Académique Documents

Professionnel Documents

Culture Documents

Well Test

Transféré par

jijinjohnTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Well Test

Transféré par

jijinjohnDroits d'auteur :

Formats disponibles

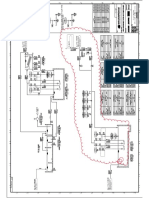

Equipment Sales

Surface Well Test Equipment

As a major supplier of well testing equipments, Expro provides a range of systems suited to specific

testing environments and has a proven track record. Expro well testing equipment allows easy expansion

of modules to handle future increasing and changing process conditions.

The pressure control is handled through an upstream Test Tree, ESD Valve,

Data Headers, Choke manifold, HP pipework. Inlet and outlet Data

Headers allow the safe monitoring of high pressure

process conditions.

GAS LINE

OIL LINE

WATER LINE

REMOTE

ESD STATIONS

3 PHASE TEST SEPARATOR

AIR LINE

HEAT EXCHANGER

SURGE TANK

The process stream, once choked

down through the choke

manifold, passes through a

heat exchange designed to

raise the temperature of the

process

fluids

for

better

downstream separation.

STEAM GENERATOR

TWIN POT SAND

FILTER ASSEMBLY

CHOKE MANIFOLD

FILL LINE

FROM RIG PUMP

RELIEF VALVE

TRANSFER PUMP

OIL

DIVERTER MANIFOLD

BURNER HEADS

SURFACE TEST TREE

HYD CONTROL PANEL

AIR COMPRESSORS

The test process stream continues on to the test

separator, allowing the individual testing of wells for monitoring

production rates.

SURFACE

SAFETY VALVE

SAFE

SWIVEL ASSEMBLY

DATA

HEADER

PROPANE RACKS

CHECK VALVE

SURFACE

TEST TREE

REMOTE

ESD STATIONS

REMOTE

ESD STATIONS

BURNER BOOMS

SURFACE

HYD CONTROL PANEL

AIR COMPRESSORS

SUBSEA HYD

CONTROL PANEL

SAFE

TUBING

SAFETY VALVE

SAFE

LUBRICATOR

VALVE

PROPANE RACKS

GAS DIVERTER

MANIFOLD

BURNER BOOMS

BURNER HEADS

Safety systems consist of a closed loop ESD system providing manual and

automatic safety shut-down. This is in addition to the relief valve and rupture disks integrated

into the process equipment.

Real-time monitoring of process conditions is handled by the Expro Edge X Data Acquisition

system which monitors separated process streams and process temperature, and pressure at

critical points.

SAFE

RETAINER VALVE

SAFE HUB SEA TEST TREE

Equipment Benefits:

Dual fisher oil level control valve

Special internals with high efficiency 99% for 10 micron and larger

Proven design used Internationally for many years

Drip pans under major equipment with drain connections

Offshore paint specification for durable life

BV and Lloyds third party certification

Easy operator access to instrumentation on equipment

High and low level switches on separator to work with ESD System

High pressure switch on steam heater shell to work with ESD System

exprogroup.com

Equipment Sales

Surface Well Test Equipment

Expro's horizontal, three-phase Test Separator has automated controls on gas pressure, gas/oil and

oil/water interfaces, mounted on an oilfield structural steel skid with drip pan, crash frame and threecoat, offshore type paint system, rated for sour (H2S) service. The unit is fully manifolded for complete

flexibility of operation, including bypassing and/or co-mingling oil, gas or water. The Test Separator is

designed with a removable crash frame which reduces the overall weight of the unit for carnage.

There are many different sizes and configurations of Expro's test separator to meet varying requirement.

Steam Heater

The Expro steam heater offers a high-efficiency heat transfer with a small foot print. The steam heater

is mounted on a sturdy, oilfield-type skid with a lifting/crash frame enclosure. Heat transfer is

accomplished by applying superheated steam directly to the high-pressure upstream pre-heat

process tube bundle with a full opening two-inch adjustable choke separating the low-pressure

downstream post-heat process tube bundle. The tubes are sealed in an ASME vessel set with

automated steam process controls for both temperature and pressure control. Steam condensate is

directed to a steam trap for recycling back to the steam generator.

The steam heater comes with a high-pressure diverter (by-pass) manifold on the inlet to the outlet for bypassing the tube bundles. Safety

systems in this type of heater include a relief-valve and rupture-disc located on the heater vessel, and a fail-safe temperature control device.

