Académique Documents

Professionnel Documents

Culture Documents

m1 U2 v2

Transféré par

2791957Titre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

m1 U2 v2

Transféré par

2791957Droits d'auteur :

Formats disponibles

Phase

Trade of Motor Mechanic

Module 1

Unit 2

Manual Handling

Produced by

In cooperation with:

Subject Matter Experts

Martin McMahon

&

CDX Global

Curriculum Revision 2.2 16-01-07

SOLAS 2013

Module 1 - Unit 2

Manual Handling

Table of Contents

Introduction......................................................................................................... 1

Unit Objective...................................................................................................... 1

1.0 Manual Handling and Safety in the Workplace....................................... 3

1.1

Employer and Employee Statutory Requirements........................ 3

2.0 The Structure of the Spine....................................................................... 4

2.1 Structure of the Spine.................................................................... 4

3.0 Functions of Muscles, Tendons and Ligaments...................................... 6

3.1 Muscles, Tendons and Ligaments................................................. 6

4.0 Injuries from Lifting and Handling Loads............................................... 7

4.1 Potential Injuries............................................................................ 7

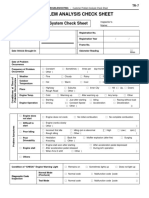

5.0 Pre-Lift Analysis of a Load...................................................................... 8

5.1 Pre-Lift Analysis of a Load............................................................ 8

6.0 Body Position before Attempting a Lift.................................................. 11

6.1 Before Attempting a Lift............................................................... 11

7.0 Good Handling Techniques for Lifting...................................................12

7.1 Stooping to Lift.............................................................................12

7.2 Bending the Knees........................................................................13

7.3 Handling Loads............................................................................14

7.4 Lifting............................................................................................15

7.5 Carrying........................................................................................16

7.6 Unloading.....................................................................................17

7.7 Special Lifts...................................................................................18

7.8 Awkward Objects and Overhead Lifts..........................................19

8.0 Pushing and Pulling............................................................................... 20

8.1 Pushing and Pulling Safety.......................................................... 20

8.2 Special Objects Require Special Handling..................................21

9.0 Procedures for Team Lifting a Load...................................................... 22

9.1 Team Effort.................................................................................. 22

9.2 Lifting and Lowering Whilst Standing........................................ 24

9.3 Manual Handling-Legal Obligations.......................................... 25

10.0 Types of Handling Devices.................................................................... 26

10.1 Handling Devices........................................................................ 26

11.0 Using a Handling Aid............................................................................. 26

11.1 Using a Handling Aid.................................................................. 26

Suggested Exercises.......................................................................................... 27

Training Resources............................................................................................ 27

Suggested Further Reading............................................................................... 28

Trade of Motor Mechanic - Phase 2 Course Notes

Revision 3.0 November 2013

Module 1 - Unit 2

Manual Handling

Introduction

Unit two covers the Manual handling. You will receive general

information on Manual handling procedures. If at any time you are

not clear on any aspect of the manual handling, section please refer

to your instructor for more information.

Module 1

Induction

Unit 1

Health, Safety

Fire Drill

& Behaviour

Unit 2

Unit 3

Manual

Handling

Computer

Skills

Unit 4

Introduction

to Customer

Skills

Unit Objective

By the end of this unit each apprentice will be able to:

List the main statutory requirements of both employers and

employees in relation to manual handling and general safety

in the workplace

Explain the structure of the spine

Explain the functions of muscles, tendons and ligaments

Explain the types of injury that may occur from lifting and

handling loads

Explain the requirement for a pre-lift analysis of a load

Explain how the body should be positioned before attempting

a lift

Explain and demonstrate good handling techniques for lifting

workplace objects

Explain and demonstrate good handling techniques for

pushing and pulling a workplace object

Demonstrate the correct procedures for team lifting a load

Describe the various types of handling devices and in what

situations they may be used

Correctly demonstrate how to handle a typical workplace load

using a handling aid

Trade of Motor Mechanic - Phase 2 Course Notes

Revision 3.0 November 2013

Module 1 - Unit 2

Manual Handling

1.0 Manual Handling and Safety

in the Workplace

Key Learning Points

Duty of employer towards employee to:

Take measures where possible to avoid manual handling

Carry out risk assessment where manual handling is unavoidable

to reduce dangers involved

Provide employee with precise information about the load

Duty of employee to:

Take reasonable care for his safety and welfare and that of

others in the workplace

Use any equipment, protective clothing or other means

provided by the employer for securing his safety and welfare

in the workplace

Report any problems or defects to his employer which might

endanger health and safety

1.1 Employer and Employee Statutory

Requirements

Duty of employer towards employee to:

Take measures where possible to avoid manual handling

Carry out risk assessment where manual handling is unavoidable

to reduce dangers involved

Provide employee with precise information about the load

Duty of employee to:

Take reasonable care for his safety and welfare and that of others

in the workplace

Use any equipment, protective clothing or other means provided

by the employer for securing his safety and welfare in the

workplace

Report any problems or defects to his employer which might

endanger health and safety

Note: Current laws and regulations have to be referred to at all times.

