Académique Documents

Professionnel Documents

Culture Documents

Fresh Ideas Growing: Case Story: Horizontal Modeling

Transféré par

RML0 évaluation0% ont trouvé ce document utile (0 vote)

12 vues2 pagesHorizontal Modelling

Titre original

t2167-360-01_Overheads_FR

Copyright

© © All Rights Reserved

Formats disponibles

PDF, TXT ou lisez en ligne sur Scribd

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentHorizontal Modelling

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

0 évaluation0% ont trouvé ce document utile (0 vote)

12 vues2 pagesFresh Ideas Growing: Case Story: Horizontal Modeling

Transféré par

RMLHorizontal Modelling

Droits d'auteur :

© All Rights Reserved

Formats disponibles

Téléchargez comme PDF, TXT ou lisez en ligne sur Scribd

Vous êtes sur la page 1sur 2

Case Story:

Horizontal Modeling

Fresh Ideas Growing

Delphi Technologies, Inc.

Driving Down Design Costs

Now, HM is proven, its patented, and it has

For decades, Delphis Saginaw Steering Systems

dramatically reduced the time and cost of

Division has been widely recognized as one of the

designing products.

worlds most modernized, well-equipped, and

efficient manufacturer of steering technology.

A New Vehicle for Design

Automotive customers General Motors, Ford,

Before HM, Delphi used the traditional method of

Toyota, and a host of others all appreciated the

feature-based modeling to create a part. Features

groups technology leadership and responsiveness.

were built on top of one another, in a vertical

hierarchy. So one feature such as a hole was

But Ron Andrews, a senior product designer,

associated with another feature, creating many

wanted more. He saw inefficiency in the way they

parent/child relationships between the features.

used their CAD software for designing steering

system parts. The software let Andrews create

The problem was that, because of these

precise 3D models of a part, but making changes

parent/child dependencies, simple changes to any

to these models such as reordering, removing,

or all of the features were usually very

or adding features was far too time-consuming.

complicated and often altogether impossible.

Product designers were often forced to dismantle

In the past, says Andrews, our design group

or completely recreate a model in order to make

might be designing a plastic reservoir for a power

a change.

steering pump and had to remove a flange.

Making this simple change took a full days work.

This is still the method endorsed and taught by

We had to move backwards through the model,

most 3D CAD software vendors. We call it the

menu by menu, feature by feature. Thats because

hack and whack method of changing models,

features were built on other features, so changing

says Andrews. You have to hack and whack your

one affected others. To make matters worse, we

way through the menus to see which features are

often destroyed half or most of the model in

related to each other.

the process.

So Ron and his colleagues took on a new

challenge: finding a better way to design parts so

that they could be more easily modified.

The team succeeded in inventing a radically

different CAD modeling approach a simple,

elegant, new methodology called Horizontal

ModelingTM (HM).

The team wanted to continue using their current

CAD software but had to eliminate the hacking

and whacking. So they decided to change the

paradigm to look beyond the standard

techniques for using their CAD software. The

result was Horizontal Modeling.

Horizontal Modeling Offers

Significant Benefits

Shortens lead, cycle, release, and

to-market times

Decreases staff requirements and

ramp-up time

With HM, designers can capture design intent

Increases available resources and flexibility

without creating parent/child feature

dependencies. HM enables rapid changes to any

and all features in the model without the

HM Becomes a Great Success

need for arduous dismantling and rebuilding of

Horizontal Modeling is a huge success. Its a

the design.

method of designing products that Andrews and

his colleagues could only have dreamed of just a

few years ago.

Old vs. New:

A Head-to-Head Comparison

The team realized that for HM to be fully

HM now plays a key strategic role at Delphi,

appreciated and supported, they needed some

improving total design productivity by 35%,

credible, verifiable proof that it worked and

enabling many more projects without adding

provided significant business benefits

resources, and increasing innovation. HM is

for Delphi.

now in production use at 14 Delphi and partner

sites worldwide.

