Académique Documents

Professionnel Documents

Culture Documents

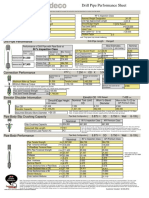

Drill Pipe Performance Sheet

Transféré par

Garcia C L AlbertoDescription originale:

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Drill Pipe Performance Sheet

Transféré par

Garcia C L AlbertoDroits d'auteur :

Formats disponibles

Drill Pipe Performance Sheet

www.NOV.com/GrantPrideco

Phone: +1 (281) 878-8000

Warning: Connection thread shear strength is too weak; the connection must be streamlined or a waiver must be signed. Advisory: Elevator Capacity is weaker than nominal pipe in tension. Note:

Unbalanced Connection, Box weak (Connection OD should be larger or ID larger).

Drill Pipe Configuration

Pipe Body OD

Pipe Body Wall Thickness

Pipe Body Grade

Drill Pipe Length

Connection

Tool Joint OD

Tool Joint ID

Pin Tong

Box Tong

(in)

(in)

(in)

(in)

(in)

(in)

80 % Inspection Class

Nominal Weight Designation

10.40

(ft) 31.7

Drill Pipe Approximate Length

(in) 3/32 Raised

SmoothEdge Height

(psi) 120,000

Tool Joint SMYS

Upset Type

EU

(in) 3.188

Max Upset OD (DTE)

Friction Factor

1.0

2.875

0.362

G-105

Range2

XT26

3.375

1.500

10

15

Note: Tong space may include hardfacing.

Drill-Pipe Length

Drill Pipe Performance

Best Estimates

Performance of Drill Pipe with Pipe Body at

(without Coating)

80 % Inspection Class

Applied Make-up

Torque

Max Tension

Operational

Torque (ft-lbs)

(lbs)

(ft-lbs)

Maximum MUT

7,900

Minimum MUT

6,600

Tension Only

Combined Loading

Tension Only

Combined Loading

0

6,800

233,100

195,500

0

5,400

233,100

210,100

Drill Pipe Adjusted Weight

Fluid Displacement

Fluid Displacement

Fluid Capacity

Fluid Capacity

Drift Size

11.45

0.17

(Bbls/ft) 0.0042

(gal/ft) 0.17

(Bbls/ft) 0.0042

(in) 1.375

XT26

3.375

Applied Make-up

Tension at Shoulder

Torque

Separation

(ft-lbs)

7,900

6,600

(ft-lbs)

(lbs)

Tensile Limited

337,600

SmoothEdge Height

(in)

(lbs)

3/32 Raised

3.562

166,400

Assumed Elevator Bore Diameter

11.04

0.17

0.004

0.18

0.0043

(lbs/ft)

0.17

0.0041

(lbs)

OD X

(in)

1.500

Tension at Connection

Yield

(lbs)

326,200

363,700

ID

(in)

120,000

(psi)

Tool Joint Dimensions

Balanced OD

(in)

Minimum Tool Joint OD for API

(in)

Premium Class

Minimum Tool Joint OD for

Counterbore

(in)

3.471

3.238

3.238

13,200

363,700

Elevator Shoulder Information

Box OD

Elevator Capacity

(least accurate)

(gal/ft)

Note: The maximum make-up torque should be applied when possible.

Note: To maximize connection operational tensile, a MUT (T4) = 7,100 (ft-lbs) should be applied.

Tool Joint Torsional Strength

Tool Joint Tensile Strength

Nominal

(with Coating)

Note: Oil field barrel equals 42 US gallons.

Note: Drill pipe assembly values are best estimates and may vary due to pipe body mill tolerance, internal plastic coating, and other factors.

Connection Performance

Maximum Make-up Torque

Minimum Make-up Torque

Range2

(in)

Elevator OD 3/32 Raised

Nominal Tool Joint

Worn to Bevel

OD

Diameter

Worn to Min TJ OD for

API Premium Class

3.375

53,900

3.238

0

Pipe Body Slip Crushing Capacity

Pipe Body Configuration

Nominal

Assumed Slip Length

Transverse Load Factor (K)

(lbs)

(in)

Pipe Body Performance

245,000

(ft-lbs)

(ft-lbs)

(psi)

(psi)

(in)

(in)

(in)

(in^2)

(in^2)

(in^2)

(in^3)

(in^3)

2.875 (in) OD

80 % Inspection Class

192,400

Pipe Body Configuration

(lbs)

0.362 (in) Wall

G-105 )

API Premium Class

192,400

Note: Slip Crushing: Slip crushing load is calculated with the Spiri-Reinhold equation from Why Does Drill Pipe

Fail in the Slip Area World Oil, 1959 for the slip length and transverse load factor shown and is for reference

only. Slip crushing is dependent on the slip design and condition, coefficient of friction, loading conditions, time in

slips, drill pipe OD and wall variation, and other factors. Consult with the slip manufacturer for additional

information.