Trade of Motor Mechanic - Phase 2 Course Notes

Revision 3.0 November 2013

Module 1 - Unit 2

Manual Handling

2.0 The Structure of the Spine

Key Learning Points

Structure of the spine: spinal cord, spinal canal, vertebrae,

intervertebral discs

2.1 Structure of the Spine

Our spine is the main support of our upper bodies. It lets us stand

up straight, bend or twist. It also encases and protects the spinal

cord. The spinal cord is a thin, tubular bundle of nerves that is an

extension of the central nervous system from the brain and is

enclosed in and protected by the bony vertebral column. The main

function of the spinal cord is transmission of neural inputs between

the periphery and the brain. The nerves branch out from our spine

to the rest of our bodies.

The spine is made up of vertebrae. At the top are the cervical

vertebrae. There are 7 of them and they are referred to as C1-C7,

starting at the top. The seventh one joins to the first of the thoracic

vertebrae. These are the 12 that run down the back and provide a

place for our ribs to attach. They are referred to as T1-T12, again

from the top down. The lower inward curve of our back is made

up of the five lumbar vertebrae. They are called L1-L5. Below that

comes a set of 5 fused vertebrae called the sacrum that lies between

the hip bones. Lastly comes the coccyx or the tailbone, another set

of fused vertebrae.

Trade of Motor Mechanic - Phase 2 Course Notes

Revision 3.0 November 2013

Module 1 - Unit 2

Manual Handling

The vertebrae join together at what are called the facet joints. Between

each of the vertebrae are the disks, which provide cushioning and

act as shock absorbers.

Travelling down the centre of the spine is the spinal cord and at

each of the vertebrae, nerves branch out through what are called

the foramen to the rest of the body. Intervertebral discs lie between

adjacent vertebrae in the spine. Each disc forms a cartilaginous joint

to allow slight movement of the vertebrae and acts as a ligament to

hold the vertebrae together.

Trade of Motor Mechanic - Phase 2 Course Notes

Revision 3.0 November 2013

Module 1 - Unit 2

Manual Handling

3.0 Functions of Muscles,

Tendons and Ligaments

3.1 Muscles, Tendons and Ligaments

Muscles contract (shorten) to bring the ends closer together and

relax (lengthen) to let the ends move apart.

Muscles are attached to bones by cord-like extensions called tendons.

In the adolescent skeleton, tendons attach to a growthplate called

an apopyses (a-pof-i-sez). The area where the tendon attaches may

be weaker than the tendon itself. In adults, where the growthplate

fuses the tendon is weaker than the bone.

Ligaments are strong bands of tissue that attach to the bones and

form a joint. Ligaments provide stability to the joint by restricting

movement and holding the bones in place.

Trade of Motor Mechanic - Phase 2 Course Notes

Revision 3.0 November 2013

Module 1 - Unit 2

Manual Handling

4.0 Injuries from Lifting and

Handling Loads

Key Learning Points

Injuries resulting from lifting heavy loads: Prolapsed/slipped

disc, cuts and abrasions, crushed feet and hands, muscle and

joint strain

4.1 Potential Injuries

Why

should

I learn the

Right Way to

move and lift

things?

Because youll

help reduce the

risk of accidents

and injury.

Dont take chances with:

Strains and Sprains

Muscles and joints can

be injured by overexertion.

Fractures

Dropping a

heavy load can

break bones.

Hernias

The strain of

lifting can cause

painful ruptures

in the abdominal

wall.

Make your move to

safety...

Trade of Motor Mechanic - Phase 2 Course Notes

Wounds

Handling sharp,

rough surfaces

can cut and

bruise skin.

not

injury!!

Revision 3.0 November 2013

Module 1 - Unit 2

Manual Handling

5.0 Pre-Lift Analysis of a Load

Key Learning Points

Pre-lift analysis of a load (Checking object for sharp edges,

difficult to grasp, unstable, teamwork required)

Other factors that may hinder movement such as clothing

or personal protective equipment

Safe working practices at all times when handling heavy

objects

5.1 Pre-Lift Analysis of a Load

Moving Things The Wrong

Way May Injure Your Back!

People May Also Be At

Risk If They Are Not:

Properly trained to work safely

Provided with safe systems

of work and adequate

supervision

Physically suited or in proper

shape to carry out a given

task

Wearing the proper clothing,

footwear and other

protective equipment for the

type of work they do

Fortunately, back injuries and

other sprains, strains, cuts and

bruises can usually be prevented!

Trade of Motor Mechanic - Phase 2 Course Notes

Revision 3.0 November 2013

Module 1 - Unit 2

Manual Handling

5.2 Prevent Pain, Injuries and Damage

Examine the object

Determine its weight and

look for sharp edges. All loads

which are heavy or awkward

should be marked. Check

to see if the load is stable

and equally distributed. This

is a responsibility that your

supervisor shares with you.

Plan the job

Check

with

your

supervisor on a safe

system of work. Plan

a route thats free from

tripping and slipping

hazards. Know where the

object will be unloaded

and plan rest stops

along the way.

Get a good grip

Decide in advance

how to hold the object.

Protect your hands and

feet by grasping the

load firmly. If you wear

gloves to prevent cuts or

burns, make sure they fit

properly.

