Académique Documents

Professionnel Documents

Culture Documents

Yash, M. (2015) .Re-Refining of Used Lubricating Oil PDF

Transféré par

Henry PabonTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Yash, M. (2015) .Re-Refining of Used Lubricating Oil PDF

Transféré par

Henry PabonDroits d'auteur :

Formats disponibles

International Journal of Scientific & Engineering Research, Volume 6, Issue 3, March-2015

ISSN 2229-5518

329

Re-refining of used lubricating oil.

Merai Yash P.

Abstract - Small amount pure lubricating oil can pollute major amounts of water eg: groundwater as well as the land on which it is spilled. Used

engine oil itself contains a number of additives and is contaminated by impurities and residues resulting from the combustion process. Some of

them are poisonous and carcinogenic like lead and PAH (poly-aromatic hydrocarbons). Also the oils used in transformers contains PCBs (polychlorinated biphenyls), which are highly carcinogenic as well. From various sources such kind of used lubricating oils are generated and are

disposed improperly. The burning of used oil in kilns and incinerators produces lots of ash and carcinogens causing environmental pollution.

Waste lubricating oil is a resource that cannot be disposed of randomly due to the presence of pollutants. In response to economic problems and

environmental protection, there is a growing trend to regenerate and reuse waste lubricants. By proper recovery and refinement of it, a lot of

valuable product can be obtained. The objective of re-refining is to remove the degraded additives and contaminants and to restore the properties

of the oil identical to the standards provided by SAE (Society of Automobile Engineers).

Keywords Base oil, contaminants, crude oil, lubricating oil, re-refining, SAE standards, used engine oil.

1. Introduction

Lubricant oils have been used primarily for reducing friction

between moving parts of various machinery or equipment,

minimize material wear, and improve the efficiency of

equipment /machinery and for fuel and energy savings.

Access to lubricants is essential to any modern society and

not only does lubrication reduce friction and wear by

interposition of a thin liquid film between moving surfaces,

but it also removes heat, keeps equipment clean, and

prevents corrosion. One of its important applications

includes gasoline and diesel engine oils [1].

IJSER

Typically lubricants contain 90% base oil (most often

petroleum fractions, called mineral oils) and less than

10% additives. A large number of additives are used to

impart performance characteristics to the lubricants. The

main families of additives are:

Antioxidants

Anti-wear

Metal deactivators

Corrosion inhibitors, Rust inhibitors

Friction modifiers

Extreme Pressure

Anti-foaming agents

Viscosity index improvers

Demulsifying/Emulsifying

Stickiness improver, provide adhesive

property towards tool surface (in metalworking)

Complexing agent (in case of greases)

______________________________________________________

Merai Yash P. is currently pursuing bachelors degree program in

chemical engineering in University of Pune, India.

Mobile no-09960424132; E-mail: yashmerai24@gmail.com

Fig 1 Constituents of lubricating oil

2. Sources of waste lubricating oils

By far the largest source for used oil in developing countries

is lubricating oils from motor vehicles, combustion engines

and gear boxes. Apart from that, minor amounts are

generated from hydraulic systems, transformers and other

diverse industrial applications. Due to increase of the

automotive traffic in developing countries the amount of

used oil from motor vehicles increased steadily in the past.

The majority of used engine oil is generated in small

quantities at a great number of places, e.g. garages, small

workshops and private premises. There are few major

generator of waste oil like railways, large truck fleet

operators and large industries.

Waste lubricating oil refers to the engine oil,

transmission oil, hydraulic and cutting oils after use. It is also

refers to the degradation of the fresh lubricating components

that become contaminated by metals, ash, carbon residue,

water, varnish, gums, and other contaminating materials, in

addition to asphaltic compounds which result from the

bearing surface of the engines [2]. These oils must be

changed and removed from the automobile after a few

thousand kilometres of driving because of stress from serious

deterioration in service. The amount of lubricating oils that is

collected annually in Europe and USA is very large,

approximately 1.7 to 3.5 million tons. This large amount of

waste engine oils has a significant impact on both economic

and environmental aspects.

IJSER 2015

http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 6, Issue 3, March-2015

ISSN 2229-5518

330

Oxidation products: Some of the oil molecules, at

elevated temperatures, will oxidize to form complex and

corrosive organic acids.