16.5

4.2

Nominal

Pipe Tensile Strength

Pipe Torsional Strength

TJ/PipeBody Torsional Ratio

80% Pipe Torsional Strength

Burst

Collapse

Pipe OD

Wall Thickness

Nominal Pipe ID

Cross Sectional Area of Pipe Body

Cross Sectional Area of OD

Cross Sectional Area of ID

Section Modulus

Polar Section Modulus

(in)

Note: Elevator capacity based on assumed Elevator Bore, no wear factor, and contact stress of 110,100psi.

Note: A raised elevator OD increases elevator capacity without affecting make-up torque.

3.281

Slip Crushing Capacity

3.219

0

3.562

300,100

16,200

0.82

12,900

23,137

23,112

2.875

0.362

2.151

2.858

6.492

3.634

1.602

3.204

2.875 (in) OD

80 % Inspection Class

233,100

12,400

1.06

9,900

21,153

19,912

2.730

0.290

2.151

2.220

5.854

3.634

1.228

2.456

0.362 (in) Wall

G-105 )

API Premium Class

233,100

12,400

1.06

9,900

21,153

19,912

2.730

0.290

2.151

2.220

5.854

3.634

1.228

2.456

Note: Nominal Burst

calculated at 87.5% RBW

per API.

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully

responsible for the accuracy and suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied

warranty is intended. Drill pipe assembly properties are calculated based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear

conditions (remaining body wall) is for information only and does not represent or imply acceptable operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance

ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the application. For API connections that have different pin and box IDs, tool joint ID refers to

the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

www.NOV.com/GrantPrideco/CustomerFeedback

Customer Created 03-20-2014

Operational Limits of Drill Pipe

Connection

Pipe Body

XT26

80 % Inspection Class

Tool Joint OD

(in)

3.375

Tool Joint ID

Pipe Body OD

(in)

2.875

Wall Thickness (in) 0.362

(in)

Combined Loading for Drill Pipe at

Maximum Make-up Torque = 7,900

Operational Assembly

Torque

Max Tension

(ft-lbs)

0

400

700

1,100

1,400

1,800

2,100

2,500

2,800

3,200

3,600

3,900

4,300

4,600

5,000

5,300

5,700

6,000

6,400

6,800

233,100

233,000

232,800

232,200

231,700

230,700

229,800

228,400

227,100

225,300

223,100

221,300

218,700

216,500

213,400

210,800

207,100

204,000

199,700

195,500

Operationa Assembly

l Torque

Max Tension

(ft-lbs)

(lbs)

Pipe Body

Max Tension

(lbs)

(ft-lbs)

Connection

Max Tension

(lbs)

(lbs)

233,100

233,100

337,600

233,100

326,200

233,000

326,200

300

233,100

233,100

337,600

326,200

600

232,900

232,900

337,600

337,600

232,800

232,200

326,200

800

232,700

232,700

231,700

326,200

1,100

232,200

232,200

337,600

230,700

326,200

1,400

231,700

231,700

337,600

229,800

326,200

1,700

230,900

230,900

337,600

326,200

2,000

230,100

230,100

337,600

326,200

2,300

229,100

229,100

337,600

326,200

2,500

228,400

228,400

337,600

337,600

228,400

227,100

225,300

223,100

326,200

2,800

227,100

227,100

221,300

326,200

3,100

225,700

225,700

337,600

218,700

326,200

3,400

224,200

224,200

337,600

216,500

326,200

3,700

222,500

222,500

337,600

326,200

4,000

220,700

220,700

337,600

326,200

4,200

219,400

219,400

337,600

217,300

217,300

337,600

337,600

213,400

210,800

207,100

G-105

Minimum Make-up Torque = 6,600

(ft-lbs)

(lbs)

Pipe Body Grade

Combined Loading for Drill Pipe at

Connection Max

Pipe Body

Max Tension Tension

(lbs)

Tool Joint Specified Minimum

120,000

(psi)

Yield Strength

1.500

4,500

326,200

204,000

326,200

4,800

215,000

215,000

199,700

326,200

5,100

212,500

212,500

337,600

195,500

326,200

5,400

210,100

210,100

337,600

Operational drilling torque is limited by the Make-up Torque.