Get help

Use the mechanical

aids provided and get help

if you have any doubt

about moving an object

by yourself.

Trade of Motor Mechanic - Phase 2 Course Notes

Revision 3.0 November 2013

Module 1 - Unit 2

Manual Handling

Wear the right equipment!

This may include:

anti-slip safety shoes

a hard hat

safety goggles

a respirator

protective gloves

durable clothing,

loose enough for free

movement but tight

enough to avoid snags

Rest or rotate tasks

Avoid becoming over-tired!

Frequent lifting, lowering and

moving is demanding work

and can result in cumulative

stress.

Talk to your supervisor

Do not hesitate to discuss

any problems or moves you

arent sure about.

Trade of Motor Mechanic - Phase 2 Course Notes

10

Lift with your legs

Assume a comfortable

stance. Lift smoothly,

keeping the load close to

the body. Avoid twisting

your body as you lift move your feet instead.

Minimise lifts above

your shoulders or below

your knees.

Keep hands in the

clear

Be careful not to crush

fingers when unloading

Revision 3.0 November 2013

Module 1 - Unit 2

Manual Handling

6.0 Body Position before

Attempting a Lift

Key Learning Points

Use of good posture before beginning to lift a load

6.1 Before Attempting a Lift

Use of good posture before beginning to lift a load

8 key points to remember:

1.

Assess the task, the area & the load

2.

Broad stable base - feet flat on floor

3.

Bend the knees

4.

Back straight

5.

Firm grip

6.

Arms in line with trunk

7.

Weight close to centre of gravity

8.

Turn feet in direction of movement

Trade of Motor Mechanic - Phase 2 Course Notes

11

Revision 3.0 November 2013

Module 1 - Unit 2

Manual Handling

7.0 Good Handling Techniques

for Lifting

Key Learning Points

Workplace obstacles/hazards such as slippery/uneven

surfaces, poor lighting conditions, steps

7.1 Stooping to Lift

Stooping to Lift is Dangerous!

Because:

The arched spine may

cause a slipped disc

It can overload the

lower back muscles

We are lifting the load AND the upper body weight in that posture!

Trade of Motor Mechanic - Phase 2 Course Notes

12

Revision 3.0 November 2013

Module 1 - Unit 2

Manual Handling

7.2 Bending the Knees

Bending the Knees to Lift Ensures:

That the leg muscles do the lifting not the smaller back

muscles

That a good lifting posture can be adopted

That the load can be reached without arching the spine

Trade of Motor Mechanic - Phase 2 Course Notes

13

Revision 3.0 November 2013

Module 1 - Unit 2

Manual Handling

7.3 Handling Loads

Avoid

Very heavy loads.

Arching of the spine.

Excessive or repeated twisting.

Over-stretching or over-reaching.

Ensure

A good secure grip

Awareness of the weight and stability of the load.

Correct stance and lift posture.

Smooth quick lift.

Correct protective clothing and equipment.

Proper co-ordination of team lifts.

That there are no obstacles such as;

Slippery/uneven surfaces

Poor lighting

Due care is taken when using steps.

Trade of Motor Mechanic - Phase 2 Course Notes

14

Revision 3.0 November 2013

Module 1 - Unit 2

Manual Handling

7.4 Lifting

One Person Lift - Squat Lift

1.

Think before doing anything.

2.

Stand as close to the load as possible. Spread you feet to

create a stable base (slide the load close if its on a shelf).

3.

Bend your knees and keep your back in a natural line.

Dont bend your knees fully as this will leave little power to

lift.

4.

Grasp the load firmly.

5.

Raise you head.

6.

Lift with your legs. Use your leverage , momentum, balance

and timing for a smooth action. Move your feet.

7.

Hold the load close to the centre of your body.

To avoid injury do warm-up exercises before lifting.

Trade of Motor Mechanic - Phase 2 Course Notes

15

Revision 3.0 November 2013

Module 1 - Unit 2

Manual Handling

7.5 Carrying

You can help prevent injuries when carrying objects too!

Heres how:

Keep the load close

to take full advantage

of the mechanical

leverage of

your body.

Keep your

arms tucked in

to prevent injury

or fatigue to your

neck or shoulder

muscles.

Dont change

your grip

in the load

unless its

weight is

supported.

Avoid

twisting

your body,

stooping,

bending or

leaning back. If you must change

direction, move your feet instead.

Trade of Motor Mechanic - Phase 2 Course Notes

16

Dont block your vision

by carrying too large a

load. Use a mechanical

aid, or get help if you

need it.

Face the spot

the load will

rest in by turning

your feet and

whole body in the

direction.

Revision 3.0 November 2013

Module 1 - Unit 2

Manual Handling

7.6 Unloading

Be as careful setting down the load as you are when lifting. Repeat

the same procedure in reverse.

Place the load

on a bench or fable

by resting it on the

edge and pushing it

Be sure the load

forward

with your

is secure wherever

arms and body.

you place it. Make

certain it wont

Be careful

fall, tip over,

with fingers

roll or block

and toes.

someones way.

Allow enough

room for them

when the load

is set down.

Slide the load

into tight spaces - its

much easier and safer

than trying to lift it.

