 2022-09-14 (Web)Document41 pagesLegacy - IOM-LDS-Leak Defense 2237 2022-09-14 (Web)ryanPas encore d'évaluation

- Pools CPD July16Document51 pagesPools CPD July16Vladimir ZaljevskiPas encore d'évaluation

- Transhorizon Radiowave PropagationDocument12 pagesTranshorizon Radiowave PropagationoldjanusPas encore d'évaluation

- Experiment 2Document5 pagesExperiment 2Muhammad Aleem nawazPas encore d'évaluation

- HOYADocument4 pagesHOYAÉva VáncsaPas encore d'évaluation

- Humidex Based Heat Response Plan FD - HumidexDocument1 pageHumidex Based Heat Response Plan FD - HumidexDevanand RamnarinePas encore d'évaluation

- RadioShack TERMOHIGROMETRO DatasheetDocument20 pagesRadioShack TERMOHIGROMETRO DatasheetKarlita Princesita Mala MalaPas encore d'évaluation

- NCERT - Class 7 Geog - GistDocument53 pagesNCERT - Class 7 Geog - GistAjith AjPas encore d'évaluation

- Balances - CatalogDocument9 pagesBalances - Catalogdéborah_rosalesPas encore d'évaluation

- Method Statement: Sikalastic®-450 (I)Document9 pagesMethod Statement: Sikalastic®-450 (I)Bhavanishankar shettyPas encore d'évaluation

- Cold Weather (CWLC, CWOC & ALIT) Student Handout, Winter 2011 - 2012 (Ed. 11, Oct2011)Document365 pagesCold Weather (CWLC, CWOC & ALIT) Student Handout, Winter 2011 - 2012 (Ed. 11, Oct2011)Sven WeißenbergerPas encore d'évaluation

- (Firemask) sq476 2465Document3 pages(Firemask) sq476 2465Rosdin IsmailPas encore d'évaluation

- Arevalo Et Al., 2018Document20 pagesArevalo Et Al., 2018Jerhine May DaquioPas encore d'évaluation

- Instruction ManualDocument35 pagesInstruction ManualmiltoncPas encore d'évaluation

- CHE531 2012-JanDocument9 pagesCHE531 2012-JanBiLL ShAmSPas encore d'évaluation

- L. Cowell, 2019Document27 pagesL. Cowell, 2019Dika FaujiPas encore d'évaluation

- Cargo Ventilation and Precautions To Minimise SweatDocument5 pagesCargo Ventilation and Precautions To Minimise SweatAysun GençcanPas encore d'évaluation

- Weather Study Guide Earth ScienceDocument11 pagesWeather Study Guide Earth Sciencefailures12Pas encore d'évaluation

- C512 Manual PDFDocument93 pagesC512 Manual PDFreinaldoPas encore d'évaluation

- Ria Final ChaitanyaDocument10 pagesRia Final ChaitanyaChaitanya WalkePas encore d'évaluation

- Thermal Comfort: What Affects Thermal Indoor Environment?Document6 pagesThermal Comfort: What Affects Thermal Indoor Environment?Pitz Shady ShinPas encore d'évaluation

- Mass Transfer Questions and Answers - Drying-Rate of Batch DryingDocument1 pageMass Transfer Questions and Answers - Drying-Rate of Batch Dryingmaduu bongsPas encore d'évaluation

- ChE ReviewerDocument82 pagesChE ReviewerKristinePas encore d'évaluation