Operational drilling torque is limited by the Make-up Torque.

Connection

Make-up Torque Range

Make-up Torque

(ft-lbs)

Min MUT

Max MUT

6,600

6,700

6,900

7,000

7,200

7,300

7,500

7,600

7,800

7,900

Connection Max

Tension

(lbs)

337,500

342,600

352,900

358,000

359,600

354,800

345,300

340,500

331,000

326,200

Note: Recommended MUT should always be used when possible. If not possible, MUT should be as close to Recommended MUT as possible.

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully responsible for the accuracy and

suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated

based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable

operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the

application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

03-20-2014

Connection Wear Table

Connection

XT26

Tool Joint OD

Connection

Wear

Tool

Joint OD

New OD

(in)

3.375

3.363

3.35

3.338

3.325

3.313

3.3

3.288

3.275

3.263

3.25

3.238

Worn OD

(in)

3.375

Tool Joint ID

(in)

Tool Joint Specified Minimum

120,000

(psi)

Yield Strength

1.500

Connection Max

Tension

Connection

Torsional

Strength (ft-lbs)

Max

MUT

13,200

13,100

12,900

12,700

12,500

12,300

12,100

11,900

11,700

11,500

11,300

11,100

7,900

7,800

7,700

7,600

7,500

7,400

7,200

7,100

7,000

6,900

6,800

6,700

(ft-lbs)

Connection Max

Tension

Min MUT

(lbs)

(lbs)

(ft-lbs)

326,200

329,900

333,500

337,100

340,600

337,600

337,700

333,800

329,000

324,700

315,800

305,200

6,600

337,500

6,500

333,500

6,400

329,600

6,300

325,600

6,200

321,700

6,100

311,600

6,000

300,700

5,900

290,500

5,800

280,000

5,800

274,900

5,700

264,700

5,600

255,100

Pipe Body

Combined Loading Table (Torque-Tension)

Pipe Body

Pipe Body OD

80 % Inspection Class

Pipe Body Torque

(in)

2.875

Wall Thickness (in) 0.362

Pipe Body Grade

G-105

1,100

2,300

3,400

4,500

5,600

6,800

7,900

9,000

10,100

11,300

12,400

232,200

229,100

224,200

217,300

208,000

195,000

179,700

160,400

135,300

96,100

3,500

(ft-lbs)

Pipe Body Max

233,100

Tension

(lbs)

Note: The technical information contained herein, including the product performance sheet and other attached documents, is for reference only and should not be construed as a recommendation. The user is fully responsible for the accuracy and

suitability of use of the technical information. NOV Grant Prideco cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated

based on uniform OD and wall thickness. No safety factor is applied. The information provided for various inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable

operating limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices, and to apply a prudent safety factor suitable for the

application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

03-20-2014

Vous aimerez peut-être aussi

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsD'EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsÉvaluation : 4 sur 5 étoiles4/5 (9)

- Drilling Supervisor: Passbooks Study GuideD'EverandDrilling Supervisor: Passbooks Study GuidePas encore d'évaluation

- Cat III Inspection Mud 2021Document56 pagesCat III Inspection Mud 2021Fāōū ZīPas encore d'évaluation

- API 4G - Cat 3 and 4 RequirementDocument1 pageAPI 4G - Cat 3 and 4 RequirementMurali SambandanPas encore d'évaluation

- GX Annular BOP Training-One FileDocument30 pagesGX Annular BOP Training-One FileGoumidi MohamedPas encore d'évaluation

- Drilling Engineering Problems and Solutions: A Field Guide for Engineers and StudentsD'EverandDrilling Engineering Problems and Solutions: A Field Guide for Engineers and StudentsÉvaluation : 5 sur 5 étoiles5/5 (1)

- DrillPipe, 80%, 3.500 OD, 0.449 Wall, EU, G-105.. XT39 (4.938 X 2.563) PDFDocument3 pagesDrillPipe, 80%, 3.500 OD, 0.449 Wall, EU, G-105.. XT39 (4.938 X 2.563) PDFGarcia C L Alberto100% (1)