A high-pressure pilot monitoring the vessel pressure is available for interfacing with an Expro ESD system.

The steam heater is built in accordance with Expro Equipment Sales Engineering Standards and Practices which meets or exceeds most

International standards and codes, and is offered with third party Independent Design Review Certification and fabrication Certificate of

Conformance.

Multi Sensor Relief Valve (MSRV)

The MSRV is a rapid acting relief valve without the limitations of existing safety valves, allowing a greater

flexibility in safety system design. In an over-pressure situation the MSRV will respond through utilization

of its safety logic and protect the whole system. Its ball valve design is hydraulically actuated by well

pressure from primary sensor points. These points constantly monitor the process pressure, and when

it exceeds a pre-determined value, the rupture disc inside the sensor point ruptures and the respective

impulse line is energized thus opening the valve. Once actuated, the MSRV will remain open until

pressure is applied to the respective closure.

The MSRV is typically installed between the choke manifold and the heater. The purpose is to protect

the heater tube bundle from over pressure if the upstream choke cuts out due to sand erosion etc.

The MSRV has the following advantages over a conventional relief valve:

High relief capacity

Insensitive to system back pressure

Positive acting with no simmering or chattering

Accurate set point pressure

Extreme high pressure integrity

Four impulse port multi sensor facility

Multi operable capability

ESD control logic

exprogroup.com

Expro International Group LTD

EquipmentSales 29032010_v1

Vous aimerez peut-être aussi

- Exploration and Appraisal Well Testing Delivering The Complete PackageDocument16 pagesExploration and Appraisal Well Testing Delivering The Complete Packagerahul84803Pas encore d'évaluation

- Prevention of Actuator Emissions in the Oil and Gas IndustryD'EverandPrevention of Actuator Emissions in the Oil and Gas IndustryPas encore d'évaluation

- Appendix 7 - Wellsite Well Test Equipment Preparation ChecklistDocument6 pagesAppendix 7 - Wellsite Well Test Equipment Preparation Checklistsergiopuyo9184100% (3)

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!D'EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Évaluation : 5 sur 5 étoiles5/5 (2)

- Well Test ProgramDocument24 pagesWell Test ProgramLaw100% (1)

- Microbial Enhancement of Oil Recovery - Recent AdvancesD'EverandMicrobial Enhancement of Oil Recovery - Recent AdvancesPas encore d'évaluation

- Separator GeneralDocument12 pagesSeparator GeneralMeshariAlEnezi100% (1)

- Site Safety Handbook for the Petroleum IndustryD'EverandSite Safety Handbook for the Petroleum IndustryÉvaluation : 5 sur 5 étoiles5/5 (1)

- Well IntegrityDocument17 pagesWell Integritymustafaelsaid21Pas encore d'évaluation

- Well Testing Project Management: Onshore and Offshore OperationsD'EverandWell Testing Project Management: Onshore and Offshore OperationsPas encore d'évaluation

- Production Logging Tools and InterpretationsDocument34 pagesProduction Logging Tools and InterpretationsRizwan FaridPas encore d'évaluation

- Underground Gas Storage Facilities: Design and ImplementationD'EverandUnderground Gas Storage Facilities: Design and ImplementationPas encore d'évaluation

- Christmas TreeDocument11 pagesChristmas TreezaideidPas encore d'évaluation

- At The Heart of Halliburton Is Well TestingDocument9 pagesAt The Heart of Halliburton Is Well TestingYasir Ahmed100% (1)

- Lecture 2A Well Head EquipmentDocument25 pagesLecture 2A Well Head Equipmentnitesh kumarPas encore d'évaluation

- Well Integrity for Workovers and RecompletionsD'EverandWell Integrity for Workovers and RecompletionsÉvaluation : 5 sur 5 étoiles5/5 (3)

- Well Testing ProjectDocument24 pagesWell Testing ProjectLuis Abdul-MelendezPas encore d'évaluation

- Common Well Control Hazards: Identification and CountermeasuresD'EverandCommon Well Control Hazards: Identification and CountermeasuresÉvaluation : 4.5 sur 5 étoiles4.5/5 (4)

- Sr. Well Test OperatorDocument4 pagesSr. Well Test Operatorjohn MPas encore d'évaluation