Composition of used oil consists of four major groups, which

have average values of 76.7% saturates, 13.2%

monoaromatics, 3.7% diaromatics and 6.5% polyaromaticpolar material.

Due to degradation of fresh lubricating, it has to be

changed from time to time. The removed used oil is then

discarded [3].

4. Environmental aspect

Fig. 2 - Percentage of contribution of waste oils

3. Used lubricating oil

Used lube oil is defined as the petroleum derived or

synthetic oil which remains after applications in lubrications,

cutting purposes, etc. After a certain period of useful life, the

lubricating oil loses its properties and cannot be used as such

in machinery. Buildup of temperature degrades the

lubricating oil, thus leading to reduction in properties such

as: Viscosity, Specific gravity, etc. Dirt and metal parts worn

out from the surfaces are also deposited into the lubricating

oils. With increased time of uses, the lubricating loses its

lubricating properties as a result of over reduction of desired

properties and thus must be replaced with fresh one. It is

surprising to know that base oil never gets spoiled, it only

gets dirty. Lubricating oil becomes unfit for further use for

two main reasons: accumulation of contaminants in the oil

and chemical changes in the oil. The main contaminants are

listed below.

3.1 Combustion products

5. Importance of used oil recycling

IJSER

Water: Fuel burns to CO2 and H2O. For every litre of fuel

burnt, a litre of water is created. This normally passes out

through the exhaust when the engine is hot, but when cold it

can run down and collect in the oil. This leads to sludge

formation and rust.

Soot and carbon: These make the oil go black. They form as

the result of incomplete combustion, especially during

warm-up with a rich mixture.

Lead: Tetraethyl lead, which used to be used as an anti-knock

agent in petrol, passes into the oil. Typical used engine oil

may have contained up to 2% lead, but today any lead comes

from bearing wear and is likely to be in the 2 - 12 ppm range.

Fuel: Unburnt gasoline or diesel can pass into the lubricant,

again especially during start-up.

3.2 Abrasives

Road dust: This passes into the engine through the aircleaner. Composites of small particles of silicates, wear

metals, iron, copper and aluminum are released due to

normal engine wear.

3.3 Chemical products

Mismanagement of used lubricating oil is a serious

environmental problem. All automotive oils have the

potential to be recycled safely and productively, saving

energy

and

avoiding

environmental

pollution.

Unfortunately, most used motor oil is handled improperly.

Some is emptied into sewers, adversely affecting water

treatment plants or going directly into waterways. Some is

dumped directly onto the ground to kill weeds or is poured

onto dirt roads. Millions of gallons are thrown into the trash,

ending up in landfills, where it can contaminate surface and

ground water [4].

Improper used oil disposal is simply a waste of a valuable

resource. Every gallon of used motor oil not recovered

results in the need to drill for more oil and in some cases it

results in increases in oil import. Today, however, most of

the crude petroleum produced throughout the world

contains very little of the special hydrocarbon chains

necessary for motor oil. As a result, refining crude petroleum

to produce virgin lube oil is an elaborate, complex, and

expensive process that requires nearly three times energy as

much as rerefining used oil. Lube base oil can be recovered

and regenerated to the quality equal to or better than its

original virgin form [3].

A large range of waste oils can be recycled and

recovered in a variety of ways, either directly or after some

form of separation and refinement. As per the waste

management hierarchy, the first option is to conserve the

original properties of the oil allowing for direct reuse. Other

options could include recovering its heating value and/or

using in other lower level applications. Certain types of

waste oils, lubricants in particular, can be reprocessed

allowing for their direct reuse. The use of waste oils, after

treatment, can be either as lube base stock comparable to

refined virgin base oil or as clean burning fuel.[4].

6. Treatment Technologies

The idea of recycling used lubricating oil was presented in

the year of 1930. Initially the used lubricating oils were burnt

to produce energy, and later these oils were re-blended to

engine oils after treatment. Due to the increasing necessity

for environmental protection and more stringent

environmental legislation, the disposal and recycling of

waste oils has become very important. The recycling of waste

lubricating oils can be accomplished through three basic

methods, which are reprocessing, re-refining and

destruction.[4]

IJSER 2015

http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 6, Issue 3, March-2015

ISSN 2229-5518

331

6.1 Re-refining

Re-fining is the use of distilling or refining processes on used

lubrication oil to produce high quality base stock for

lubricants or other petroleum products. The use of this

method has increased tremendously in developed countries,

some countries reaching up to 50% of the countrys need for

lubricating oil [7]. It requires the conversion of waste oil to a

product with similar characteristics to those of virgin oil. The

process typically involves, but is not limited to, pre-treatment

by heat or filtration, followed by either vacuum distillation

with hydrogen finishing and solvent extraction.