They asked 70 Delphi product designers to use

HM to create a new part that was nearly identical

Looking back, Andrews says, Essentially we

to one they had created in the past. The goal was

went from an inflexible, time-consuming approach

to compare the total time spent using HM versus

to a quicker, more automated one. And it paid off

the traditional method.

in a big way.

They found that with HM, Delphi product

For More Information

designers spent 20% less time creating models

Delphi Technologies, Inc., a subsidiary of Delphi

and 65% less time editing models.

Corporation (NYSE:DPH), is sharing Delphis

CAD/CAM methodologies with other

Product

Productivity

Design Activity

Improvement

CAD Operator Functions

Using HM & DPD

~70 CAD Operators

(% of total time spent)

Create Models

20%

Detail Drawings 30%

Edit Models

50%

(% of total time spent)

20% Reduction

65% Reduction

manufacturers through licensing and training

arrangements. For more information, please visit

www.delphi.com/dti or contact Jeffrey Solash

using the information below:

Jeffrey Solash, Ph.D.

Licensing Executive

Delphi Technologies, Inc.

jeffrey.solash@delphi.com

office: (248) 813-8073

Vous aimerez peut-être aussi

- Professional Test Driven Development with C#: Developing Real World Applications with TDDD'EverandProfessional Test Driven Development with C#: Developing Real World Applications with TDDPas encore d'évaluation

- Delphi Horiz ModelingDocument7 pagesDelphi Horiz Modelingsh33Pas encore d'évaluation

- Strategies For MassDocument7 pagesStrategies For MassMirza SinanovicPas encore d'évaluation

- Assignment: Title Submitted To Submitted by Roll No Programme Session SectionDocument10 pagesAssignment: Title Submitted To Submitted by Roll No Programme Session SectionQUDOOS ꍏꌚꀍꎇꍏQ̸Pas encore d'évaluation

- White Paper - The Future of Parametric Design Is Collaboration - ESPpdfDocument26 pagesWhite Paper - The Future of Parametric Design Is Collaboration - ESPpdfPixelPlotPas encore d'évaluation

- The Myths of CFD: Printer-Friendly VersionDocument3 pagesThe Myths of CFD: Printer-Friendly Versionalagarg137691Pas encore d'évaluation

- SPMDocument10 pagesSPMQUDOOS ꍏꌚꀍꎇꍏQ̸Pas encore d'évaluation

- Kalani Kordus: Karl AdamDocument24 pagesKalani Kordus: Karl AdamNanee DevaPas encore d'évaluation

- DevopsDocument25 pagesDevopsmiljenko2Pas encore d'évaluation

- The Five Myths of Computational Fluid DynamicsDocument3 pagesThe Five Myths of Computational Fluid DynamicsYasser NaguibPas encore d'évaluation

- DFMAPaper FullDocument13 pagesDFMAPaper FullahasimplemailPas encore d'évaluation

- Lean ConceptsDocument4 pagesLean ConceptsSilian MarianPas encore d'évaluation

- Tech Clarity IssueinFocus CAD PLMDocument11 pagesTech Clarity IssueinFocus CAD PLMMit GuptaPas encore d'évaluation

- Computers in EngineeringDocument4 pagesComputers in EngineeringIvanPas encore d'évaluation

- Concurrent Engineering Road To The FutureDocument9 pagesConcurrent Engineering Road To The FutureSena PrabawaPas encore d'évaluation

- Ollaborative Esign: Markets, in Which The Customers' Tastes Keep Changing Fast Because The Customers Are NowDocument10 pagesOllaborative Esign: Markets, in Which The Customers' Tastes Keep Changing Fast Because The Customers Are NowSaras ChandraPas encore d'évaluation

- Strategies For Mass CustomizationDocument8 pagesStrategies For Mass CustomizationMirza SinanovicPas encore d'évaluation

- Design For Modular It yDocument4 pagesDesign For Modular It yĐứcTrầnPas encore d'évaluation