- Advanced Water Injection for Low Permeability Reservoirs: Theory and PracticeD'EverandAdvanced Water Injection for Low Permeability Reservoirs: Theory and PracticeÉvaluation : 4 sur 5 étoiles4/5 (2)

- 02 - Testing & Drilling IntroDocument39 pages02 - Testing & Drilling Introibson045001256100% (1)

- Fluid Phase Behavior for Conventional and Unconventional Oil and Gas ReservoirsD'EverandFluid Phase Behavior for Conventional and Unconventional Oil and Gas ReservoirsÉvaluation : 5 sur 5 étoiles5/5 (2)

- Drilling Waste Management and Control The Effects 2090 4568 1000166Document9 pagesDrilling Waste Management and Control The Effects 2090 4568 1000166Mateo MrsPas encore d'évaluation

- Gas Well Deliquification: Solutions to Gas Well Liquid Loading ProblemsD'EverandGas Well Deliquification: Solutions to Gas Well Liquid Loading ProblemsPas encore d'évaluation

- IWOCS SMS Intervention and Workover Control Systems DatasheetDocument1 pageIWOCS SMS Intervention and Workover Control Systems DatasheetPedro DutraPas encore d'évaluation

- Senior Pump Operator: Passbooks Study GuideD'EverandSenior Pump Operator: Passbooks Study GuidePas encore d'évaluation

- Dider-1 Well Test Program, DraftDocument30 pagesDider-1 Well Test Program, DraftOghale B. E. Omuabor0% (1)

- Production Operator CVDocument5 pagesProduction Operator CVramdpcPas encore d'évaluation

- Natural Gas: Operations and Transport: A Handbook for Students of the Natural Gas IndustryD'EverandNatural Gas: Operations and Transport: A Handbook for Students of the Natural Gas IndustryPas encore d'évaluation

- SPE Certification Exam 2014 PDFDocument1 pageSPE Certification Exam 2014 PDFMarcelo VeronezPas encore d'évaluation

- Offshore Gas Hydrates: Origins, Development, and ProductionD'EverandOffshore Gas Hydrates: Origins, Development, and ProductionPas encore d'évaluation

- Flow AssuranceDocument7 pagesFlow AssuranceMubarik AliPas encore d'évaluation

- Facilities 1Document9 pagesFacilities 1Prem NagappanpillaiPas encore d'évaluation

- Oil Gas Separators Internals ChemSepTDocument6 pagesOil Gas Separators Internals ChemSepTAnonymous bHh1L1Pas encore d'évaluation

- Working Guide to Drilling Equipment and OperationsD'EverandWorking Guide to Drilling Equipment and OperationsÉvaluation : 5 sur 5 étoiles5/5 (9)

- D-002 System Requirements Well Intervention EquipmentDocument70 pagesD-002 System Requirements Well Intervention Equipmentbrucce13Pas encore d'évaluation

- Integrated Sand Management For Effective Hydrocarbon Flow AssuranceD'EverandIntegrated Sand Management For Effective Hydrocarbon Flow AssurancePas encore d'évaluation

- Well Test Tools - PPTDocument46 pagesWell Test Tools - PPTkartikeyPas encore d'évaluation

- Inspection Sheet Well Control Equipment V3 - HCUDocument4 pagesInspection Sheet Well Control Equipment V3 - HCUeng7mohamed7hashimPas encore d'évaluation

- Carbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyD'EverandCarbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyPas encore d'évaluation

- Drilling Rig Components Illustration - Komponen Utama PemboranDocument86 pagesDrilling Rig Components Illustration - Komponen Utama PemboranPuji LestariPas encore d'évaluation

- Measurement While Drilling: Signal Analysis, Optimization and DesignD'EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignPas encore d'évaluation

- Well Testing General GuidelinesDocument8 pagesWell Testing General GuidelinesAnugrah FadhlanPas encore d'évaluation

- Hydrostatic and Hydro-Testing in the Oil and Gas FieldD'EverandHydrostatic and Hydro-Testing in the Oil and Gas FieldÉvaluation : 3 sur 5 étoiles3/5 (2)

- Gas Lift Design With Self-Well GasDocument12 pagesGas Lift Design With Self-Well GasMohanad HussienPas encore d'évaluation