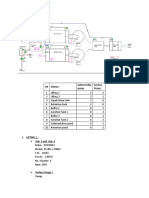

Fig.4 - simple dehydration and distillation

Process: 2 Vacuum Distillation

The vacuum distillation column internals must provide

good vapor-liquid contacting while, at the same time,

maintaining a very low pressure increase from the top of the

column top to the bottom. Therefore, the vacuum column

uses distillation trays only where withdrawing products

from the side of the column (referred to as side draws). Most

of the column uses packing material for the vapor-liquid

contacting because such packing has a lower pressure drop

than distillation trays. This packing material can be either

structured sheet metal or randomly dumped packing such

as Raschig rings.

The dehydrated oil is then fed continuously into a vacuum

distillation plant for fractionation in exactly the same fashion

as crude petroleum. The fractions obtained are as follows:

1. Light fuel and diesel: It can produce enough diesels from

the used oil feedstock to run all the burners and boilers,

giving total self-sufficiency in fuel.

2. Lubricating oil: The bulk of the feedstock will distill off in

the plant to produce a lubricating oil fraction.

3. Residue: The non-distillable part of the feedstock. This

contains all the carbon, wear metals, degraded additives and

most of the lead and oxidation products. This residue is

successfully used as bitumen extender for roading [5].

IJSER

Fig. 3 - Block diagram of re-refining of used lubricating oil

The amount of crude oil required to produce a certain

volume of lubricating oil is nearly 9 times higher to produce

the same volume of lubricating oil from used oil [8].

Process: 3-Solvent extraction and final atmospheric

distillation

6.2 Process involved

Process: 1 - Dehydration

The oil is heated to 130oC in a closed vessel to boil off

emulsified water and some of the fuel diluents. The point at

which oil contains the maximum amount of dissolved water

is termed the saturation point. Higher the temperature,

higher is the saturation point and hence more water held in

solution, in the dissolved phase. Similarly, older the oil,

higher is the level of water that can be dissolved. Water is a

generator of other contaminants in the oil such as waxes,

suspensions, carbon and oxide insolubles and even microorganisms, so it is removed by dehydration.

Methyl Ethyl Ketone (MEK) is a selective aromatic solvent

employed in the solvent extraction process. The lubricating

oil obtained by vacuum distillation is mixed by agitation

with MEK in ratio of 2:1. The lubricating oil and solvent

mixture is allowed to settle in separator tank. The aromatic

content and degraded additives present in the lubricating oil

fraction will settle at the bottom and the lubricating oil

fraction and solvent mixture layer forms at the top. Solvent

mixture is again subjected to atmospheric distillation. The

atmospheric distillation is carried out at temperature of

around 80oC which is the boiling point of MEK. The MEK

vapor produced is condensed and is again used as solvent by

blending with fresh solvent. The lubricating oil produced at

this stage is similar to that of the base lubricating oil.

IJSER 2015

http://www.ijser.org

International Journal of Scientific & Engineering Research, Volume 6, Issue 3, March-2015

ISSN 2229-5518

3.

Additives have to be added to further improve the properties

and to make them eligible for use in the automobile engines

[5]. Zinc Dialkyl Dithiosulphate is the common additive

added to the lubricating oil.

4.

5.

6.

7.

8.

332

"Used Oil. A Renewable Resource and an Environmental

Pollutant" by David Layzell.

Motshumi J. Diphare, Edison Muzenda, Tsietsi J. Pilusa and

MansoorMollagee Lubricating OilTreatment Techniques

ICEAFS 2013.

ShriKannan C, Mohan Kumar KS, DeepaPriya N, Re-Refined

Used Automotive Lubricating Oil Res. J. Engineering Sci.

2014.

S. Arnaout, Options for vehicle waste oil management,

Lebanon, Ministry of Environment, 1997.

J. D. Udonne, A comparative study of recycling of used

lubricating oils Journal of petroleum and Gas Engineering,

vol2.

Ogbeide S.O, An Investigation To The Recycling Of Spent

Engine Oil, Journal of engineering science and technology

review.