- My Unit1Document44 pagesMy Unit1Om MishraPas encore d'évaluation

- Computers in EngineeringDocument4 pagesComputers in EngineeringIvanPas encore d'évaluation

- Execution Plan PDFDocument9 pagesExecution Plan PDFVatsal SharmaPas encore d'évaluation

- FigmaDocument28 pagesFigmaNguyen Huyen TrangPas encore d'évaluation

- Nuway Software: Part 1: The "Old" WayDocument15 pagesNuway Software: Part 1: The "Old" WayfridayPas encore d'évaluation

- Extreme ProgrammingDocument3 pagesExtreme ProgrammingM Sin GhPas encore d'évaluation

- The Collaborative New Product Development ProcessDocument15 pagesThe Collaborative New Product Development ProcessIngvild Sundby100% (9)

- Siemens SW What They Didnt Teach You in School About Pressure Drop WP tcm70-66470Document12 pagesSiemens SW What They Didnt Teach You in School About Pressure Drop WP tcm70-66470Cassio Antonio Neto AmaralPas encore d'évaluation

- CFD Mentorpaper - 47725Document4 pagesCFD Mentorpaper - 47725oteastPas encore d'évaluation

- An Introduction To Domain Driven Design and Its Benefits - DZone AgileDocument4 pagesAn Introduction To Domain Driven Design and Its Benefits - DZone AgilealexandreomirandaPas encore d'évaluation

- LPD CapabilitiesDocument44 pagesLPD CapabilitiesthisisghostactualPas encore d'évaluation

- Developers Guide To Customer Experience Management Powered by The Adobe Digital Enterprise PlatformDocument10 pagesDevelopers Guide To Customer Experience Management Powered by The Adobe Digital Enterprise PlatformAbhinav MishraPas encore d'évaluation

- Agile: An Iterative Approach To Project Management and Software DevelopmentDocument22 pagesAgile: An Iterative Approach To Project Management and Software Developmentvictor soskinPas encore d'évaluation

- White Paper: Practical Implementation of Best Practices For Analysis in A Design EnvironmentDocument14 pagesWhite Paper: Practical Implementation of Best Practices For Analysis in A Design EnvironmentsonchemenPas encore d'évaluation

- Department of Mechanical Engineering Faculty of Engineering Semester 2 Session 2012/2013 PrototypingDocument4 pagesDepartment of Mechanical Engineering Faculty of Engineering Semester 2 Session 2012/2013 Prototypingdanish91Pas encore d'évaluation

- Using DFA Analysis To Integrate Outside Designs Into The Motorola EMB New Product Development ProcessDocument23 pagesUsing DFA Analysis To Integrate Outside Designs Into The Motorola EMB New Product Development ProcessAdrian ZunigaPas encore d'évaluation

- What Is Catia Mechanical EngineeringDocument3 pagesWhat Is Catia Mechanical EngineeringDhyan AcademyPas encore d'évaluation

- DFMA LiteratureDocument27 pagesDFMA LiteratureRajeshLSPas encore d'évaluation

- Class Handout CES502192 C3D Templates Restructuring For Collaboration and Maximum EfficiencyDocument27 pagesClass Handout CES502192 C3D Templates Restructuring For Collaboration and Maximum Efficiencysicimwork8Pas encore d'évaluation

- Strategies ForDocument6 pagesStrategies ForMirza SinanovicPas encore d'évaluation

- Unit - IIIDocument36 pagesUnit - IIIchandra mouliPas encore d'évaluation

- TopicDocument2 pagesTopicJohn Carlo JaucianPas encore d'évaluation

- Co Create P ('t':3) Var B Location Settimeout (Function (If (Typeof Window - Iframe 'Undefined') (B.href B.href ) ), 15000)Document2 pagesCo Create P ('t':3) Var B Location Settimeout (Function (If (Typeof Window - Iframe 'Undefined') (B.href B.href ) ), 15000)rendrapradanaPas encore d'évaluation