- HeavyWeight 3.5 25.58lbs NC-38Document3 pagesHeavyWeight 3.5 25.58lbs NC-38Инженер Луис А. ГарсиаPas encore d'évaluation

- Stabilizer TypeDocument14 pagesStabilizer TypeAdin PraviMoški PartAdisPas encore d'évaluation

- Inspection Casing On Location Procedure22222222Document11 pagesInspection Casing On Location Procedure22222222hamdi hamdiPas encore d'évaluation

- 2 JFE BEAR Design FeatureDocument15 pages2 JFE BEAR Design FeatureDaniel ChiriacPas encore d'évaluation

- Thread CompoundDocument5 pagesThread CompoundJas SumPas encore d'évaluation

- 3 - Drilling String Equipment - enDocument21 pages3 - Drilling String Equipment - enام فاطمة البطاطPas encore d'évaluation

- Cold Rolling Info GuideDocument11 pagesCold Rolling Info Guide72espoPas encore d'évaluation

- 20-1718 Rig Tongs AOTDocument10 pages20-1718 Rig Tongs AOTRahul M.R100% (1)

- Final Tie Back Compl Program For Muzhil 8 (12!08!2015 GE)Document21 pagesFinal Tie Back Compl Program For Muzhil 8 (12!08!2015 GE)Mahmoud Ahmed Ali AbdelrazikPas encore d'évaluation

- DrillingDocument9 pagesDrillingHakan ÖzkaraPas encore d'évaluation

- Drilling Tools CatalogDocument96 pagesDrilling Tools CatalogRzvn100% (1)

- Tubulars - Connections (W250) Mar 08 - Part 3Document15 pagesTubulars - Connections (W250) Mar 08 - Part 3Mike Ross100% (1)

- Drilling Tools - 1Document269 pagesDrilling Tools - 1berrouiPas encore d'évaluation

- Rig DesginDocument25 pagesRig DesginImam PranadipaPas encore d'évaluation

- Well Control EquiptDocument115 pagesWell Control EquiptGhavban David100% (3)

- Fishing ToolsDocument10 pagesFishing Toolsdanarkurniadi123Pas encore d'évaluation

- Parveen Well Head PDFDocument25 pagesParveen Well Head PDFRatnakar PatilPas encore d'évaluation

- Seminar Casing FailureDocument27 pagesSeminar Casing FailurehshobeyriPas encore d'évaluation

- Drilling EquipmentDocument63 pagesDrilling EquipmentYudha negaraPas encore d'évaluation

- ED Brochure Clean Up ToolsDocument8 pagesED Brochure Clean Up ToolsilkerkozturkPas encore d'évaluation

- Manual: CDQ (S) Sucker Rod ElevatorsDocument5 pagesManual: CDQ (S) Sucker Rod ElevatorsDarshan MakwanaPas encore d'évaluation

- Aluminum Alloy Drill PipeDocument20 pagesAluminum Alloy Drill PipeMark Garrett100% (1)

- Drill String MaintenanceDocument6 pagesDrill String MaintenanceJohan GermonprePas encore d'évaluation

- Know The Maximum Ton Miles You Can Actually Run Drill Line Before A Slip/cut?Document16 pagesKnow The Maximum Ton Miles You Can Actually Run Drill Line Before A Slip/cut?ashadPas encore d'évaluation

- 01-Conventional - Casing HeadsDocument61 pages01-Conventional - Casing HeadsChairul AbdiPas encore d'évaluation

- Visual SL APEXDocument3 pagesVisual SL APEXOscar Gomez Gonzalez100% (1)

- Casing and TubingDocument13 pagesCasing and TubingHany AhmedPas encore d'évaluation

- GyroDrill Mud Motor Handbook 2013Document103 pagesGyroDrill Mud Motor Handbook 2013Don BraithwaitePas encore d'évaluation

- 1 API Introduction StandardsDocument29 pages1 API Introduction StandardsImam MalikPas encore d'évaluation

- Cement PlugDocument7 pagesCement PlugJayesh ChavanPas encore d'évaluation

- 5 5 DP-HT55-repDocument1 page5 5 DP-HT55-repChristopher Jones100% (1)

- Drill Pipe and Drill Collars From ChinaDocument186 pagesDrill Pipe and Drill Collars From ChinavangoethePas encore d'évaluation

- Junk Subs (JUNK BASKET)Document1 pageJunk Subs (JUNK BASKET)mosli_Pas encore d'évaluation