- Well Test SetupDocument54 pagesWell Test SetupADNANPas encore d'évaluation

- Pvtsim Technical Overview 2016 Download v3Document16 pagesPvtsim Technical Overview 2016 Download v3Jorge Vásquez CarreñoPas encore d'évaluation

- Assignment-01: Petroleum EngineeringDocument7 pagesAssignment-01: Petroleum Engineeringomair babarPas encore d'évaluation

- Vel PBV WebDocument6 pagesVel PBV WebjijinjohnPas encore d'évaluation

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsD'EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsPas encore d'évaluation

- Geothermal Pipe Line DesignDocument15 pagesGeothermal Pipe Line DesignjohnjuantamadPas encore d'évaluation

- CDN Probuilt Design ManualDocument35 pagesCDN Probuilt Design ManualjijinjohnPas encore d'évaluation

- Filtration Master CatalogDocument156 pagesFiltration Master Catalogharshal161987Pas encore d'évaluation

- Vel VTP WebDocument6 pagesVel VTP WebjijinjohnPas encore d'évaluation

- WCE4459Document12 pagesWCE4459jijinjohnPas encore d'évaluation

- Broadway Hilti Handrail Base PDFDocument4 pagesBroadway Hilti Handrail Base PDFjijinjohnPas encore d'évaluation

- cd-1400 Centrifugal D-Gasser PDFDocument2 pagescd-1400 Centrifugal D-Gasser PDFjijinjohnPas encore d'évaluation

- Topic - Connections - Typical Joints PDFDocument56 pagesTopic - Connections - Typical Joints PDFKanako NozawaPas encore d'évaluation

- Placa de OrificioDocument74 pagesPlaca de OrificioAriely Menacho MontenegroPas encore d'évaluation

- PR Over Tanks 41Document5 pagesPR Over Tanks 41jijinjohnPas encore d'évaluation

- Balustrade SolutionsDocument80 pagesBalustrade SolutionsariyarathnePas encore d'évaluation

- Type ChartDocument4 pagesType Chartمحمد فطري فيك نظامPas encore d'évaluation

- ARE YOU PROPERLY SPECIFYING MATERIALS? 1 of 3Document4 pagesARE YOU PROPERLY SPECIFYING MATERIALS? 1 of 3vPas encore d'évaluation

- ISO Freight 06Document2 pagesISO Freight 06jijinjohnPas encore d'évaluation

- Horizontal D GasserDocument2 pagesHorizontal D GasserjijinjohnPas encore d'évaluation

- Geometrical Tolerancing On Technical Drawings: IS: 8000 (Part IV) - 1976Document7 pagesGeometrical Tolerancing On Technical Drawings: IS: 8000 (Part IV) - 1976jijinjohnPas encore d'évaluation

- Indian Standard: Technical Drawings - Geometrical TolerancingDocument24 pagesIndian Standard: Technical Drawings - Geometrical TolerancingjijinjohnPas encore d'évaluation

- Ajax Rivets HandbookDocument15 pagesAjax Rivets HandbooknextreaderPas encore d'évaluation

- Well Test PDFDocument2 pagesWell Test PDFjijinjohnPas encore d'évaluation

- 8000 1Document28 pages8000 1jijinjohnPas encore d'évaluation

- Seismic Code RequirementsDocument34 pagesSeismic Code Requirementsronison78Pas encore d'évaluation

- ISO Freight 06Document2 pagesISO Freight 06jijinjohnPas encore d'évaluation

- AD00839V Butterfly Valves Broch - LRDocument44 pagesAD00839V Butterfly Valves Broch - LRMaulia SabrinaPas encore d'évaluation

- A-Lok & Cpi Fittings PDFDocument84 pagesA-Lok & Cpi Fittings PDFjijinjohnPas encore d'évaluation

- Barton RecorderDocument40 pagesBarton Recordersbirawan11100% (2)

- Thornhill Craver Operations ManualDocument3 pagesThornhill Craver Operations ManualjijinjohnPas encore d'évaluation

- Thornhill Craver Operations ManualDocument3 pagesThornhill Craver Operations ManualjijinjohnPas encore d'évaluation

- Seismic Code RequirementsDocument34 pagesSeismic Code Requirementsronison78Pas encore d'évaluation

- Vane Pump (Denison)Document28 pagesVane Pump (Denison)Francisco ArayaPas encore d'évaluation