Bend your

knees

to lower the

load. Keep your

back straight

and the weight

close to your

body.

Trade of Motor Mechanic - Phase 2 Course Notes

17

Revision 3.0 November 2013

Module 1 - Unit 2

Manual Handling

7.7 Special Lifts

One arm loads

These are not a good idea, but

if they cannot be avoided:

Brace your body with the

opposite arm, if possible.

Reach for the load - bend

your knees and waist and

keep your back straight.

Grasp the load firmly. Use

a handle if possible.

Lift with your legs, using

the free arm for balance.

Team lifts

Work with someone of

similar build and height if

possible.

Choose one person to call

the signals.

Lift from the hips at the

same time, then raise the

load to the desired level.

Move smoothly and in

unison.

Keep your shoulders level

- switch hands regularly.

Divide the load if possible.

Now

we turn.

Trade of Motor Mechanic - Phase 2 Course Notes

18

Revision 3.0 November 2013

Module 1 - Unit 2

Manual Handling

7.8 Awkward Objects and Overhead

Lifts

Awkward Objects

Stand over one corner of

the load, with your feet

comfortably apart.

Grasp the bottom inside

and top outside corners.

Bend your knees and loft,

keeping the same grip.

Seek advice of you have

any doubts.

Overhead Lifts

Lifting to a High Place:

Lighten the load if possible

Stand on something sturdy,

with one foot in front of

the other, unless using a

stepladder.

Use a mechanical aid or get

help if the load is awkward

or heavy.

Lowering from a High Place:

Test the loads weight by

pushing up on it. Check to

see if the load will lift it.

Stand as close to the load

as possible.

Grasp the object firmly,

sliding it down your body

Use a mechanical aid or get

help if necessary.

Trade of Motor Mechanic - Phase 2 Course Notes

19

Revision 3.0 November 2013

Module 1 - Unit 2

Manual Handling

8.0 Pushing and Pulling

Key Learning Points

Good handling techniques for pushing and/or pulling an

object using a handling device

8.1 Pushing and Pulling Safety

For either movement, remember:

Lean in the

direction youre

Stay close to

pushing or pulling.

the object.

Get a good

grip on it.

Watch out for

obstructions.

Keep your

back straight,

stomach in and

knees bent.

Keep the strain of your back.

Let your bodys weight and leg muscles do the work for you.

Trade of Motor Mechanic - Phase 2 Course Notes

20

Revision 3.0 November 2013

Module 1 - Unit 2

Manual Handling

8.2 Special Objects Require Special

Handling

Barrels, Drums and

Kegs

Roll a heavy barrel if you

move by yourself. Rocking

will help get it started. If

you must move it on end,

use a mechanical aid or get

help.

Boxes and Cartons

Grasp opposite bottom

corners and keep the object

close to the middle of your

body.

Sacks

Carry the sack on your

shoulder, braced by your

hand on your hip. Or hold

it at opposite ends, resting

the load against your hip

and stomach. Use extra

care with slippery plastic

sacks.

Trade of Motor Mechanic - Phase 2 Course Notes

21

Revision 3.0 November 2013

Module 1 - Unit 2

Manual Handling

9.0 Procedures for Team Lifting a

Load

Key Learning Points

Coordination of team activity when team lifting

Raising a load correctly

Putting the load down correctly

9.1 Team Effort

It takes a team effort to organise safe systems for handling loads....

Your employer is

working hard to:

To do your part,

you should:

Assess loads and determine

whether mechanical or other

aids will be required to

minimise risk of injury

Take all training seriously

and make use of what you

know at all times.

Notify your employer of any medical

conditions that could affect your

ability to handle loads- for example

pregnancy, illness or injury.

Provide information and training

regarding safe work systems

along with details (weight,

centre of gravity, etc.) on

various loads.

Trade of Motor Mechanic - Phase 2 Course Notes

22

Report any hazards or potential

hazards to your supervisor at

once. Make your safety and the

safety of others a top priority!

Revision 3.0 November 2013

Module 1 - Unit 2

Manual Handling

.... so be sure to handle objects safely.

Know yourself

and your limits.

Know how to move

materials

Use mechanical aids and

the safety equipment

provided by your employer

Know when to get help

You can get the job done safely and easily!

Trade of Motor Mechanic - Phase 2 Course Notes

23

Revision 3.0 November 2013

Module 1 - Unit 2

Manual Handling

9.2 Lifting and Lowering Whilst

Standing

Full Height

5kg

10kg

Shoulder

Height

10kg

20kg

Elbow Height

15kg

25kg

Knuckle

Height

10kg

20kg

Mid-lower Leg

5kg

Trade of Motor Mechanic - Phase 2 Course Notes

10kg

24

Revision 3.0 November 2013

Module 1 - Unit 2

Manual Handling

9.3 Manual Handling-Legal

Obligations

If a manual handling task involves a risk of back injury the

Employer must:

Eliminate it or

Mechanise it or

Assess it and

Train employees and

Ensure they can cope

Trade of Motor Mechanic - Phase 2 Course Notes

25

Revision 3.0 November 2013

Module 1 - Unit 2

Manual Handling

10.0 Types of Handling Devices

10.1 Handling Devices

There are many handling devices used in a garage environment.