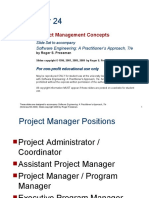

- Chapter 24 - Project Management ConceptsDocument32 pagesChapter 24 - Project Management Conceptsmalik assad100% (1)

- StrategiesDocument5 pagesStrategiesMirza SinanovicPas encore d'évaluation

- Kuliah 11 Model Rekabentuk Instruksional SAMDocument43 pagesKuliah 11 Model Rekabentuk Instruksional SAMRaymondPas encore d'évaluation

- HP Alm PDFDocument56 pagesHP Alm PDFmuralisadaPas encore d'évaluation

- Concurrent Engineering SeminarDocument24 pagesConcurrent Engineering SeminarArjun Prasad100% (1)

- Change Point Analysis and DRBFM: A Winning CombinationDocument8 pagesChange Point Analysis and DRBFM: A Winning CombinationPrabhat SharmaPas encore d'évaluation

- New Products Management: Merle Crawford Anthony Di Benedetto 10 EditionDocument18 pagesNew Products Management: Merle Crawford Anthony Di Benedetto 10 EditionmzumziPas encore d'évaluation

- ASSIGNMENT NO 001-WPS OfficeDocument16 pagesASSIGNMENT NO 001-WPS Officenouman khanPas encore d'évaluation

- Chea Polay Bus649 Research PaperDocument8 pagesChea Polay Bus649 Research PaperChea PolayPas encore d'évaluation

- Design Patterns SW Quality - English VersionDocument18 pagesDesign Patterns SW Quality - English VersionAdemir Constantino100% (1)

- Concurrent Engineering: S.P.TayalDocument5 pagesConcurrent Engineering: S.P.TayalkrishnaPas encore d'évaluation

- SPM Unit 2Document43 pagesSPM Unit 2akonunivrslPas encore d'évaluation

- Individual Assignment of MKTDocument5 pagesIndividual Assignment of MKTDao Tuan Kiet (K17 HCM)Pas encore d'évaluation

- Pensonic Blender DFMA (Group 1)Document51 pagesPensonic Blender DFMA (Group 1)Shf Kamaludin100% (3)

- BertrandMeyer Agile ACMWebinar 021815 PDFDocument41 pagesBertrandMeyer Agile ACMWebinar 021815 PDFkilambazzPas encore d'évaluation

- Adobe Case Study - DTI Intelligent DocumentsDocument3 pagesAdobe Case Study - DTI Intelligent DocumentsrpcooperPas encore d'évaluation

- Industria L Design AND DesignerDocument21 pagesIndustria L Design AND DesignerJerome ReyesPas encore d'évaluation

- Putting Concurrent Engineering Into Practice - 2Document5 pagesPutting Concurrent Engineering Into Practice - 2Reddy LokeshPas encore d'évaluation

- DSLR Auto-Focus Modes Explained: PhotzyDocument15 pagesDSLR Auto-Focus Modes Explained: PhotzyRMLPas encore d'évaluation

- Diction ArDocument101 pagesDiction ArRMLPas encore d'évaluation

- Is Rene Girards Things Hidden Since TheDocument37 pagesIs Rene Girards Things Hidden Since TheRMLPas encore d'évaluation

- Plain Bearings Lecture eDocument9 pagesPlain Bearings Lecture eRMLPas encore d'évaluation

- Acuzativ Cu InfinitivDocument55 pagesAcuzativ Cu InfinitivRMLPas encore d'évaluation

- Filetage M PG G NPTDocument1 pageFiletage M PG G NPTRMLPas encore d'évaluation

- About Changing Part AccuracyDocument1 pageAbout Changing Part AccuracyRMLPas encore d'évaluation

- Disc Springs - Schnorr Handbook (2008)Document151 pagesDisc Springs - Schnorr Handbook (2008)RMLPas encore d'évaluation

- SR ISO 8062 - Piese TurnateDocument20 pagesSR ISO 8062 - Piese TurnateRMLPas encore d'évaluation

- The Permission Wheel Hawkes L PDFDocument8 pagesThe Permission Wheel Hawkes L PDFNandita Asthana SankerPas encore d'évaluation

