Académique Documents

Professionnel Documents

Culture Documents

Concrete

Transféré par

Monica PresiliaCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Concrete

Transféré par

Monica PresiliaDroits d'auteur :

Formats disponibles

CONCRETE

History

The word concrete comes from the Latin word "concretus" Which means

compact or condensed.

German archaeologist Heinrich Schliemann found concrete floors, which

were made of lime and pebbles, in the royal palace of Tiryns, Greece, which

dates roughly to 1400-1200 BC.

Intoduction

Definition of Concrete

Concrete is a composite material in which a binding material mixed in

water on solidification binds the inert particles of well graded fine and coarse

aggregates.

Cement and lime are generally used as binding materials, whereas sand

cinder is used as fine aggregates and crushed stones, gravel, broken bricks,

clinkers are used as coarse aggregates.

Freshly prepared concrete till it has not yet set is called wet or green

concrete. After it has thoroughly set and fully hardened it is called set concrete or

just concrete.

Types of Concrete and Its Uses

Concrete are classified into different types:

1. According to binding material used in concrete.

2. According to design of concrete.

3. According to purpose of concrete.

(1)

CLASSIFICATION ACCORDING TO BINDING MATERIAL:

According to binding material used concrete are classified into two types.

Cement concrete (2) lime concrete.

CEMENT CONCRETE

The concrete consisting of cement, sand and coarse aggregates mixed in

a suitable proportions in addition to water is called cement concrete. In this type

of concrete cement is used as a binding material, sand as fine aggregates and

gravel, crushed stones as coarse aggregates.

In cement concrete useful proportions of its ingredients are

1 part cement:1-8 part sand:2-16 parts coarse aggregates.

USES :

cement concrete is commonly used in buildings and other important

engineering works where strength and durability is of prime importance.

LIME CONCRETE

The concrete consisting of lime, fine aggregates, and coarse aggregates

mixed in a suitable proportions with water is called lime concrete.

In this type of concrete hydraulic lime is generally used as a binding

material, sand and cinder are used as fine aggregates and broken bricks, gravel

can be used as coarse aggregates.

PLACING OF LIME CONCRETE :

Placing of concrete shall be completed within three hours of adding water

in case of concrete is prepared with hydraulic lime.

Concrete should be well cured for a period of at least 10 days.

USES:

Lime concrete is generally used for the sake of economy in foundation

works, under floors, over roof and where cement is not cheaply and easily

available in required quantity.

CLASSIFICATION ACCORDING TO DESIGN OF CONCRETE

(1) Plain cement concrete.

(2) Reinforced cement concrete(RCC).

(3) Pre-stressed cement concrete(PCC).

PLAIN CEMENT CONCRETE

The cement concrete in which no reinforcement is provided is called plain

cement concrete or mass cement concrete.

This type of concrete is strong in taking compressive stresses but weak in

taking tensile stresses.

USES:

Plain cement concrete is commonly used in for foundation work and

flooring of buildings.

REINFORCED CEMENT CONCRETE(RCC)

The cement concrete in which reinforcement is embedded for taking

tensile stress is called reinforced cement concrete.

In this type of concrete the steel reinforcement is to be used generally in

the form of round bars,6mm to 32mm dia. This concrete is equally strong in

taking tensile, compressive and shear stresses. Usual proportions of ingredients

in a reinforced concrete are 1part of cement:1-2parts of sand:2-4parts of crushed

stones or gravel.

USES:

RCC is commonly used for construction of slabs, beams, columns,

foundation, precast concrete.

PRE-STRESSED CEMENT CONCRETE (PCC)

The cement concrete in which high compressive stresses are

artificially induced before their actual use is called pre-stresses cement concrete.

in this type of cement concrete, the high compressive stresses are

induced by pre-tensioning the reinforcement before placing the concrete, and the

reinforcement is released when final setting of the concrete take place.

USES :

This concrete can take up high tensile and compressive stresses without

development of cracks. The quantity of reinforcement can be considerably

reduced by using this concrete.

CLASSIFICATION ACCORDING TO PURPOSE

According to purpose concrete is classified into following types.

Vacuum concrete:

The cement concrete from which entrained air and excess water is

removed after placing it, by suction with the help of vacuum pump is called

vacuum concrete.

In this concrete the excess water which is added to increase

workability but not required for the hydration of cement of concrete is removed by

forming vacuum chamber

Air entrained concrete

The concrete prepared by mixing aluminum in it is called air entrained

,cellular or aerated concrete. In this concrete bubbles of hydrogen gas are

liberated which forms cell and make the concrete cellular.

USES: This concrete is used for lining walls and roofs for heat and sound

insulation purpose.

Light weight concrete

The concrete prepared by using coke breeze, cinder or slag as

coarse aggregate is called light weight concrete. The concrete is light in weight

and posses heat insulating properties.

USES :

This concrete is used in making precast structural units for partition

and wall lining.

QUALITIES OF GOOD CONCRETE

STRENGTH: The concrete should be able to withstand the stresses that it is

subjected to. It is quite strong in compression but weak in tension.

DURABILITY: It should be durable enough to resist the effect of weathering

agents.

DENSITY: the concrete should be well compacted so that there are no voids or

hollows left.

WATER TIGHTNESS: when used for construction of water retaining structures

such as dams, elevated tanks and water reservoirs then this property of concrete

becomes very important. Otherwise the moisture inside the RCC would corrode

steel and leakage would start resulting in the ultimate failure of the structure.