They include a floor jack, two-post hoist, four-post hoist and an

engine hoist.

These devices are covered in Module 1 Unit 1 section 5.0. Refer to your instructor

for a more detailed list.

11.0 Using a Handling Aid

11.1 Using a Handling Aid

Please refer to Module 1 Unit 1 section 5.0

Note: It is important that proper instruction is given prior to using any type

of handling aid.

Trade of Motor Mechanic - Phase 2 Course Notes

26

Revision 3.0 November 2013

Module 1 - Unit 2

Manual Handling

Suggested Exercises

Apprentice to answer general questions on correct procedures

for lifting heavy objects

Apprentice to state the main obligations of employer and

employee in relation to safe handling in the workplace

Under supervision and using the correct handling techniques,

the apprentice is required to lift a workplace object from:

Ground to ground

Ground to bench

Ground to height

Bench to bench

Under supervision and using the correct handling techniques,

the apprentice is required to operate a handling device to move

a typical workplace object from one location to another

Training Resources

Overhead projector, transparencies, information sheets,

instructional videos

Samples of various materials/objects typical of the apprentice's

workplace

Various handling devices used in the apprentice's workplace

Trade of Motor Mechanic - Phase 2 Course Notes

27

Revision 3.0 November 2013

Module 1 - Unit 2

Manual Handling

Suggested Further Reading

Advanced Automotive

0340741236

Automobile Electrical and Electronic Systems (3rd Edition). Tom

Denton. ISBN 0750662190

Automotive Mechanics (10th Edition). William H. Crouse and

Donald L. Anglin. ISBN 0028009436

Bosch Automotive Electrics Automotive Electronics: Systems and

Components (4th Edition). Robert Bosch. ISBN 0837610508

Bosch Automotive Handbook (6th Edition). Robert Bosch. ISBN

1860584748

Bosch Automotive Technology Technical Instruction booklet series

(numerous titles)

Hilliers Fundamentals of Motor Vehicle Technology: Book One (5th

Edition). V.A.W. Hillier and Peter Coombes. ISBN 0748780823

Hilliers Fundamentals of Motor Vehicle Technology: Book Two (5th

Edition). V.A.W. Hillier and Peter Coombes. ISBN 0748780998

Modern Automotive Technology. James E. Duffy. ISBN

1566376106

Motor Vehicle Craft Studies - Principles. F.K. Sully. ISBN

040800133X

National Car Test (NCT) Manual (Department of Transport,

Vehicle Testers Manual - DoT VTM). Department of Transport

Transmission, Chassis and Related Systems (Vehicle Maintenance

and Repair Series: Level 3) (3rd Edition) John Whipp and Roy

Brooks. ISBN 186152806X

Vehicle and Engine Technology (2nd Edition). Heinz Heisler. ISBN

0340691867

http://www.cdxglobal.com/

http://auto.howstuffworks.com/

http://www.autoshop101.com/

http://www.cdxetextbook.com/

Automotive Encyclopedia and Text Book Resource (CD version

of e-textbook), Available from your instructor.

http://www.hse.gov.uk/pubns/indg398.pdf

Trade of Motor Mechanic - Phase 2 Course Notes

28

Diagnosis.

Tom

Denton.

ISBN

Revision 3.0 November 2013

Notes

27-33 Upper Baggot Street

Dublin 4

Vous aimerez peut-être aussi

- Essential Clinically Applied Anatomy of the Peripheral Nervous System in the Head and NeckD'EverandEssential Clinically Applied Anatomy of the Peripheral Nervous System in the Head and NeckPas encore d'évaluation

- M1U2 Manual HandlingDocument26 pagesM1U2 Manual HandlingViệt Đặng XuânPas encore d'évaluation

- HPC 109 Module 1 ErgoDocument22 pagesHPC 109 Module 1 ErgoKAREN SALVE MAUTEPas encore d'évaluation

- Exo-Kinetics: A Guide to Explosive Performance and TrainingD'EverandExo-Kinetics: A Guide to Explosive Performance and TrainingÉvaluation : 3 sur 5 étoiles3/5 (1)

- 1.pistol ShootingDocument91 pages1.pistol ShootingHany FathyPas encore d'évaluation

- Sim Muscle TutorialDocument20 pagesSim Muscle TutorialKiran KumarPas encore d'évaluation

- SimMuscleTutorial PDFDocument20 pagesSimMuscleTutorial PDFKavivarma Raj RajendranPas encore d'évaluation

- Ergonomics Assignment Mohammed NihadDocument27 pagesErgonomics Assignment Mohammed NihadibrahimPas encore d'évaluation

- 1402AHS Prac Manual - 2023 - FINALDocument200 pages1402AHS Prac Manual - 2023 - FINALRuan BritsPas encore d'évaluation

- Lecture Notes 2018Document111 pagesLecture Notes 2018Joel Adu-TutuPas encore d'évaluation

- Ergonomics, Biomechanics & Musculoskeletal Disorder-A ReviewDocument8 pagesErgonomics, Biomechanics & Musculoskeletal Disorder-A ReviewRenaldiPrimaSaputraPas encore d'évaluation