Fig 5. Left- Rerefined oil & right- used oil

7. Importance and benefits of rerefining:

1.

2.

3.

4.

5.

Reduce dependence on base oil imports saving

foreign exchange.

Prevent ground water contamination and pollution.

Preserve natural resources such as coal and crude

oil.

Reduce sewage treatment costs.

Eliminate improper burning of waste oil as fuel,

which generate toxic fumes and air pollution.

8. Conclusion

IJSER

Rerefining of waste lubricants could result in both

environmental and economic benefits. Rerefining of waste oil

to manufacture base oil conserves more energy than

reprocessing the waste oil for use as fuel. The energy

required to manufacture rerefined oil from used oil is only

one-third of the energy required to refine crude oil to

produce virgin base oil. Therefore, rerefining is considered

by many as a preferred option in terms of conserving

resource as well as minimizing waste and reducing damage

to the environment [6].

9. Acknowledgement

Author wishes to thank Prof. Nibe R.L for guiding

throughout.

This work was supported in part by Karansingh Rajput and

Irshad Malik.

10. REFERENCES

1.

2.

Francois, A. Waste Engine Oils Refining and Energy

Recovery, 1st ed.; Elsevier Science and Technology Books:

Amsterdam, The Netherlands, 2006.

Whisman, M.L.; Reynolds, J.W.; Goetzinger, J.W.; Cotton, F.O.;

Brinkman, D.W. Re-refining makes quality oils. Hydrocarb.

Process. 1978.

IJSER 2015

http://www.ijser.org

Vous aimerez peut-être aussi

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryD'EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryÉvaluation : 3.5 sur 5 étoiles3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)D'EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Évaluation : 4.5 sur 5 étoiles4.5/5 (120)

- Grit: The Power of Passion and PerseveranceD'EverandGrit: The Power of Passion and PerseveranceÉvaluation : 4 sur 5 étoiles4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaD'EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaÉvaluation : 4.5 sur 5 étoiles4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingD'EverandThe Little Book of Hygge: Danish Secrets to Happy LivingÉvaluation : 3.5 sur 5 étoiles3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItD'EverandNever Split the Difference: Negotiating As If Your Life Depended On ItÉvaluation : 4.5 sur 5 étoiles4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeD'EverandShoe Dog: A Memoir by the Creator of NikeÉvaluation : 4.5 sur 5 étoiles4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerD'EverandThe Emperor of All Maladies: A Biography of CancerÉvaluation : 4.5 sur 5 étoiles4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeD'EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeÉvaluation : 4 sur 5 étoiles4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyD'EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyÉvaluation : 3.5 sur 5 étoiles3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersD'EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersÉvaluation : 4.5 sur 5 étoiles4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnD'EverandTeam of Rivals: The Political Genius of Abraham LincolnÉvaluation : 4.5 sur 5 étoiles4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreD'EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreÉvaluation : 4 sur 5 étoiles4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceD'EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceÉvaluation : 4 sur 5 étoiles4/5 (895)

- Her Body and Other Parties: StoriesD'EverandHer Body and Other Parties: StoriesÉvaluation : 4 sur 5 étoiles4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureD'EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureÉvaluation : 4.5 sur 5 étoiles4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaD'EverandThe Unwinding: An Inner History of the New AmericaÉvaluation : 4 sur 5 étoiles4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)D'EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Évaluation : 4 sur 5 étoiles4/5 (98)

- Design of A Hilltop Three-Storey Parking BuildDocument62 pagesDesign of A Hilltop Three-Storey Parking BuildJuanPas encore d'évaluation

- On Fire: The (Burning) Case for a Green New DealD'EverandOn Fire: The (Burning) Case for a Green New DealÉvaluation : 4 sur 5 étoiles4/5 (73)

- Water Treatment For Foussil Power PlantsDocument187 pagesWater Treatment For Foussil Power PlantsVahit TekPas encore d'évaluation

- Materials Question PackDocument20 pagesMaterials Question PackSuper Dila12Pas encore d'évaluation

- Types & Procedures: Internal Tank Linings & CoatingsDocument22 pagesTypes & Procedures: Internal Tank Linings & CoatingsAhmed100% (1)

- Bridge 070 Passage PlanningDocument4 pagesBridge 070 Passage PlanningMiha MihaelaPas encore d'évaluation