WORKABILITY: It should be easily workable.

RESISTANCE TO WEAR AND TEAR: when used in floors and in the

construction of roads the concrete should be able to withstand abrasive forces.

Curing of Concrete

The process of keeping concrete wet to enable it to attain full strength is

known as curing.

The objective of curing is to prevent loss of moisture from concrete due

to evaporation or because of any other reasons.

Curing should be done for a period of three weeks but not less then 10

days.

To do curing, any one of the following method can be used:

The surface of concrete is coated with a layer of bitumen or similar other

waterproofing compound which gets into the pores of concrete and prevent loss

of water from concrete.

Concrete surface is covered with waterproof paper or with a layer of wet

sand. It could also be covered with gunny bags.

Advantages and Disadvantages

As a construction material Concrete has the following

The advantages:

1. Concrete can handle the compression stresses 10 times more than the tension

and the most of loads in our life is compression.

2. Concrete is a britile material which gives the advantage to make a rigid

structure.

3. Easy to handle over specially now there is plants that give you ready mix

concrete.

The disadvantages:

1. Concrete is weak in handling tension.

2. Because concrete is a britile material the strength upon shear (specially at 45

degress) must be checked.

3. Needs another material to reinforce it against excessive shear and tension

Vous aimerez peut-être aussi

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Welding TechnologyDocument26 pagesWelding TechnologyHiren Kumar100% (1)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Fabric Inspection Under 4Document5 pagesFabric Inspection Under 4texcons677150% (2)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Structural Material, Electronic CeramicsDocument22 pagesStructural Material, Electronic CeramicschuotkimhyPas encore d'évaluation

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- Bondek User GuideDocument0 pageBondek User GuidemarioxguzmanPas encore d'évaluation

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- Expt 3Document5 pagesExpt 3Debmalya1997Pas encore d'évaluation

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- H4 Pipe Friction GroupDocument31 pagesH4 Pipe Friction GroupYash PersÌePas encore d'évaluation

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (400)

- Design Concrete SleepersDocument16 pagesDesign Concrete SleepersOky Andytya Pratama100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- Seamless VS Welded TubesDocument1 pageSeamless VS Welded Tubeshirenkumar patelPas encore d'évaluation

- MB C Klasse Maintenance BookletDocument116 pagesMB C Klasse Maintenance BookletAlex BereanuPas encore d'évaluation

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- Astm A689 PDFDocument4 pagesAstm A689 PDFpradellesPas encore d'évaluation

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Sea Water Intake SystemDocument17 pagesSea Water Intake SystemJayne Mawusi Siaw-Botchway100% (1)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- Technical Specifications For 132 KV LineDocument214 pagesTechnical Specifications For 132 KV LineHemant Kumar Sharma80% (10)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

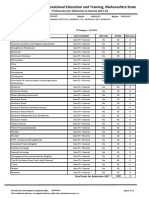

- DVET Amravati Govt ITIDocument32 pagesDVET Amravati Govt ITIVaibhav KalePas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (74)

- InsulationDocument63 pagesInsulationSH1961Pas encore d'évaluation

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (345)

- Arvedi Brief Presentation Modernisation ProgrammeDocument30 pagesArvedi Brief Presentation Modernisation ProgrammeKetnipha SukwannawitPas encore d'évaluation

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- Effects of Alloying Elements On SteelDocument2 pagesEffects of Alloying Elements On SteelKISHORPas encore d'évaluation

- Samsung Fridge Manual PDFDocument0 pageSamsung Fridge Manual PDFKuldeep DidwaniaPas encore d'évaluation

- 24 - 25 PF Furnace'12Document5 pages24 - 25 PF Furnace'12DSGPas encore d'évaluation

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Tape WrappingDocument8 pagesTape WrappingwalitedisonPas encore d'évaluation

- Cryoseal: Liquid Nitrogen Containers (Dewars) : Also Available 340/550 Liters Bulk Storage ContainersDocument2 pagesCryoseal: Liquid Nitrogen Containers (Dewars) : Also Available 340/550 Liters Bulk Storage ContainersDr. Awanish MishraPas encore d'évaluation

- Gambar ValveDocument28 pagesGambar ValveIrfan FahmiPas encore d'évaluation

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- T-4.896.425 - C01 - MS ITP For Hot Cold Insulation WorksDocument20 pagesT-4.896.425 - C01 - MS ITP For Hot Cold Insulation Worksshahid imamPas encore d'évaluation

- Kitchen: Library Study MM School of ArchitectureDocument1 pageKitchen: Library Study MM School of ArchitectureAteeq RaoPas encore d'évaluation

- Ueg 36Document2 pagesUeg 36PRADO_COMETA50% (2)

- FP 238Document32 pagesFP 238Mahmoud Atia100% (2)

- Bomba Gardner Denver TeeDocument56 pagesBomba Gardner Denver Teejulioramca100% (2)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (121)

- NSL Monobl EngDocument27 pagesNSL Monobl EngLuis Quintana GodoyPas encore d'évaluation

- Tile WorksDocument5 pagesTile WorksglenPas encore d'évaluation

- PP H2222 36Document2 pagesPP H2222 36keyur1109Pas encore d'évaluation

- Supercharging and TurbochargingDocument23 pagesSupercharging and TurbochargingTrain Placement CellPas encore d'évaluation

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)