- E039 PublishedDocument8 pagesE039 PublishedRenaldiPrimaSaputraPas encore d'évaluation

- Instructional Material Staff CourseDocument434 pagesInstructional Material Staff CoursePatricio Saldias GüntherPas encore d'évaluation

- Major Project 1Document8 pagesMajor Project 1Pranav SinghPas encore d'évaluation

- Developing Maximal Neuromuscular Power Part 2 .3Document22 pagesDeveloping Maximal Neuromuscular Power Part 2 .3Cristian Retamal ValderramaPas encore d'évaluation

- MNO2603 Textbook SearchableDocument212 pagesMNO2603 Textbook SearchableBonisile MakhubuPas encore d'évaluation

- Worksafe Manual HandlingDocument18 pagesWorksafe Manual HandlingtahseenhassantirmiziPas encore d'évaluation

- Developing Maximal Neuromuscular Power Part 1 .2Document22 pagesDeveloping Maximal Neuromuscular Power Part 1 .2Cristian Retamal Valderrama100% (1)

- Me DX TheoryDocument46 pagesMe DX Theoryjony_PPas encore d'évaluation

- Identifying and Addressing Ergonomic Hazards Workbook: Midwest Worker Center Ergonomic Training ProjectDocument28 pagesIdentifying and Addressing Ergonomic Hazards Workbook: Midwest Worker Center Ergonomic Training ProjectMariel UnabiaPas encore d'évaluation

- 14 Tesis Control Adactativo de Servomecanismos PDFDocument133 pages14 Tesis Control Adactativo de Servomecanismos PDFgabrielaPas encore d'évaluation

- Manual Handling ErgonomicsDocument18 pagesManual Handling ErgonomicsVijayakumar Narayanan100% (1)

- SITXINV001 Receive and Store Stock NGC-hazardous-manual-tasks-cop.v1.0Document73 pagesSITXINV001 Receive and Store Stock NGC-hazardous-manual-tasks-cop.v1.0Tikaram GhimirePas encore d'évaluation

- The Human Respiratory System: Anders STR Om April 28, 2014Document14 pagesThe Human Respiratory System: Anders STR Om April 28, 2014fitriaPas encore d'évaluation

- Module Conveyor ManualDocument62 pagesModule Conveyor ManualIvanRemiPas encore d'évaluation

- Hardware and Networking Service LevelDocument52 pagesHardware and Networking Service LevelMiila KaayyooPas encore d'évaluation

- SCO105 StudyGuideDocument124 pagesSCO105 StudyGuideShirley LohPas encore d'évaluation

- Human Motion ControlDocument218 pagesHuman Motion ControlHassani WalidPas encore d'évaluation

- ORDocument102 pagesORYehualashet FelekePas encore d'évaluation

- Manual Neuro TESDocument44 pagesManual Neuro TESBrendaPas encore d'évaluation

- RealDocument23 pagesRealPranav SinghPas encore d'évaluation

- Biomechanics ChapterDocument20 pagesBiomechanics Chapterttouman100% (2)

- SopDocument46 pagesSopMohamed El-Mutasim El-FeelPas encore d'évaluation

- FRCEM Basic Sciences CurriculumDocument101 pagesFRCEM Basic Sciences Curriculummohd ferdaus mohd taharPas encore d'évaluation

- M1U1 - Induction Health and SafetyDocument32 pagesM1U1 - Induction Health and SafetyViệt Đặng XuânPas encore d'évaluation

- Multiple TraumaDocument78 pagesMultiple Traumasgod34Pas encore d'évaluation

- COMSEC MaterialDocument24 pagesCOMSEC MaterialHoang PhucPas encore d'évaluation

- Papers On MusculoskeletalDocument22 pagesPapers On MusculoskeletalDevi RamadanPas encore d'évaluation

- FULLTEXT01Document57 pagesFULLTEXT01AMARNATH PRASADPas encore d'évaluation

- Ergonomics - Dental HygenistDocument30 pagesErgonomics - Dental Hygenistusama khanPas encore d'évaluation

- PhysicsinOrthodontics04 17 21SLJMRDocument43 pagesPhysicsinOrthodontics04 17 21SLJMRYaser JasPas encore d'évaluation

- Electrical Muscle Stimulation - Healing, Strengthening, Mobilization & Pain ManagementDocument22 pagesElectrical Muscle Stimulation - Healing, Strengthening, Mobilization & Pain ManagementEd RibeiroPas encore d'évaluation

- Spinal Injury and Spine Motion Restriction: Standard CompetencyDocument51 pagesSpinal Injury and Spine Motion Restriction: Standard CompetencyMichael DharshwinPas encore d'évaluation

- A Biomechanical Evaluation of Resistance - Fundamental Concepts For Training and Sports PerformanceDocument24 pagesA Biomechanical Evaluation of Resistance - Fundamental Concepts For Training and Sports PerformanceRhiannon CristinaPas encore d'évaluation

- Prevention of Ergonomic Injuries Training Manual 31Document38 pagesPrevention of Ergonomic Injuries Training Manual 31api-709086807Pas encore d'évaluation