- Well CommanderDocument8 pagesWell Commanderice_PLPas encore d'évaluation

- Stuckey Casing ScrapersDocument5 pagesStuckey Casing ScrapersGeorge Lamey0% (1)

- New BHA Connection Enhances Fatigue Performance For Difficult Drilling ApplicationsDocument3 pagesNew BHA Connection Enhances Fatigue Performance For Difficult Drilling Applicationsabegarza1Pas encore d'évaluation

- 9 - What Is A Special Drift CasingDocument2 pages9 - What Is A Special Drift CasingLuis David Concha CastilloPas encore d'évaluation

- What You Need To Know About Drilling Bit Balling Up and How To Troubleshooting ItDocument3 pagesWhat You Need To Know About Drilling Bit Balling Up and How To Troubleshooting ItShoaib KhalilPas encore d'évaluation

- Drilling Hole Opener WebDocument2 pagesDrilling Hole Opener WebBehrangPas encore d'évaluation

- Best Practices Drilling 26 inDocument6 pagesBest Practices Drilling 26 inmanuelperdomotPas encore d'évaluation

- 7in 29ppf 13Cr-80 JFE BearDocument1 page7in 29ppf 13Cr-80 JFE BearYeit HauPas encore d'évaluation

- Manual Operativo - Tijeras Wenzel Ø 6 1-2 - InglesDocument11 pagesManual Operativo - Tijeras Wenzel Ø 6 1-2 - InglesChristian Matteo100% (1)

- Drilling EDrilling - Equip2013 - PUE - Web - 2quip2013 PUE Web 2Document40 pagesDrilling EDrilling - Equip2013 - PUE - Web - 2quip2013 PUE Web 2MEREUEULEUPas encore d'évaluation

- API Ys Premium ConnectionDocument14 pagesAPI Ys Premium ConnectionAnonymous 1pblc2Y100% (1)

- EZSV-B Drilling and Milling InstructionsDocument2 pagesEZSV-B Drilling and Milling InstructionsPradhyut suntaPas encore d'évaluation

- Fundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersD'EverandFundamentals of Drilling Engineering: MCQs and Workout Examples for Beginners and EngineersPas encore d'évaluation

- Measurement While Drilling: Signal Analysis, Optimization and DesignD'EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignPas encore d'évaluation

- Wave Propagation in Drilling, Well Logging and Reservoir ApplicationsD'EverandWave Propagation in Drilling, Well Logging and Reservoir ApplicationsPas encore d'évaluation

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoPas encore d'évaluation

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoPas encore d'évaluation

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoPas encore d'évaluation

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyGarcia C L AlbertoPas encore d'évaluation

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 pagesDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaPas encore d'évaluation

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 pagesDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaPas encore d'évaluation

- DrillPipe, 80%, 5.875 OD, 0.500 Wall, IEU, X-95.. XT57 (7.000 X 4.250)Document3 pagesDrillPipe, 80%, 5.875 OD, 0.500 Wall, IEU, X-95.. XT57 (7.000 X 4.250)Garcia C L AlbertoPas encore d'évaluation

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 pagesDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaPas encore d'évaluation

- DrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Document3 pagesDrillPipe, 80%, 5.500 OD, 0.415 Wall, IEU, G-105.. XT57 (7.000 X 4.000)Johann ZabaletaPas encore d'évaluation

- DPPS PDFDocument2 pagesDPPS PDFStowartPas encore d'évaluation

- DrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Document3 pagesDrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Garcia C L AlbertoPas encore d'évaluation

- DrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Document3 pagesDrillPipe, 80%, 5.875 OD, 0.750 Wall, IEU, G-105.. XT57 (7.250 X 3.500)Garcia C L AlbertoPas encore d'évaluation

- 9702 p1 Properties of Matter All PDFDocument8 pages9702 p1 Properties of Matter All PDFkwon jiyongPas encore d'évaluation

- ENR202 Mechanics of Materials Lecture 9A Slides and Notes: Slide 1Document17 pagesENR202 Mechanics of Materials Lecture 9A Slides and Notes: Slide 1jimyPas encore d'évaluation

- Data Sheet ECW 100 400Document3 pagesData Sheet ECW 100 400Vidiya NovelinPas encore d'évaluation

- Abaqus Example Problems Manual (6Document18 pagesAbaqus Example Problems Manual (6Avinash KumarPas encore d'évaluation