- LR 7833Document11 pagesLR 7833Trung ĐinhPas encore d'évaluation

- Role of Commodity Exchange in Agricultural GrowthDocument63 pagesRole of Commodity Exchange in Agricultural GrowthSoumyalin Santy50% (2)

- PUERPERAL SEPSIS CoverDocument9 pagesPUERPERAL SEPSIS CoverKerpersky LogPas encore d'évaluation

- Rajasekhara Dasa - Guide To VrindavanaDocument35 pagesRajasekhara Dasa - Guide To VrindavanaDharani DharendraPas encore d'évaluation

- Community Service Learning IdeasDocument4 pagesCommunity Service Learning IdeasMuneeb ZafarPas encore d'évaluation

- Green and White Zero Waste Living Education Video PresentationDocument12 pagesGreen and White Zero Waste Living Education Video PresentationNicole SarilePas encore d'évaluation

- Java Magazine JanuaryFebruary 2013Document93 pagesJava Magazine JanuaryFebruary 2013rubensaPas encore d'évaluation

- KB000120-MRK456-01-HR SamplingDocument15 pagesKB000120-MRK456-01-HR SamplingMiguel Zuniga MarconiPas encore d'évaluation

- Catalogue 2021Document12 pagesCatalogue 2021vatsala36743Pas encore d'évaluation

- Novedades Jaltest CV en 887Document14 pagesNovedades Jaltest CV en 887Bruce LyndePas encore d'évaluation

- Quiz 07Document15 pagesQuiz 07Ije Love100% (1)

- Research PaperDocument9 pagesResearch PaperMegha BoranaPas encore d'évaluation

- Sheet PilesDocument5 pagesSheet PilesolcayuzPas encore d'évaluation

- Ob AssignmntDocument4 pagesOb AssignmntOwais AliPas encore d'évaluation

- Delegated Legislation in India: Submitted ToDocument15 pagesDelegated Legislation in India: Submitted ToRuqaiyaPas encore d'évaluation

- Cryptography Practical 1Document41 pagesCryptography Practical 1Harsha GangwaniPas encore d'évaluation

- GooseberriesDocument10 pagesGooseberriesmoobin.jolfaPas encore d'évaluation

- Contact Numbers of Head Office: Managing DirectorDocument6 pagesContact Numbers of Head Office: Managing DirectorRatneshPas encore d'évaluation

- Verb To Be ExerciseDocument6 pagesVerb To Be Exercisejhon jairo tarapues cuaycalPas encore d'évaluation

- NI 43-101 Technical Report - Lithium Mineral Resource Estimate Zeus Project, Clayton Valley, USADocument71 pagesNI 43-101 Technical Report - Lithium Mineral Resource Estimate Zeus Project, Clayton Valley, USAGuillaume De SouzaPas encore d'évaluation

- DE1734859 Central Maharashtra Feb'18Document39 pagesDE1734859 Central Maharashtra Feb'18Adesh NaharPas encore d'évaluation

- Demand and SupplyDocument61 pagesDemand and SupplyGirish PremchandranPas encore d'évaluation

- Grope Assignment 1Document5 pagesGrope Assignment 1SELAM APas encore d'évaluation

- Pea RubricDocument4 pagesPea Rubricapi-297637167Pas encore d'évaluation

- Barangay AppointmentDocument2 pagesBarangay AppointmentArlyn Gumahad CahanapPas encore d'évaluation

- Journal Entry EnrepDocument37 pagesJournal Entry Enreptherese lamelaPas encore d'évaluation

- Weird Tales v14 n03 1929Document148 pagesWeird Tales v14 n03 1929HenryOlivr50% (2)

- Stress Corrosion Cracking Behavior of X80 PipelineDocument13 pagesStress Corrosion Cracking Behavior of X80 Pipelineaashima sharmaPas encore d'évaluation

- Manhole DetailDocument1 pageManhole DetailchrisPas encore d'évaluation