- Eletromiography ExtradiafragmaticDocument45 pagesEletromiography Extradiafragmaticgiulio pinnolaPas encore d'évaluation

- Hazardous Manual Tasks COP 2011Document51 pagesHazardous Manual Tasks COP 2011sachiPas encore d'évaluation

- (Eng) Advanced Professional Training Non Linear and Stability 14.0Document106 pages(Eng) Advanced Professional Training Non Linear and Stability 14.0Yuri ScripnicPas encore d'évaluation

- ExFixBasicPrinciplesSolominEd. SpringerDocument15 pagesExFixBasicPrinciplesSolominEd. SpringerAhmed Elsayed AttiaPas encore d'évaluation

- 1397.1-US-En NexGen LPS-Flex and LPS Mobile Bearing SurgTech-FINAL DIGITAL1Document100 pages1397.1-US-En NexGen LPS-Flex and LPS Mobile Bearing SurgTech-FINAL DIGITAL1Andrei DumitruPas encore d'évaluation

- (Book) Study On Control System of Lower Extremity Exoskeleton Rehabilitation Robot Based On Neuromusculoskeletal ModelDocument145 pages(Book) Study On Control System of Lower Extremity Exoskeleton Rehabilitation Robot Based On Neuromusculoskeletal ModelNKSPas encore d'évaluation

- Edan Sonotrax ManualDocument47 pagesEdan Sonotrax ManualDaniel GalindoPas encore d'évaluation

- Advanced Kinesiology FinalDocument97 pagesAdvanced Kinesiology FinalTnum100% (1)

- 14-Manage Workforce LifecycleDocument82 pages14-Manage Workforce LifecycleBala SubramanyamPas encore d'évaluation

- Bionic Arm ProjectDocument41 pagesBionic Arm ProjectJessica Jackson100% (1)

- Model Cop Hazardous Manual TasksDocument71 pagesModel Cop Hazardous Manual TasksEtibar AliyevPas encore d'évaluation

- Sen301 Operations Research I: Lecture NotesDocument63 pagesSen301 Operations Research I: Lecture Notesroger david pimienta barrosPas encore d'évaluation

- Trade of Electrician: Standards Based ApprenticeshipDocument24 pagesTrade of Electrician: Standards Based Apprenticeshipayad60Pas encore d'évaluation

- IJESE 1119 Article 5808a2438fd89Document14 pagesIJESE 1119 Article 5808a2438fd892791957Pas encore d'évaluation

- Automotive (Small Engine)Document2 pagesAutomotive (Small Engine)2791957Pas encore d'évaluation

- Kelpro Engine MountsDocument107 pagesKelpro Engine Mounts27919570% (1)

- 9000-0020Document9 pages9000-00202791957Pas encore d'évaluation

- ToolsCat 74Document58 pagesToolsCat 742791957Pas encore d'évaluation

- CustomerDocument1 pageCustomer2791957Pas encore d'évaluation

- Automotive Steering SuspensionDocument1 pageAutomotive Steering Suspension2791957Pas encore d'évaluation

- Determining Battery Capacity3 PDFDocument37 pagesDetermining Battery Capacity3 PDF2791957Pas encore d'évaluation

- Swift - June 09 - 03 Instrument PanelDocument56 pagesSwift - June 09 - 03 Instrument Panel2791957Pas encore d'évaluation

- Application Note AN05 - Bench Testing OBD Interfaces: Doubly Terminated!Document3 pagesApplication Note AN05 - Bench Testing OBD Interfaces: Doubly Terminated!2791957Pas encore d'évaluation

- 10 Electric Power Steering GB Druck PDFDocument2 pages10 Electric Power Steering GB Druck PDF2791957Pas encore d'évaluation

- A Smart Way To Drive Ecu ConsolidationDocument4 pagesA Smart Way To Drive Ecu Consolidation2791957Pas encore d'évaluation

- Battery Control System: DescriptionDocument3 pagesBattery Control System: Description2791957100% (1)

- Battery Test and Charging ProcduresDocument6 pagesBattery Test and Charging Procdures2791957Pas encore d'évaluation

- G 2058Document4 pagesG 20582791957Pas encore d'évaluation

- Application Note AN06 - ELM327L and The PL-2303HX: Installing SoftwareDocument2 pagesApplication Note AN06 - ELM327L and The PL-2303HX: Installing Software2791957Pas encore d'évaluation

- LDV 200 300 400Document108 pagesLDV 200 300 4002791957Pas encore d'évaluation

- SM-AFRGen2 User GuideDocument2 pagesSM-AFRGen2 User Guide2791957Pas encore d'évaluation

- Chap 17Document96 pagesChap 172791957Pas encore d'évaluation

- Sample: Diagram 1 Early Ford C-Max Wiring DiagramsDocument4 pagesSample: Diagram 1 Early Ford C-Max Wiring Diagrams2791957Pas encore d'évaluation

- Q 117R2Document2 pagesQ 117R22791957Pas encore d'évaluation

- Merchant Circle DiagramDocument15 pagesMerchant Circle DiagramSUBHASH ANURAGPas encore d'évaluation

- 05ivm EseriesDocument56 pages05ivm Eseries27919570% (1)