- Atlas Copco ZT55 Instruction ManualDocument90 pagesAtlas Copco ZT55 Instruction ManualRafael Martin Anaya Figueroa100% (4)

- The Internal Combustion EngineDocument5 pagesThe Internal Combustion EngineHenry PabonPas encore d'évaluation

- ExcerptDocument10 pagesExcerptRajaganapathy GanaPas encore d'évaluation

- CorregidoDocument2 pagesCorregidoHenry PabonPas encore d'évaluation

- ProposalDocument1 pageProposalHenry PabonPas encore d'évaluation

- ProposalDocument1 pageProposalHenry PabonPas encore d'évaluation

- The Internal Combustion EngineDocument5 pagesThe Internal Combustion EngineHenry PabonPas encore d'évaluation

- Background Info On PondweedDocument2 pagesBackground Info On PondweednoPas encore d'évaluation

- S-000-1654-0160v - 0 - 0010 Spill Contingency Management PlanDocument16 pagesS-000-1654-0160v - 0 - 0010 Spill Contingency Management Planle huyPas encore d'évaluation

- Gas Pipe Sizing (Propane)Document6 pagesGas Pipe Sizing (Propane)Mike AdvinculaPas encore d'évaluation

- SN Station Submersible Pump Surface PumpDocument8 pagesSN Station Submersible Pump Surface PumpraizoPas encore d'évaluation

- GEK1515 - L1 Introduction IVLE VersionDocument52 pagesGEK1515 - L1 Introduction IVLE VersionYan Ting ZhePas encore d'évaluation

- Project Work On Texcoat Paint 1Document50 pagesProject Work On Texcoat Paint 1iykeejim100% (1)

- 01 Operator Manual - StirLIN-2 - J0847 - ENDocument54 pages01 Operator Manual - StirLIN-2 - J0847 - ENA TurkiPas encore d'évaluation

- Sri Lankan Bottled Water Industry Overview: January 2020Document10 pagesSri Lankan Bottled Water Industry Overview: January 2020TgemunuPas encore d'évaluation

- Pump FlowDocument2 pagesPump FlowSriPas encore d'évaluation

- State-Of-The-Art Reverse Osmosis Desalination PDFDocument77 pagesState-Of-The-Art Reverse Osmosis Desalination PDFJaime MoralesPas encore d'évaluation

- Business Ethics Assignmt - shilPA KOSURIDocument10 pagesBusiness Ethics Assignmt - shilPA KOSURIShilpa KosuriPas encore d'évaluation

- YORK Marine Screw Chiller Units: Type MCSH-SDocument2 pagesYORK Marine Screw Chiller Units: Type MCSH-SMike ErftmierPas encore d'évaluation

- Comprehensive Study On WaterstopsDocument18 pagesComprehensive Study On WaterstopsFrederick TanPas encore d'évaluation

- Negi 2018Document20 pagesNegi 2018alireza shamsPas encore d'évaluation

- Constant Chlor MC4-50 and MC4-150 Operation and Installation ManualDocument76 pagesConstant Chlor MC4-50 and MC4-150 Operation and Installation ManualChristian NdembiPas encore d'évaluation

- QuestionDocument16 pagesQuestionellis garciaPas encore d'évaluation

- RSL 1Document2 pagesRSL 1api-432721232Pas encore d'évaluation

- North West England Coastal Zone AssessmentDocument272 pagesNorth West England Coastal Zone AssessmentToby ChessonPas encore d'évaluation

- Chemical Composition of Rainwater Captured in An Oil RefineryDocument6 pagesChemical Composition of Rainwater Captured in An Oil RefineryseventhsensegroupPas encore d'évaluation

- Test PHDocument16 pagesTest PHMarielys DorantePas encore d'évaluation

- Urban Sanitation Problems and The Efforts To Overcome It in Medan City, 1909-1930sDocument12 pagesUrban Sanitation Problems and The Efforts To Overcome It in Medan City, 1909-1930sAkhmad AlwijayaPas encore d'évaluation

- Hho en Motores CiDocument18 pagesHho en Motores CiALEX LOPEZPas encore d'évaluation

- Section - 15985 Temperature Control Specifiers GuideDocument6 pagesSection - 15985 Temperature Control Specifiers GuideAntonio LebrunPas encore d'évaluation

- Eco MagazineDocument6 pagesEco MagazineArun PrasanthPas encore d'évaluation