- 01 - Stress Analysis - BasicsDocument35 pages01 - Stress Analysis - BasicsJacey Jane100% (1)

- Session 56: Theory of Non-Linear Analysis: ELEATION's ANSYS Basic To Professional Training ProgramDocument11 pagesSession 56: Theory of Non-Linear Analysis: ELEATION's ANSYS Basic To Professional Training ProgramrajuPas encore d'évaluation

- Physics Challenge For Teachers and Students: Solutions To January 2007 ChallengeDocument2 pagesPhysics Challenge For Teachers and Students: Solutions To January 2007 ChallengehenrykPas encore d'évaluation

- Aircraft Design 1 MidtermDocument3 pagesAircraft Design 1 MidtermJam DelfinPas encore d'évaluation

- Steam TrapsDocument6 pagesSteam TrapssaurabhPas encore d'évaluation

- Chem 11Document12 pagesChem 11AmaliaPas encore d'évaluation

- Problem Explanation - 09-24-2010Document2 pagesProblem Explanation - 09-24-2010King OfheartsPas encore d'évaluation

- 4.1.2 - 6695-PRC-000-FB-0101 - 0105 - 03 - Legend Sheets - P - IDDocument5 pages4.1.2 - 6695-PRC-000-FB-0101 - 0105 - 03 - Legend Sheets - P - IDKiran KumarPas encore d'évaluation

- Fluid Mechanics UNIT-1 (Part-1)Document32 pagesFluid Mechanics UNIT-1 (Part-1)Achyutha AnilPas encore d'évaluation

- ME 218 - Spring 2018 - Week01 HandoutDocument15 pagesME 218 - Spring 2018 - Week01 HandoutHassan KhalidPas encore d'évaluation

- Centrifugal Pump Basics: Terms Commonly Used in The Pumping IndustryDocument18 pagesCentrifugal Pump Basics: Terms Commonly Used in The Pumping Industrykomed diPas encore d'évaluation

- Lecture Reading 3: Astm A36 Steel: I. SI Units (Systeme International D'unites)Document3 pagesLecture Reading 3: Astm A36 Steel: I. SI Units (Systeme International D'unites)Mary Rose CabidesPas encore d'évaluation

- Heat EnergyDocument18 pagesHeat EnergyCrazzy RamPas encore d'évaluation

- Liquefaction Cycles 00Document30 pagesLiquefaction Cycles 00Wael_Barakat_3179100% (1)

- Closed Form Solutions For Element Matrices of 4-Node Rectangular Plate Element Using IFMDocument10 pagesClosed Form Solutions For Element Matrices of 4-Node Rectangular Plate Element Using IFMMallesh NenkatPas encore d'évaluation

- ASME PTC 7.1 Displacement PumpsDocument22 pagesASME PTC 7.1 Displacement PumpsLorenzo Antonio CordovaPas encore d'évaluation

- Dentosphere - World of Dentistry - Dental Materials MCQS - Physical PropertiesDocument17 pagesDentosphere - World of Dentistry - Dental Materials MCQS - Physical PropertiesSuraj RaiPas encore d'évaluation

- Feb 17th, Fatigue Failure, Part 2Document52 pagesFeb 17th, Fatigue Failure, Part 2TrentPas encore d'évaluation

- High Latent Cooling Load Applications (Low RSHF)Document17 pagesHigh Latent Cooling Load Applications (Low RSHF)f 3Pas encore d'évaluation

- ME 423 Finals Formula SheetDocument2 pagesME 423 Finals Formula SheetNicolai CeloPas encore d'évaluation

- F2 DP 2015 Ayas Mehmet MASTER THESIS - PdfinalcorrectionDocument66 pagesF2 DP 2015 Ayas Mehmet MASTER THESIS - PdfinalcorrectionSyed YousufuddinPas encore d'évaluation

- Inception General ScienceDocument74 pagesInception General ScienceFarzana Akter 28Pas encore d'évaluation

- Ciht Industrial Training FileDocument48 pagesCiht Industrial Training FileRishabPas encore d'évaluation

- Is 800-2007 - Indian Code of Practice For Construction in SteelDocument41 pagesIs 800-2007 - Indian Code of Practice For Construction in SteelshiivendraPas encore d'évaluation

- Sistema Electrico DL300Document5 pagesSistema Electrico DL300Juan Luque LPas encore d'évaluation

- Objective QuestionsDocument2 pagesObjective QuestionsZaffu Zealy100% (2)