- GA 75 VSD AP CAGI SheetDocument1 pageGA 75 VSD AP CAGI SheetWil MontoPas encore d'évaluation

- Non Conventional SyllabusDocument1 pageNon Conventional SyllabusRohit SahuPas encore d'évaluation

- Automatic Fire Sprinkler CalcualtionDocument2 pagesAutomatic Fire Sprinkler CalcualtionKyaw HtayPas encore d'évaluation

- RX RVRDocument7 pagesRX RVRpcatruongPas encore d'évaluation

- Ethylene Plant 350 000 Tpy 2242Document1 pageEthylene Plant 350 000 Tpy 2242xtrooz abiPas encore d'évaluation

- Lab Week 5 Ecw341 (Turbine Performance and Pump Effiency)Document8 pagesLab Week 5 Ecw341 (Turbine Performance and Pump Effiency)Muhammad IrfanPas encore d'évaluation

- Selected Reference Material United StateDocument1 103 pagesSelected Reference Material United StatehaibhPas encore d'évaluation

- Fan EquipmentDocument16 pagesFan Equipmentpenglei jiPas encore d'évaluation

- Sunflower Solar RooftopDocument12 pagesSunflower Solar RooftopTejas ValaPas encore d'évaluation

- Auxiliary Units of CompressorDocument5 pagesAuxiliary Units of CompressoriaftPas encore d'évaluation

- Brochure TM EngDocument20 pagesBrochure TM EngCCPas encore d'évaluation

- Production WellDocument2 pagesProduction WellRenard JaenPas encore d'évaluation

- Fluid MachineriesDocument20 pagesFluid MachineriesgenondevinegracePas encore d'évaluation

- AFRC - Improving Performance of Coker HeatersDocument29 pagesAFRC - Improving Performance of Coker Heatersashutosh_garg_10Pas encore d'évaluation

- Trina Solar Honey M TSM De08m 08 360 385w Scheda Tecnica Moduli Fotovoltaici MonocristalliniDocument2 pagesTrina Solar Honey M TSM De08m 08 360 385w Scheda Tecnica Moduli Fotovoltaici MonocristalliniFrengo6388Pas encore d'évaluation

- Carrier VRF PDFDocument12 pagesCarrier VRF PDFThếSơnNguyễnPas encore d'évaluation

- KKS Code DescriptionDocument31 pagesKKS Code DescriptionAmal Chinthaka100% (3)

- Us9366187 PDFDocument12 pagesUs9366187 PDFFernando TaleroPas encore d'évaluation

- Refrigeration Comp. LinkedDocument6 pagesRefrigeration Comp. LinkedDin TescoPas encore d'évaluation

- Geothermal Drilling Problems 1649188331Document10 pagesGeothermal Drilling Problems 1649188331Abdulaziz QasimPas encore d'évaluation

- Renewable Energy Planning Database: Table HeadingsDocument29 pagesRenewable Energy Planning Database: Table HeadingsShashank VijayvergiaPas encore d'évaluation

- Hybrid SystemDocument8 pagesHybrid SystempriyadarshniPas encore d'évaluation

- GREET Update For H2 Tab For SMR PathwayDocument7 pagesGREET Update For H2 Tab For SMR PathwaySergioPas encore d'évaluation

- ArsonDocument25 pagesArsonapi-292042538Pas encore d'évaluation

- Dae AnnDocument290 pagesDae AnnTICKER PORTPas encore d'évaluation

- 61 TOP MOST Hydraulic Machines - Mechanical Engineering Multiple Choice Questions and Answers Mechanical Engineering Multiple Choice QuestionsDocument9 pages61 TOP MOST Hydraulic Machines - Mechanical Engineering Multiple Choice Questions and Answers Mechanical Engineering Multiple Choice QuestionsArpitRanderiaPas encore d'évaluation

- P&ID - Effulent Pump Line To Seal Pit DrawingDocument1 pageP&ID - Effulent Pump Line To Seal Pit DrawingAnish BalaguruPas encore d'évaluation

- Adiabatic Compressed Air Energy Storage For Electricity SupplyDocument12 pagesAdiabatic Compressed Air Energy Storage For Electricity SupplysutardiPas encore d'évaluation

- Technology and Economics of Modern Biogas EnginesDocument36 pagesTechnology and Economics of Modern Biogas EnginesnguyenbmtsvPas encore d'évaluation