- 5.2combustion and Combustion Chamber For SI EnginesDocument53 pages5.2combustion and Combustion Chamber For SI EnginesTamene Tesfaye100% (2)

- Focus WiresDocument816 pagesFocus Wiresionutnespus100% (2)

- Ford Wiring Diagram 1994 9404Document11 pagesFord Wiring Diagram 1994 94042791957Pas encore d'évaluation

- Alto2011 CatalogDocument538 pagesAlto2011 CatalogIsa Restrepo Fernandez0% (1)

- Emergency Response Guide-ToyotaDocument143 pagesEmergency Response Guide-Toyota2791957100% (1)

- 1GRFE Engine4.0Document77 pages1GRFE Engine4.0Mauricio Andrés Montenegro71% (7)

- Eng Trouble Diag Aug 09Document48 pagesEng Trouble Diag Aug 09279195750% (2)

- Iyengar Yoga For Herniated DiscDocument13 pagesIyengar Yoga For Herniated Discaquabuck100% (8)

- Management of Bone InjuriesDocument13 pagesManagement of Bone InjuriesKURIMAONGPas encore d'évaluation

- Cure & CareDocument10 pagesCure & CareZee ShanPas encore d'évaluation

- UltimatePower-DensityWorkout2 0Document56 pagesUltimatePower-DensityWorkout2 0gareththomasnz100% (3)

- Meniscal InjuryDocument19 pagesMeniscal InjuryRAMPas encore d'évaluation

- Flexion: To Improve Movement of The PivotalDocument3 pagesFlexion: To Improve Movement of The PivotalKelsey MacaraigPas encore d'évaluation

- Nouveau Texte OpenDocumentDocument8 pagesNouveau Texte OpenDocumentClmentPas encore d'évaluation

- List of 206 Bones and Their LocationDocument3 pagesList of 206 Bones and Their LocationJemaicah ArañoPas encore d'évaluation

- Special All LabsDocument50 pagesSpecial All LabsZameer HaiderPas encore d'évaluation

- Pembagian Tugas Presentasi Bimbingan Daring: NO Nama Materi Pengajar Dr. IrvanDocument2 pagesPembagian Tugas Presentasi Bimbingan Daring: NO Nama Materi Pengajar Dr. IrvanDjustiela KarrangPas encore d'évaluation

- Anatomical Position, Directional Terms and MovementsDocument36 pagesAnatomical Position, Directional Terms and MovementsPaul Nichol De VeraPas encore d'évaluation

- CervicalDocument88 pagesCervicalAnnis FathiaPas encore d'évaluation

- Posterior Compartment of The ThighDocument1 pagePosterior Compartment of The ThighLuqman Al-Bashir FauziPas encore d'évaluation

- 3.3 The Intercostal Spaces and MuscleDocument8 pages3.3 The Intercostal Spaces and MuscleCearlene GalleonPas encore d'évaluation

- PECTORALIS MAJO-WPS OfficeDocument13 pagesPECTORALIS MAJO-WPS OfficeLakshita PrajapatiPas encore d'évaluation

- Surgical and Molecular Advances in OsteonecrosisDocument252 pagesSurgical and Molecular Advances in OsteonecrosisEmaPas encore d'évaluation

- Cailliet-Exercise 2Document116 pagesCailliet-Exercise 2Nieko Caesar AgungPas encore d'évaluation

- Mr. Fat Loss: in This IssueDocument45 pagesMr. Fat Loss: in This IssueXie Zhen WuPas encore d'évaluation

- Colles FractureDocument20 pagesColles FracturedhinahafizPas encore d'évaluation

- Medial Collateral Ligament Injuries in Football (1980)Document4 pagesMedial Collateral Ligament Injuries in Football (1980)lite.trawler-0xPas encore d'évaluation

- Atlas of Nerve Conduction Studies and Electromyography (2 Ed.)Document10 pagesAtlas of Nerve Conduction Studies and Electromyography (2 Ed.)rodrigocorcino899959Pas encore d'évaluation

- Trunk and Cervical OrthosisDocument21 pagesTrunk and Cervical OrthosisKanwal Khan100% (1)

- Edexcel Past Paper 2006Document28 pagesEdexcel Past Paper 2006David BrownPas encore d'évaluation

- Efectele VojtaDocument6 pagesEfectele VojtaTarachiu Radita100% (1)

- International Journal of Surgery Case ReportsDocument5 pagesInternational Journal of Surgery Case Reports'fanny Quenhita'Pas encore d'évaluation

- Assignment Therapeutics 3rdDocument2 pagesAssignment Therapeutics 3rdSidra AlamPas encore d'évaluation

- Assessment Techniques Normal Findings Abnormal Findings A. Gait InspectionDocument12 pagesAssessment Techniques Normal Findings Abnormal Findings A. Gait Inspectionshannon c. lewisPas encore d'évaluation

- Upper EssentialsDocument5 pagesUpper EssentialsThành Trung NguyễnPas encore d'évaluation

- Radiology Reference Guide PDFDocument24 pagesRadiology Reference Guide PDFmyokamaltaPas encore d'évaluation

- TensDocument38 pagesTensOden MahyudinPas encore d'évaluation